Sand washing machine

A water sand machine and water sand technology, applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve problems such as affecting the operator's sight and health, high dust from dry sand blasting equipment, and inability to apply to explosion-proof occasions. The effect of suppressing spark generation, large striking force and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

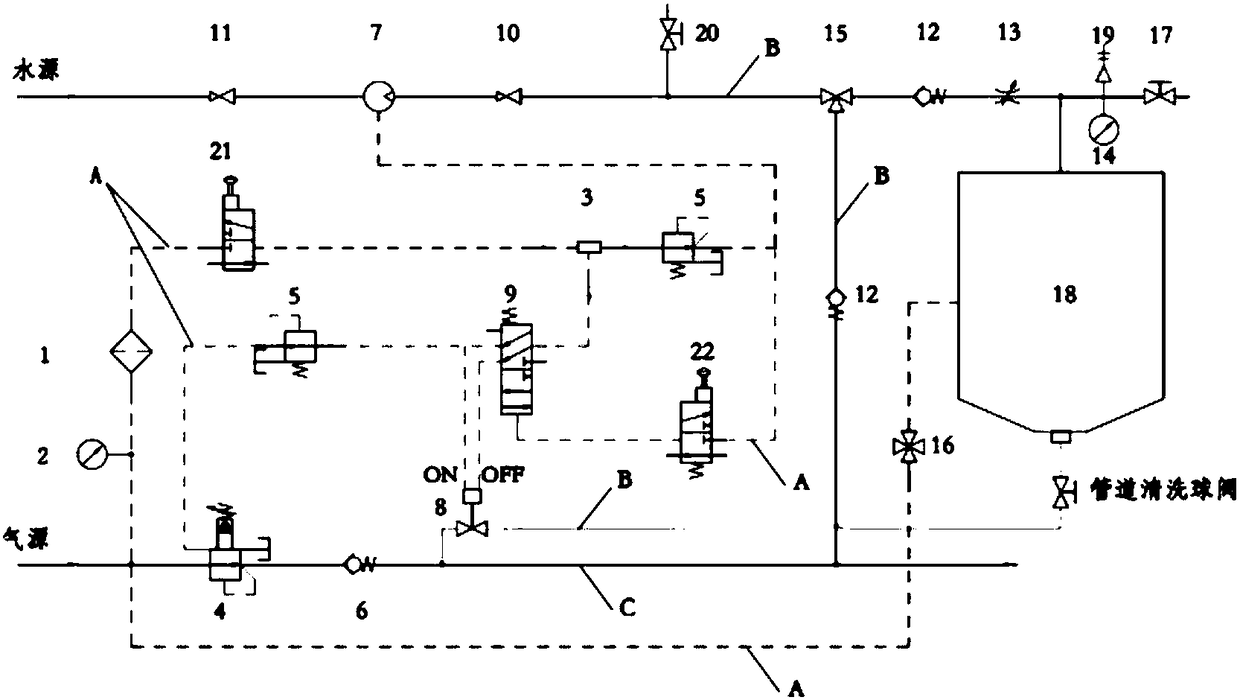

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0014] figure 1 It is the schematic diagram of the present invention. Such as figure 1 As shown, the water sand machine in the present invention includes a control circuit A, a high-pressure water pipeline B, and a compressed air circuit C; the control circuit A is used to control the switching status of the compressed air circuit C and the high-pressure water pipeline B.

[0015] The water sand machine provided by the present invention includes a filter 1, an air inlet pressure gauge 2, an air distribution block 3, a regulating valve 4, a pressure regulating valve 5, a quick hoop check valve 6, a pneumatic plunger pump 7, a pneumatic ball valve 8, Two-position five-way reversing valve 9, high-pressure pressure reducing valve 10, low-pressure pressure reducing valve 11, vertical check ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com