Controllable electro-hydraulic pulse jet flow washing unit

A pulse jet and cleaning device technology, which is applied in the direction of liquid injection devices, injection devices, injection devices, etc., can solve the problems of high pressure and water flow, poor cleaning quality, and high labor intensity, so as to achieve stronger impact, easy implementation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

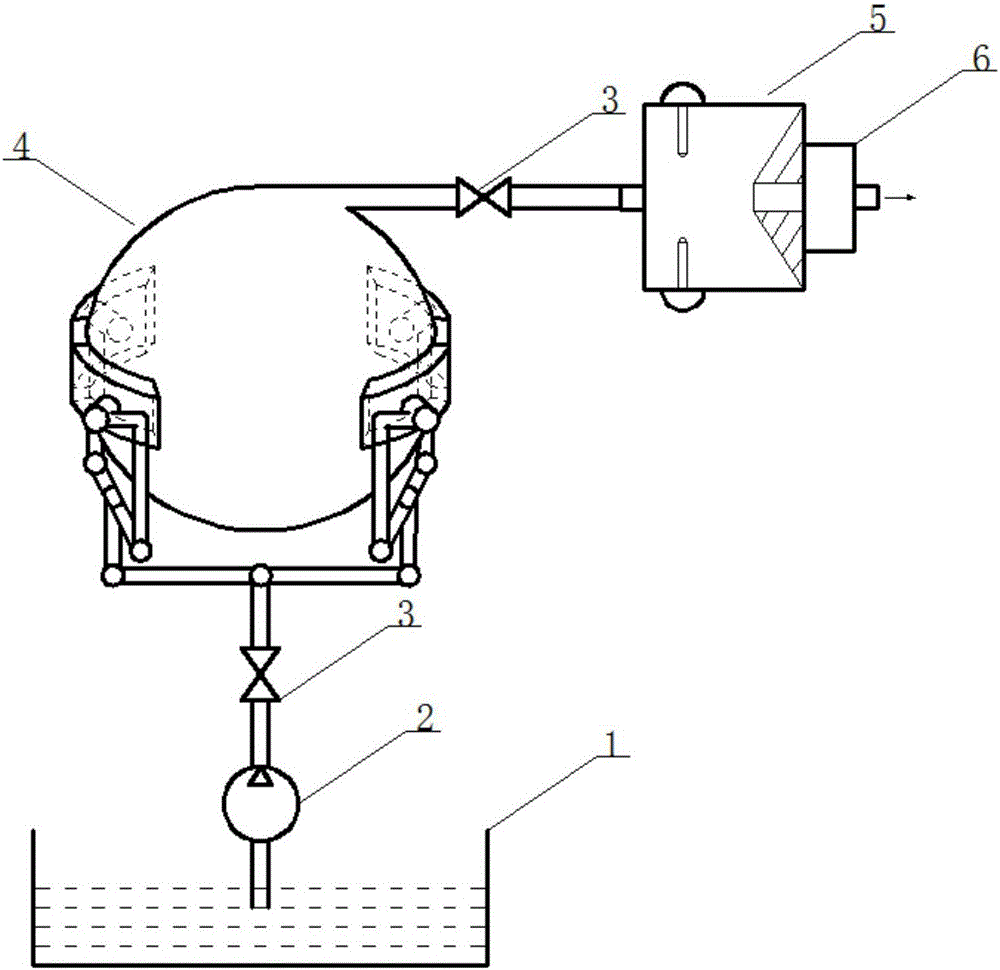

[0012] Attached below Figure 1-3 The present invention will be described in more detail.

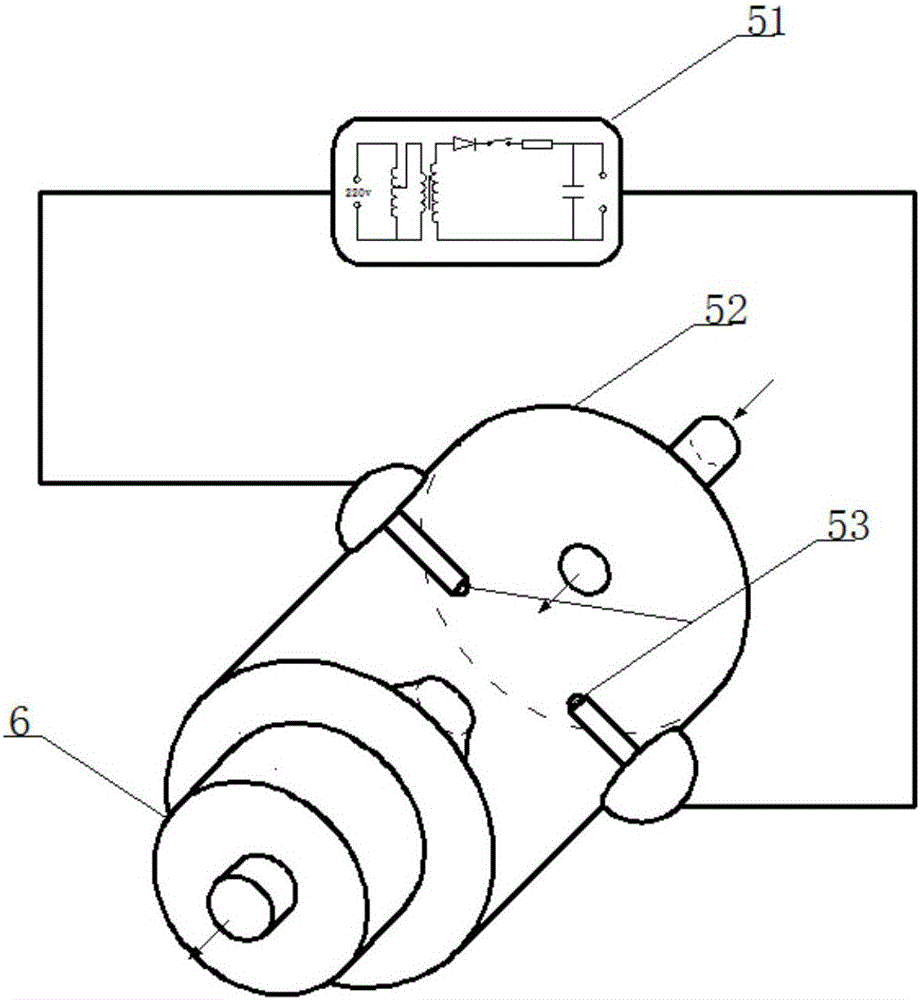

[0013] The invention discloses a controllable electro-hydraulic pulse jet cleaning device, which mainly includes a water tank 1, a water pump 2, a spherical eddy current generator 4, an electro-hydraulic pulse jet device 5 and an annular ultrasonic generator 6, wherein:

[0014] The water tank 1 is used for water supply.

[0015] The water pump 2 is connected to the water tank 1 and is used to draw water in the water tank 1 and pressurize the water flow.

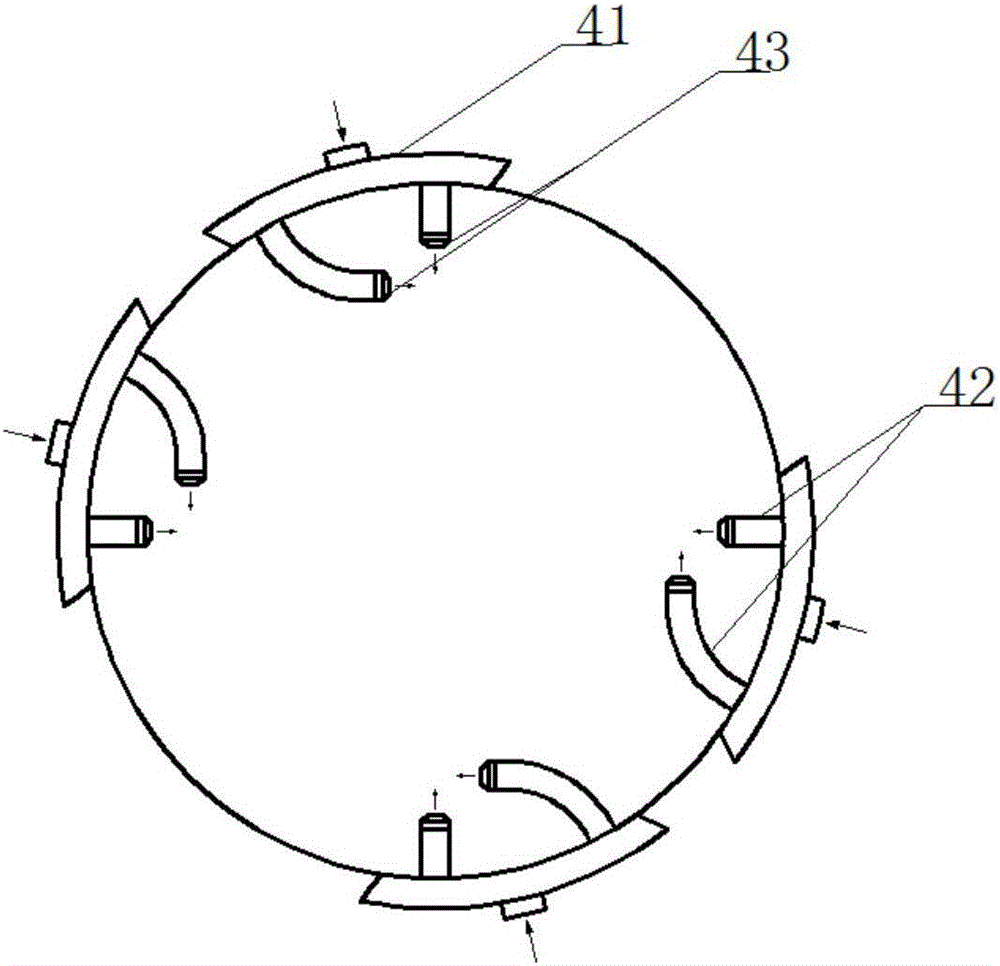

[0016] The spherical vortex generator 4 is connected to the water pump 2, and is used to convert the water pressurized by the water pump into a vortex water jet. The spherical vortex generator 4 includes 2-8 annular guide chambers 41 , 4-16 guide tubes 42 and 2-8 pairs of nozzles 43 . The annular guide cavity 41 is horizontally distributed on the outer surface of the spherical vortex generator 4, the outside of the annular guide ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com