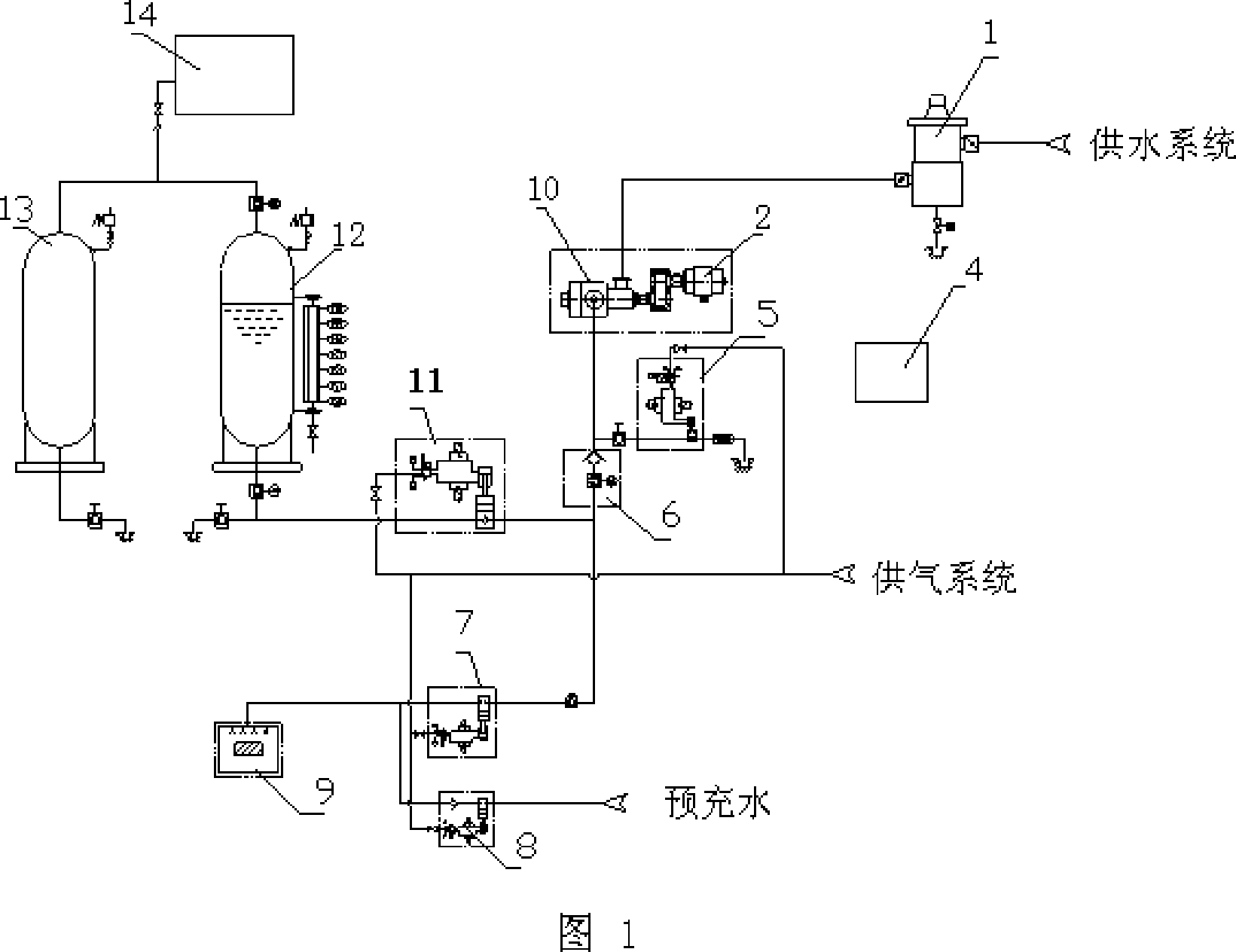

High-pressure water descaling system for hot continuous rolling production line

A high-pressure water descaling and production line technology, which is applied to the descaling system of strip rolling, the high-pressure water descaling system, and the field of slab, can solve the problems of increased production cost, unfavorable energy saving, large slab temperature drop, etc. Achieve the effect of reducing equipment cost, significant power consumption and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

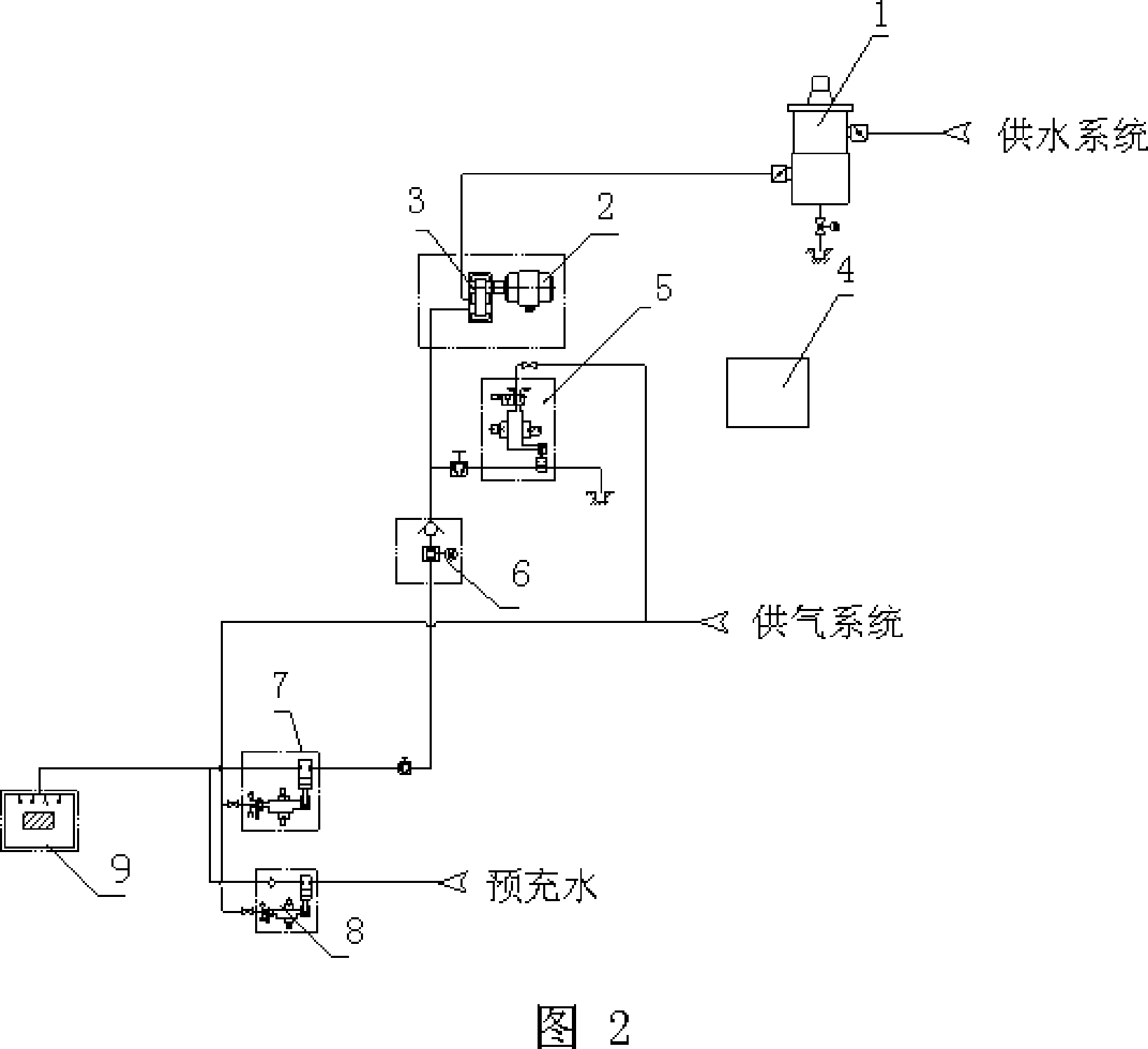

[0013] The present invention will be further described in detail below in conjunction with FIG. 2 .

[0014] The main equipment configurations of the present invention include: self-cleaning filter 1, AC motor 2, high-pressure plunger pump 3, electrical control cabinet 4, bypass unloading valve group 5, electric control valve and check valve group 6, descaling injection It consists of valve group 7, low-pressure pre-flush water valve group 8, descaling header and descaling nozzle 9, etc. Compared with the existing equipment, high-pressure water tank 12, high-pressure gas tank 13, air compressor 14, minimum liquid level valve 11 and other devices are omitted, which not only simplifies the equipment composition, but also reduces the operating costs of the above-mentioned equipment.

[0015] In the present invention, the descaling pump group uses a high-pressure plunger pump to directly provide high-pressure water to the descaling system, and the system pressure can reach 25MPa-5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com