Hammer sheet crusher

A technology of pulverizer and hammer, which is applied in the direction of grain processing, etc. It can solve the problems of easy concave in the middle part of the sieve plate, damage in the middle part of the sieve plate, and hinder the powder from passing through the sieve holes, so as to improve the crushing quality and ensure stability The effect of reliability, quality assurance and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

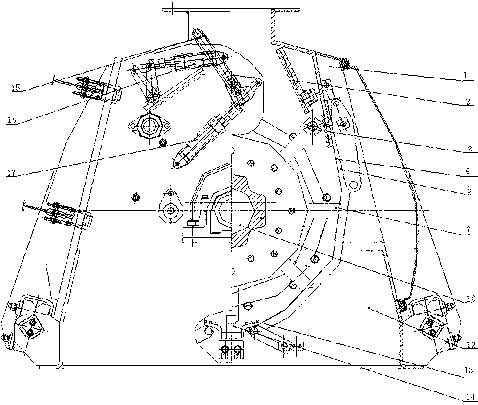

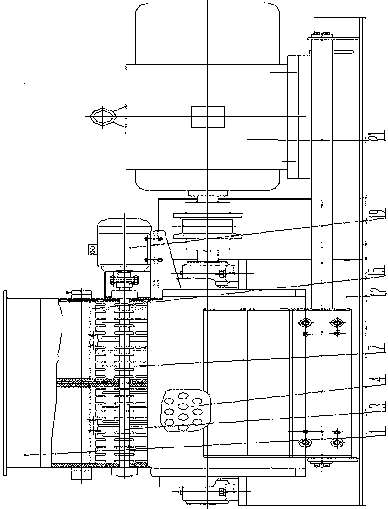

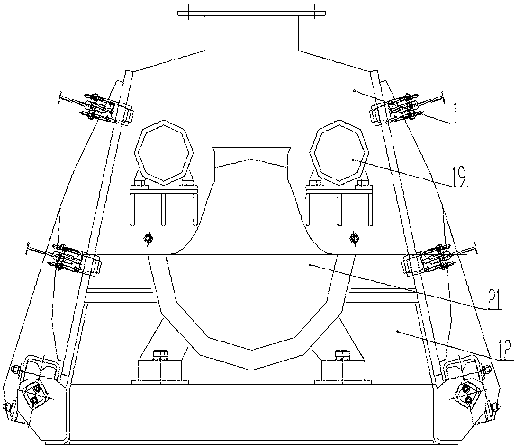

[0033] Such as Figure 1 to Figure 6 As shown, the present invention discloses a hammer mill, which includes an upper body 1, a main motor 21 arranged outside the upper body 1, a main shaft 10 connected to the main motor 21, a sieve plate 4, a hammer 7, a rotating shaft Knife 3 and auxiliary motor 19, hammer 7 are arranged on the main shaft 10, sieve plate 4 is arranged outside the hammer 7 and in the upper body 1 around the main shaft 10, auxiliary motor 19 is arranged outside the upper body 1, and the rotating shaft and moving knife 3 are parallel The main shaft 10 is arranged in the upper body 1, and the rotating shaft movable knife 3 is connected with the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com