Patents

Literature

66results about How to "Increase the striking power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

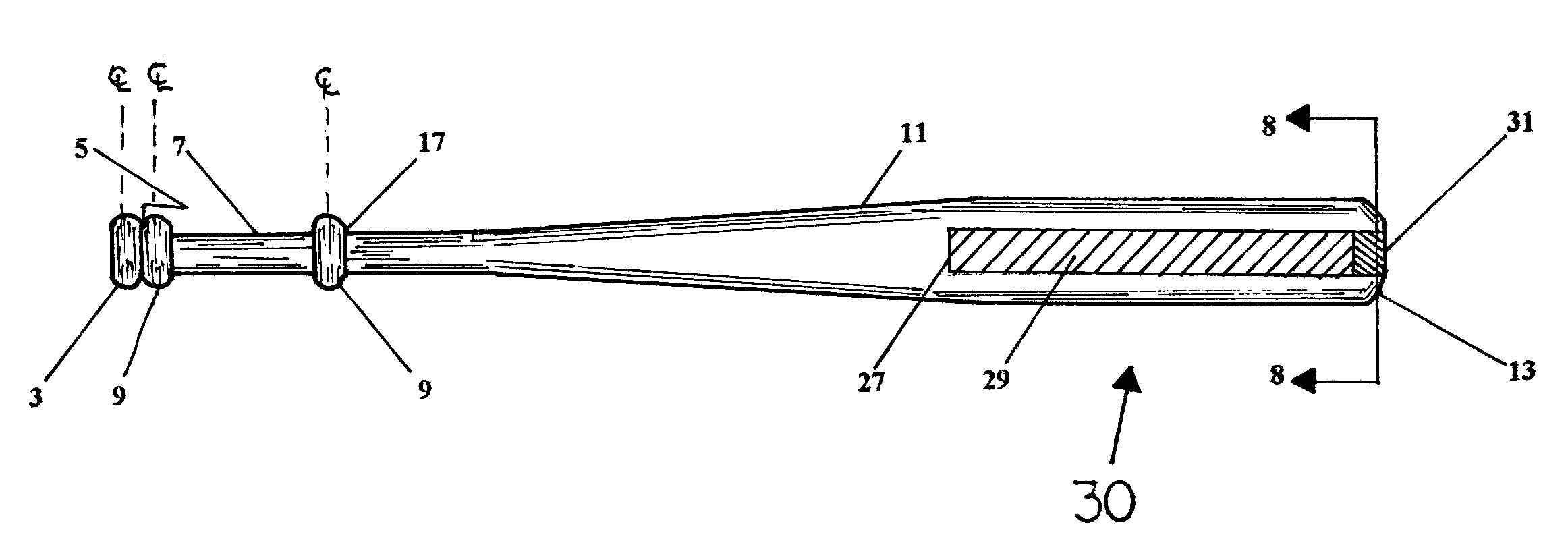

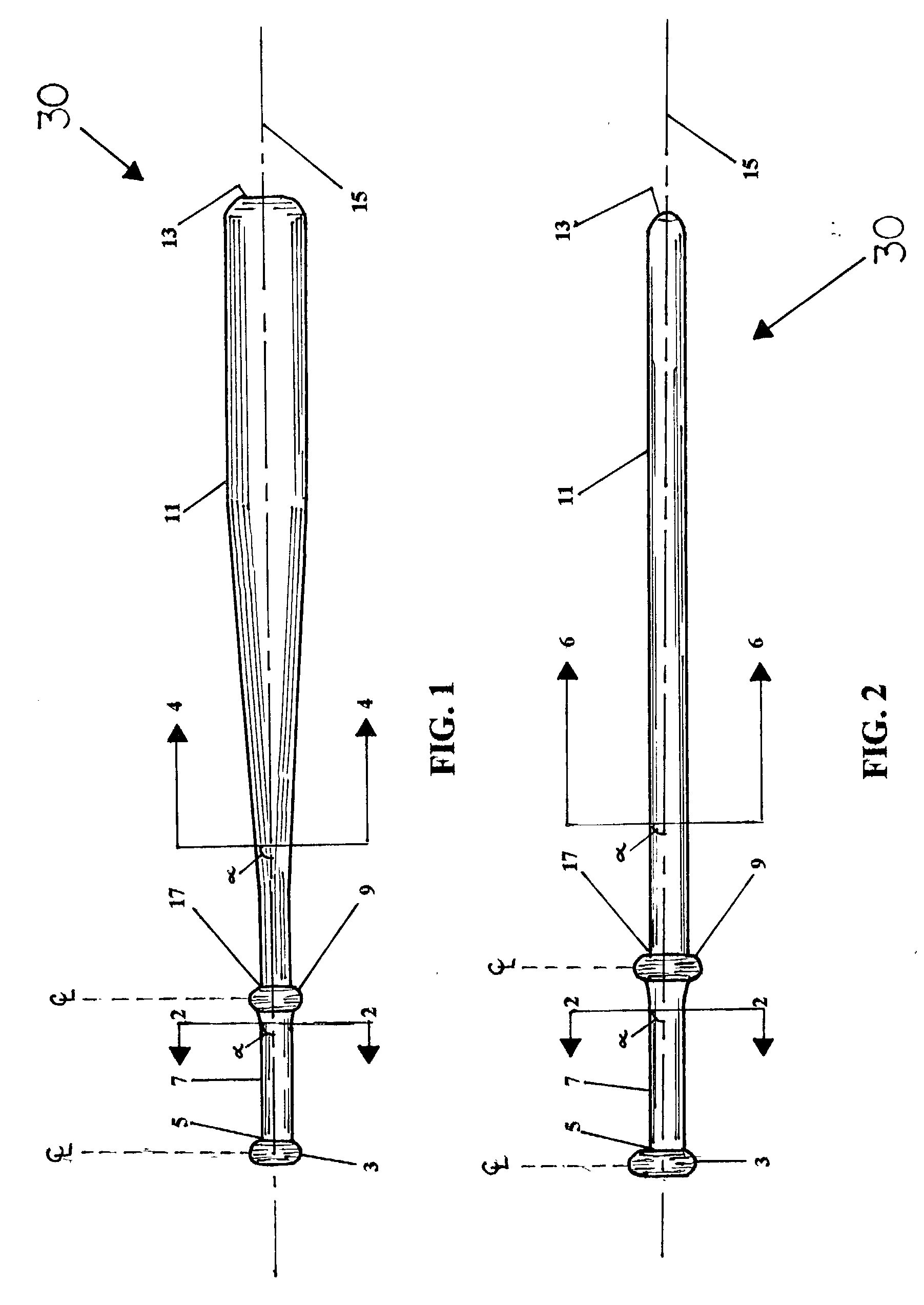

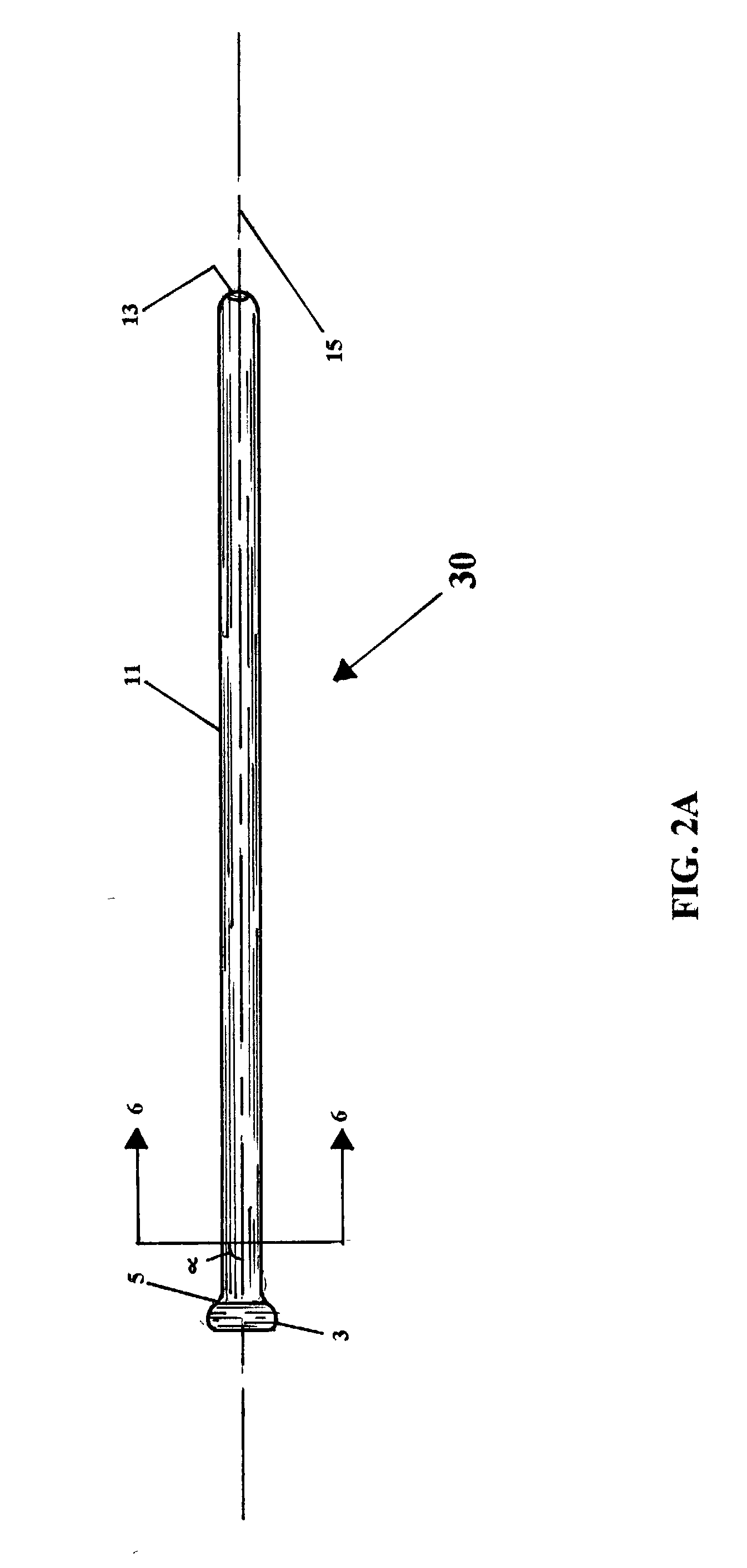

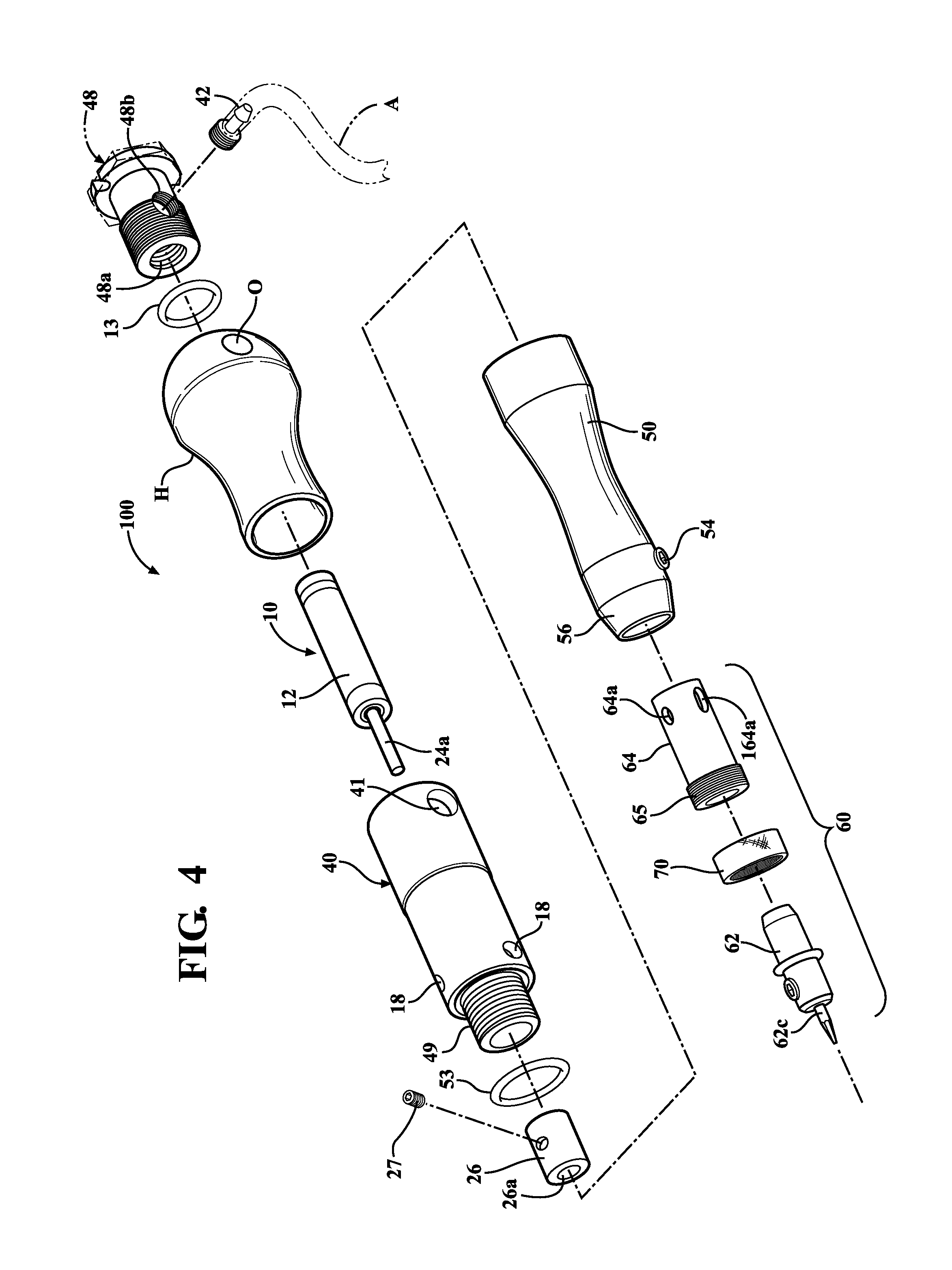

Training device and method of training a batter

InactiveUS20040023736A1Efficiently and effectively swingIncrease the striking powerRacket sportsEngineeringBody segment

A baseball training device comprises a rod having a handle end portion containing a handle end knob, an intermediate handle portion containing one or more intermediate handle knob(s), a body portion and a distal end. The intermediate handle portion, along with the handle end portion creates a recessed handle area between two knobs providing for an enhanced, repeatable grip of the device, allowing for increased bat speed and resultant swinging power while improving the safety of swinging the device at a ball or similar object. The configuration of the body portion coupled with the enhanced gripping handle of the training device will provide for desired, graduated levels of training a batter to improve hand-eye coordination while optimizing swinging power to strike an effective blow to a ball or similar object. A method comprising steps to: choose a training device with an enhanced gripping handle and desired body portion, grip the training device, and swing the training device to repeatedly strike a ball or similar object with confidence, increased swinging power and improved hand-eye coordination.

Owner:CARDINALE RONALD S

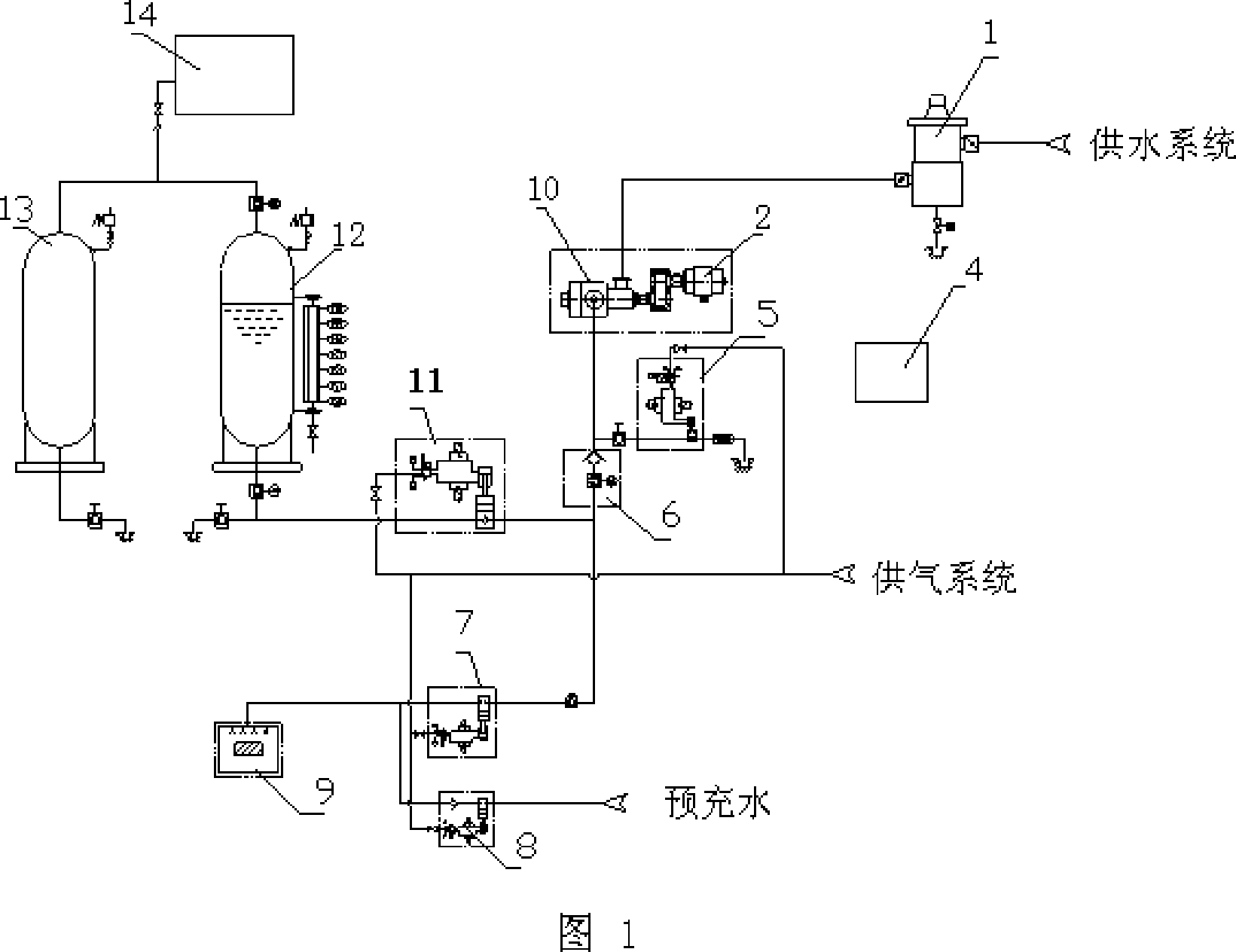

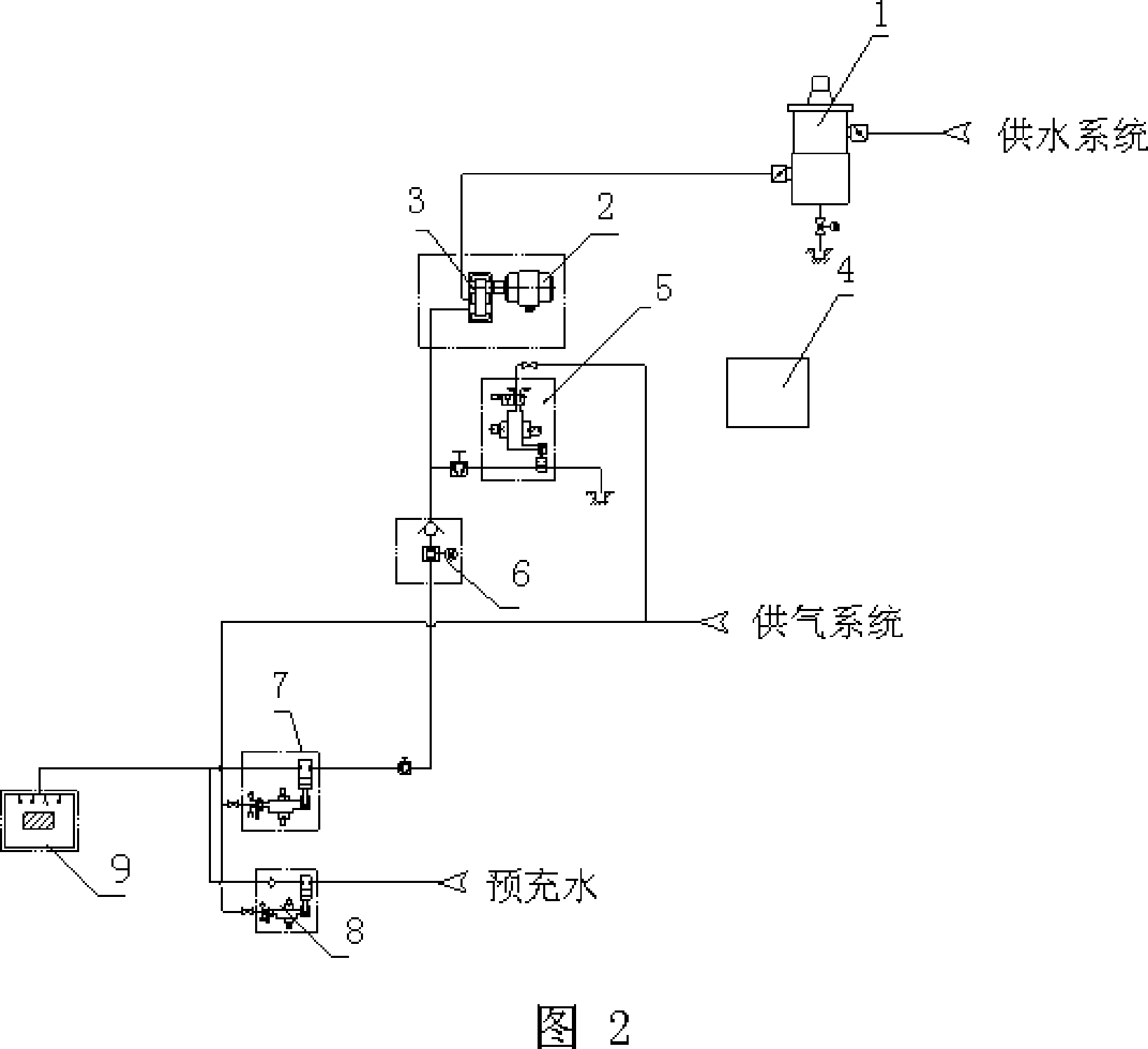

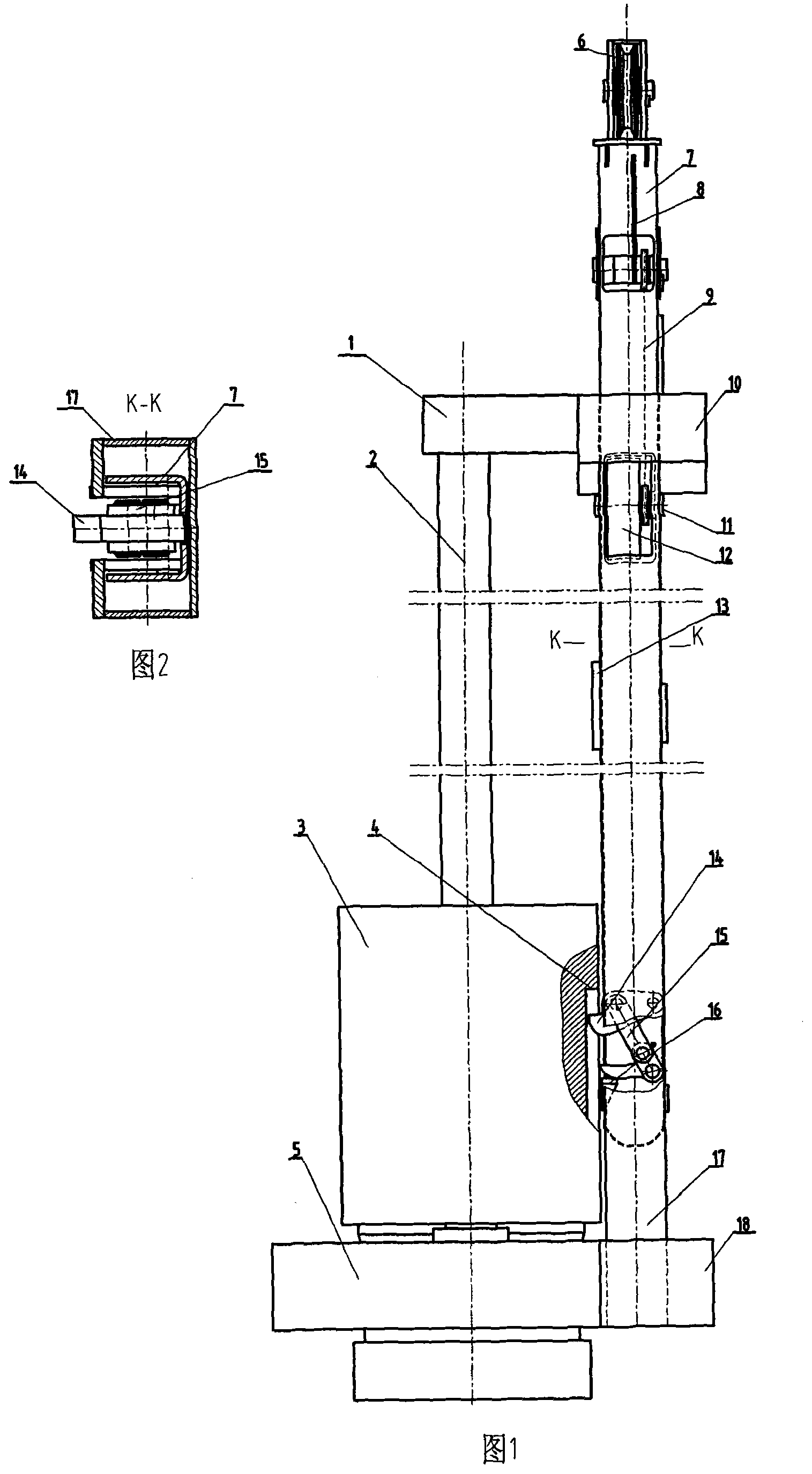

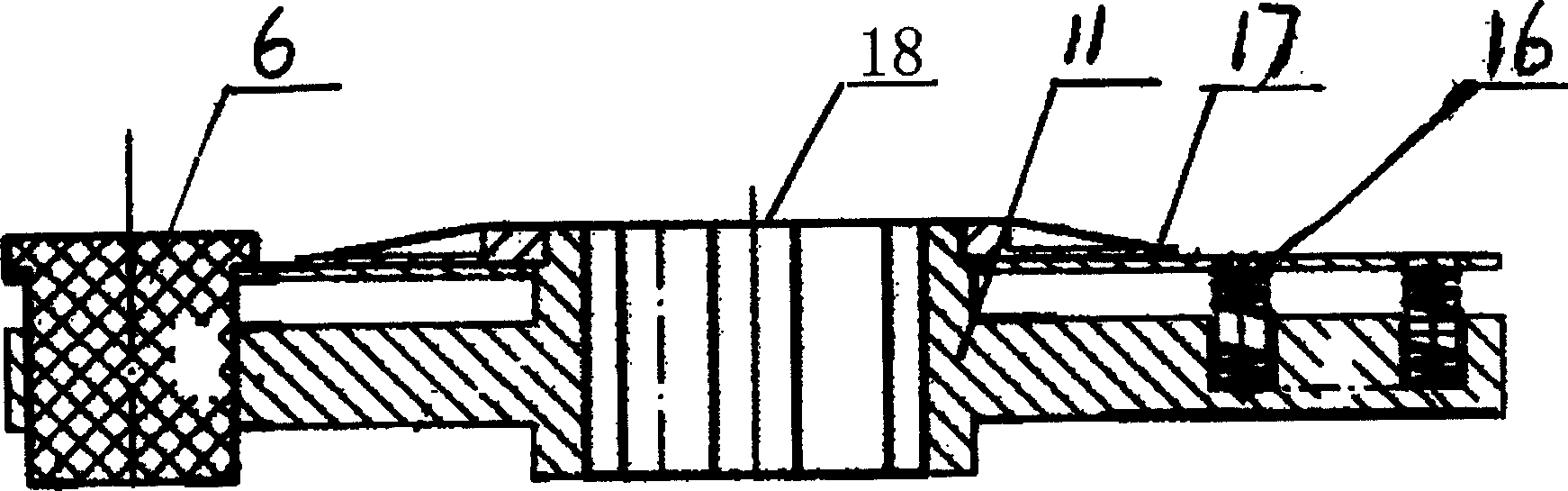

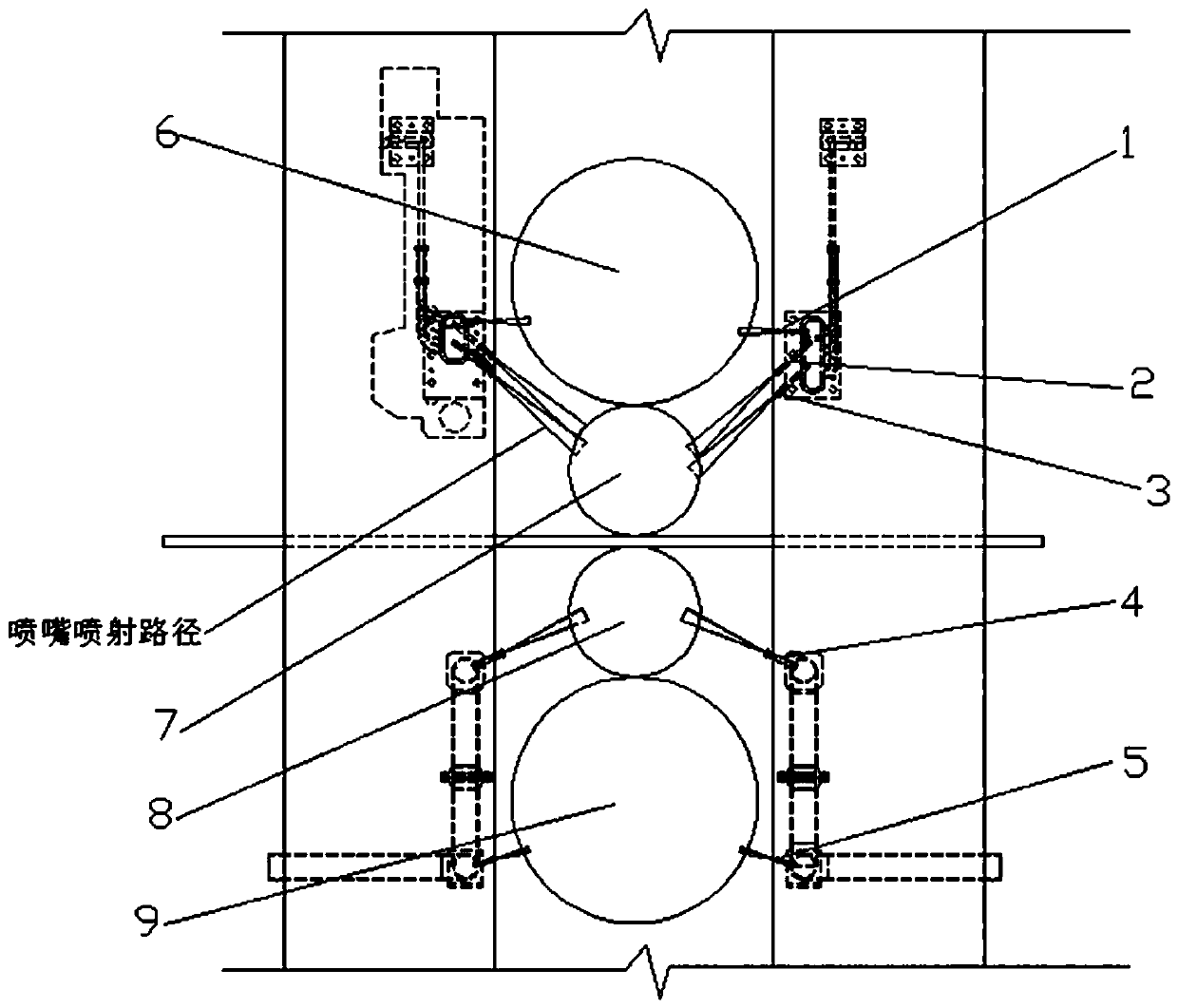

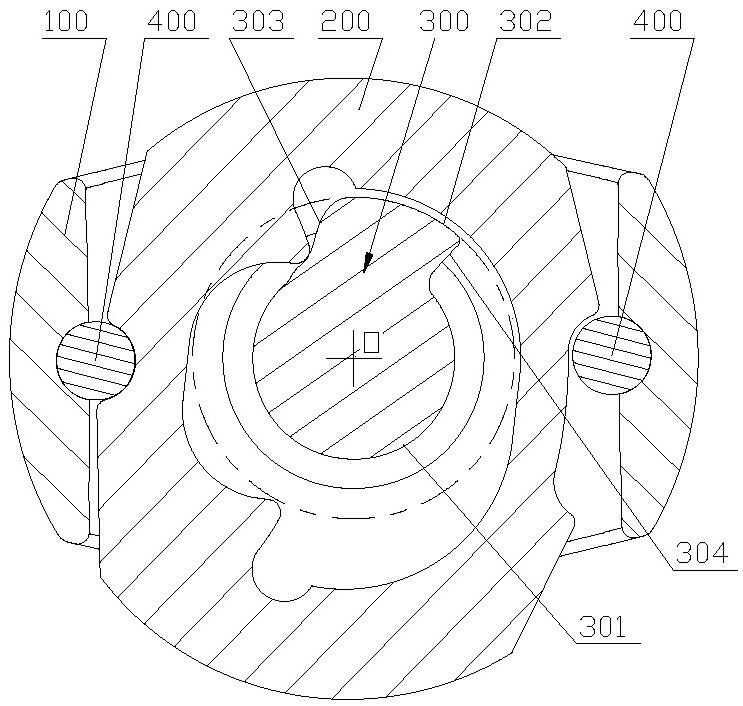

High-pressure water descaling system for hot continuous rolling production line

ActiveCN101147923AEasy temperature controlSmall footprintWork treatment devicesExtrusion cleaning devicesProduction lineElectricity

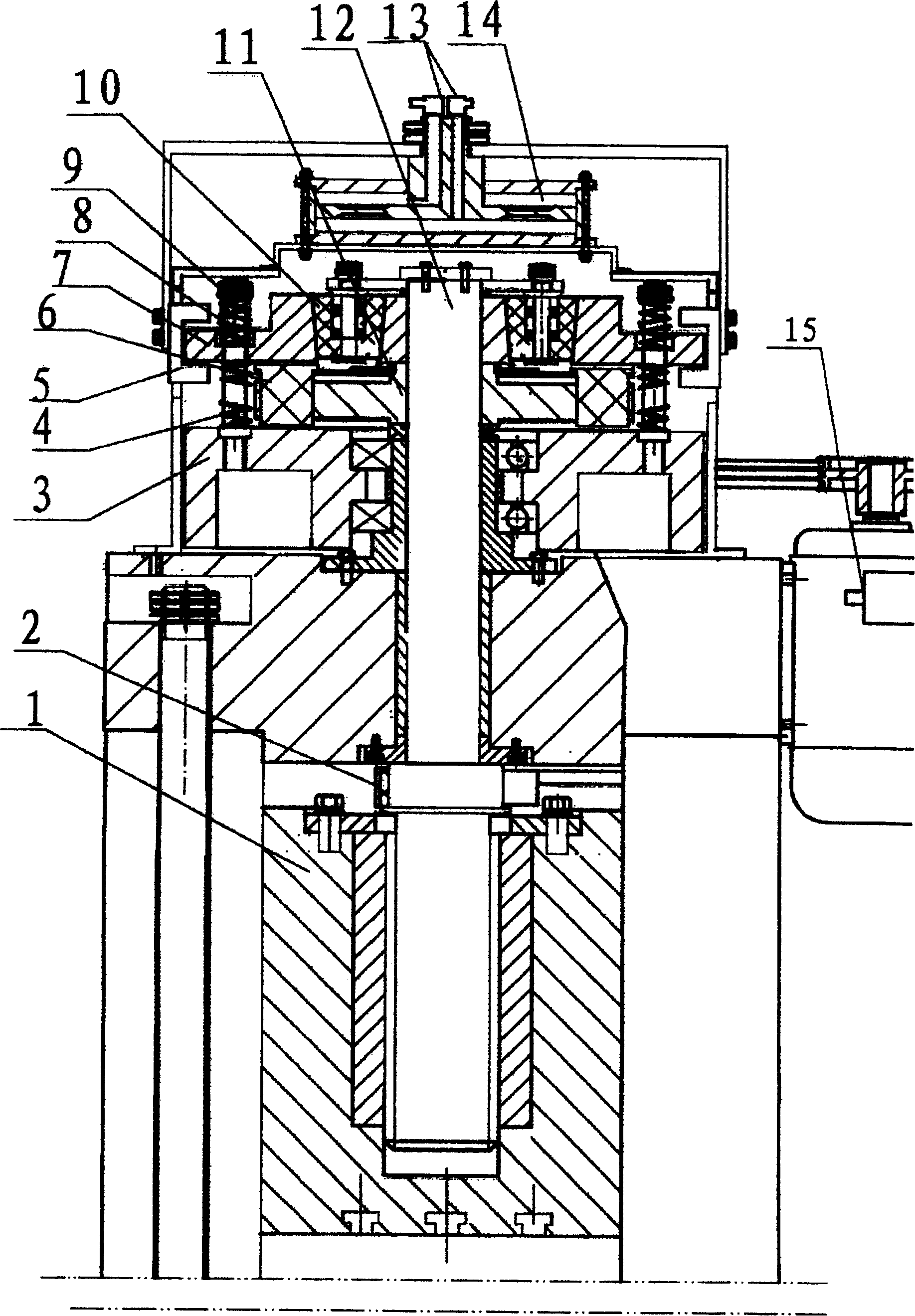

The present invention relates to a high-pressure water descaling system which can be used in the rolling process in the iron and steel metallurgical field. In particular, it relates to a descaling system which can be used in the process of rolling slab and sheet strip. It is characterized by that said invention is aimed at providing an ultrahigh-pressure small-flow high-pressure water descaling system for sheet bar hot continuous rolling production line. The water-out pressure of its descaling pump group is 25MPa-50MPa, and the water flow rate of its descaling nozzle is 20-40L / min..

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

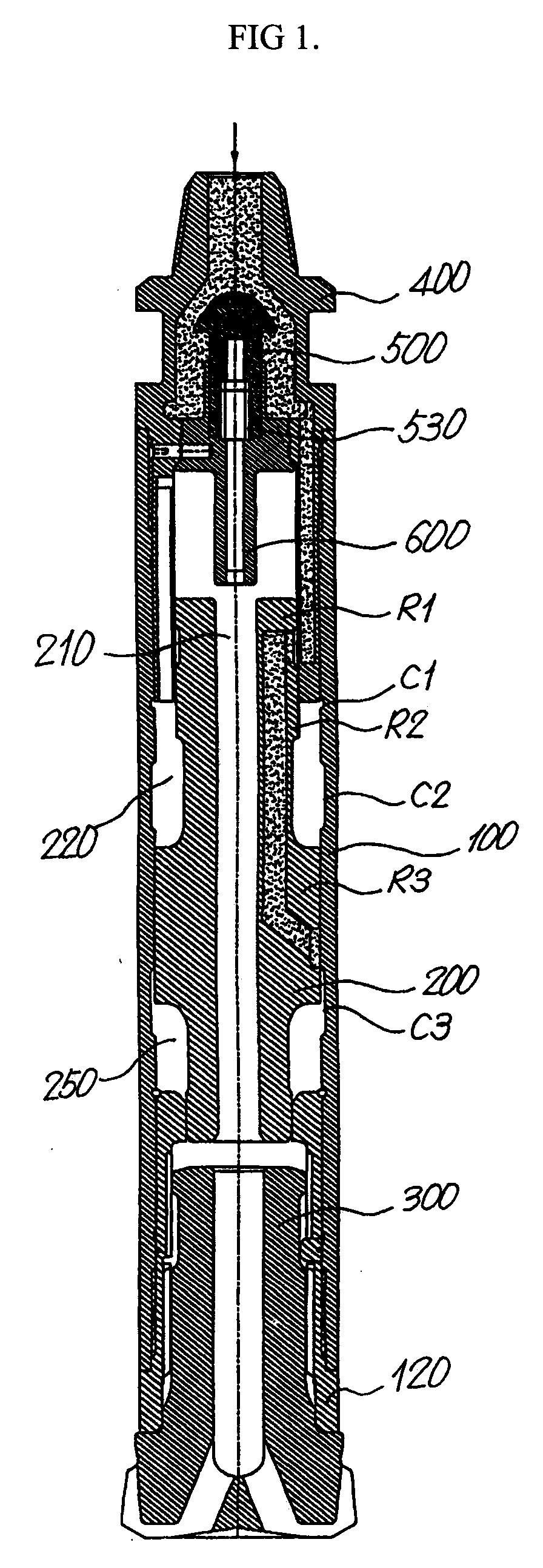

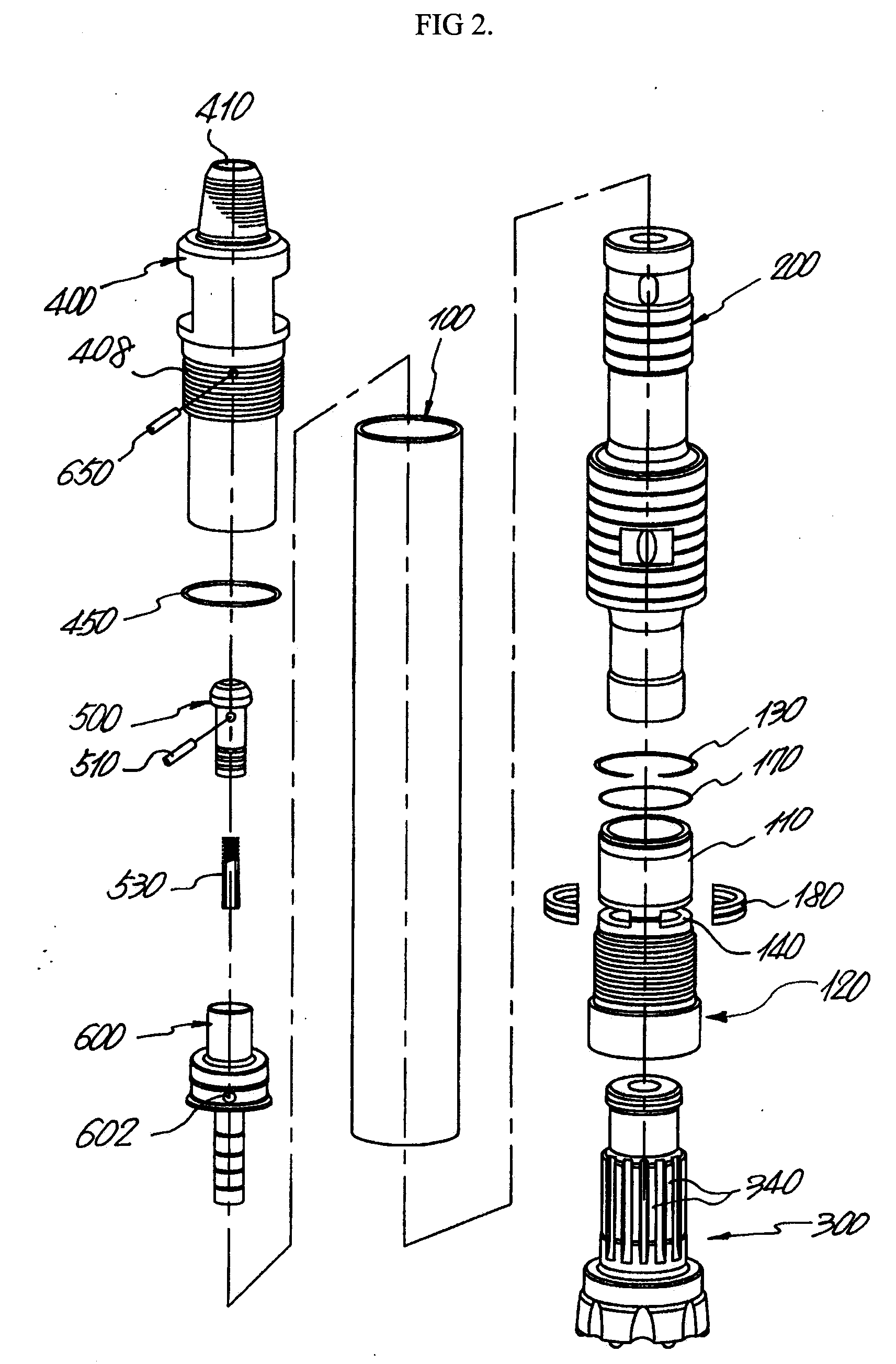

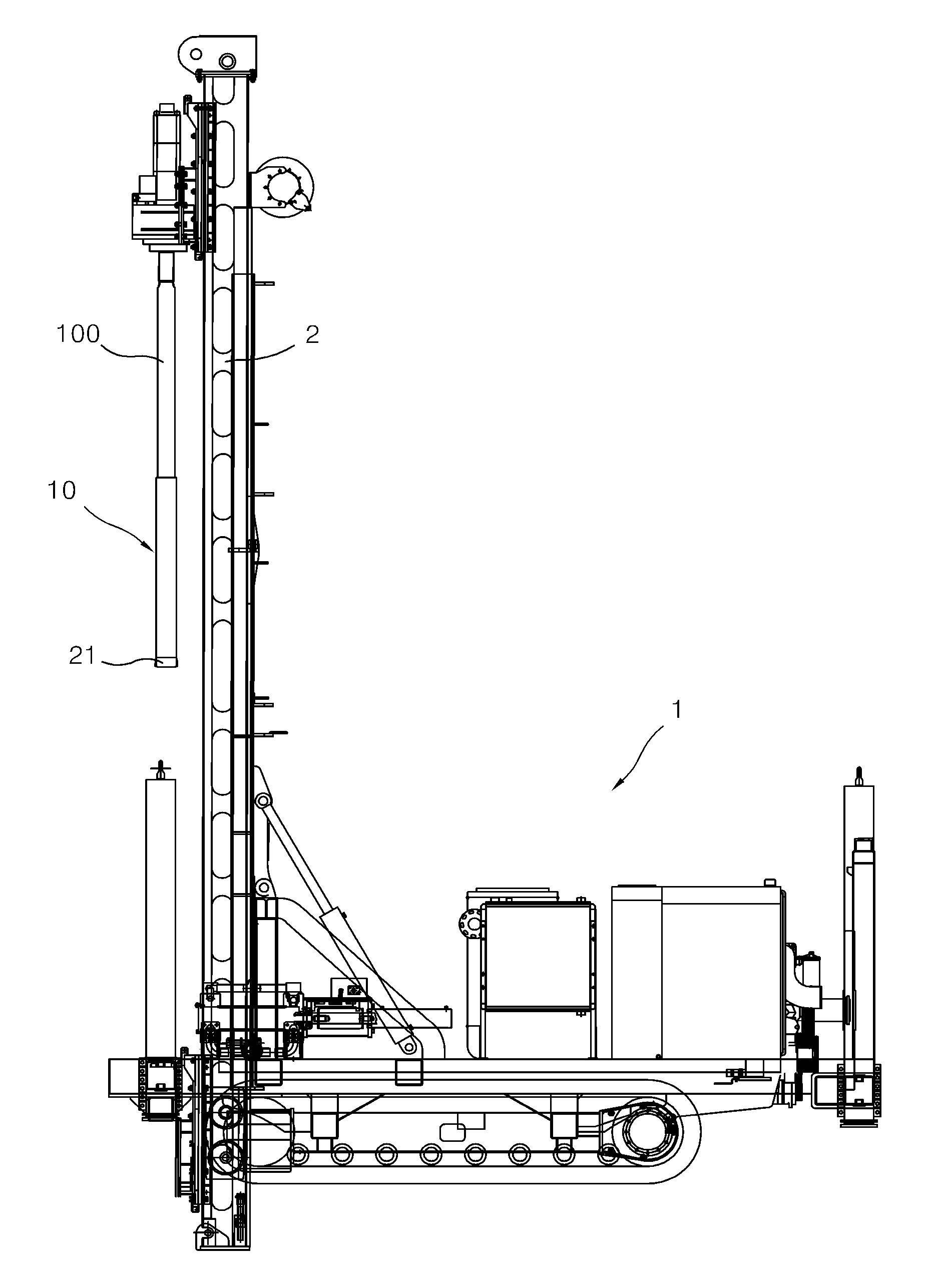

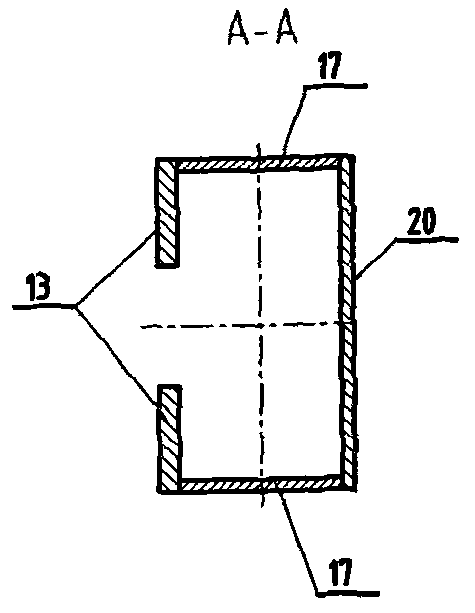

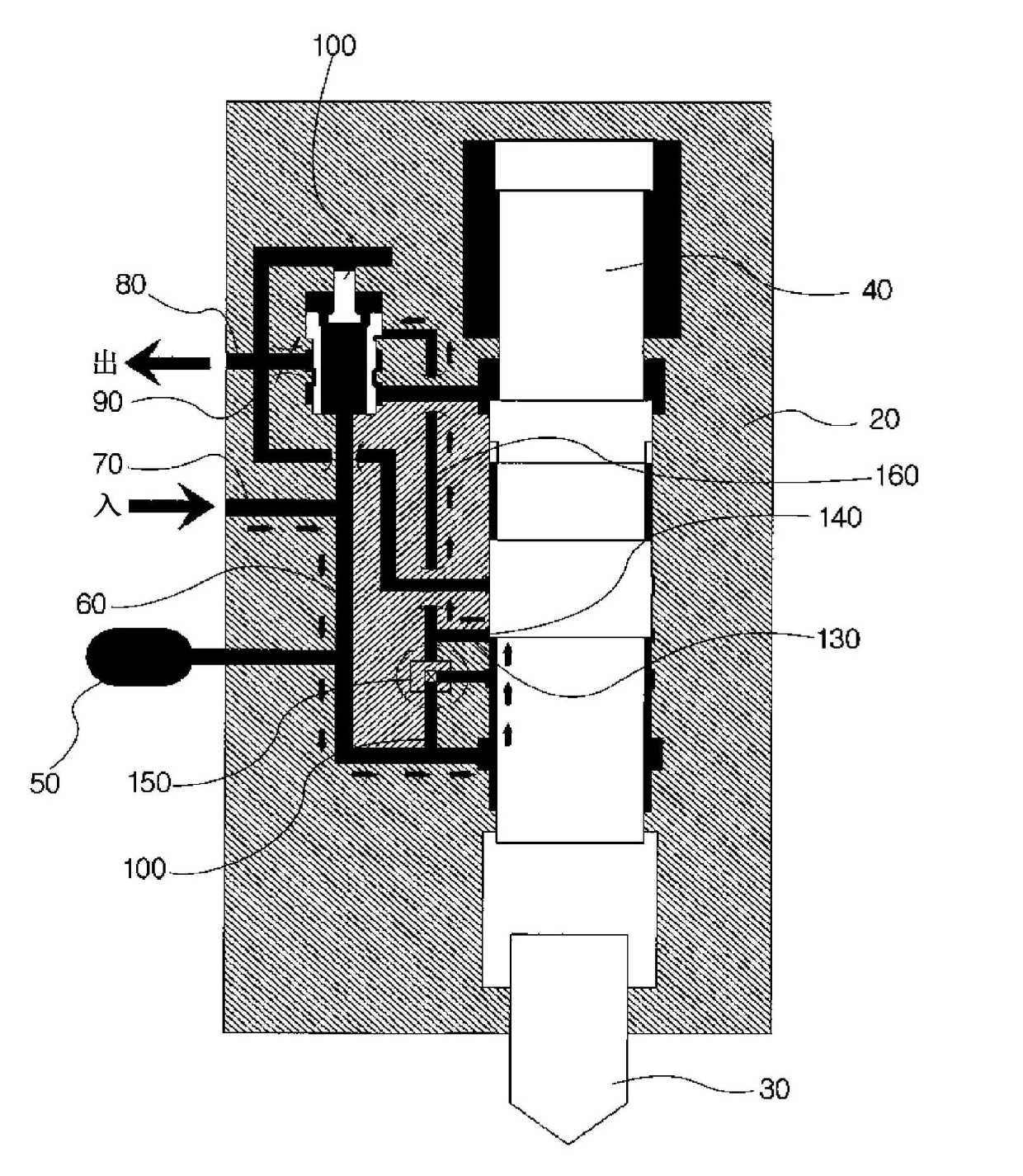

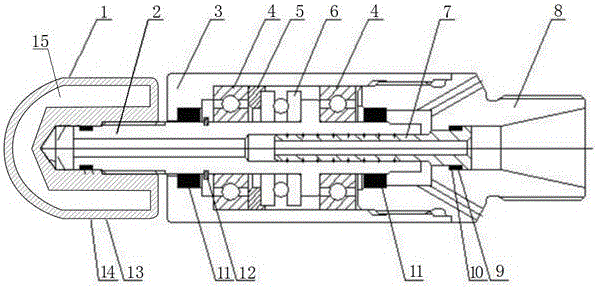

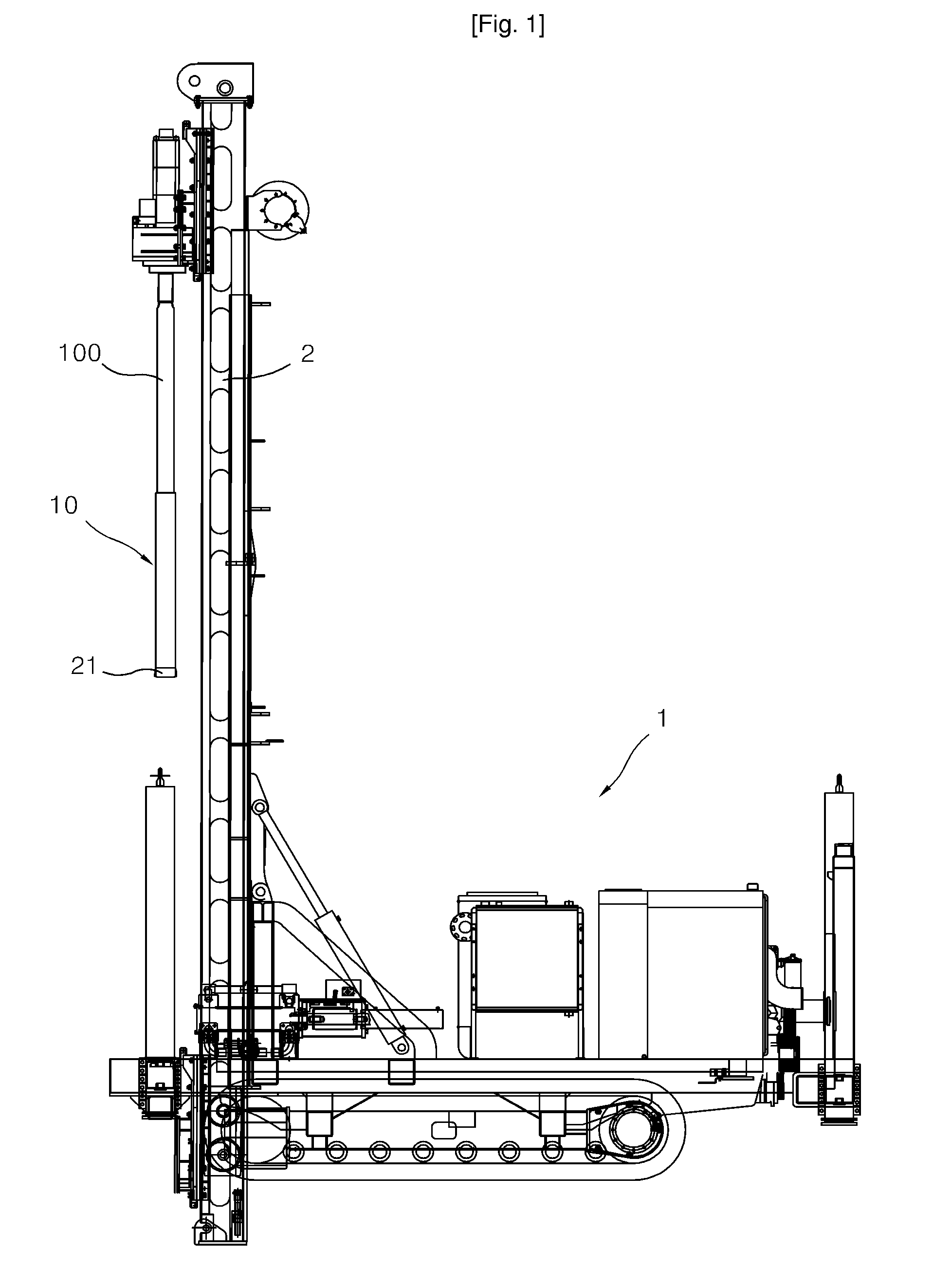

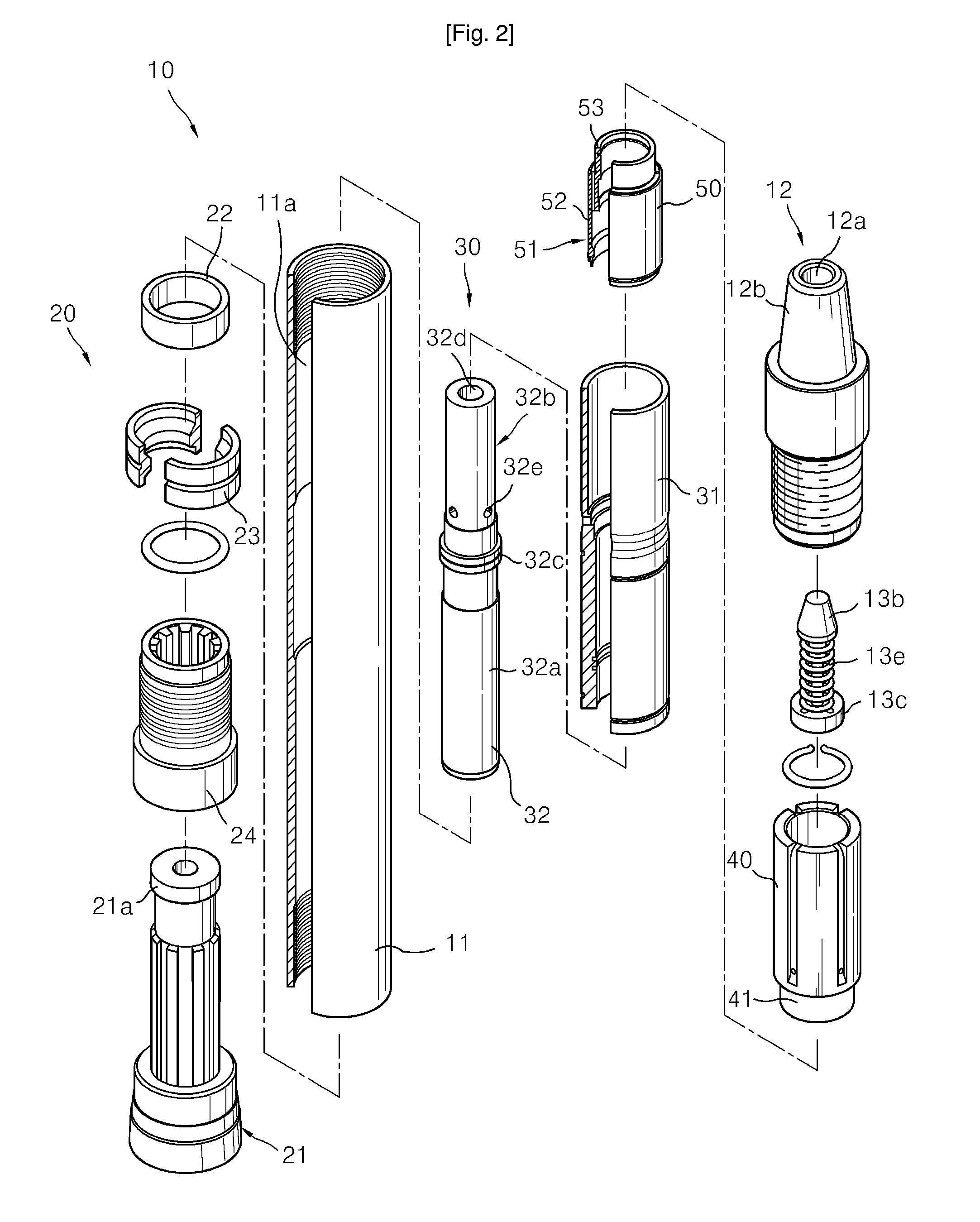

Ground Drilling Hammer and the Driving Method

InactiveUS20070251710A1Prevent functional degradationImprove the environmentReciprocating drilling machinesConstructionsFree stateEngineering

Disclosed herein is a pneumatic operated hammer for rock drilling, the hammer comprising a cylindrical casing, a back head mounted at an upper portion of the casing, a check valve for opening / closing a compressed air passageway in the casing, a guide for supporting the check valve, a piston adapted to ascend and descend with compressed air in the casing, and a button bit for performing a drilling work through the striking of the piston. The piston is extended to a certain length to conform to the work condition of the pneumatic hammer to thereby prevent a water back-flow phenomenon in which underground water, etc., is introduced into the drilling equipment during the drilling work, compressed air passageways and variable compressed air chambers are formed between the piston and the casing so that when the piston ascends by the compressed air, it abruptly ascends at a load-free state, and the piston has axial portions with a reference diameter and different outer diameters so that it is possible to manufacture a hammer bit having a plurality of variable compressed air chambers formed between the casing the piston to fit for the work capacity. The piston ascended in a load-free state strikes the button bit with its rapid and strong striking force produced by the compressed air supplied from the variable chambers while abruptly descending to thereby perform the drilling work.

Owner:EVERDIGM ROCK TOOLS CORP

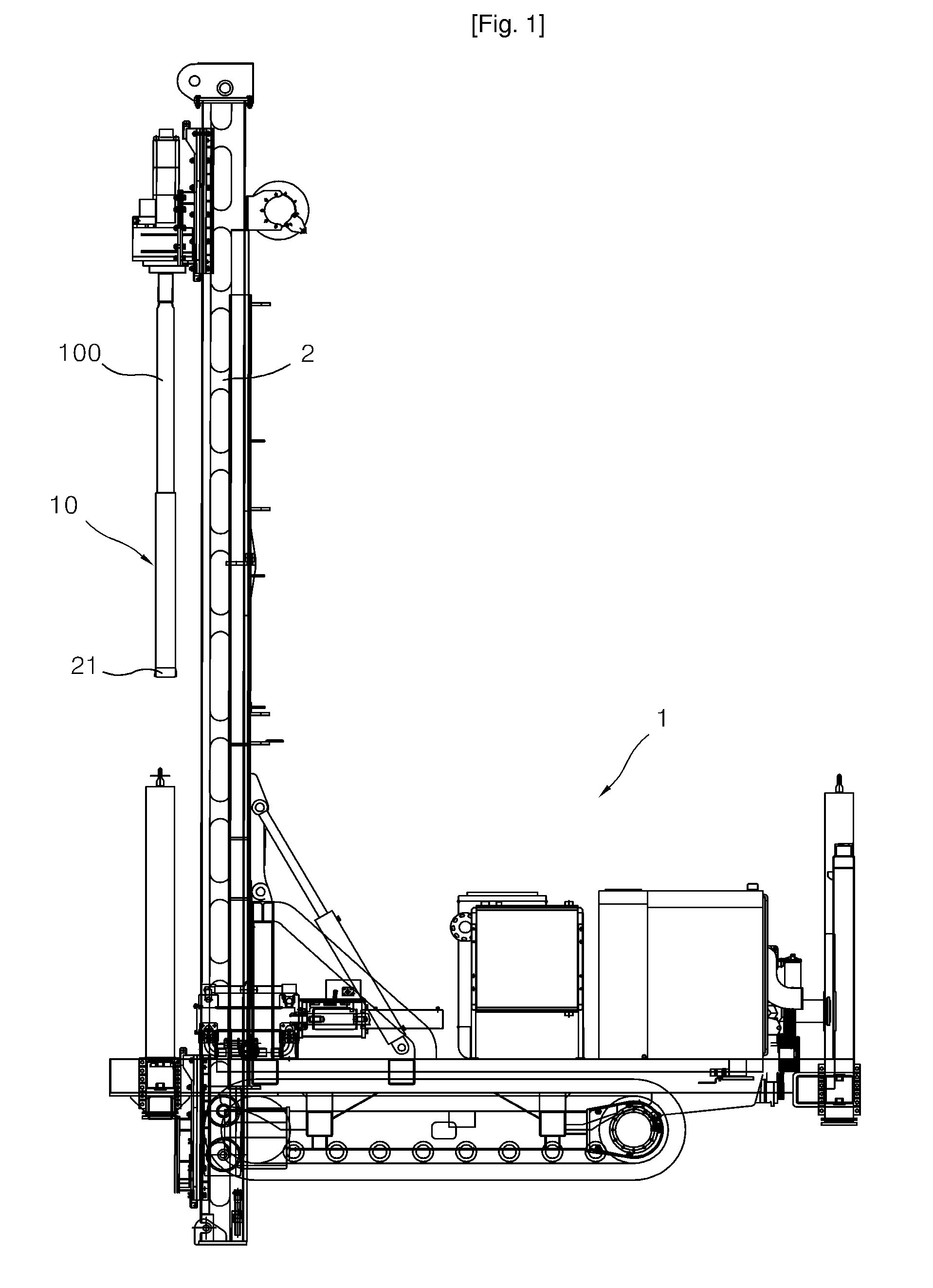

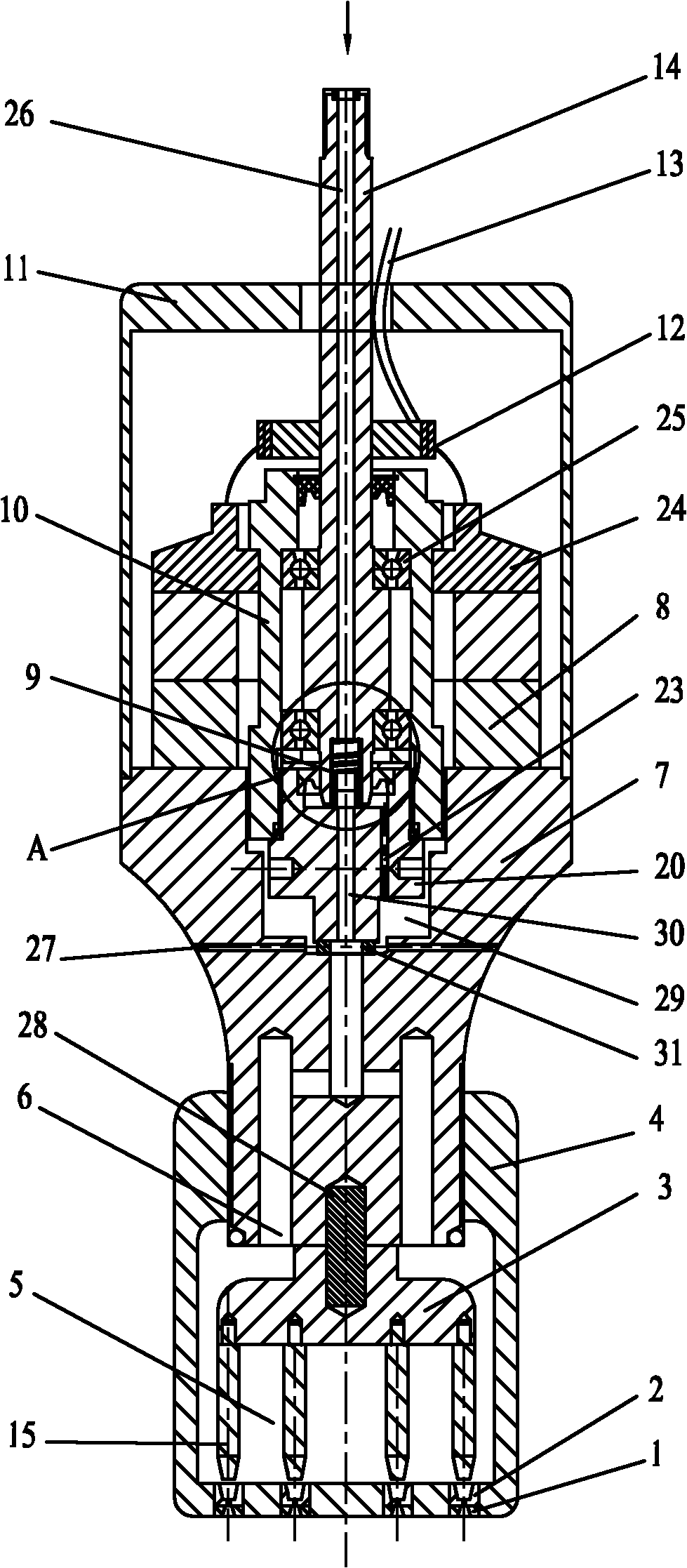

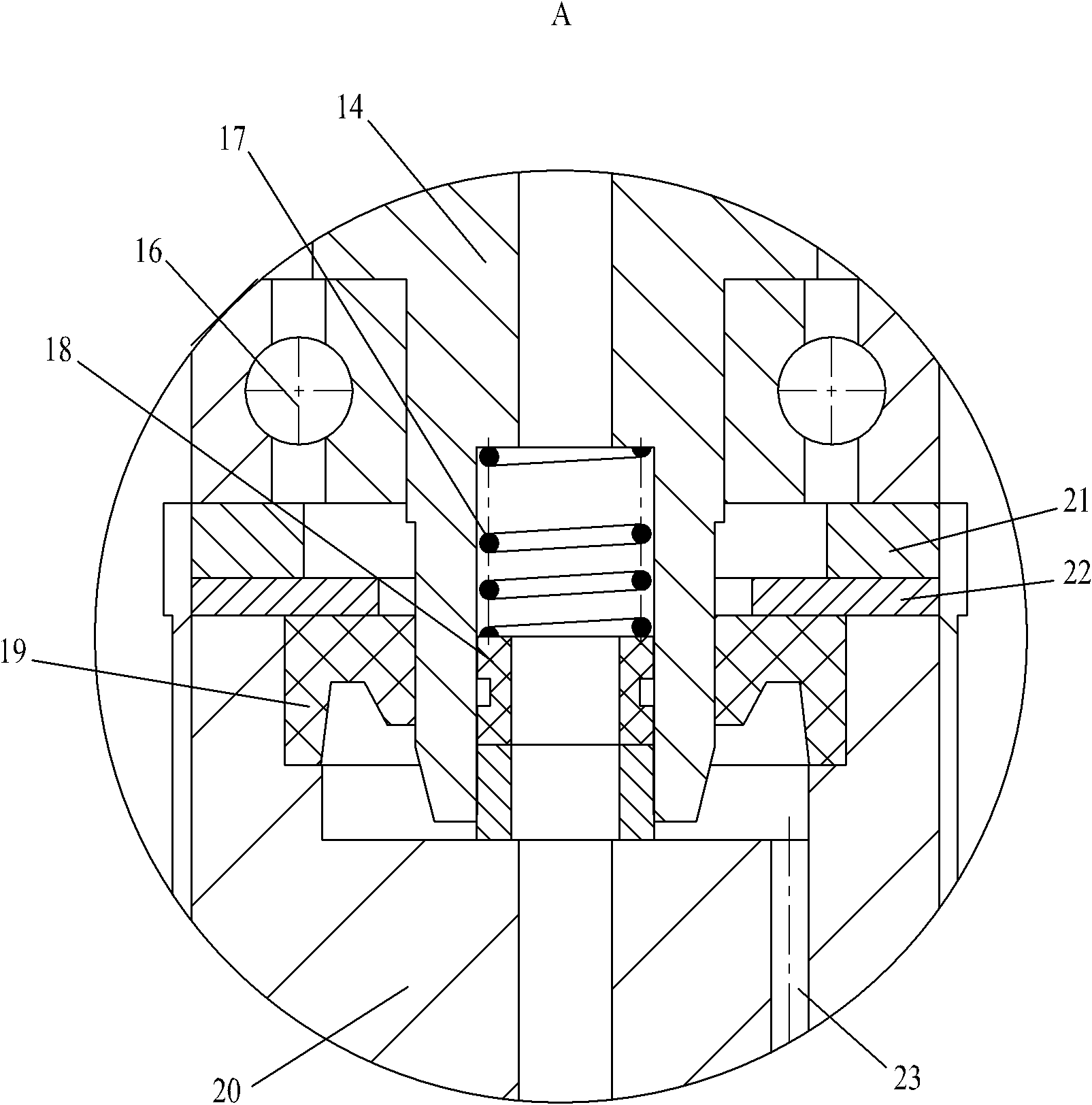

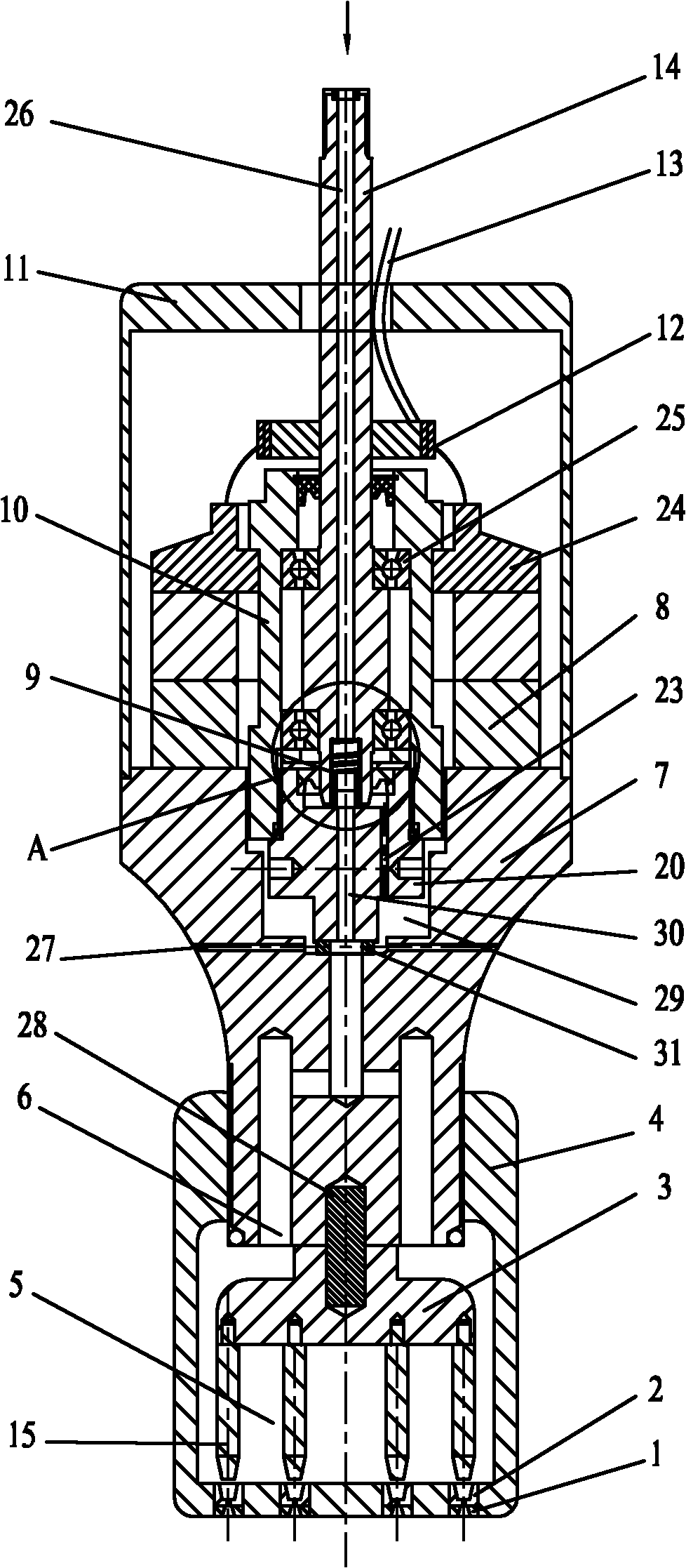

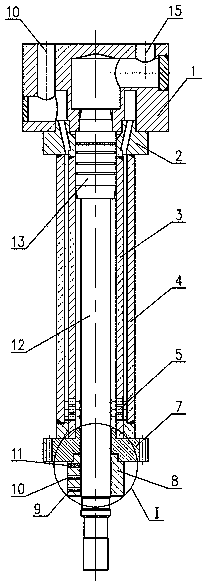

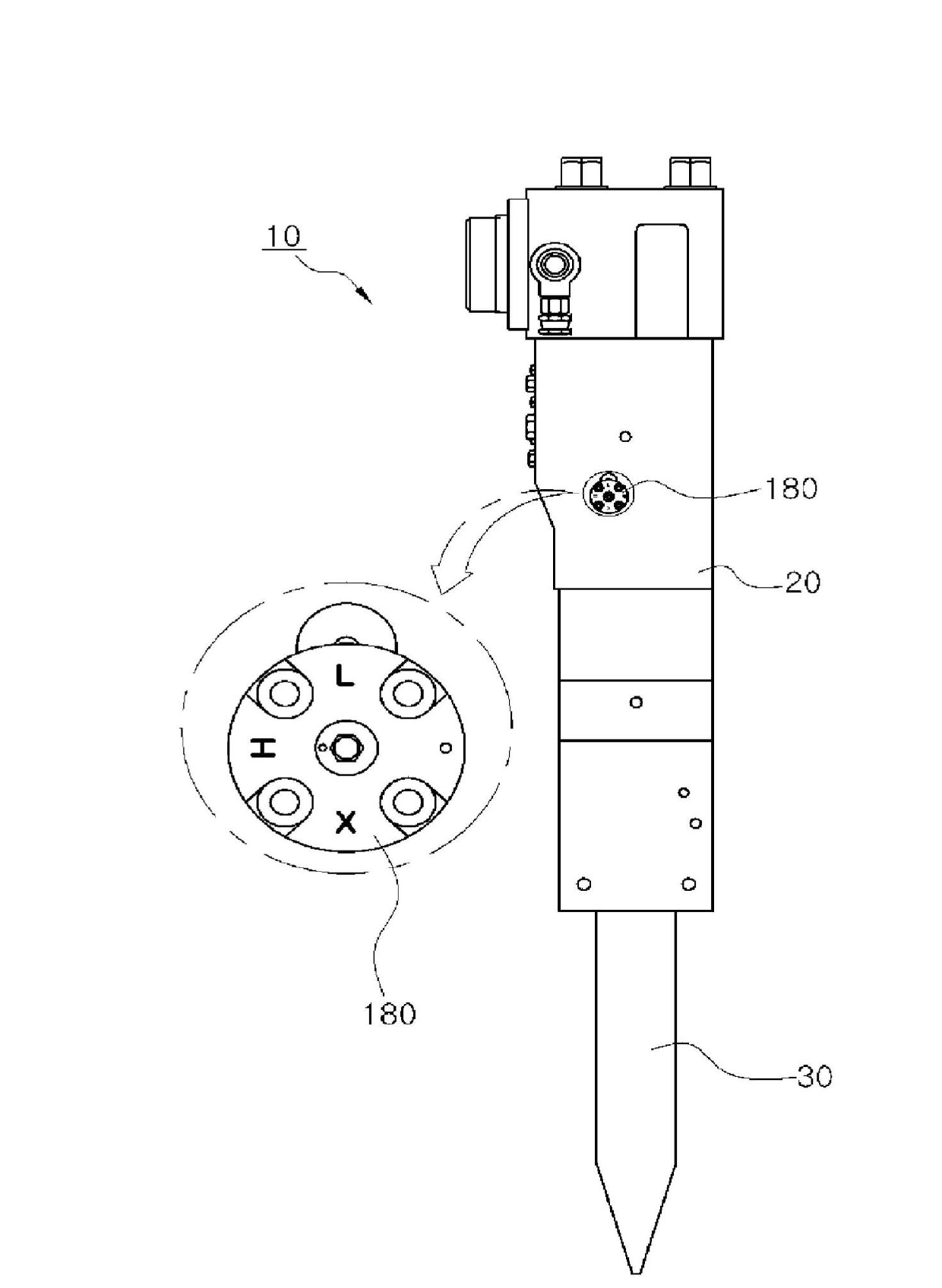

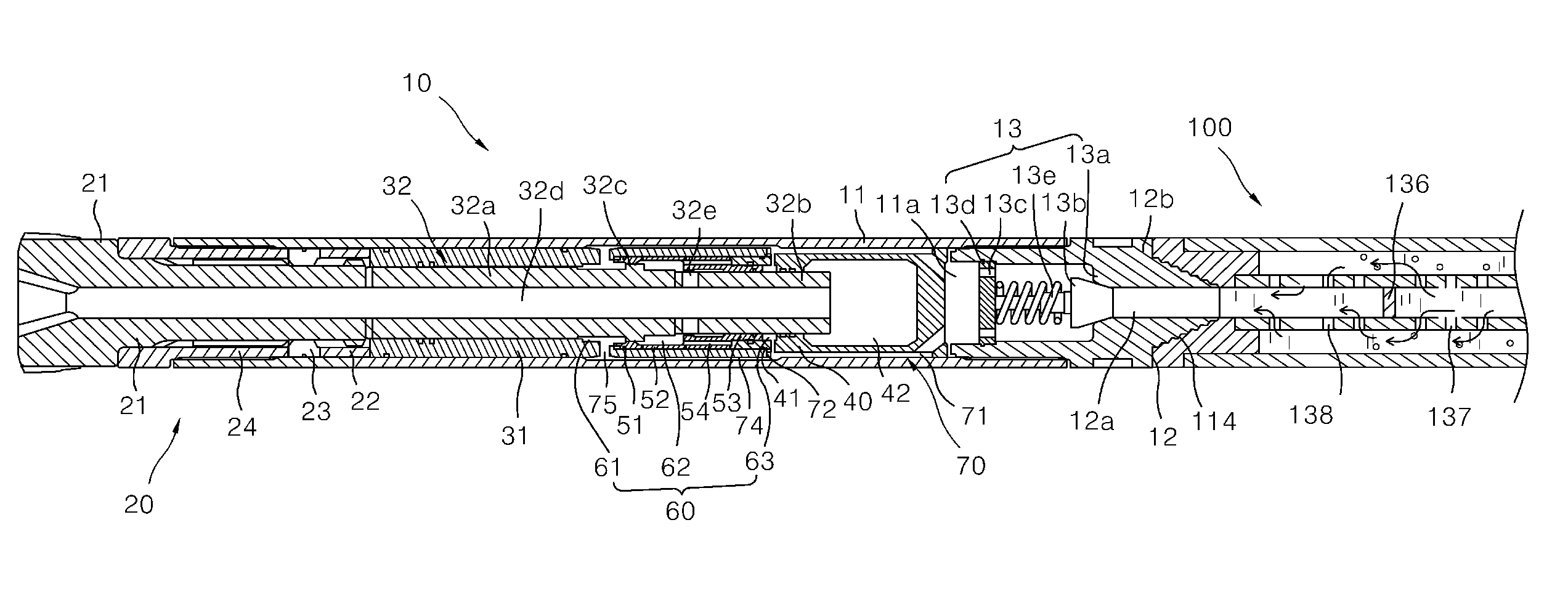

Water Hammer

ActiveUS20070261869A1Reduce consumptionIncrease the striking powerConstructionsReciprocating drilling machinesHigh pressure waterHigh pressure

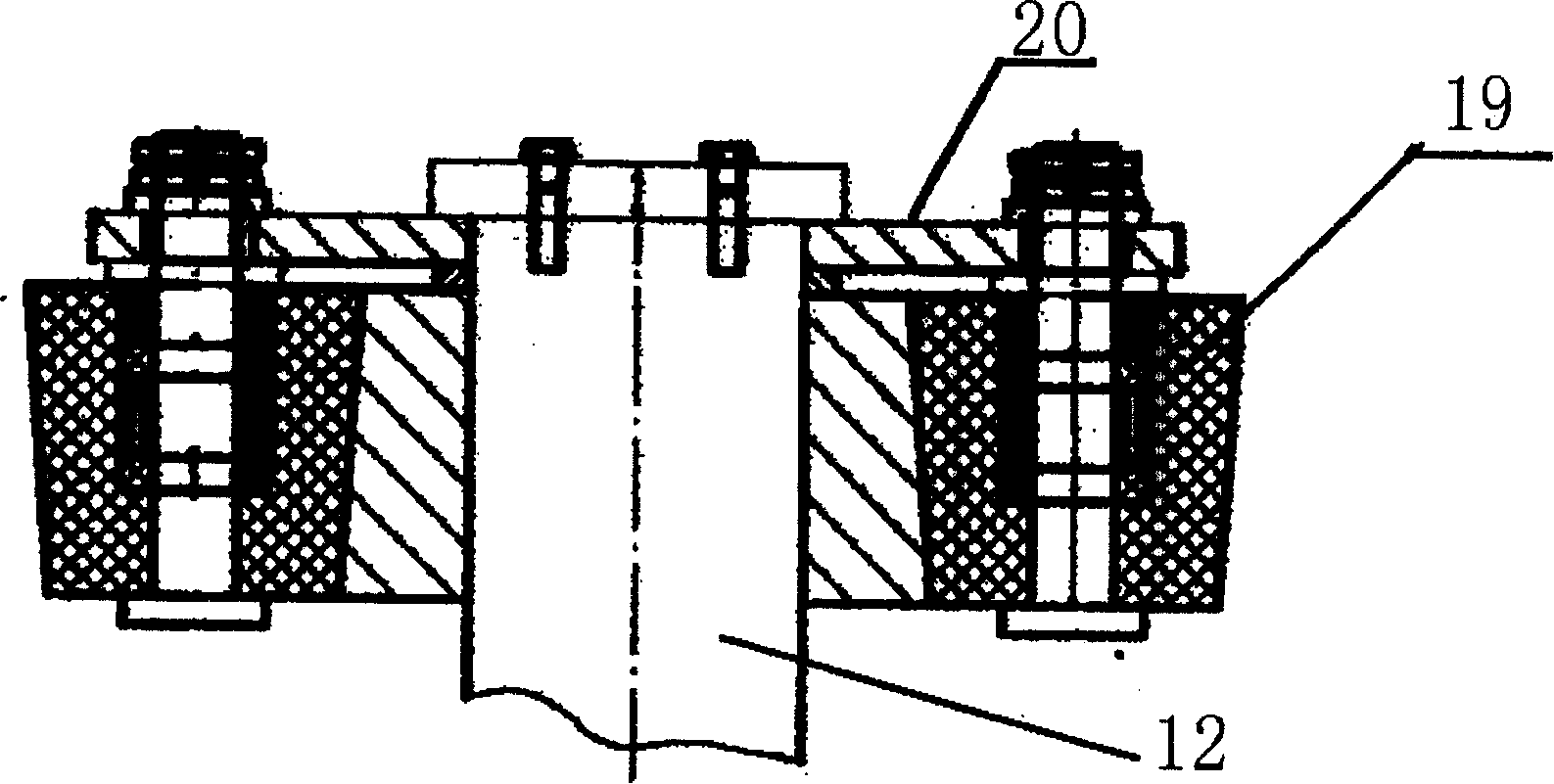

A water hammer using a drive rod is provided. The water hammer includes a tubular main body having a hollow portion; a socket coupled to an upper end of the main body and having a water pressure supply passage; a cylindrical piston housing connected to the main body; a piston slidably installed in the piston housing, for striking a bit of a bit unit installed at a lower portion of the main body, having a hollow portion through which water is discharged, an annular pressurizing portion protruding on its outer circumferential surface, and a first communication hole connected to the hollow portion; a sliding member fitted into the main body to be coupled to the piston housing, defining a valve installation space, and creating a space portion in which the piston is received when the piston is elevated; a valve member defining the valve installation space into first and third space portions along the length of the piston, the first and second space portions having different cross-sectional areas from each other, and valve member forming a second space portion between the first and third space portions, connected to the hollow portion of the piston and connected to the first space portion when the piston is elevated; and a water pressure supply unit for supplying high pressure water delivered to the water pressure supply passage of the socket to the first and second space portions.

Owner:IN

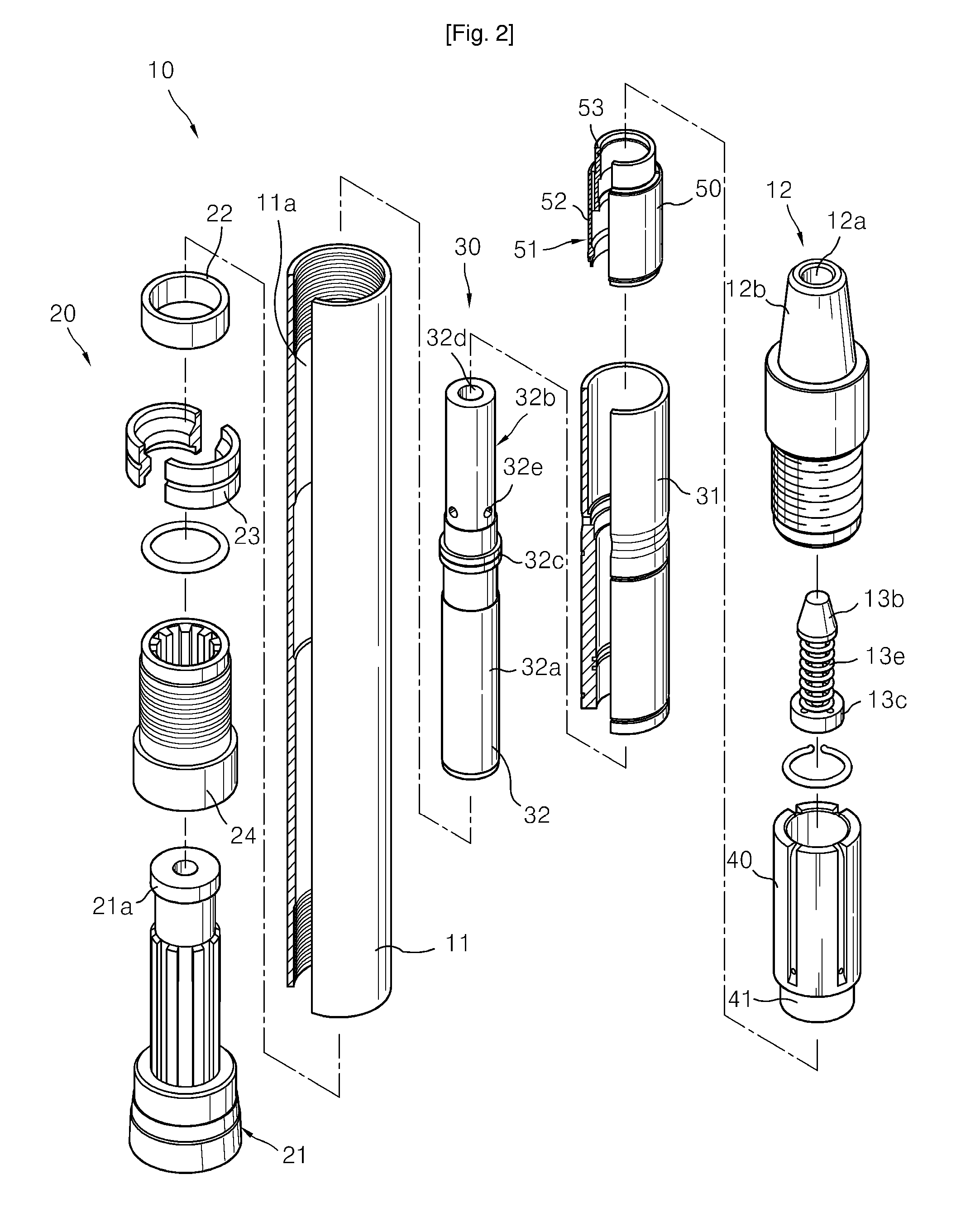

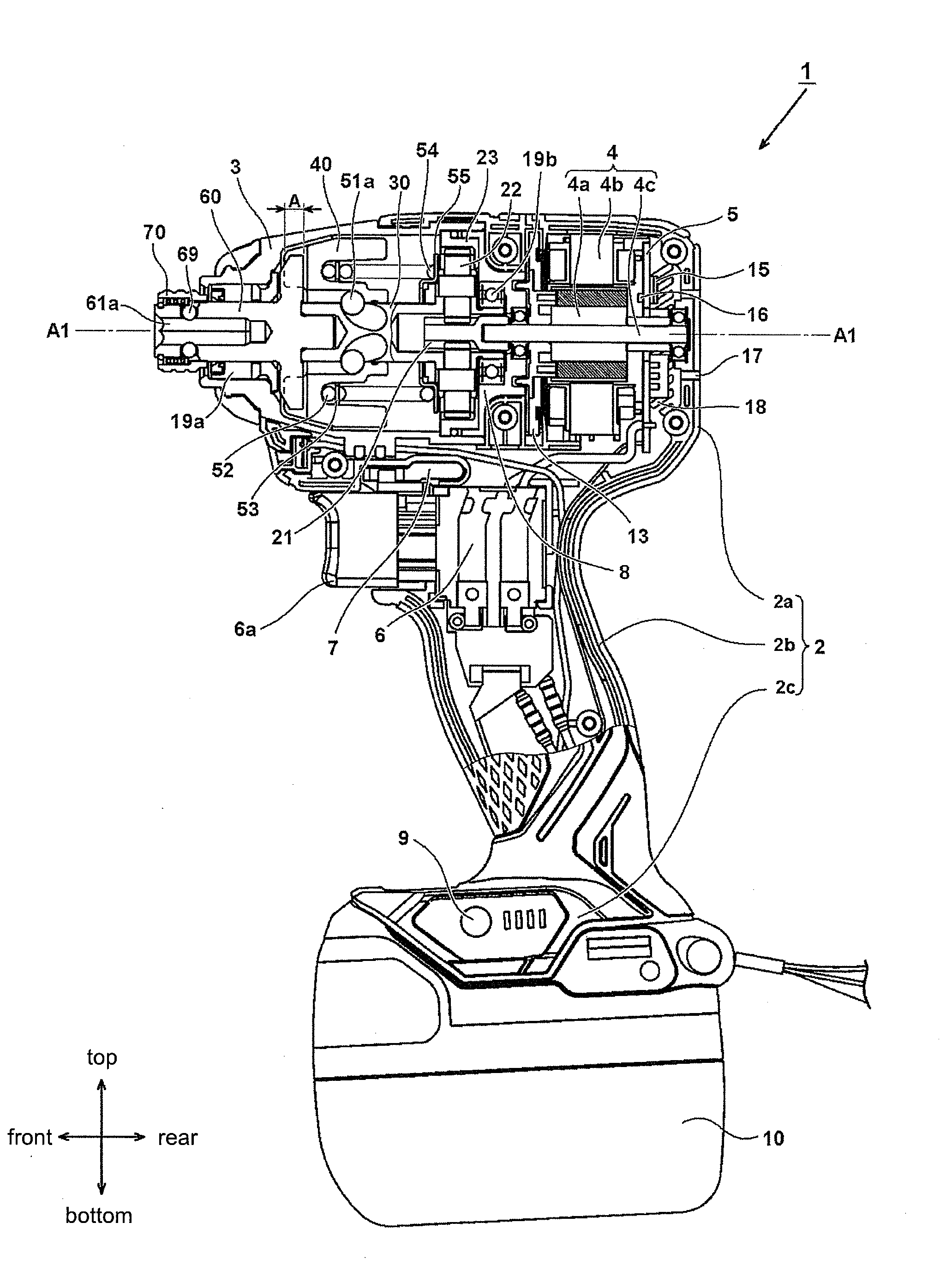

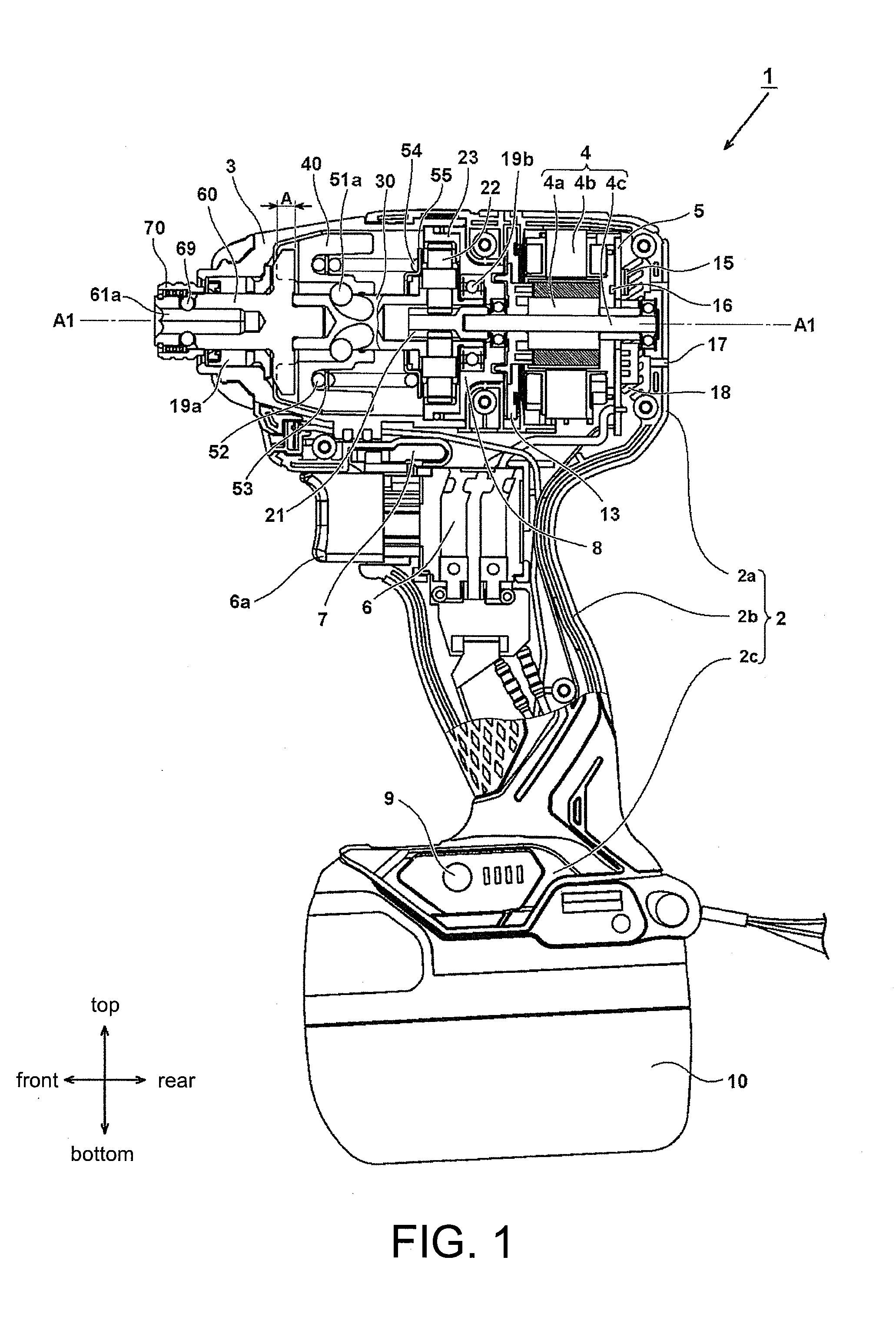

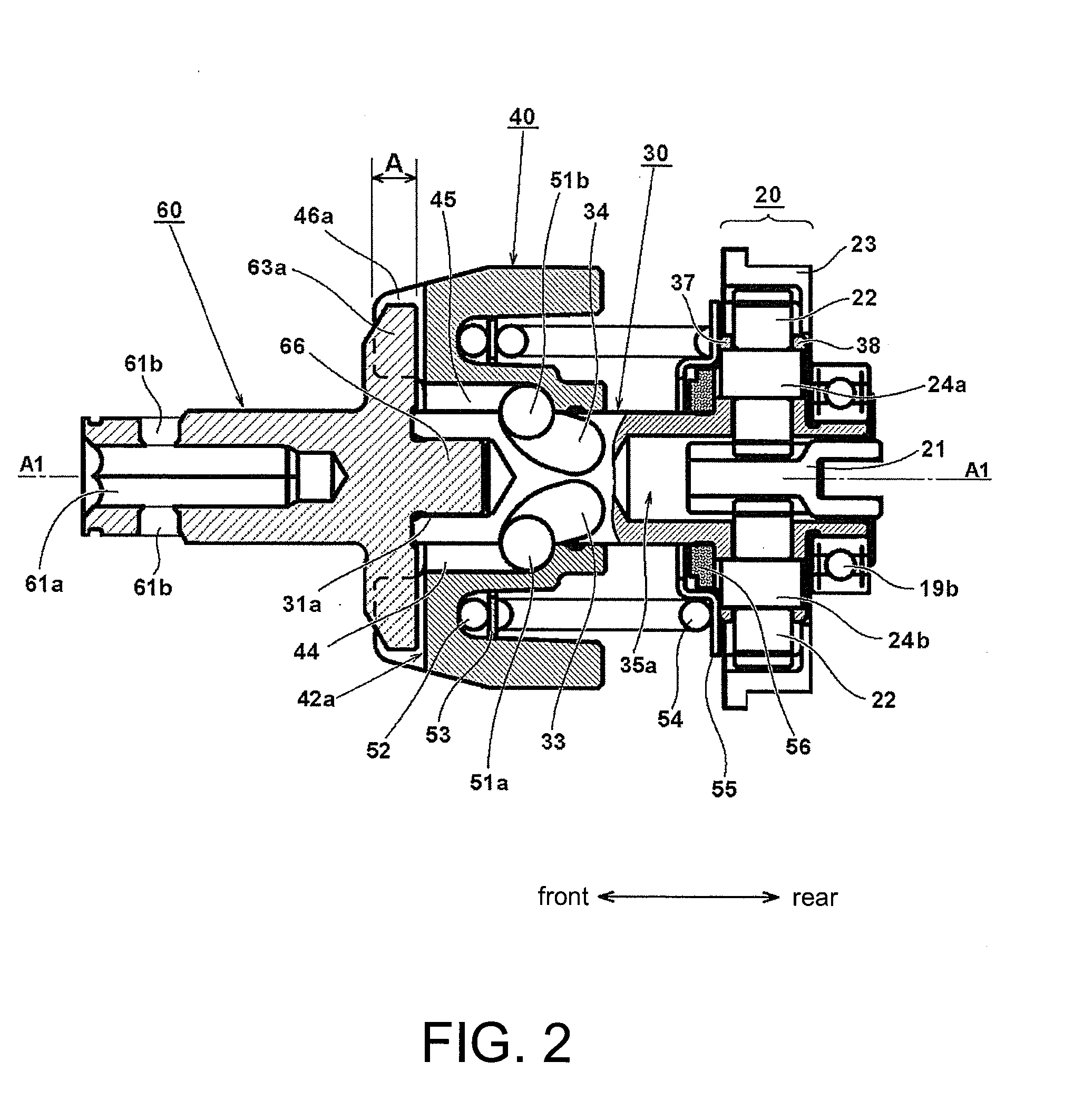

Electric tool

InactiveUS20170036327A1Preventing cam-outShorten the timePortable power-driven toolsPower driven toolsPower toolHigh torque

Provided is an impact type electric tool. A striking mechanism is used, which uses a hammer having striking claws that are equally arranged in the rotational direction and an anvil having struck claws. A relationship between a striking energy E, which the hammer has right before striking the anvil, and a disengaging torque TB, which is applied between the hammer and the anvil right before the hammer is disengaged from the anvil, is set as 5.3×TB<E<9.3×TB in the case of three claws and set as 9.3×TB<E<15.0×TB in the case of two claws, so as to perform striking by skipping one of the claws of the hammer and the anvil when a high torque is required. Accordingly, the electric tool achieves output of a high torque while maintaining a favorable operational feeling during striking.

Owner:HITACHI KOKI CO LTD

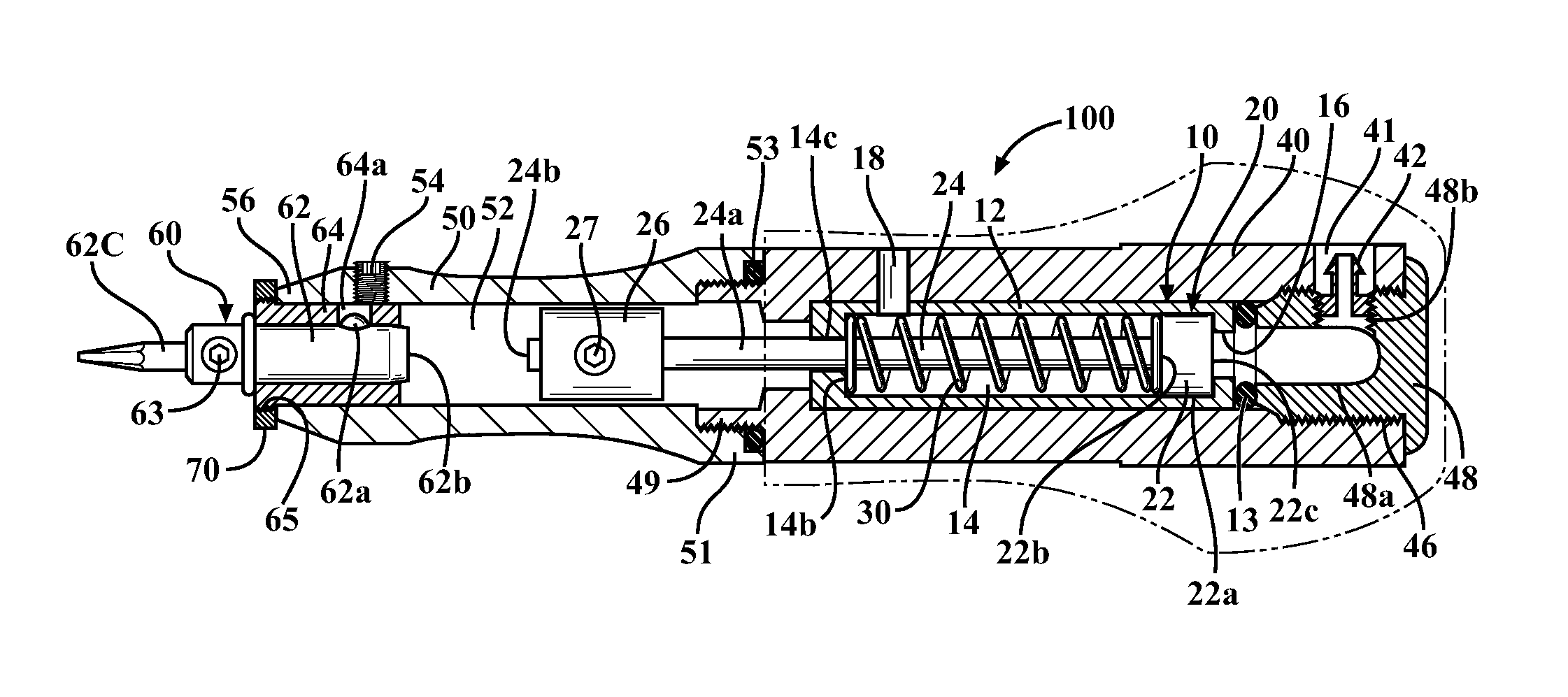

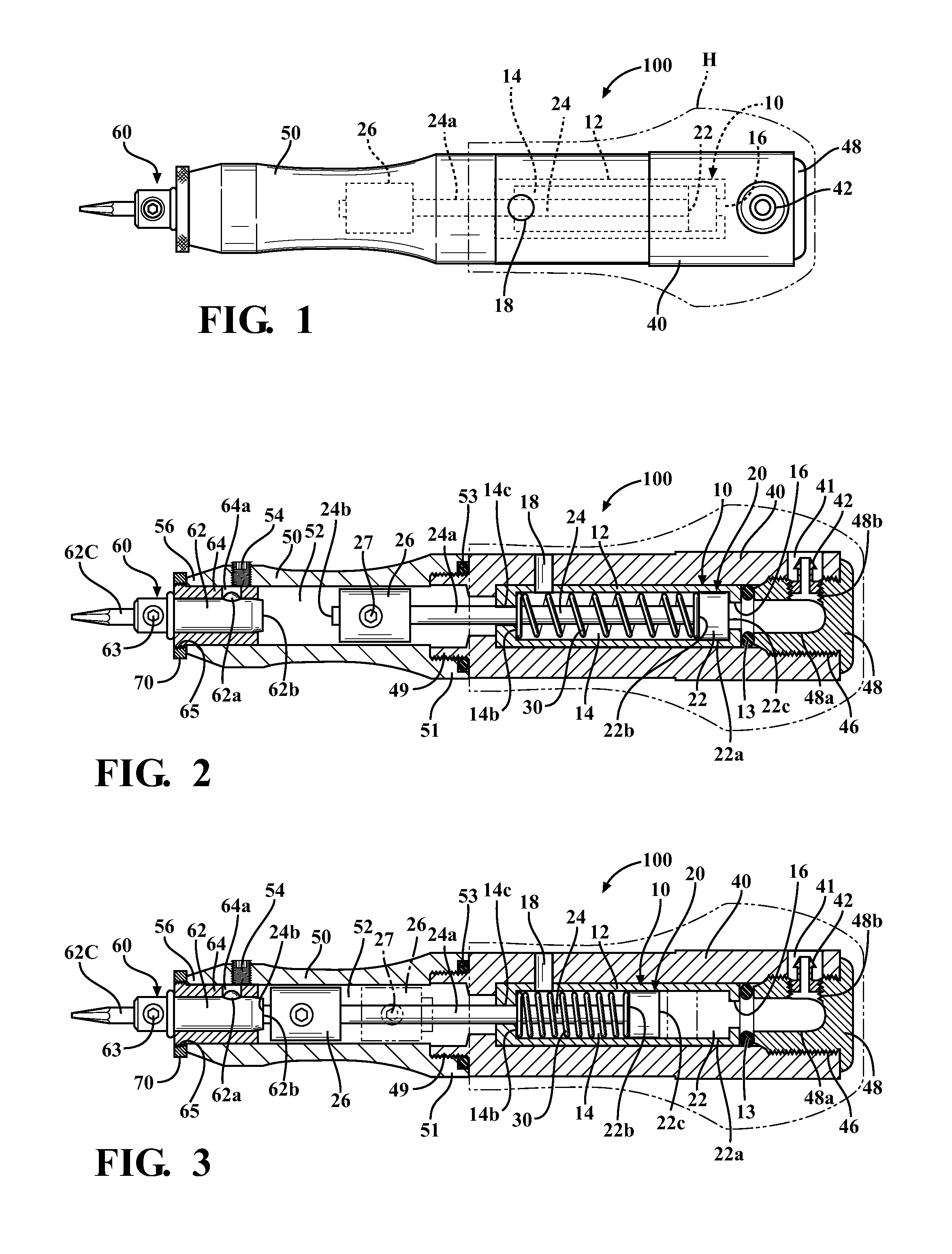

Pneumatic actuator for impact engraving tool

ActiveUS9079286B1Control moreReduce rateHand artistic toolsPortable percussive toolsReciprocating motionEngineering

A pneumatic actuator for use in pneumatic impact tools of the type used to engrave jewelry, and an impact tool adapted for the pneumatic actuator. The actuator includes a cylinder body with a pneumatic chamber housing a piston assembly reciprocating in response to pulses of pressurized air. The piston assembly includes a piston base and a striker pin in the pneumatic chamber, an outer end of the striker pin extending through and residing outside a forward end of the chamber. The outer end of the striker pin has an enlarged striker head of greater mass than the striker pin and / or the piston base in the chamber. A pneumatic impact tool is also disclosed, and includes a forward stylus section having a guide bore for the striker head and holding a graver assembly in spaced relationship to the striker head.

Owner:GRABOUTIL

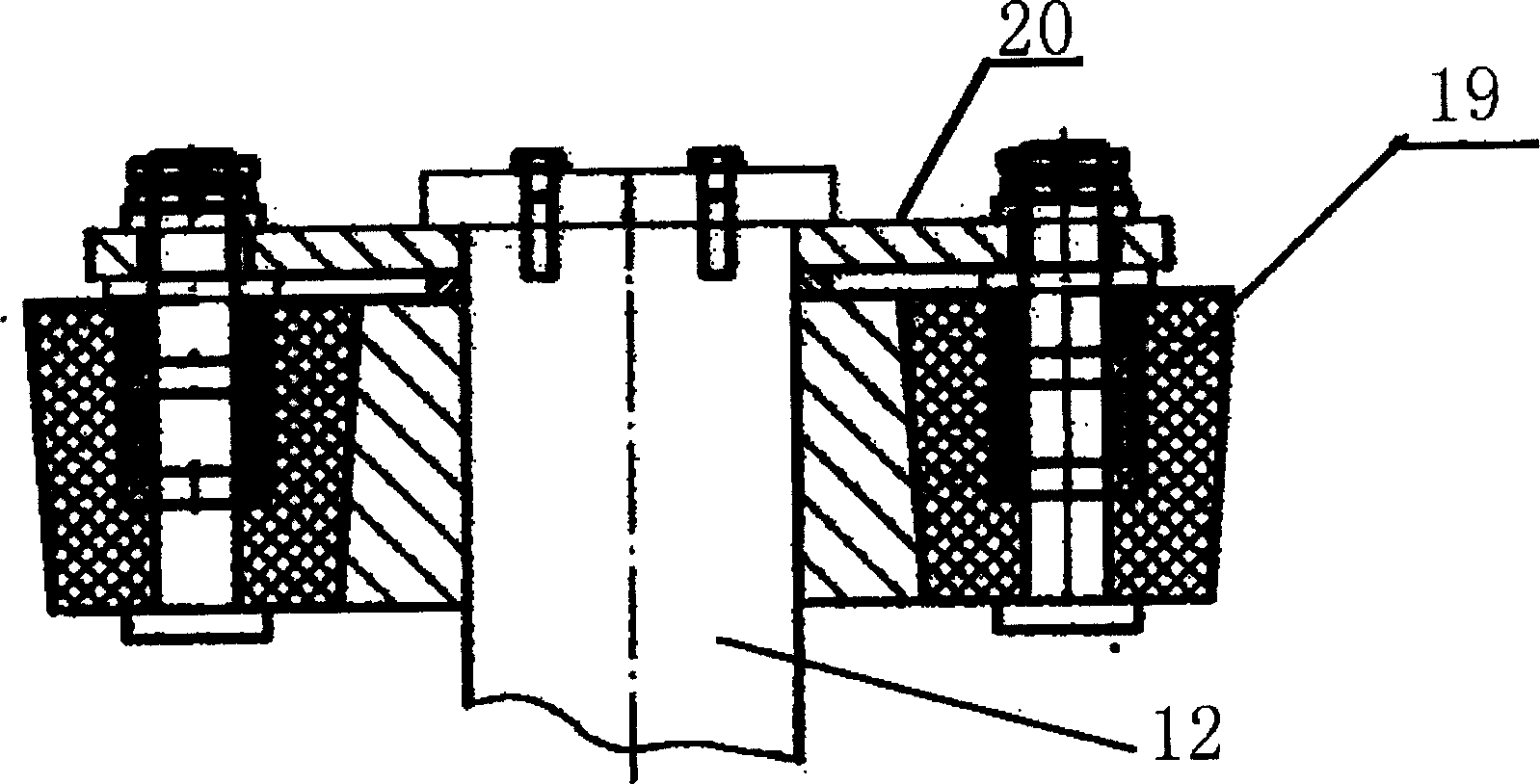

Ultrasonic pulse resonance jet rotary spray-head device

InactiveCN101940994AImprove energy conversion efficiencyIncrease cleaning width and areaLiquid spraying apparatusCleaning using liquidsSpray nozzleEnergy conversion efficiency

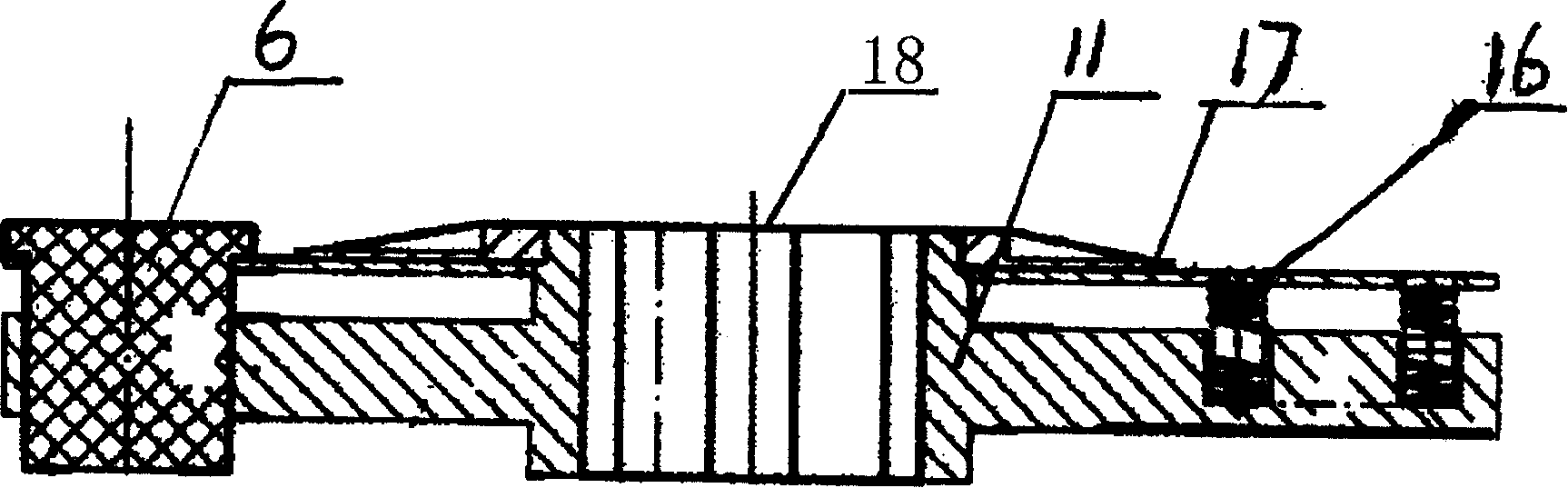

The invention relates to an ultrasonic pulse resonance jet rotary spray-head device which comprises an ultrasonic transducer and a spray head, wherein a longitudinal pulse jet inlet is drilled in an ultrasonic transducer body, the ultrasonic transducer body is rotatably installed on the central shaft of the transducer, a high-pressure rotary sealing device is arranged between the central shaft of the transducer and the ultrasonic transducer body, an axial high-pressure water channel communicated with the longitudinal pulse jet inlet is drilled in the central shaft of the transducer, and an ultrasonic transduction vibrator is arranged outside the central shaft of the transducer; and an oscillation cavity is arranged in the shell of the spray head, a plurality of nozzles are arranged at the lower end of the shell of the spray head, a multi-head amplitude-changing rod is arranged in the oscillation cavity, and a plurality of miniature amplitude-changing heads are fixedly connected onto the multi-head amplitude-changing rod. The design of the rotary ultrasonic transducer and the spray head is adopted by the invention, the oscillation cavity is arranged in the shell of the spray head, and the multi-head amplitude-changing rod is arranged in the oscillation cavity, thereby improving the energy conversion efficiency, increasing the cleaning width and area of the ultrasonic pulse resonance jet rotary spray-head device and greatly improving the cleaning efficiency of the ultrasonic pulse resonance jet rotary spray-head device.

Owner:西安远诚机电科技有限公司

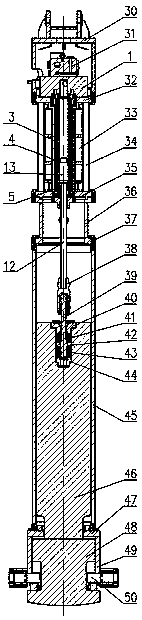

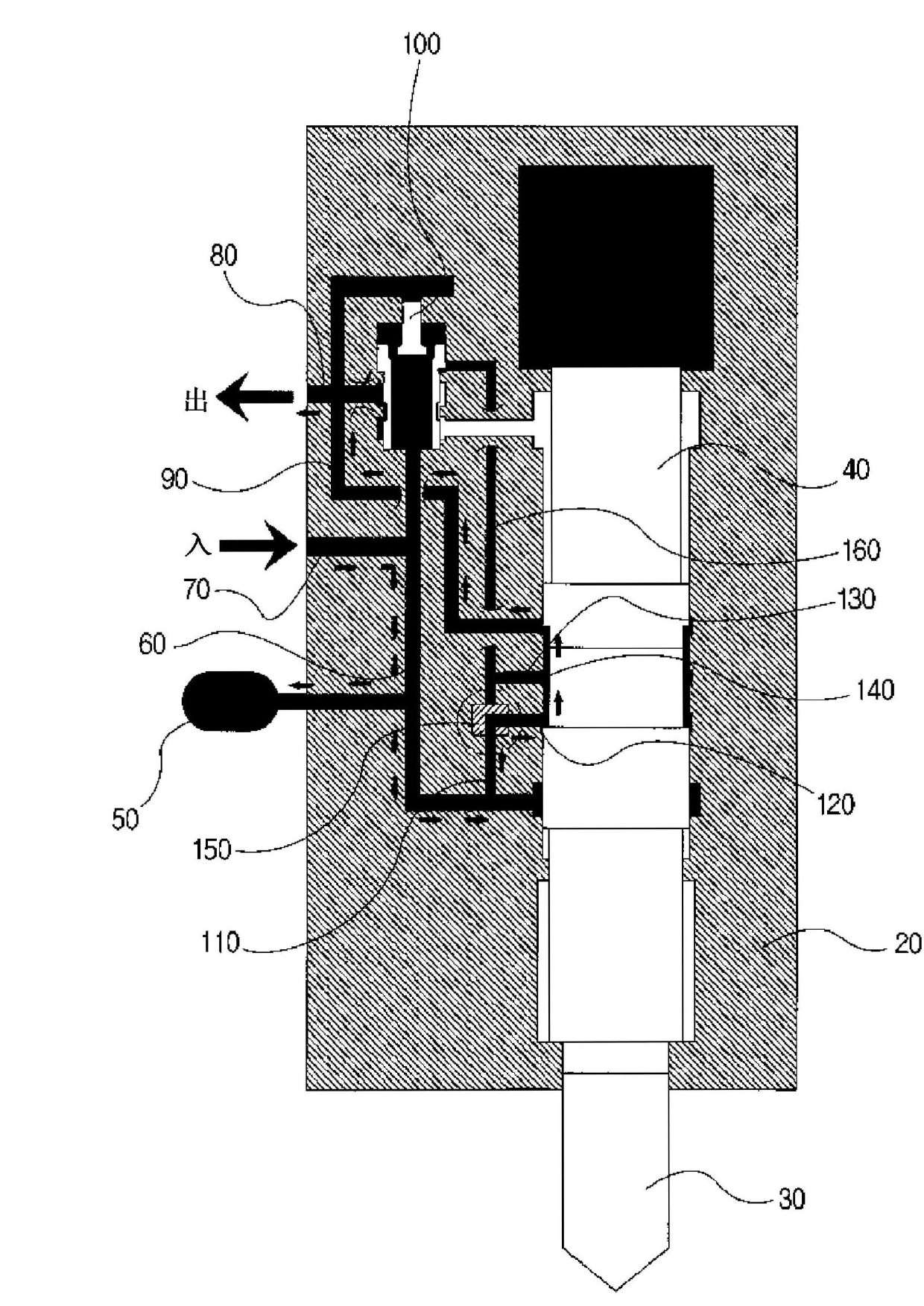

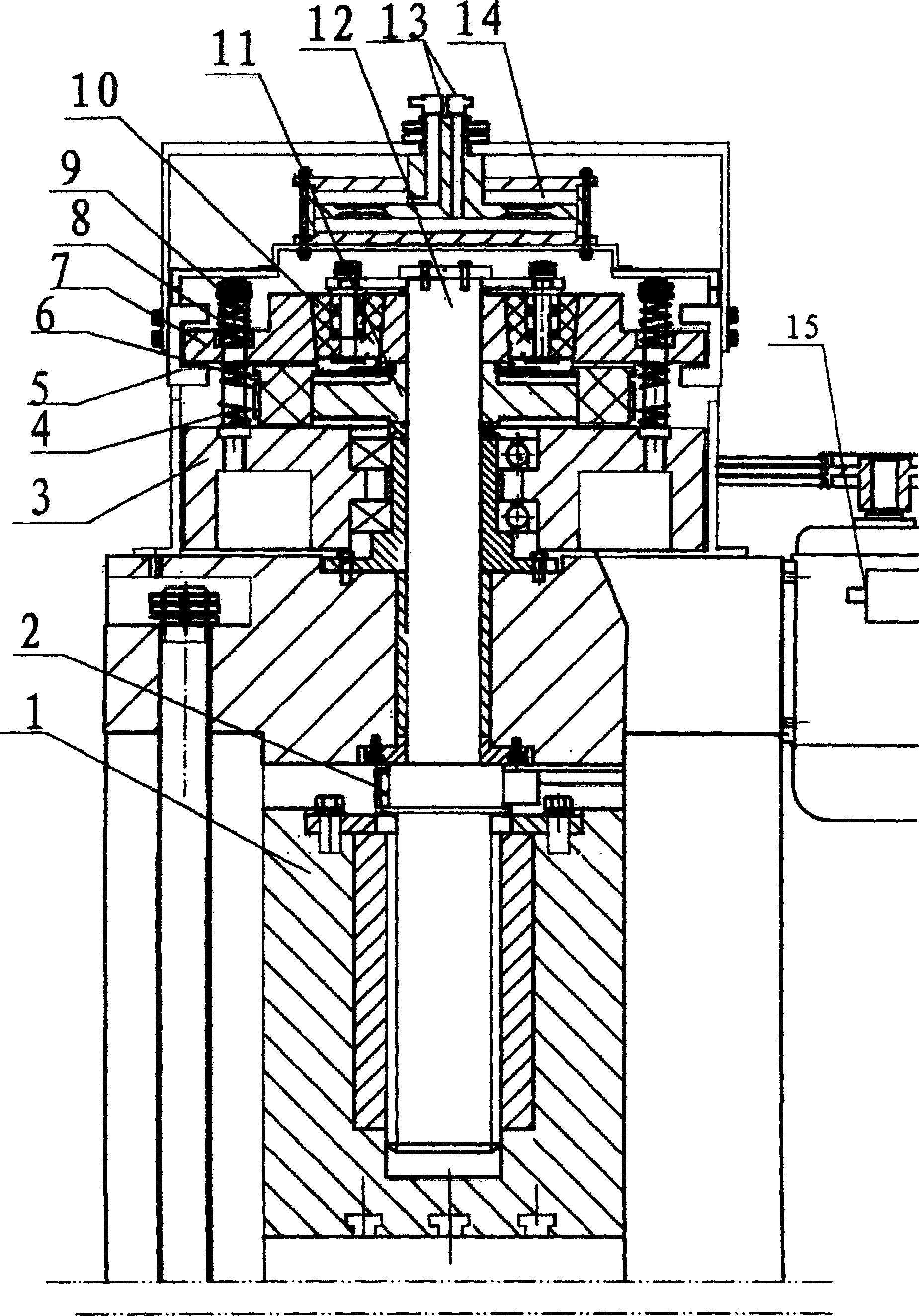

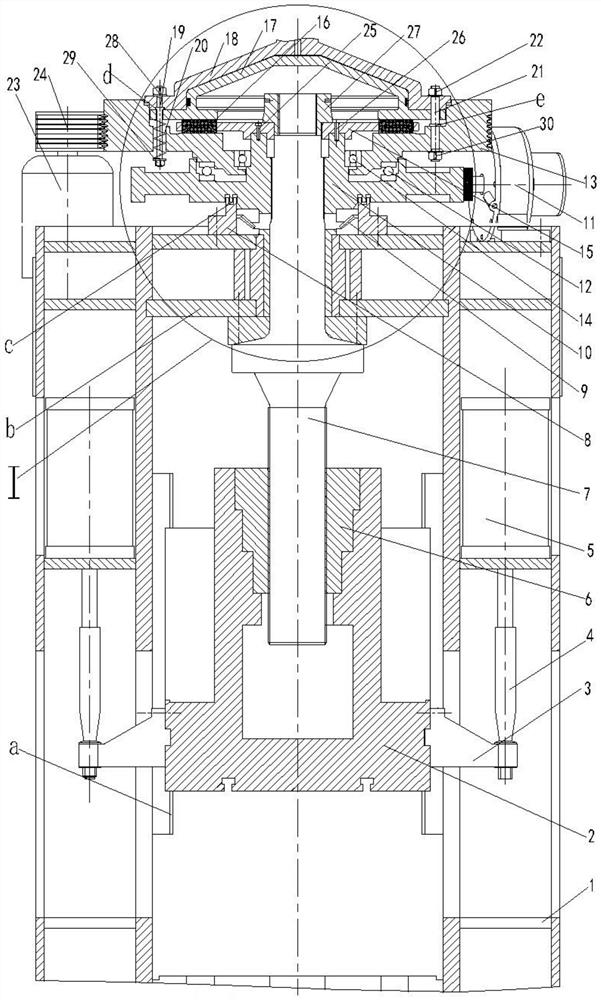

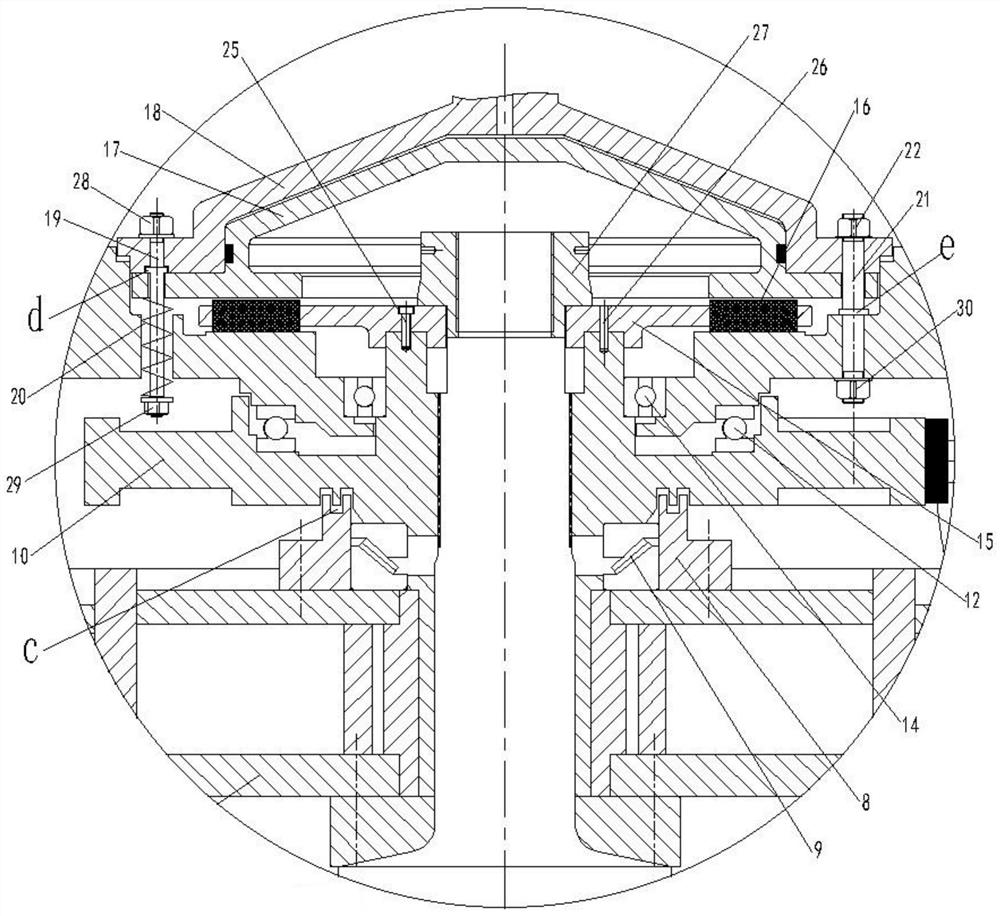

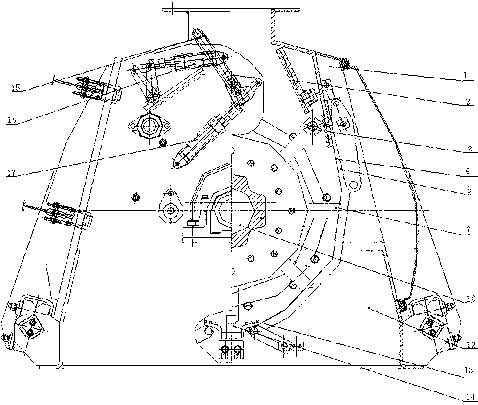

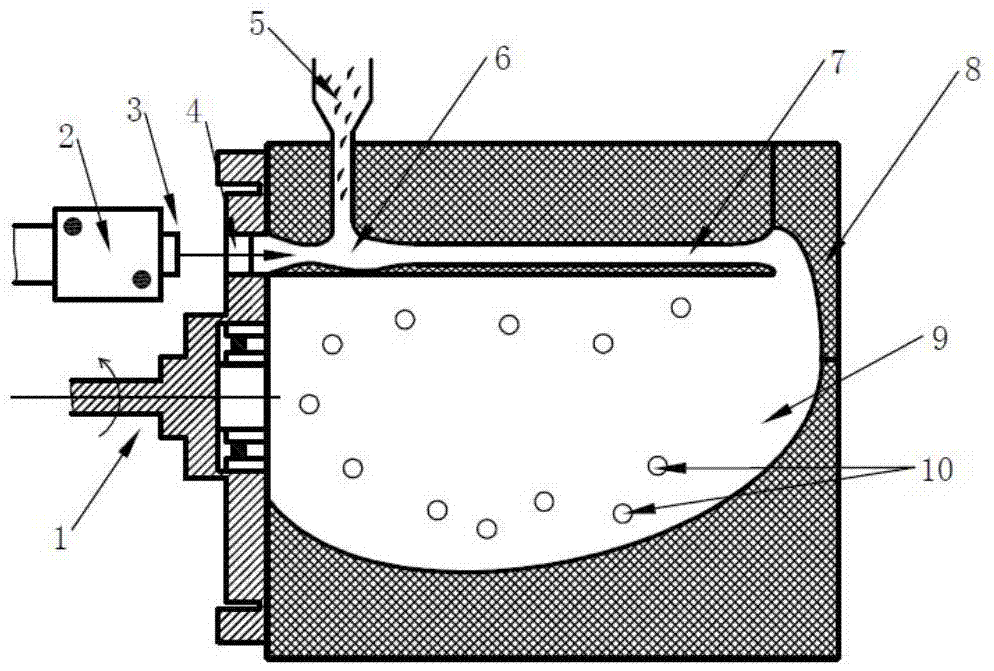

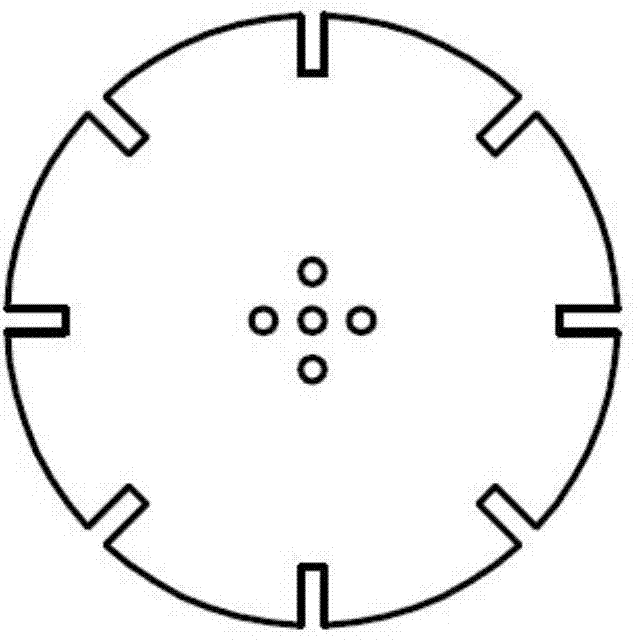

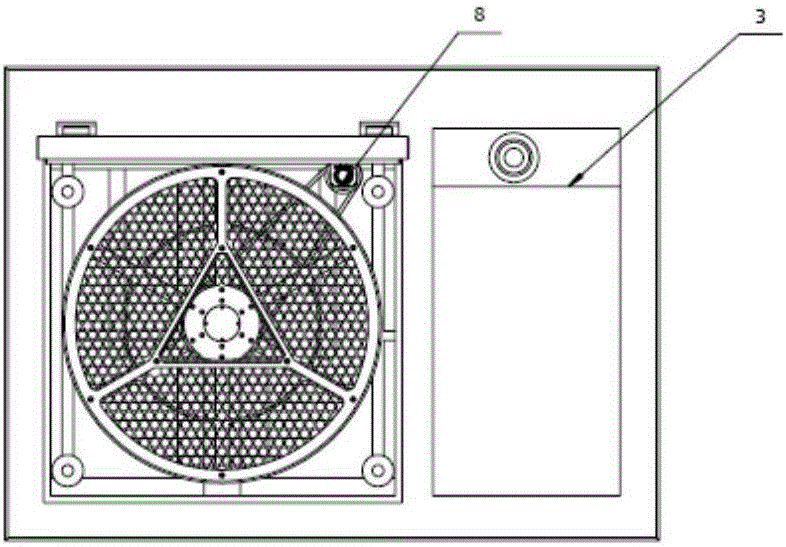

High frequency macro-energy hydraulic pile hammer

PendingCN108239979AImprove rigidityImprove structural stabilityBulkheads/pilesHydraulic cylinderInlet channel

The invention discloses a high frequency macro-energy hydraulic pile hammer which comprises a hydraulic pump and a hammer core, wherein the hydraulic core comprises an inner cylinder sleeve and an outer cylinder sleeve mounted in a spaced manner in a sleeving manner, and an oil inlet channel is formed between the inner cylinder sleeve and the outer cylinder sleeve; a piston rod fixedly connected to a piston penetrates through a cylinder cover and a static supporting sleeve axially to be supported on the static supporting sleeve, a cylinder oil inlet and a cylinder oil outlet are formed in thecylinder bottom, the cylinder oil inlet is communicated to the oil inlet channel between the inner cylinder sleeve and the outer cylinder sleeve; the oil inlet channel is communicated to a rod cavityof the hydraulic cylinder through the oil inlet hole in the inner cylinder sleeve, and a cylinder oil return hole is communicated to a rodless cavity of the hydraulic cylinder; the oil outlet of the hydraulic pump communicates to the cylinder oil inlet and a pressure oil hole of a second inserting valve in parallel, and an oil hole B of the first inserting valve is connected to the cylinder oil outlet; and a control valve as a pilot valve forms a direction control loop with the second inserting valve. The hydraulic pile hammer is simple and reasonable in structure and small in influence on ambient environment, can drive a pile at a high frequency with micro-energy, so that the hydraulic pile hammer is particularly suitable for large foundation pile construction.

Owner:JIANGSU JUWEI MACHINERY

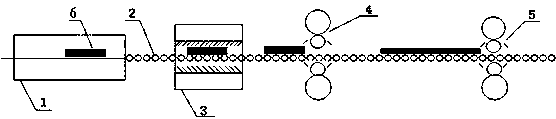

A high-pressure water descaling method for alloy steel plates

InactiveCN106140843BSolve the problem of descalingEnhance cleaning abilityRoll mill control devicesWork treatment devicesHigh pressure waterCounter rotation

The invention discloses a high-pressure water descaling method for alloy steel plates. When a plate blank is heated, a heating temperature and a soaking temperature are controlled so as to reduce oxide scale produced in a furnace. Low-temperature high-pressure water is used for descaling in a descaling box, and by regulating the parameters of nozzles, hitting force and water quantity in unit area on the surface of the plate blank are increased so as to enhance the capability of clearing the oxide scale. The plate blank rotates for 90 degrees before a roughing mill so as to change high-pressure water hit positions and is slowly fed into a gap between upper and lower rollers. By controlling a small rolling reduction quantity and jet water pressure, stubborn remaining scales are thoroughly removed, after descaling, the plate blank anticlockwise rotates for 90 degrees to the initial position, and then, normal rolling operation is carried out. During the descaling of a finishing mill rack, high-pressure water jet descaling is separately carried out in the front three times to clear the oxide scale. The high-pressure water descaling method solves the problem that the descaling of the hot-rolled steel plates with high alloy content is not thorough without increasing equipment investment, saves energy, is favorable to environmental protection and makes a remarkable progress.

Owner:SHANDONG IRON & STEEL CO LTD

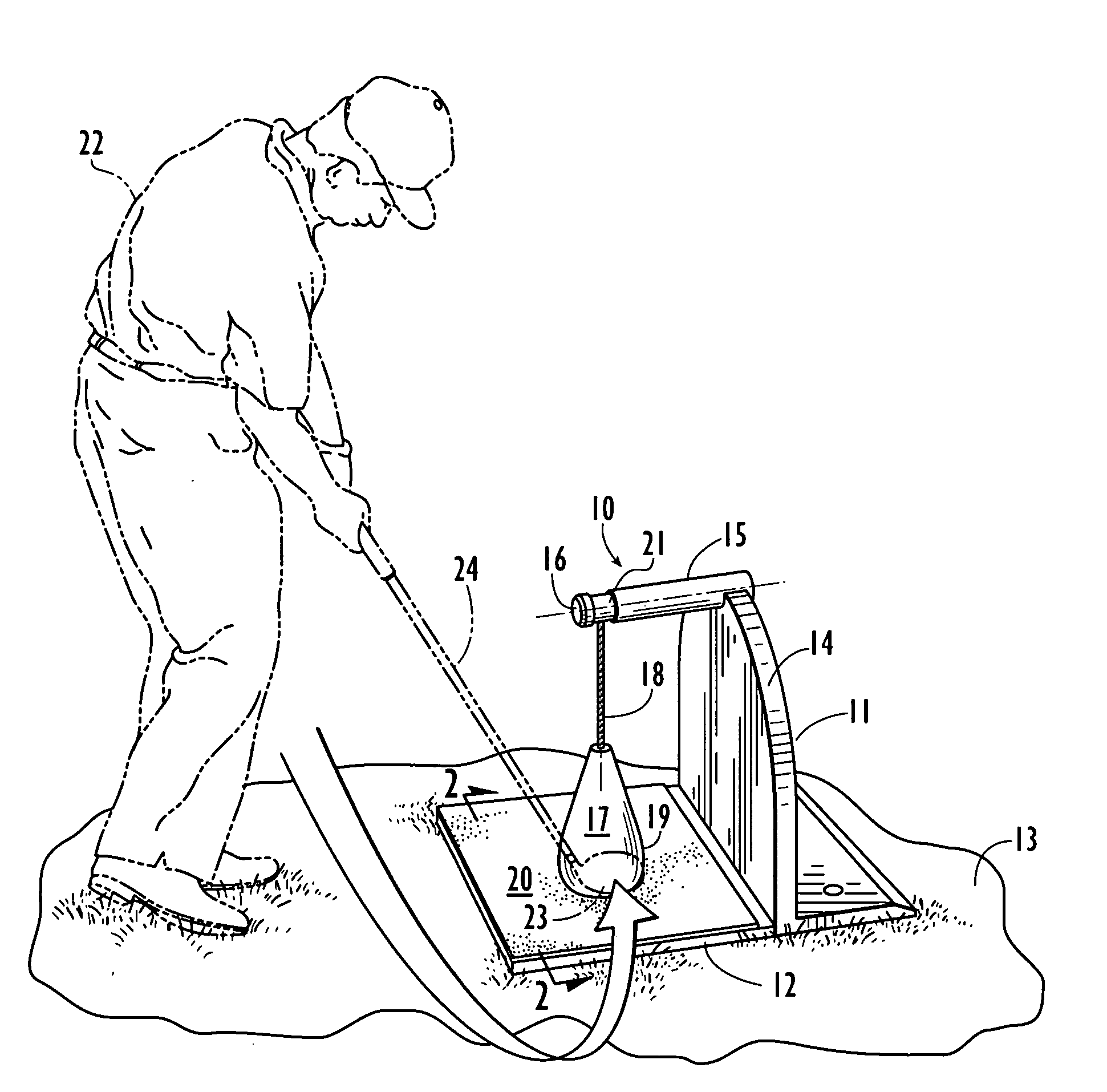

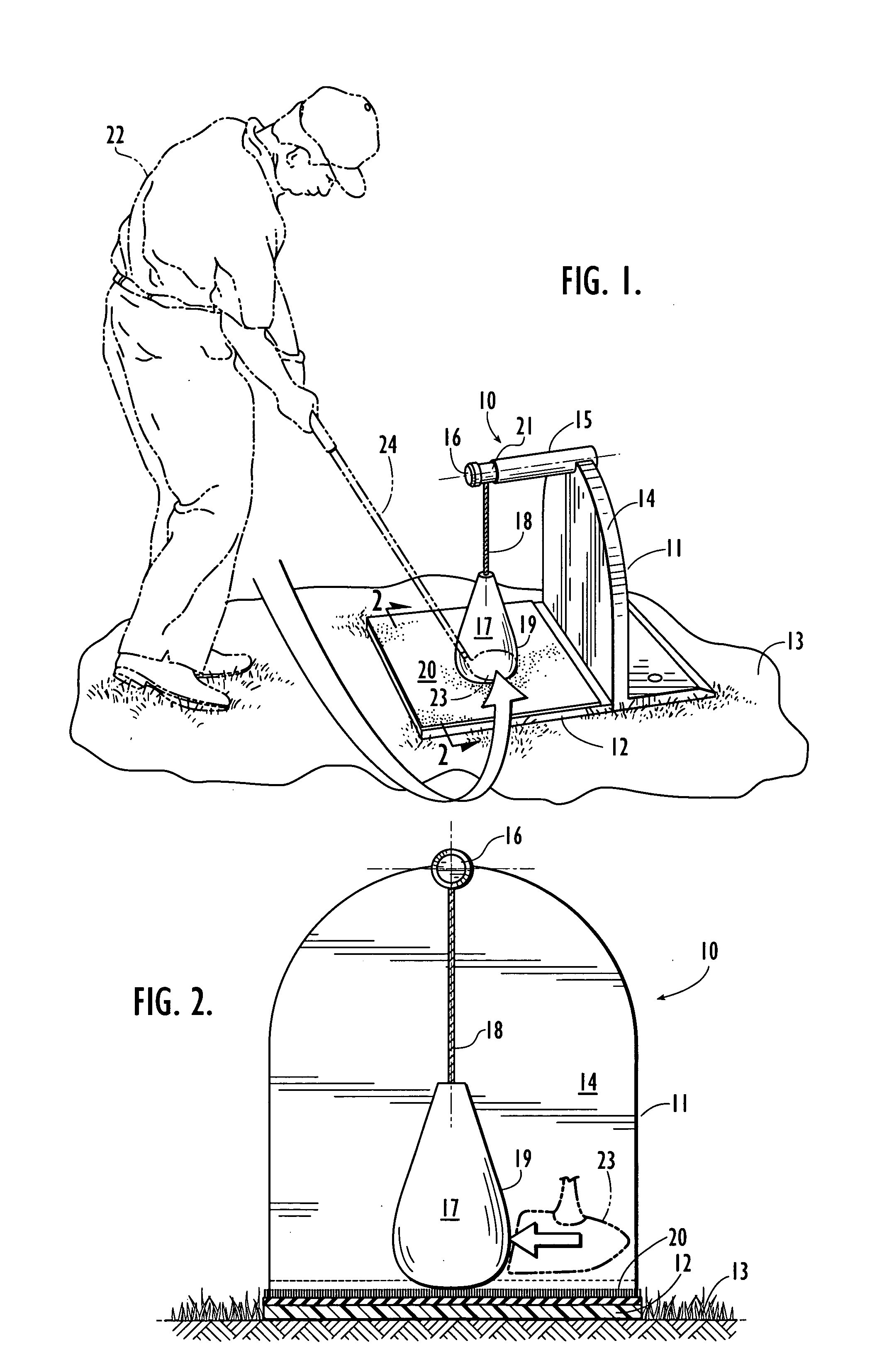

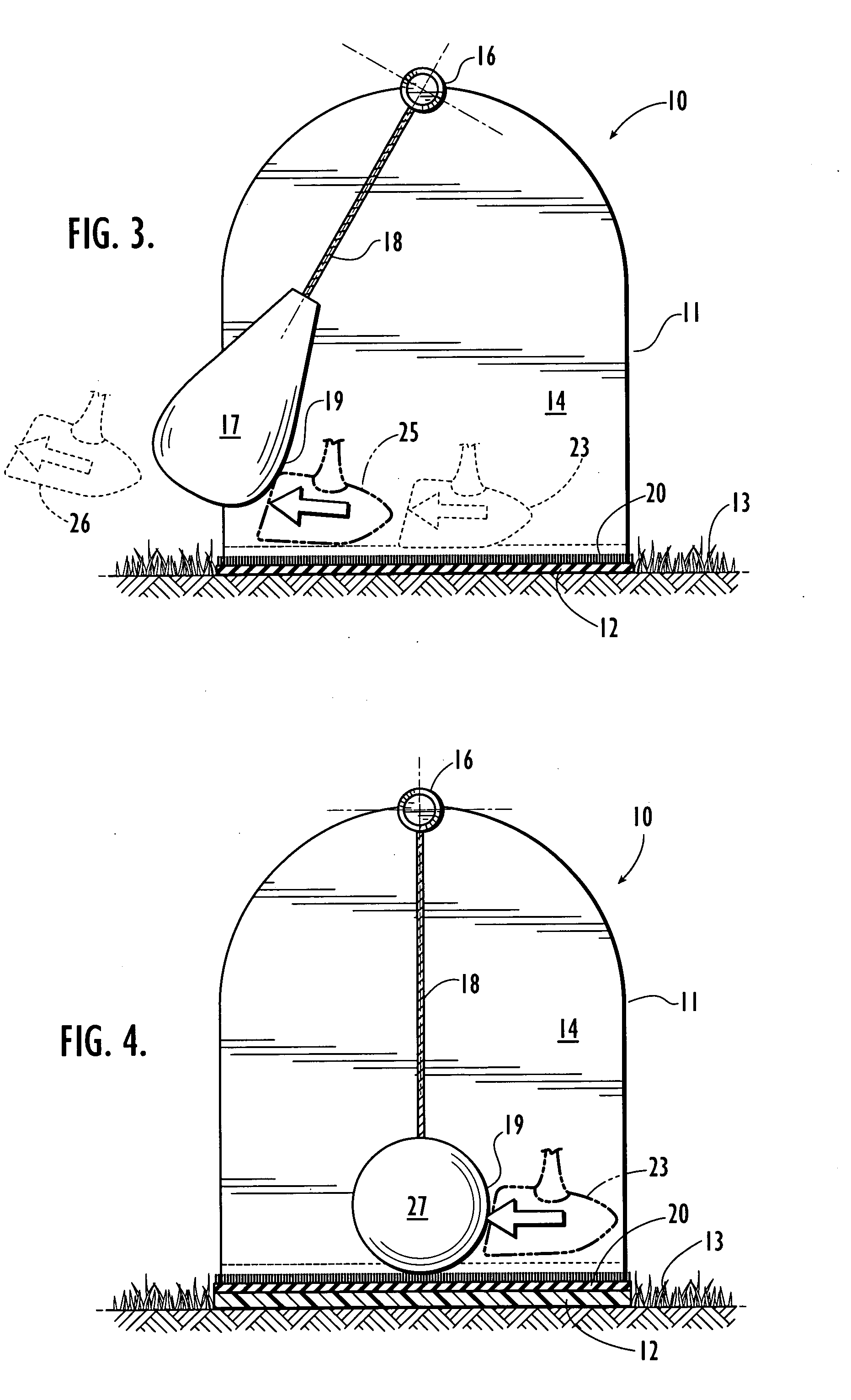

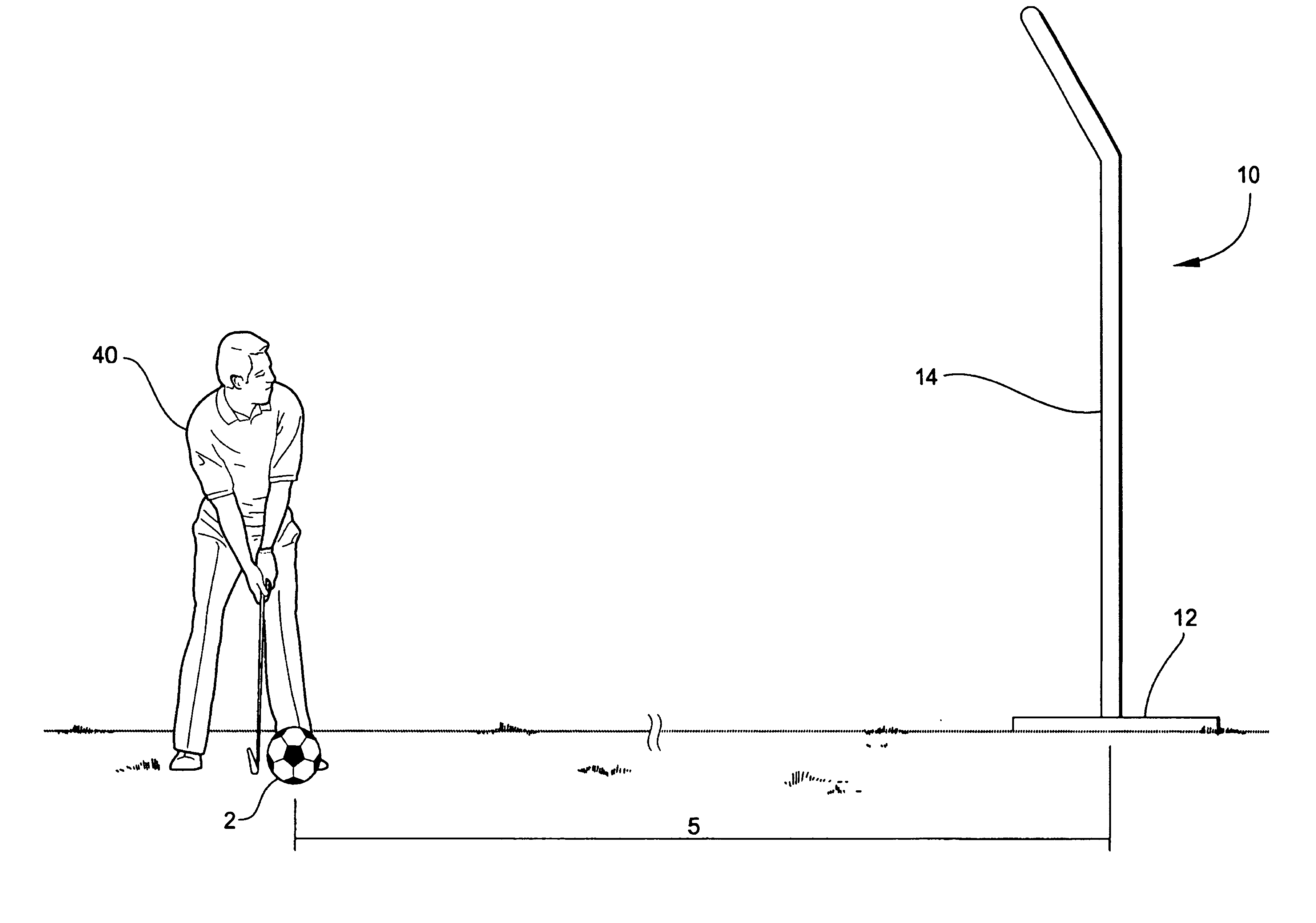

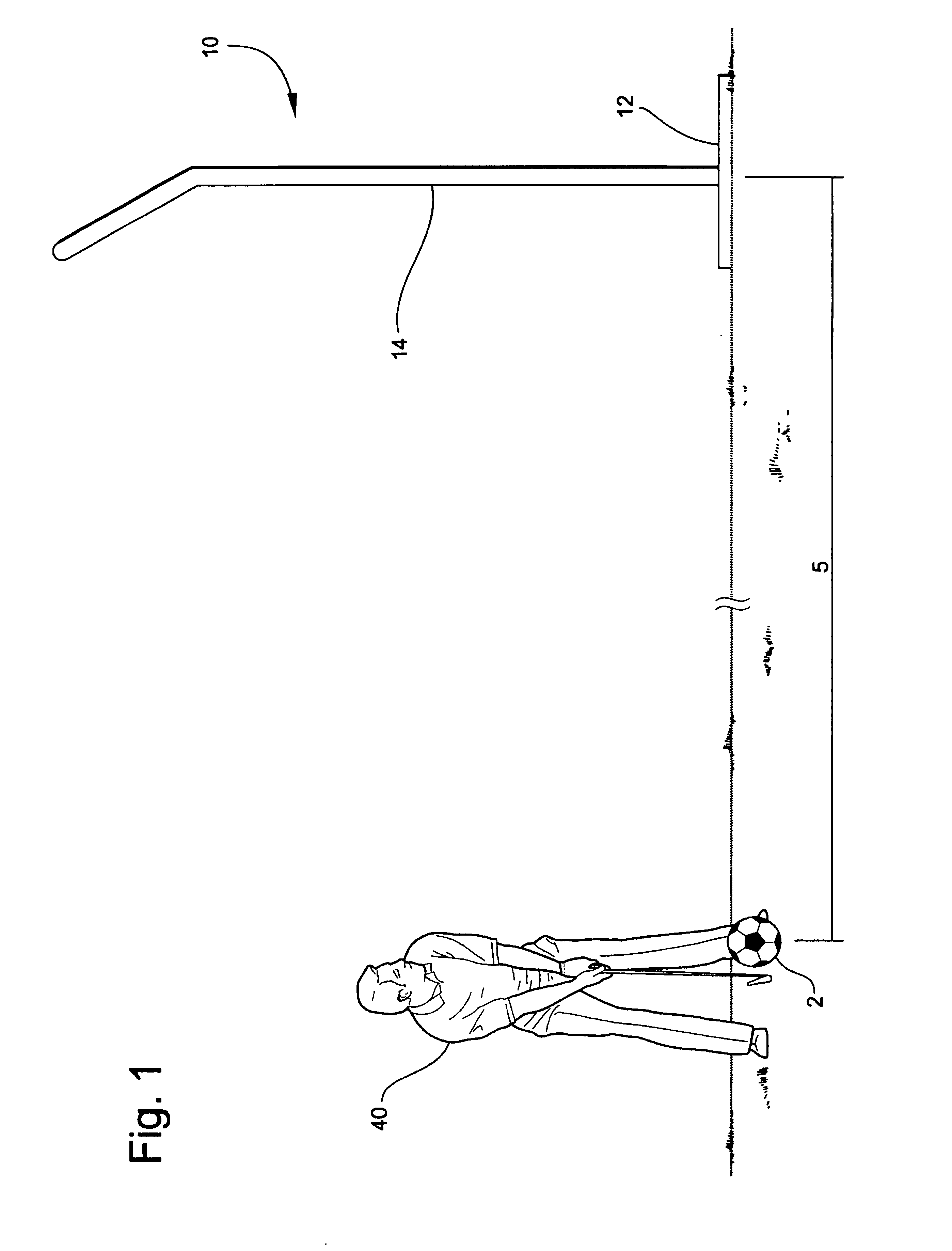

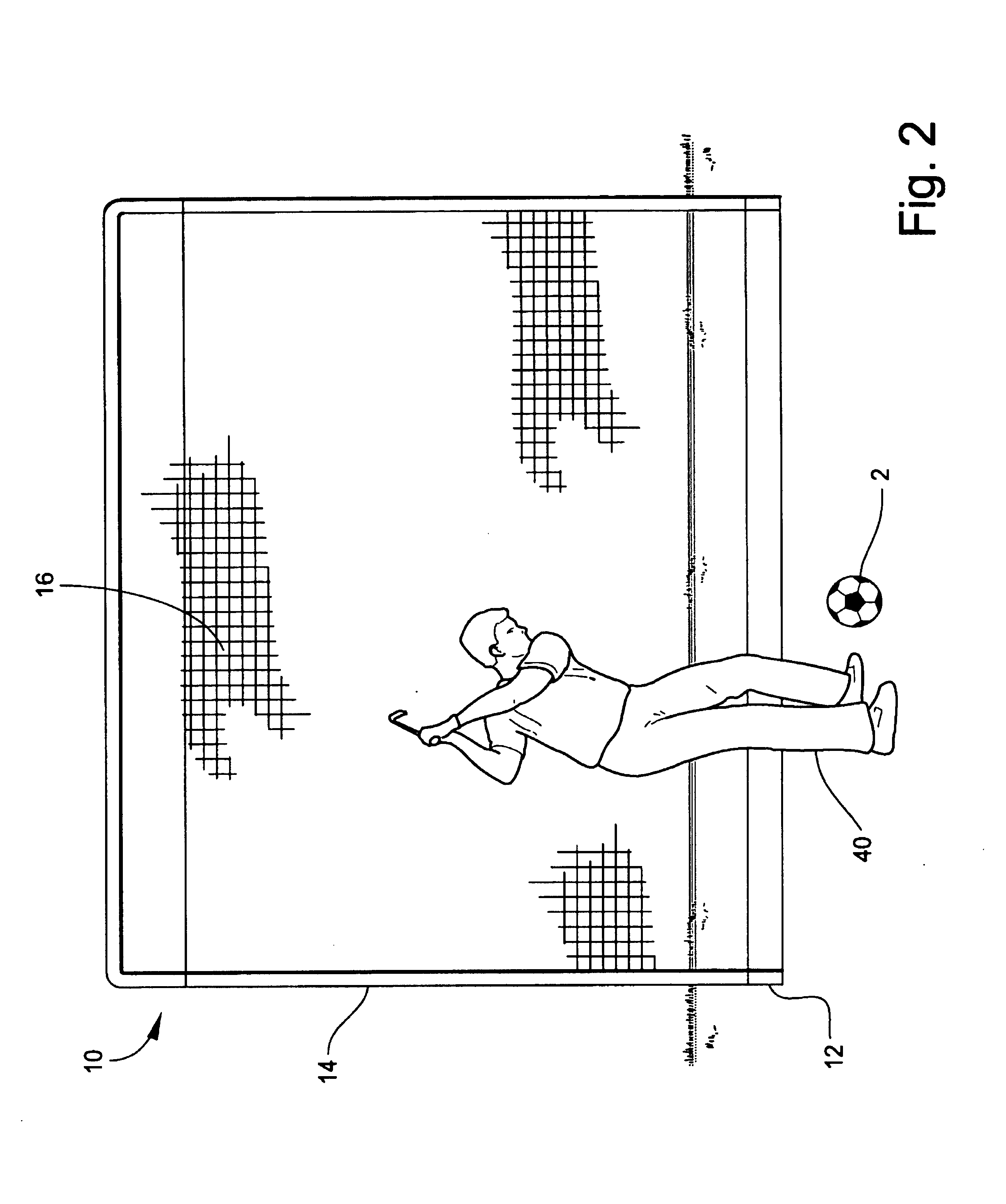

Golf practice and exercise device

A golf practice and exercise device having a frame with a horizontally projecting arm spaced from a base or from the ground and from which is suspended by a cord an object that may take various forms, such as similar to a standard softball, a teardrop-shaped punching bag, a body punching bag, or any other suitable form. The object is positioned with a clubhead impact surface in position for striking by the clubhead of a golf club being swung by a golfer. The impact surface is sufficiently large that a golfer need not concentrate on striking a small target as is required when swinging at a golf ball. The mass of the object is sufficient to provide substantial resistance to the impact of a golf club to impose muscle strain on the golfer for muscle development, but is limited in mass to allow the head of the golf club to swing the object sufficiently for the golf clubhead to ultimately pass under the object and allow the golfer to complete the follow-through of the golf swing. In an alternate form, the object to be struck rests on the ground and is attached to a flexible cord which, in turn, is attached to a spike, secured in the ground. The cord and spike provide a limit to the distance the object will move so that the device can be used in a restricted space.

Owner:SHIODA YOSHIHIKO

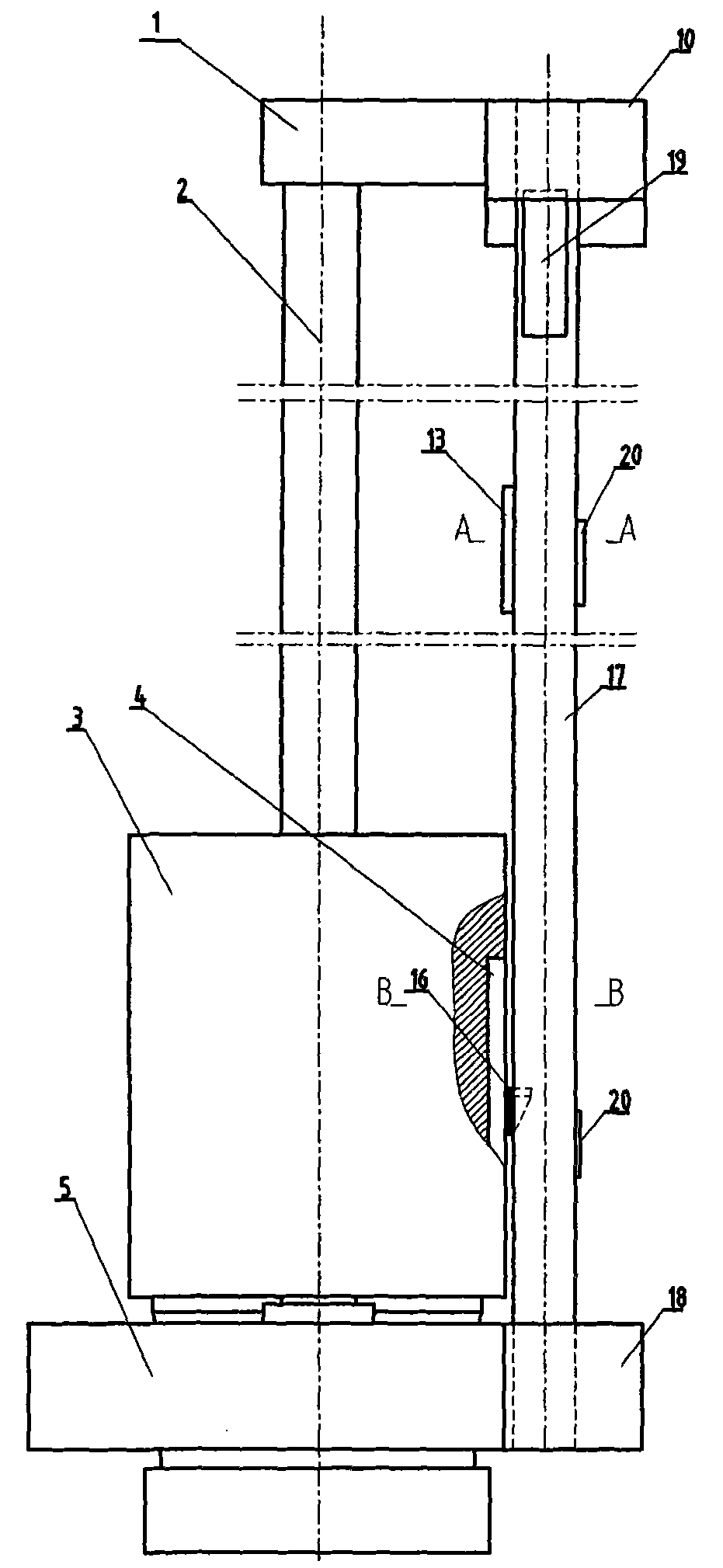

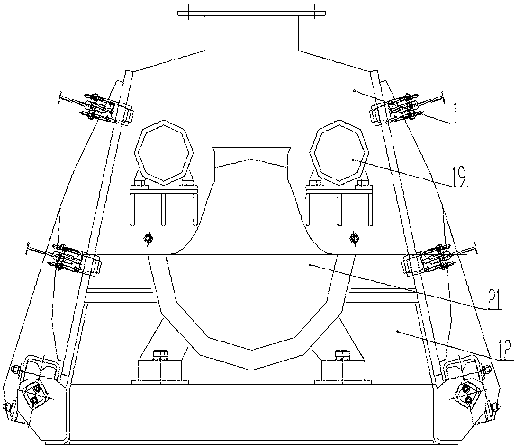

Guide rod type diesel pile hammer with vertical landing gear

ActiveCN101929156AImprove piling efficiencyAchieve normal startupBulkheads/pilesArchitectural engineeringHooking

The invention discloses a guide rod type diesel pile hammer with a vertical landing gear, which comprises a top transverse beam, a guide rod, a cylinder hammer and a piston, wherein the top transverse beam and the piston are respectively installed on the upper and the lower ends of the guide rod; the cylinder hammer can slide upwards and downwards along the guide rod; a landing gear is vertically arranged outside the cylinder hammer, and is provided with a lifting hook and a hammer lifting hook; the hammer lifting hook corresponds to a cylinder hammer hook groove on the cylinder hammer, and is connected with a link mechanism of the hammer lifting hook; and a decoupling stop block and a hammer hooking stop block are fixedly connected between the top transverse beam and the piston. The pile hammer has the advantages of completely preventing the landing gear from colliding with the cylinder hammer and the top transverse beam in a work process, automatically hooking and decoupling the landing gear and facilitating the operation.

Owner:JIANGSU JUWEI MACHINERY

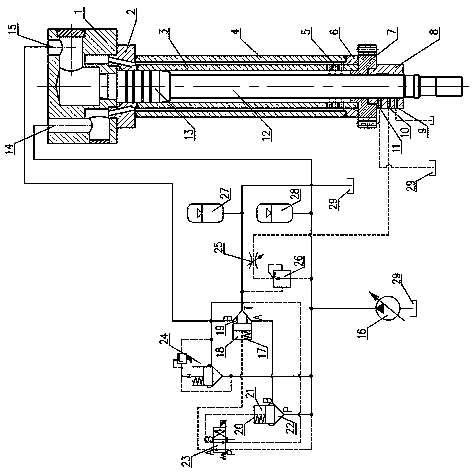

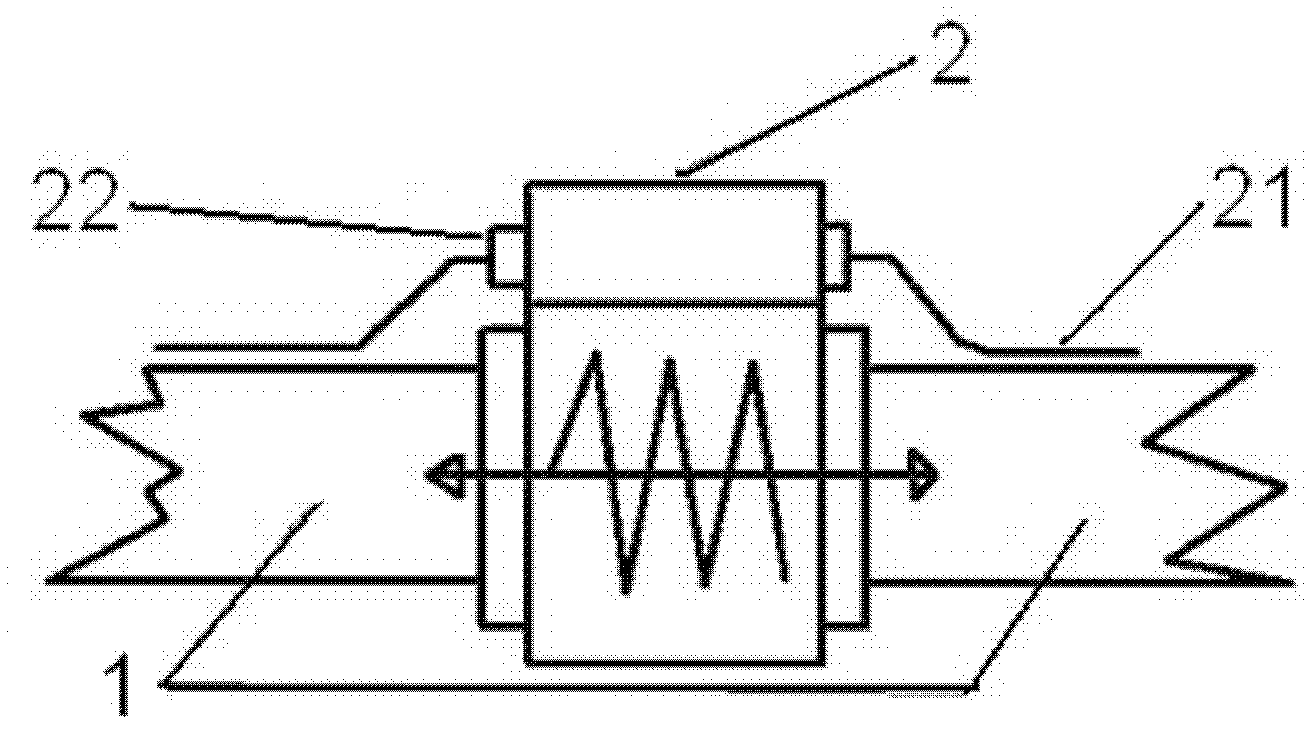

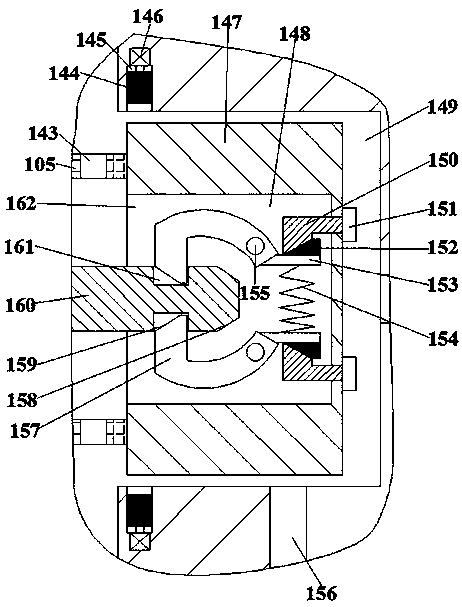

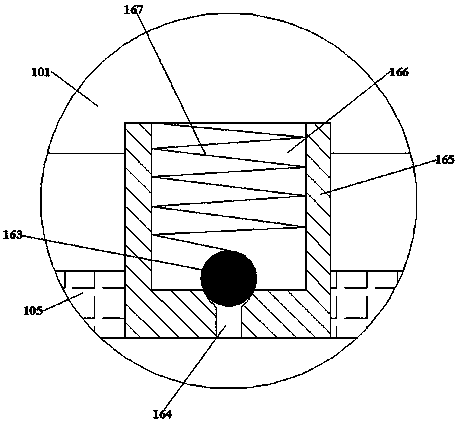

System for preventing idle blow and adjusting hitting power of breaker

ActiveCN102686819AAvoid damageIncrease the striking powerReciprocating drilling machinesConstructionsPistonEngineering

The present invention relates to a system for preventing an idle blow and adjusting hitting power of a breaker, which can set an idle blow-preventive direction converting unit by rotating the direction converting unit in a desired direction and adjust the hitting power of the breaker that is provided on the outer side of a cylinder of a hydraulic breaker which is a hydraulic hitting apparatus. Thus, the invention is capable of smoothly carrying out strong and weak hitting operations and disabling an idle blow of a hitting rod that is operated by a piston and the cylinder of the breaker through a hitting adjustment valve connected with the direction converting unit.

Owner:SOOSAN HEAVY IND

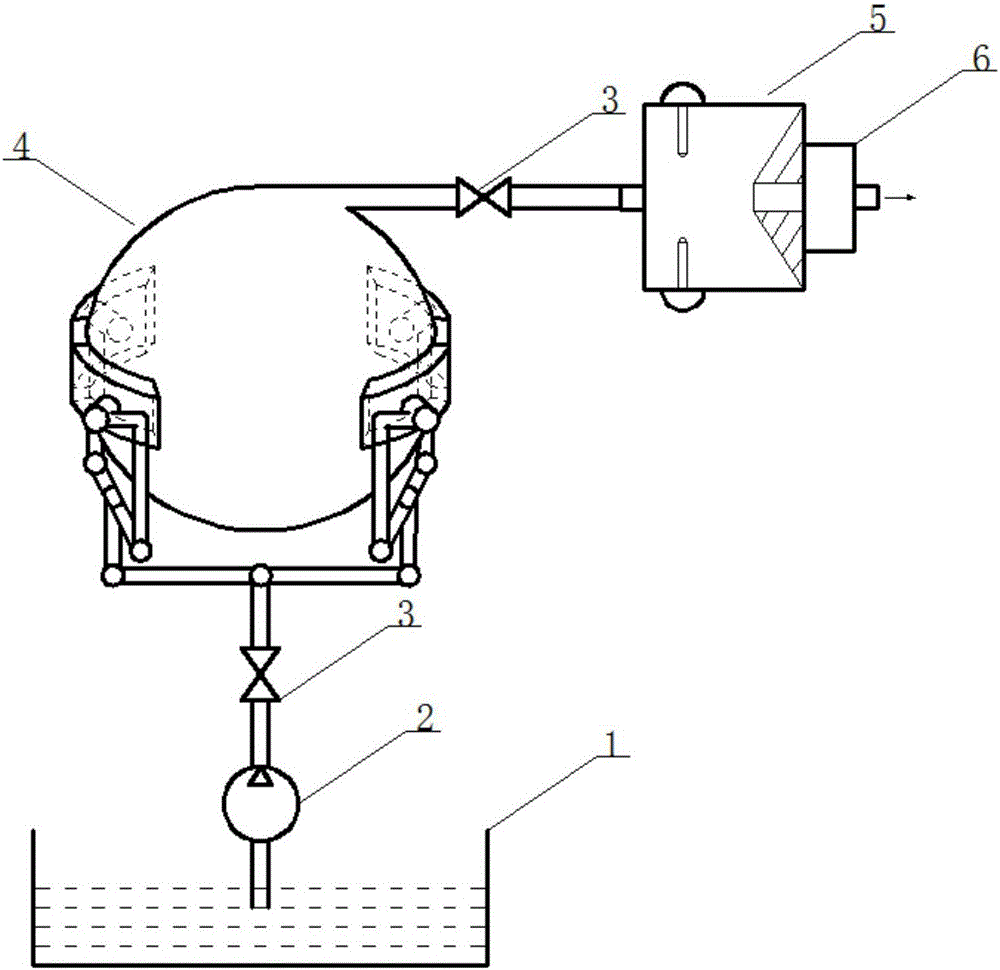

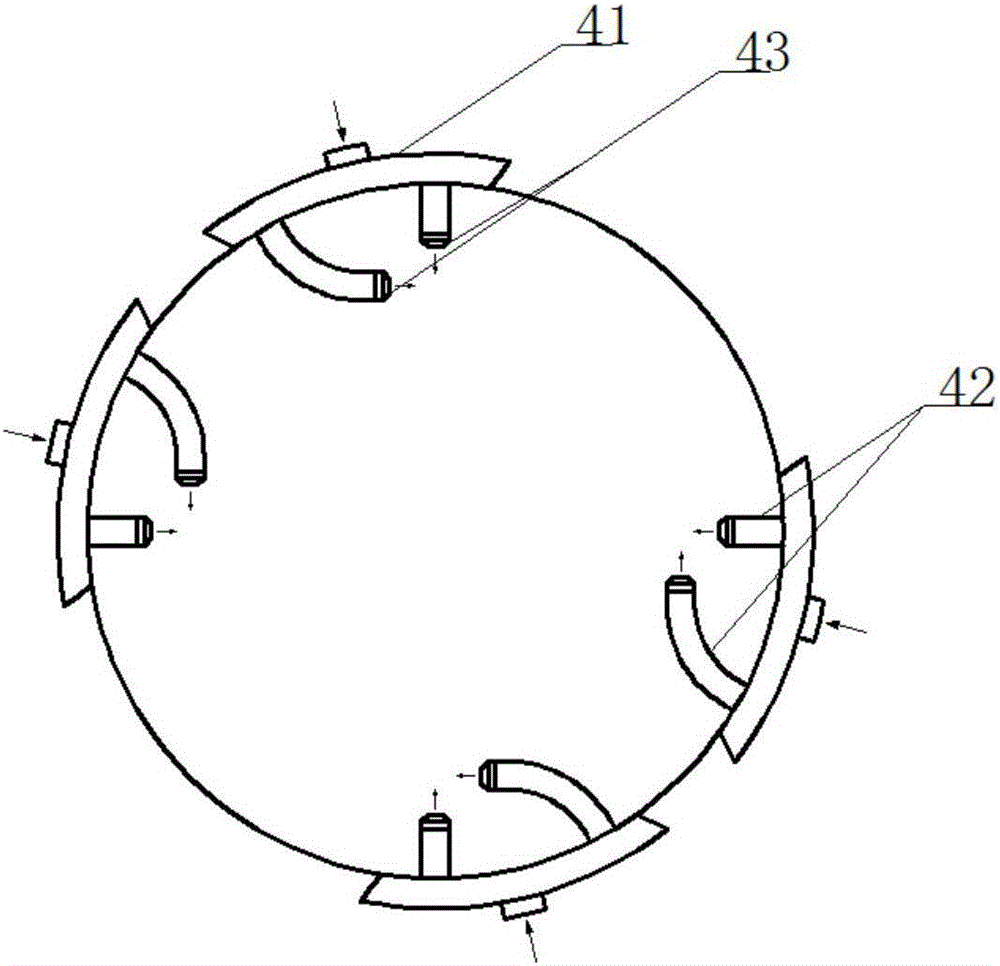

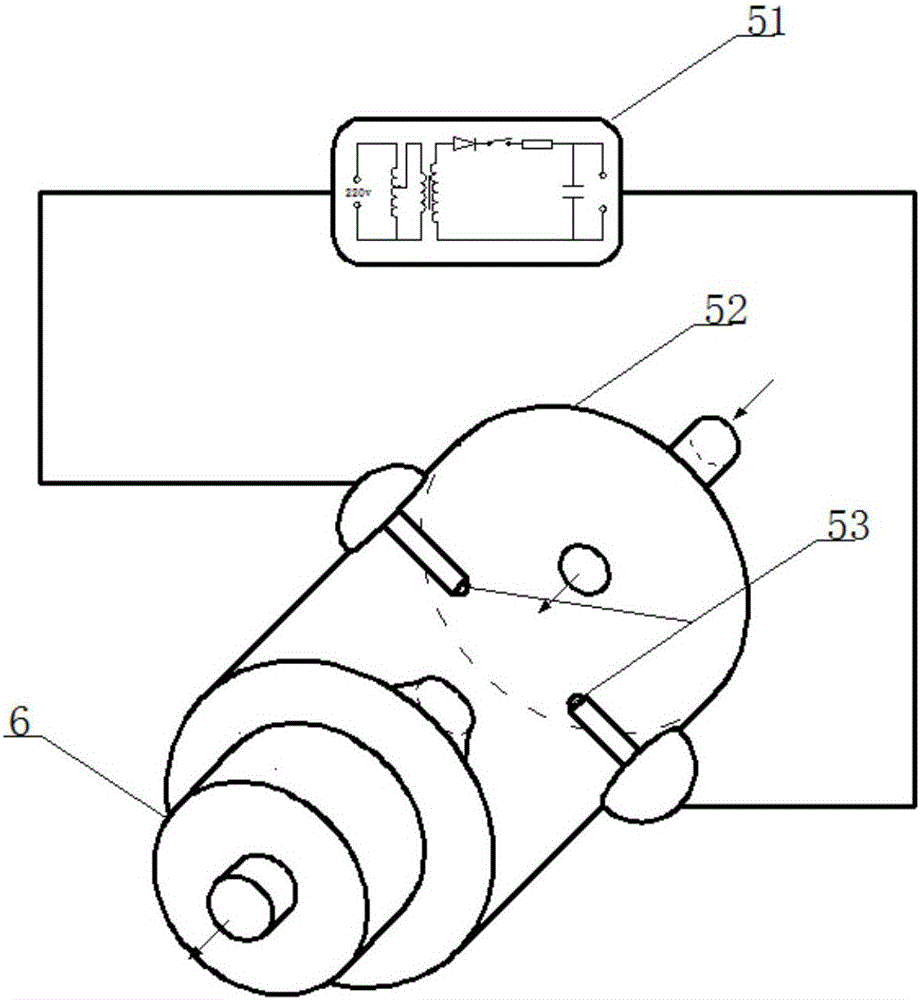

Controllable electro-hydraulic pulse jet flow washing unit

InactiveCN106583318AStrong process controllabilitySimple structureSpray nozzlesLiquid spraying apparatusJet flowElectro hydraulic

The invention discloses a controllable electro-hydraulic pulse jet flow washing unit. The controllable electro-hydraulic pulse jet flow washing unit mainly comprises a water tank, a water pump, a globular eddy generator, an electro-hydraulic pulse jet flow device and an annular ultrasonic generator; the water tank is used for supplying water; the water pump is connected to the water tank and used for pumping water in the water tank and achieving pressure boosting of water flow; the globular eddy generator is connected to the water pump and used for converting water obtained after pressure boosting through the water pump into eddy turbulence water jet flow; the electro-hydraulic pulse jet flow device is connected to the globular eddy generator and used for converting the eddy turbulence water jet flow into electro-hydraulic pulse jet flow; and the annular ultrasonic generator is arranged at the outlet end of the electro-hydraulic pulse jet flow device and used for assisting shot blasting of the electro-hydraulic pulse jet flow on dirt or attachment. By means of the controllable electro-hydraulic pulse jet flow washing unit, dirt or attachment which is difficult to remove and located on the surfaces of equipment and materials can be effectively removed; and the jet flow controllability is improved so that better washing can be achieved, the application scope is wide, the structure is simple, and implementation is easy.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

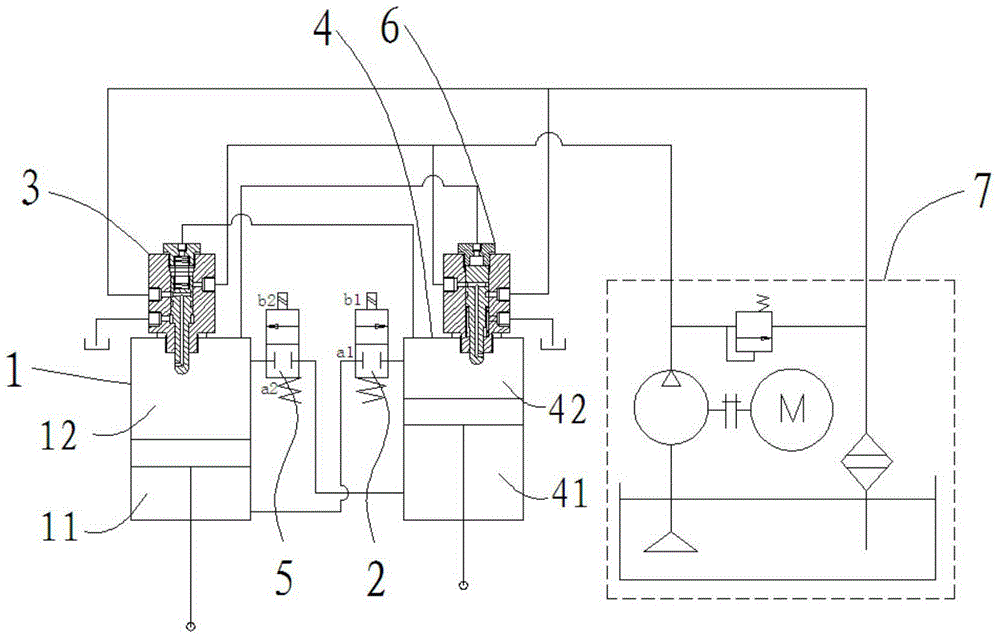

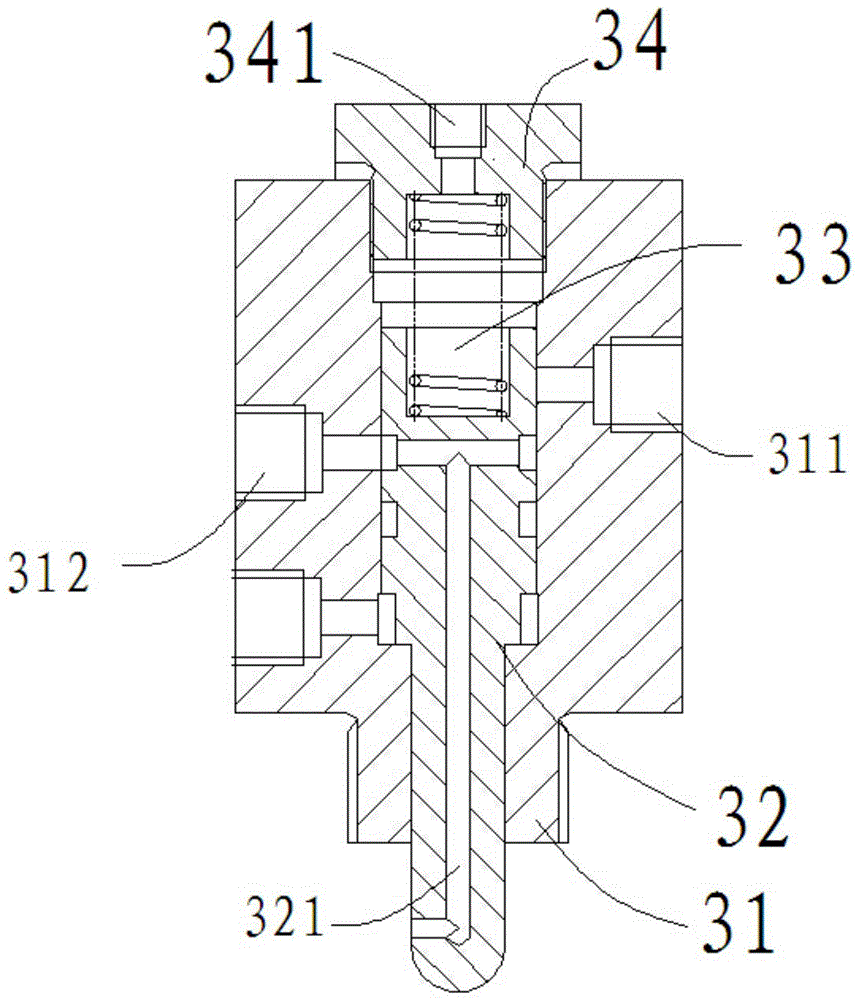

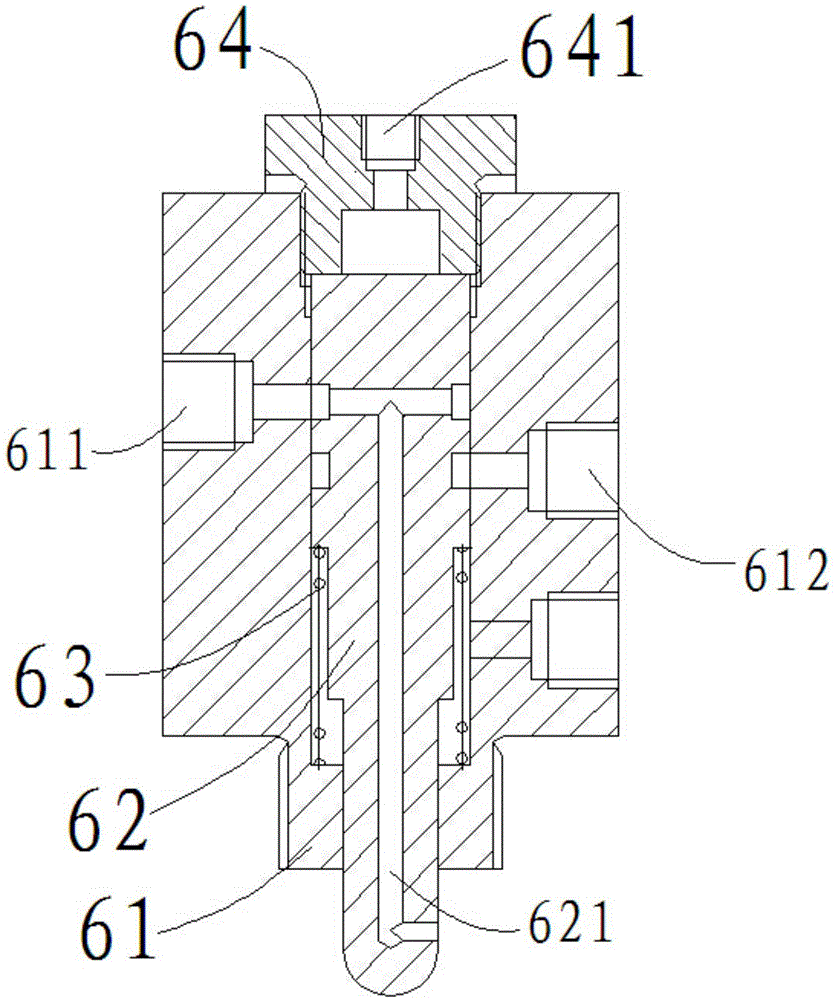

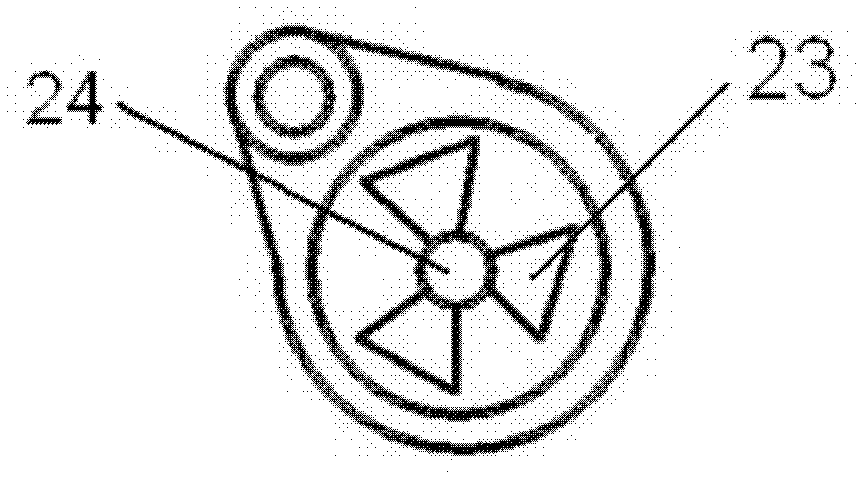

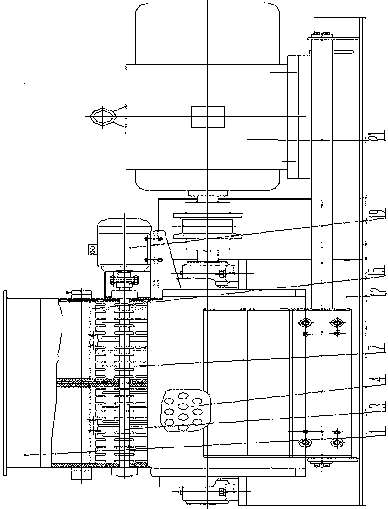

Hydraulic system of vibrating pile driver

ActiveCN104930010AIncrease the striking powerReduce reaction forceServomotor componentsBulkheads/pilesVibration controlControl theory

The invention discloses a hydraulic system of a vibrating pile driver. The hydraulic system comprises a first oil cylinder, a first electromagnetic valve, a first vibration control valve, a second oil cylinder, a second electromagnetic valve, a second vibration control valve and a driving mechanism. The first vibration control valve is connected with the first oil cylinder, and the second vibration control valve is connected with the second oil cylinder; one end of the first electromagnetic valve and one end of the second electromagnetic valve are connected with the first oil cylinder, and the other end of the first electromagnetic valve and the other end of the second electromagnetic valve are connected with the second oil cylinder; and the first vibration control valve and the second vibration control valve are both connected with the driving mechanism. The electromagnetic valves and the vibration control valves are utilized for controlling the working sequence of the first oil cylinder and the second oil cylinder, and therefore the two oil cylinders constantly and alternatively vibrate for pile driving; on the basis of the pile driving principle, the impact fore is large, too large pile driving mass is not needed, the reactive force is small, and the reliability is high; and in addition, the full-hydraulic system is adopted to carry out driving and control, and the hydraulic system is simple in structure, large in driving force, convenient to control and use, and also low in manufacturing cost.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

Clutch type screw press

The clutch type screw press includes a frame, a sliding block, a flywheel and a motor. On the frame, there are screw in the center, brake and sliding block connected to the lower part of the screw, flywheel and clutch, comprising a power disc and a friction wheel train, connected to the upper part of the screw, compressed air driven cylinder connected to the clutch, pressing board around the lower part of the friction wheel train, guide post with spring and with upper end fixed to the flywheel and lower end connected movably to the pressing board, and operating block around the pressing board and connected to the cylinder. The clutch type screw press has compressed air as operating power of the clutch, less pressure releasing links, fast pressure release, simple structure, great impact force and other advantages, and may be used in pressure formation of metal material in different industry.

Owner:韩宝林

Golf practice system

A golf practice and exercise system having a practice ball and a target assembly, using either a conventional or practice golf club. The practice ball is any generally spherical shape made of a flexible material and having an internal pressure of approximately atmospheric, for example an uninflated soccer ball. The weight of the practice ball is sufficient to provide muscle development, but is limited to allow the golfer to complete the follow-through of the golf swing. The target assembly has an energy absorbing surface attached to a rigid frame held in place by a frame support structure. Alternatively, the target assembly is a flat surface made of a hard material. The practice golf club has a substantially oversized club head with a peripheral rim defining a large opening through the club head. The club head may be selectively weighted. The grip of the club has alternating annular ridges and recesses.

Owner:SHIODA YOSHIHIKO

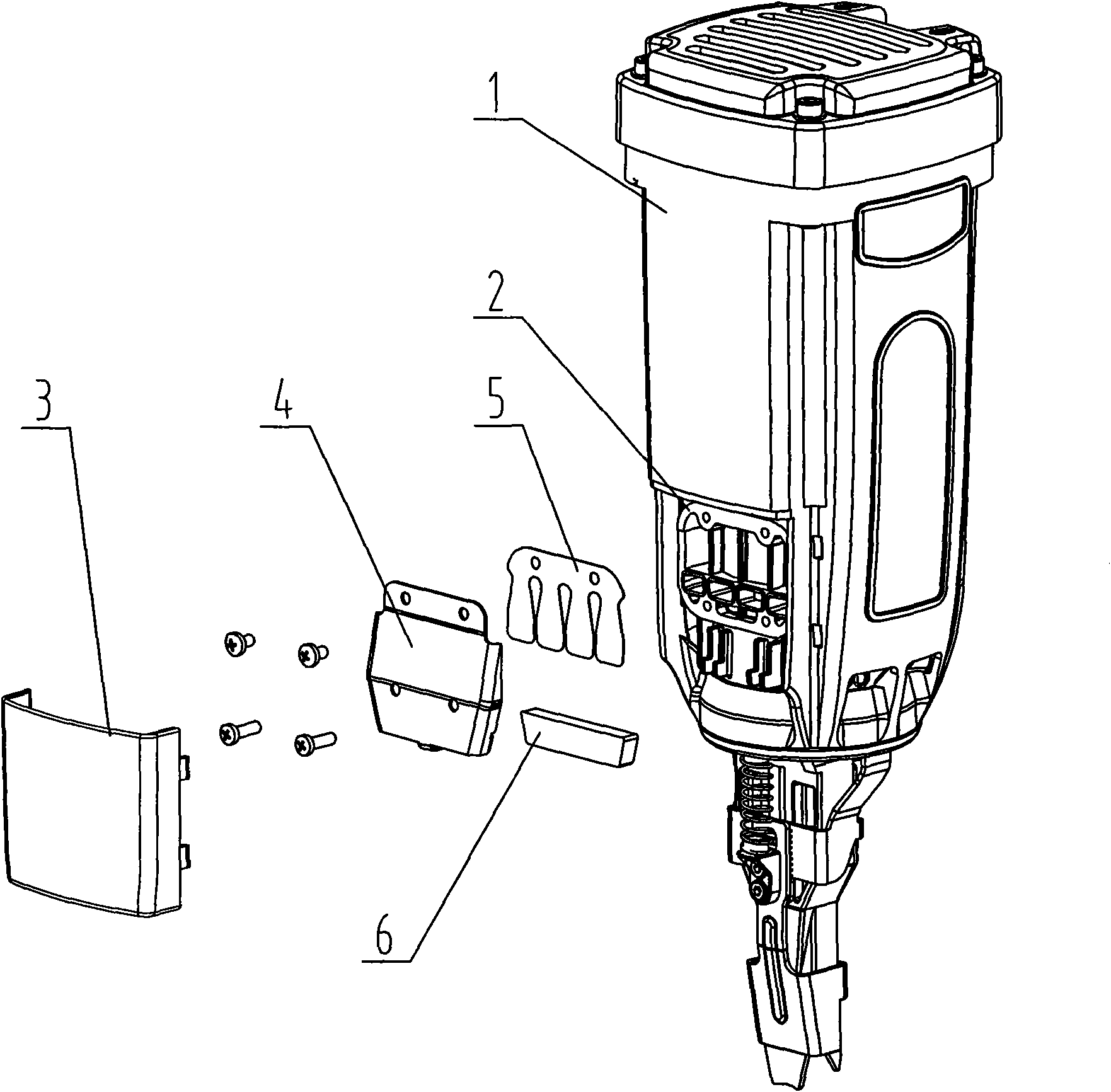

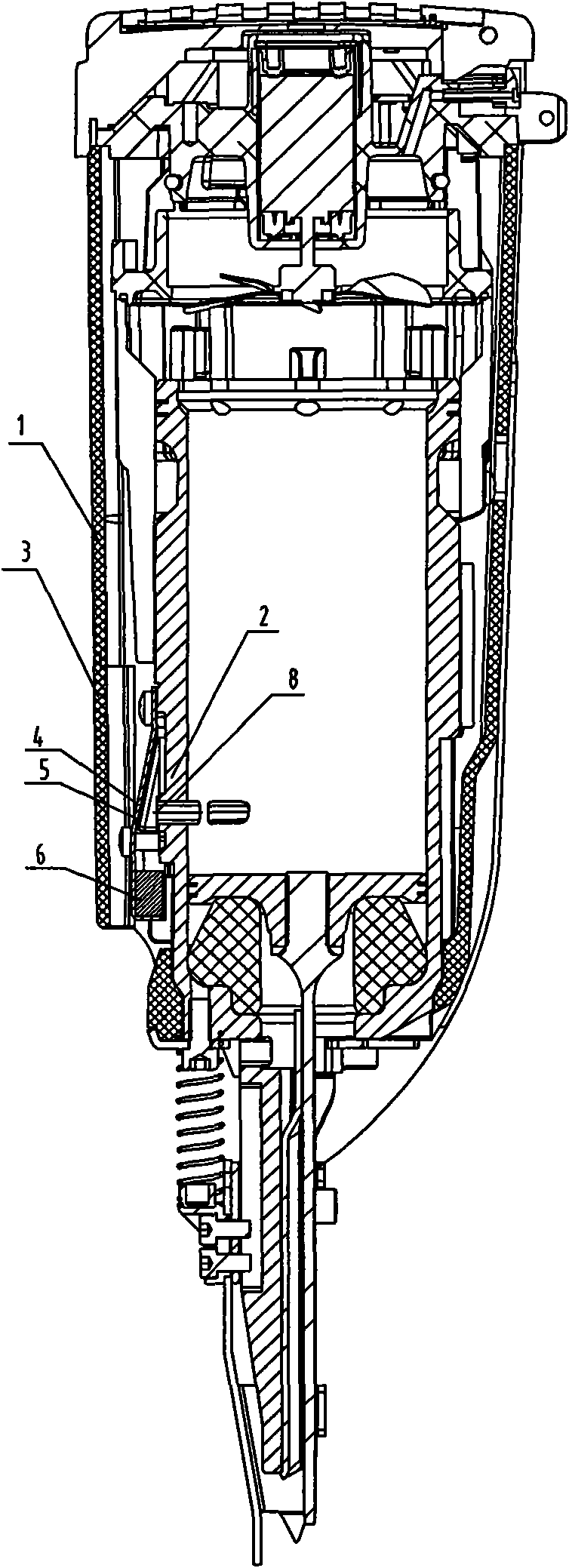

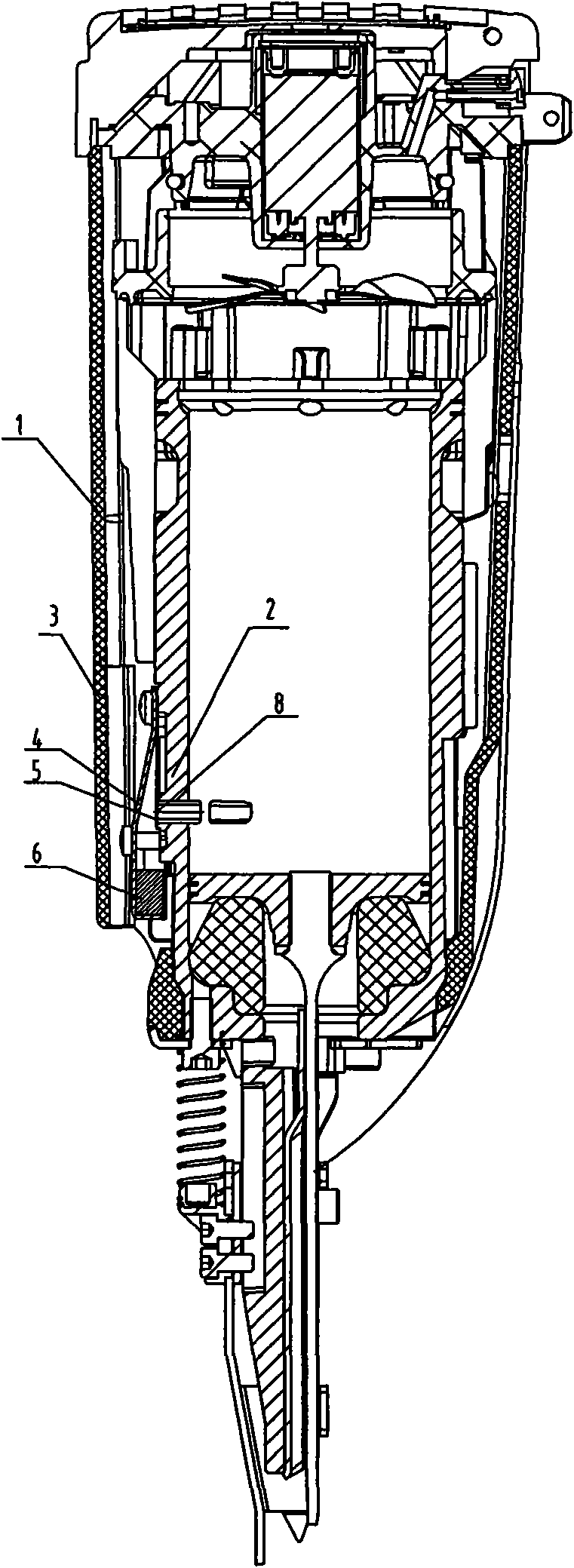

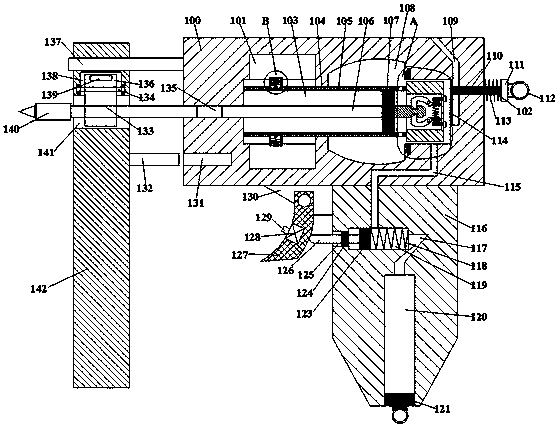

Fuel-gas-powered nail gun allowing for convenient cleaning, exhaust and radiation

ActiveCN102120322AIncrease the striking powerExtended service lifeNailing toolsEngineeringCylinder block

The invention relates to a fuel-gas-powered nail gun allowing for convenient cleaning, exhaust and radiation, which comprises a cylinder body (2) arranged in a shell (1), and an exhaust port (8), a one-way wave plate (5), an exhaust filter element (6) and an exhaust cover (4), which are arranged on the lower part of the cylinder body (2), and is characterized in that: the exhaust port (8) is correspondingly and tightly jointed with the one-way wave plate (5); the one-way wave plate (5) is connected with the exhaust cover (4); the upper part of the exhaust cover (4) and the upper part of the one-way wave plate (5) are overlapped and positioned and connected on the cylinder body (2); and the exhaust filter element (6) is arranged on the lower part of the exhaust cover (4). The one-way wave plate of the nail gun and the exhaust port of the air cylinder are directly connected, so the waste gas of the fuel-gas-powered nail gun is exhausted more completely and consequently the combustion at next time is more complete, the shooting force of the nail gun is bigger and the service life of the one-way wave plate is prolonged; and the shell has a window, so that, detachment, cleaning and quick radiation are convenient, and the reliability of the tool is improved.

Owner:CHONGQING HYBEST TOOLS GRP CO LTD

High pressure water noise-reduction spinning nozzle

InactiveCN106423603AIncrease the striking powerGood cleaning effectMovable spraying apparatusWater jetHigh pressure

The invention provides a high pressure water noise-reduction spinning nozzle which comprises a rotary head, a rotary shaft assembly, a shell and a water inlet connector. An eccentric hole is drilled in the rotary head. The rotary head is connected with the front end of the rotary shaft assembly through threads and is of a hollow structure. The outer layer of the rotary head is made from titanium alloy materials, and a middle layer of the rotary head is made from rubber anechoic materials. Annular ladder type steps are arranged on the inner side of the shell. The rotary shaft assembly is installed in the shell. The rotary shaft assembly is composed of a hollow rotary shaft and a hollow gap sealing rod. The gap sealing rod is installed in the hollow rotary shaft. The rotary shaft is fixed in the shell through a front deep groove ball bearing, a rear deep groove ball bearing and a thrust bearing. The two ends of the rotary shaft are provided with oil seals. Compared with the prior art, the high pressure water noise-reduction spinning nozzle has the remarkable advantages and beneficial effects that water jet hitting power is improved, a cleaning effect is better, the structure is more simple, disassembly, assembly and replacement are more convent and faster, a noise reduction effect is good, noise can reach industrial noise standards, and large-range application can be achieved.

Owner:天津福禄机电设备有限公司

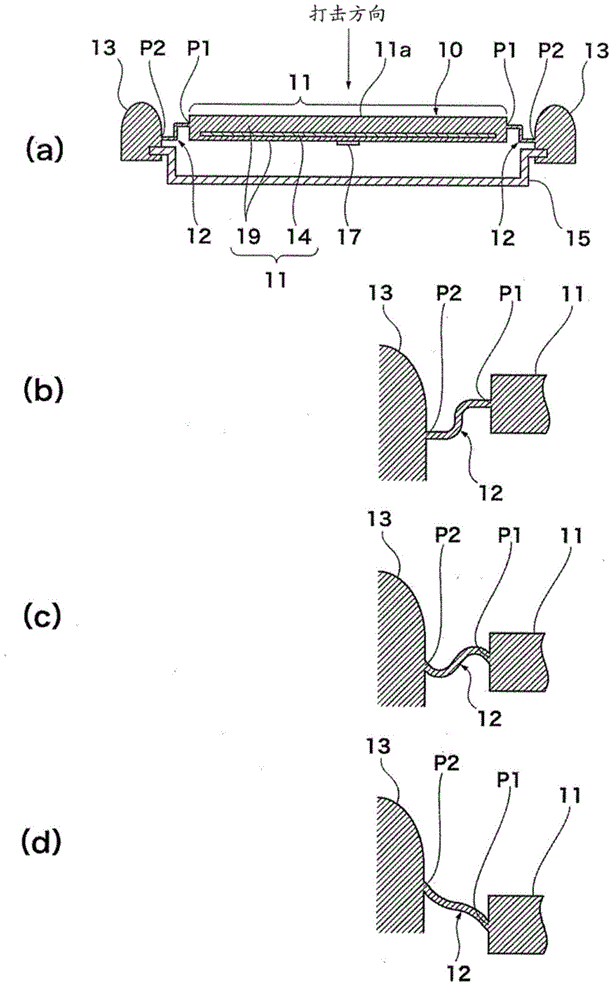

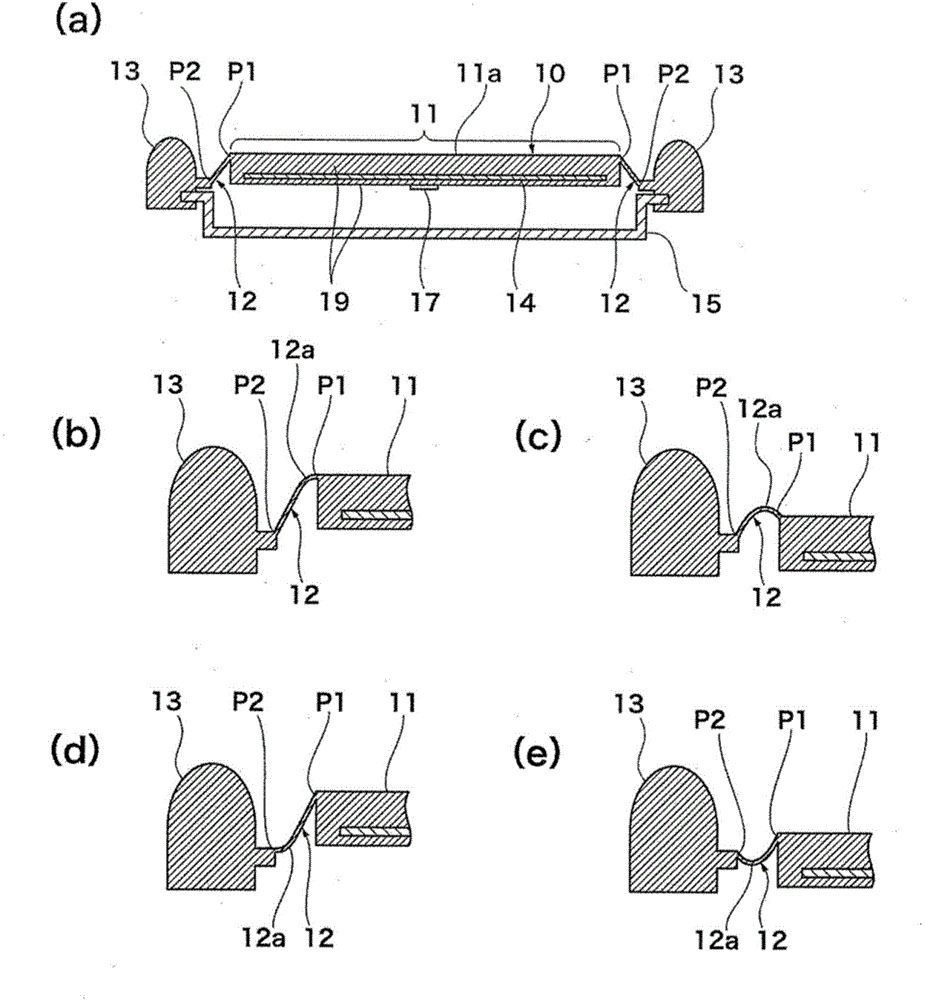

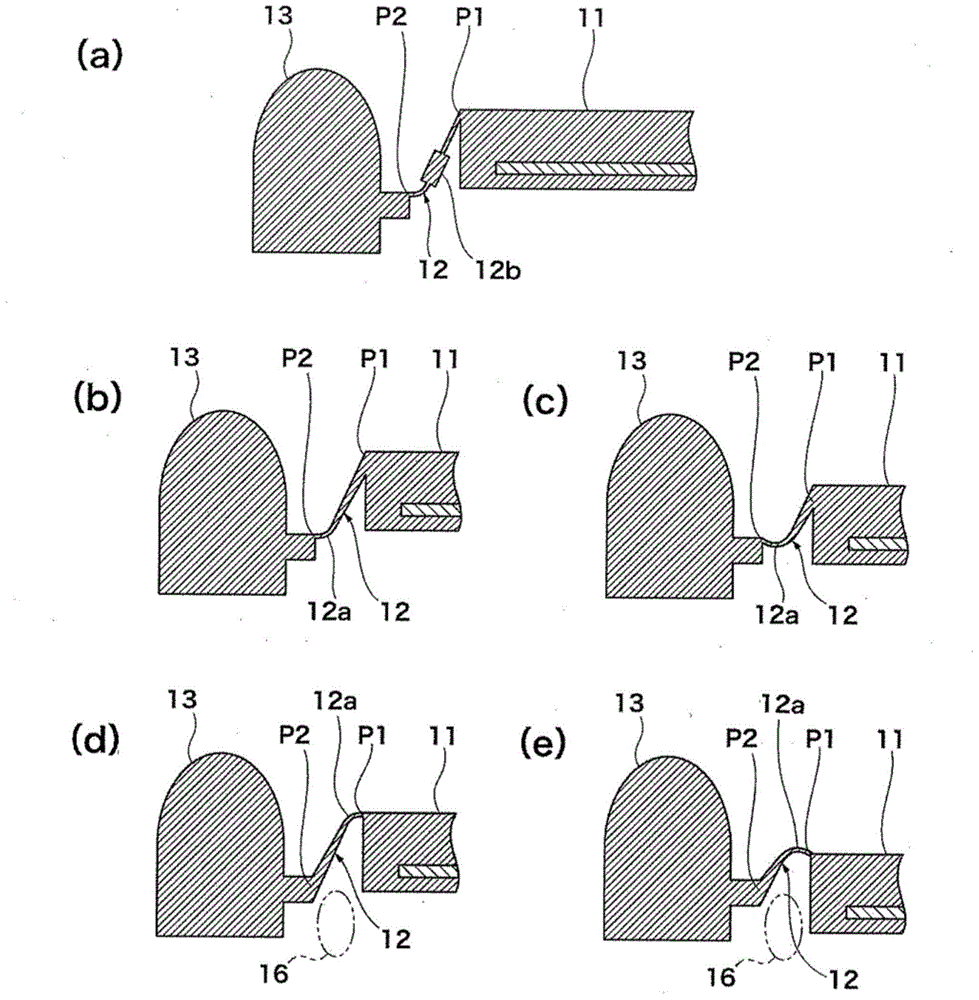

Strike pad

InactiveCN105185360AIncrease the striking powerIncreased sense of impactElectrophonic musical instrumentsPercussion musical instrumentsRubber materialEngineering

Owner:YAMAHA CORP

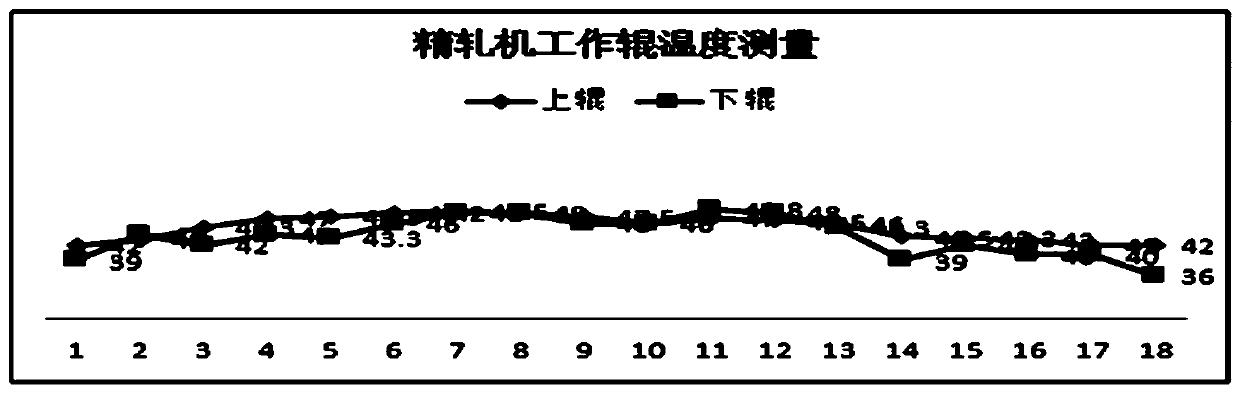

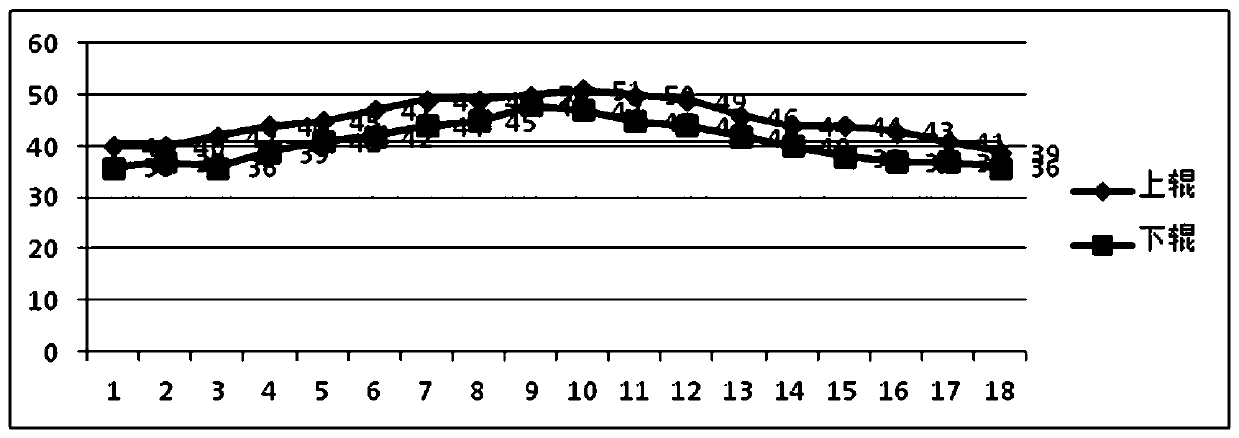

Roller cooling control method

ActiveCN111389923AExtend your stayImprove cooling uniformityTemperature control deviceRollsCooling effectEngineering

The invention discloses a roller cooling control method. A device used by the method comprises a spray beam and a nozzle which are connected. The method comprises the following steps that firstly, a water pipe fixing plate and the spraying beam are mounted, a regulating valve is replaced, then nozzle distribution is simulated to calculate suitable nozzle distribution position matrix points, and then parameters of an upper supporting roller nozzle (1), upper working roller upper row nozzles (2), upper working roller lower row nozzles (3), a lower working roller nozzle (4) and a lower supportingroller nozzle (5) of a rolling mill are sequentially adjusted; and finally, a roller is cooled. The method has the advantages that three-stage roller cooling is achieved, the defects of the edge partof a steel plate are reduced, a plate type and transverse same plate difference of the steel plate are ensured, all-point monitoring is conducted, different injection force and flows are adjusted fordifferent parts, the cooling effects of all sections are accurately controlled, the cooling efficiency and the cooling uniformity of the roller are improved, and the quality of the cooled roller is guaranteed.

Owner:NANJING IRON & STEEL CO LTD

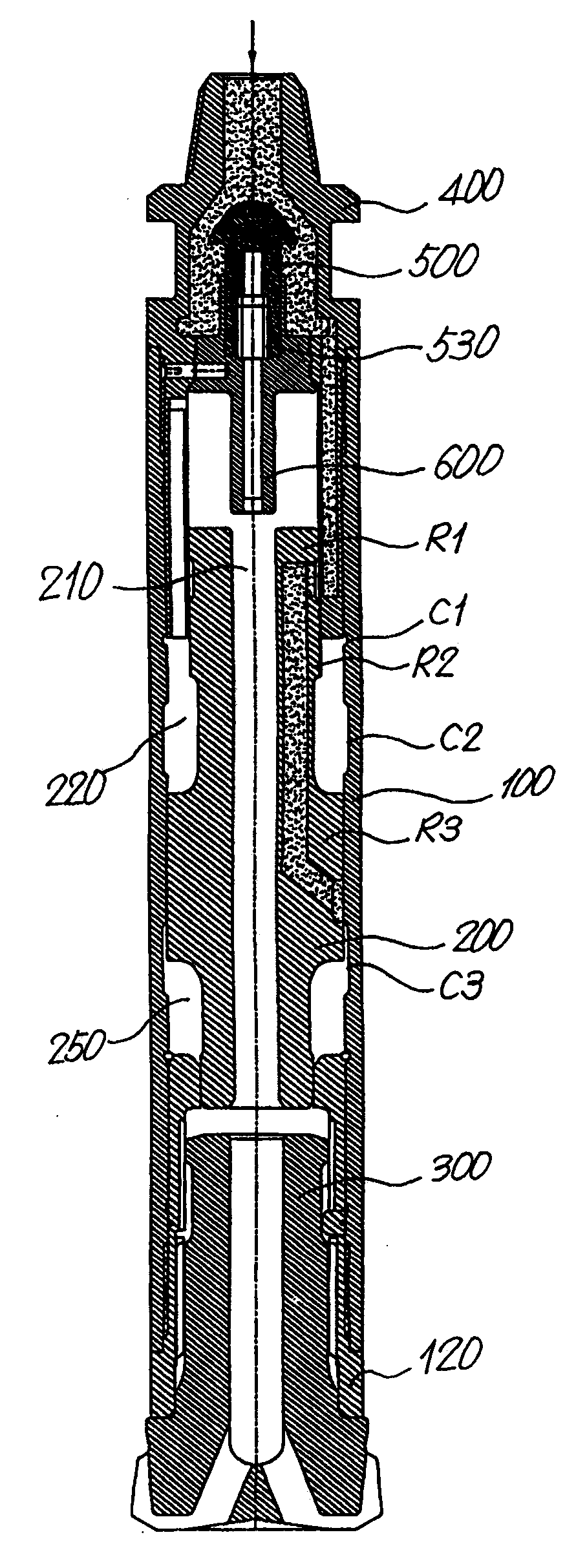

Water hammer

ActiveUS7712552B2Reduce consumptionIncrease the striking powerDrill bitsConstructionsEngineeringHigh pressure water

A water hammer using a drive rod is provided. The water hammer includes a tubular main body having a hollow portion; a socket coupled to an upper end of the main body and having a water pressure supply passage; a cylindrical piston housing connected to the main body; a piston slidably installed in the piston housing, for striking a bit of a bit unit installed at a lower portion of the main body, having a hollow portion through which water is discharged, an annular pressurizing portion protruding on its outer circumferential surface, and a first communication hole connected to the hollow portion; a sliding member fitted into the main body to be coupled to the piston housing, defining a valve installation space, and creating a space portion in which the piston is received when the piston is elevated; a valve member defining the valve installation space into first and third space portions along the length of the piston, the first and second space portions having different cross-sectional areas from each other, and valve member forming a second space portion between the first and third space portions, connected to the hollow portion of the piston and connected to the first space portion when the piston is elevated; and a water pressure supply unit for supplying high pressure water delivered to the water pressure supply passage of the socket to the first and second space portions.

Owner:IN

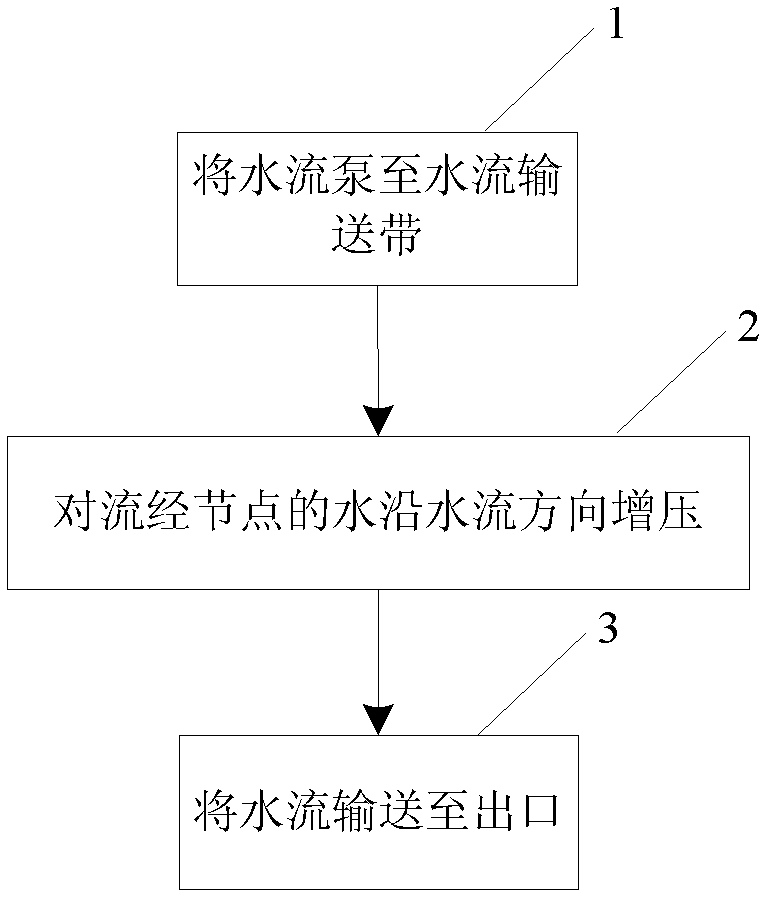

Water band pressurizing device and method and fire fighting apparatus

InactiveCN102430220ADoes not significantly increase spaceIncrease the striking powerFire rescuePipe-jointsWater flowEngineering

The invention provides a water band pressurizing device, a water band pressurizing method and a fire fighting apparatus. The water band pressurizing device comprises a water flow conveying belt consisting of a plurality of sections of water bands which are mutually communicated, wherein an axial-flow electric pump is arranged at a node between every two adjacent sections of water bands; the axial center of a blade of the axial-flow electric pump is parallel to the water flow direction in the water bands; and the axial-flow electric pump is used for pressurizing water flowing through the node along a water flow direction. After sequentially flowing through the node, the water flow is pressurized in a way of relay, so the problem that it is difficult to delivery water to a high floor during fire fighting is solved. The water band pressurizing device has the advantages of high fire-fighting efficiency, flexible operation, compact structure and the like.

Owner:SANY HEAVY IND CO LTD (CN)

High-speed clutch type spiral closed punch press

InactiveCN111716785AAccelerating mass is smallSensitive stroke controlPress ramPunch pressBall bearing

The invention relates to a high-speed clutch type spiral closed punch press. The high-speed clutch type spiral closed punch press comprises a press body, a sliding block, lifting supporting arms, lifting rods, pneumatic return cylinders, a copper nut, a screw rod, a radial cylindrical roller bearing seat, a radial cylindrical roller bearing, a brake disc, a brake cylinder, a one-way ball bearing,a belt wheel type large flywheel, a deep groove ball bearing, a friction clutch disc, friction blocks, a piston, a cylinder body, a spring piston guide screw rod, a piston return spring, a piston guide screw rod, a right upper fastening nut, a motor and a small belt pulley. According to the high-speed clutch type spiral closed punch press, the sliding block stroke is automatically adjusted, the motor power is reduced, power is saved, and energy saving is remarkable; the sliding block can stop at any position of the press stroke, the service life of a die is long, the unbalance loading resistance is high, and multi-station die forging can be achieved; the sliding block rapidly returns, the production efficiency is high, and the output energy is high; and the sliding block striking speed ishigh, the striking force is large, environmental friendliness is achieved, the overload safety protection effect is achieved, and operation is reliable. The high-speed clutch type spiral closed punchpress can be widely applied to the forge piece pressure forming process, in particular to the stamping process.

Owner:青岛浩源益友锻压机械有限公司

Air inflated pistol

The invention discloses an inflated pistol, which comprises a pistol body and a pistol bore arranged in the pistol body. Symmetric first air cavities are formed in upper and lower inner walls of the pistol bore in a communication mode; second air cavities located at the left ends of the first air cavities are formed in the upper and lower inner walls of the pistol bore in a communication mode, anda third air cavity is formed in the inner wall of the right end of the pistol bore in a communication mode; an impact pipe body is arranged on the end face of the left end of the pistol bore, the impact pipe body is internally provided with an impact channel, The tail end of the right end of the impact pipe body is fixedly connected with a launching valve located in the third air cavity, the launching valve is internally provided with a launching cavity with a leftward opening and communicates with the impact channel, elastic switch valve assemblies located in the first air cavities are arranged on the upper and lower wall bodies of the impact pipe body, and openings are formed in the upper and lower wall bodies of the impact pipe body in a communication mode.

Owner:玉环市万进新能源科技有限公司

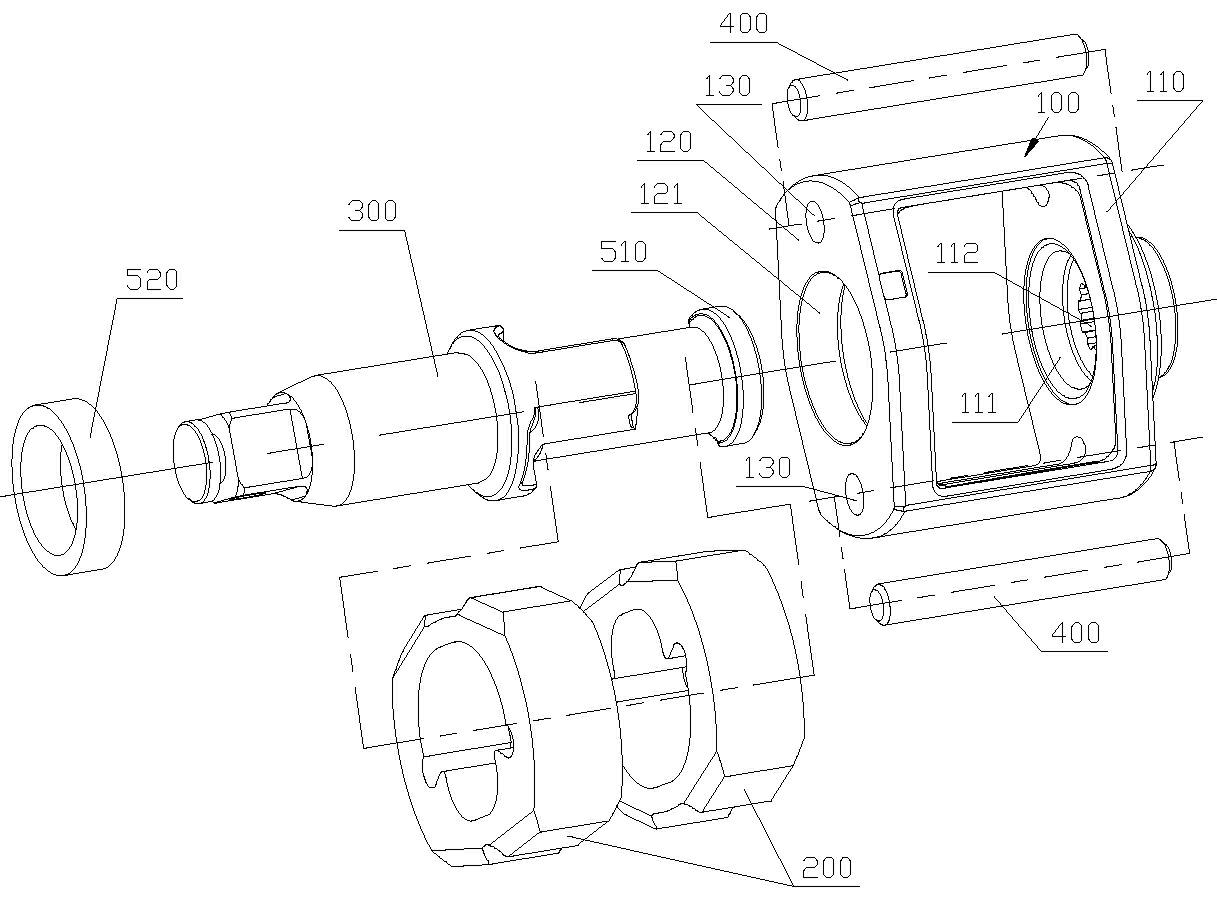

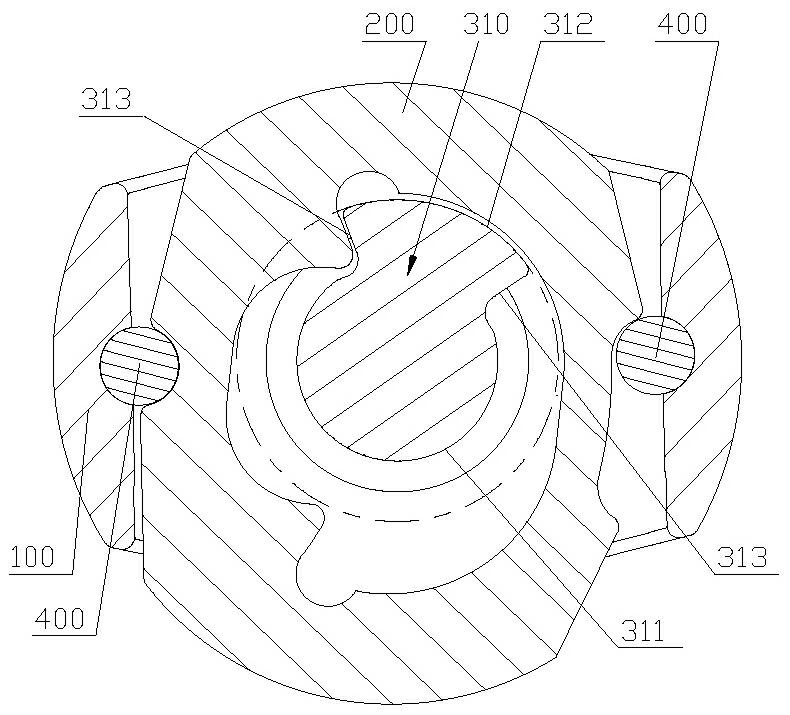

Torque limiting impact mechanism for pneumatic impact wrench

InactiveCN102092034AIncrease the striking powerThe overall impact is smallPortable percussive toolsSpannersImpact wrenchStraight segment

The invention relates to a torque limiting impact mechanism for a pneumatic impact wrench. The torque limiting impact mechanism comprises an impact cover, an impact hammer and an impact shaft, wherein the impact cover is driven by a pneumatic motor to rotate at high speed, the impact cover can throw the impact hammer by two impact pins to peen the impact shaft at high frequency, so that the impact shaft can output a continuous impact torque. The torque limiting impact mechanism is characterized in that the radial section of the impact shaft which corresponds to the impact hammer is composed of two circular arcs which are concentric with the axis of the impact shaft and have different radiuses, a smooth curve which connects the end points of the two circular arcs at one side and a straight segment which connects the end points of the two circular arcs at the other side and can pass through the center of the circular arc after being extended. When the pneumatic motor rotates anticlockwise, the impact face of the impact shaft is a plane formed by the straight segment, and the output torque is larger; when the pneumatic motor rotates clockwise, the impact hammer contacts with the impact shaft by ways of plane and line slide contact, the output torque is smaller, and thereby the output torque is limited. The torque limiting impact mechanism is suitable for occasions which need limiting a clockwise output torque and require a larger output torque.

Owner:SHANGHAI INGERSOLL RAND COMPRESSOR CO LTD

Hammer sheet crusher

ActiveCN103212468AIncrease the striking powerEnsure quality stabilityGrain treatmentsElectric machineryCrusher

The invention discloses a hammer sheet crusher. The hammer sheet crusher comprises an upper body, a main motor arranged outside the upper body, a main shaft connected with the main motor, a sieve plate, hammer sheets, a rotating shaft moving cutter and an auxiliary motor, the hammer sheets are arranged on the main shaft, the sieve plate is arranged outside the hammer sheets and is arranged in the upper body around the main shaft, the auxiliary motor is arranged outside the upper body, the rotating shaft moving cutter is arranged in the upper body and parallels to the main shaft, and the rotating shaft moving cutter is connected with the auxiliary motor. How to improve the crushing capability of the crusher and destroy a circulation layer in the crusher is a technique problem to be solved. The hammer sheet crusher which adopts the rotating shaft moving cutter driven by the auxiliary motor increases the cutting force to a material and is in favor of destroying the circulation layer of the material in the crusher, so the crushing efficiency and the crushing quality are effectively improved.

Owner:TSZJANSU CHZHEHNCHAN SIRIEHL OIL EHND FID MASHINERI KO

Sand washing machine

ActiveCN108127572AExtended service lifeIncrease the striking powerAbrasive feedersAbrasive blasting machinesSand blastingEngineering

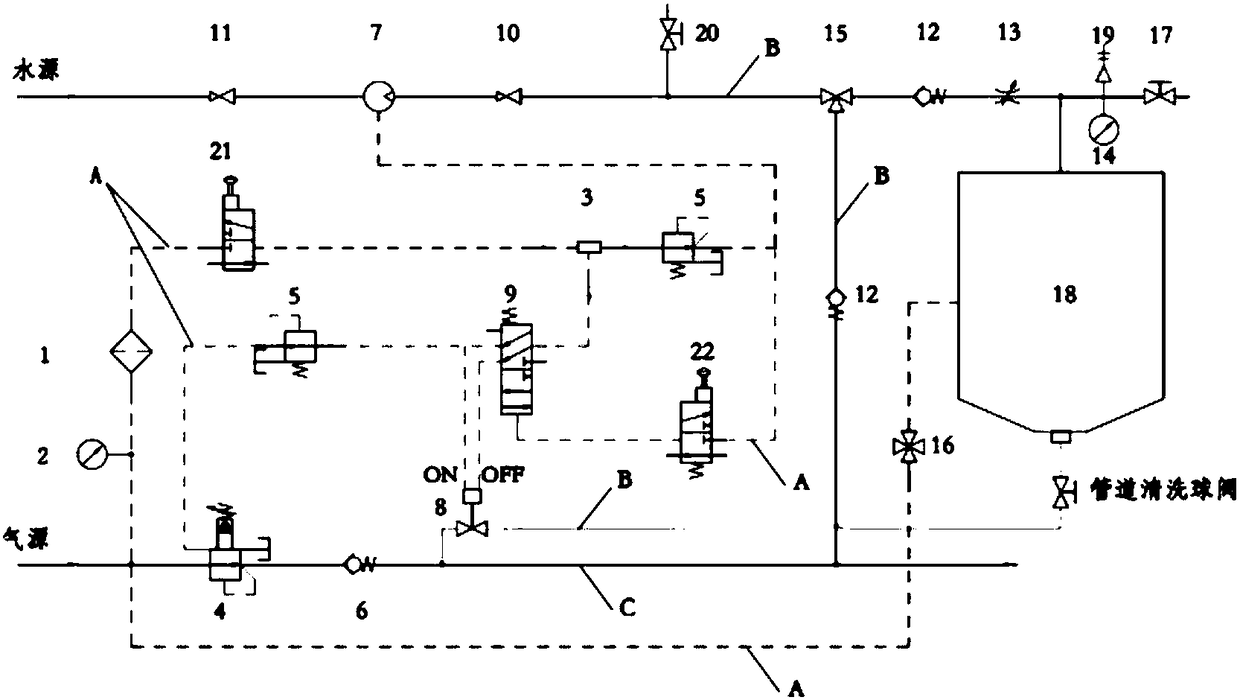

The invention relates to a sand washing machine which comprises a control circuit A, a high-pressure water pipeline B and a compressed air channel C. The control circuit A is used for controlling theopening-closing states of the compressed air channel C and the high-pressure water pipeline B, and comprises a switching-on state and a switching-off state of a control switch at the tail end of a sand blasting pipe. When the control switch at the tail end of the sand blasting pipe is switched on, a pneumatic operated opening of a two-position five-way pneumatic operated directional valve is subjected to ventilation switchover, a control opening of a regulating valve is connected with compressed air, and at the moment, the normally closed state of the regulating valve is converted into the opened state, and the compressed air channel C is opened; an opening of a pneumatic ball valve is connected with compressed air, and the high-pressure water pipeline B is opened; the control switch at the tail end of the sand blasting pipe is closed, the two-position five-way pneumatic operated directional valve resets, the regulating valve is not connected with control air pressure, and is in the normally closed state, and the compressed air channel C is closed; and a close opening of the pneumatic ball valve is connected with compressed air, and the high-pressure water pipeline B is closed. According to the sand washing machine, by introducing a medium and adding water, dust is suppressed, and moreover, the structure is simple, sand blasting and pipe cleaning are facilitated, and the efficiency is high.

Owner:上海水威环境技术股份有限公司

Clutch type screw press

The clutch type screw press includes a frame, a sliding block, a flywheel and a motor. On the frame, there are screw in the center, brake and sliding block connected to the lower part of the screw, flywheel and clutch, comprising a power disc and a friction wheel train, connected to the upper part of the screw, compressed air driven cylinder connected to the clutch, pressing board around the lower part of the friction wheel train, guide post with spring and with upper end fixed to the flywheel and lower end connected movably to the pressing board, and operating block around the pressing board and connected to the cylinder. The clutch type screw press has compressed air as operating power of the clutch, less pressure releasing links, fast pressure release, simple structure, great impact force and other advantages, and may be used in pressure formation of metal material in different industry.

Owner:韩宝林

Method for preparing neodymium-iron-boron permanent magnetic alloy powder by water/oil flow grinding

The invention relates to a method for preparing neodymium-iron-boron permanent magnetic alloy powder by water / oil flow grinding. The method includes: taking hydrogen absorption neodymium-iron-boron particles as raw materials, and crushing the hydrogen absorption neodymium-iron-boron particles under water hammer action of high-pressure pulse water jet, water wedge stretch action, friction shearing action, strong impact action between particles and targets, grinding action between particles and grinding media and the like to finally prepare neodymium-iron-boron alloy powder proper in granularity. The method has the advantages that powder preparation is realized by high-pressure pulse water / oil flow jet, impact force for crushing the particles is greatly increased by the water hammer action of high-pressure pulse water jet, the water wedge stretch action, the shearing action, the strong impact action between particles and targets and the like besides high-speed collision among particles, and effectiveness and efficiency in crushing are improved; oxygen content of alloy powder is effectively reduced by adoption of passivated water or oil.

Owner:UNIV OF SCI & TECH BEIJING

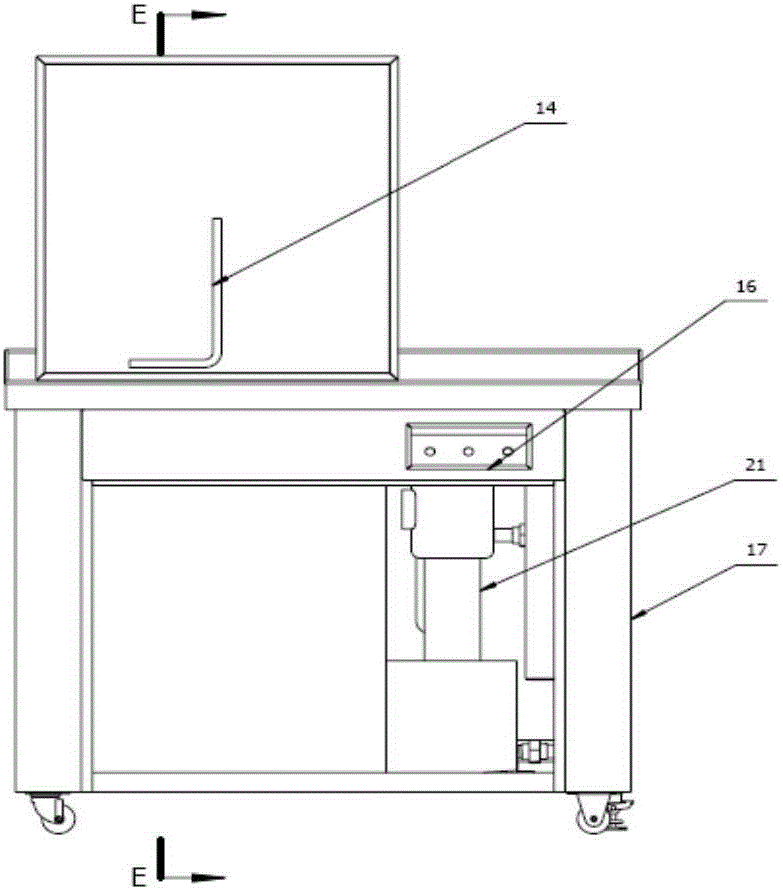

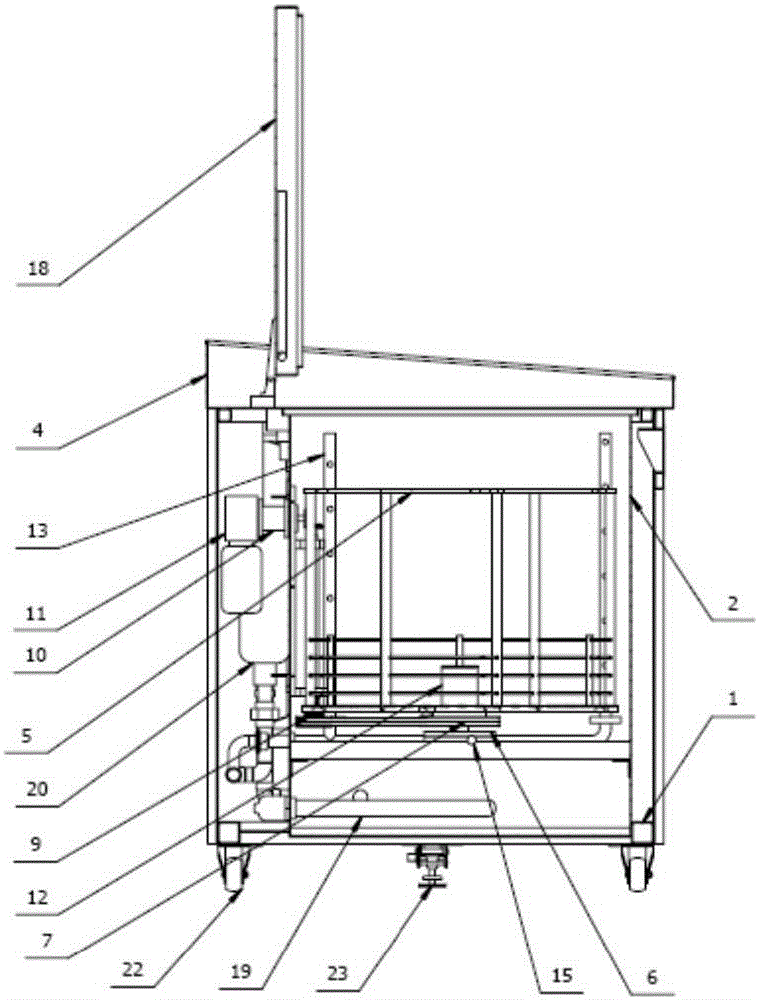

Rotary high-pressure spray cleaning machine

The invention provides a rotary high-pressure spray cleaning machine. The rotary high-pressure spray cleaning machine comprises a machine frame (1), a cleaning tank (2), a rotary basket (5), a motor (11), a high-pressure pump (21), a spraying device and a transmission device. The cleaning tank (2) is connected with the motor (11). The motor (11), the transmission device and the rotary basket (5) are connected in sequence. The cleaning tank (2) is connected with a water inlet of the high-pressure pump (21). The high-pressure pump (21) is mounted on the machine frame (1) and connected with the spraying device. The rotary high-pressure spray cleaning machine has the advantages that the efficiency is high, that is, the rotary basket has large diameter and depth and contains multiple workpieces, and the long workpieces can be cleaned; the impact face range is wide, that is, spraying pipes are arranged on the rotation periphery and up and down, and the effect that no dead space exist on the spraying impact face is ensured; the cleanliness is high, that is, due to the adoption of the high-pressure spraying pump, impact force of water flow acting on the workpieces is larger, and grease dirt on the surfaces of the workpieces is better removed; and the structure is compact, and the maneuverability is high.

Owner:中国船舶重工集团公司第七二六研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com