Strike pad

A technology of percussion pads and percussion surfaces, applied to percussion instruments, musical instruments, electro-acoustic instruments, etc., which can solve the problem of insufficient displacement of the pad 101

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, a percussion pad according to an embodiment of the present invention will be described with reference to the drawings.

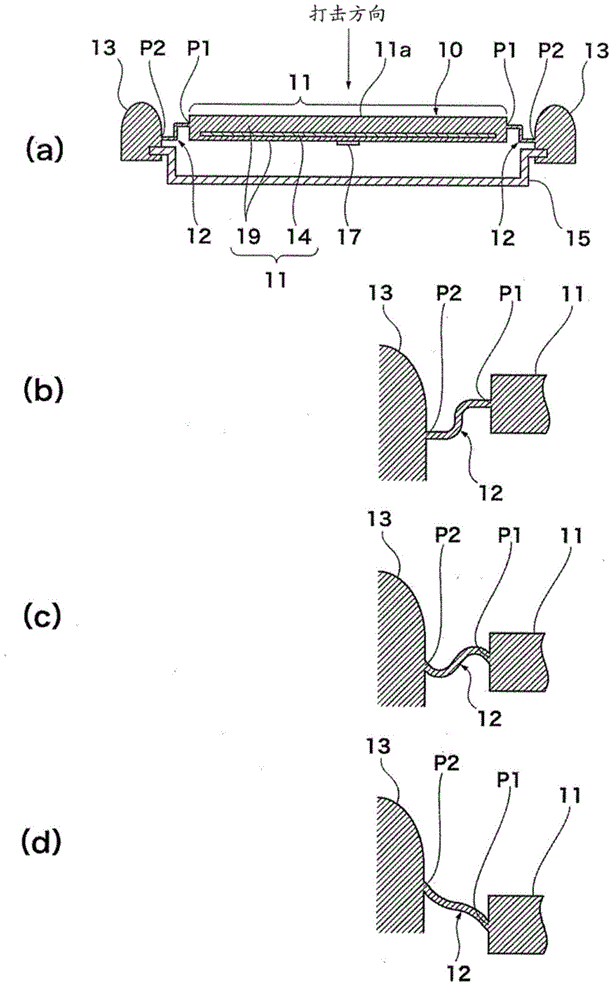

[0020] figure 1 (a) is a schematic sectional view of the striking pad according to one embodiment of the present invention, showing a non-strike state. It is assumed that the percussion pad of the present invention is suitable for electronic percussion instruments, but it is not limited thereto. For example, it can also be configured as a special pad for practice.

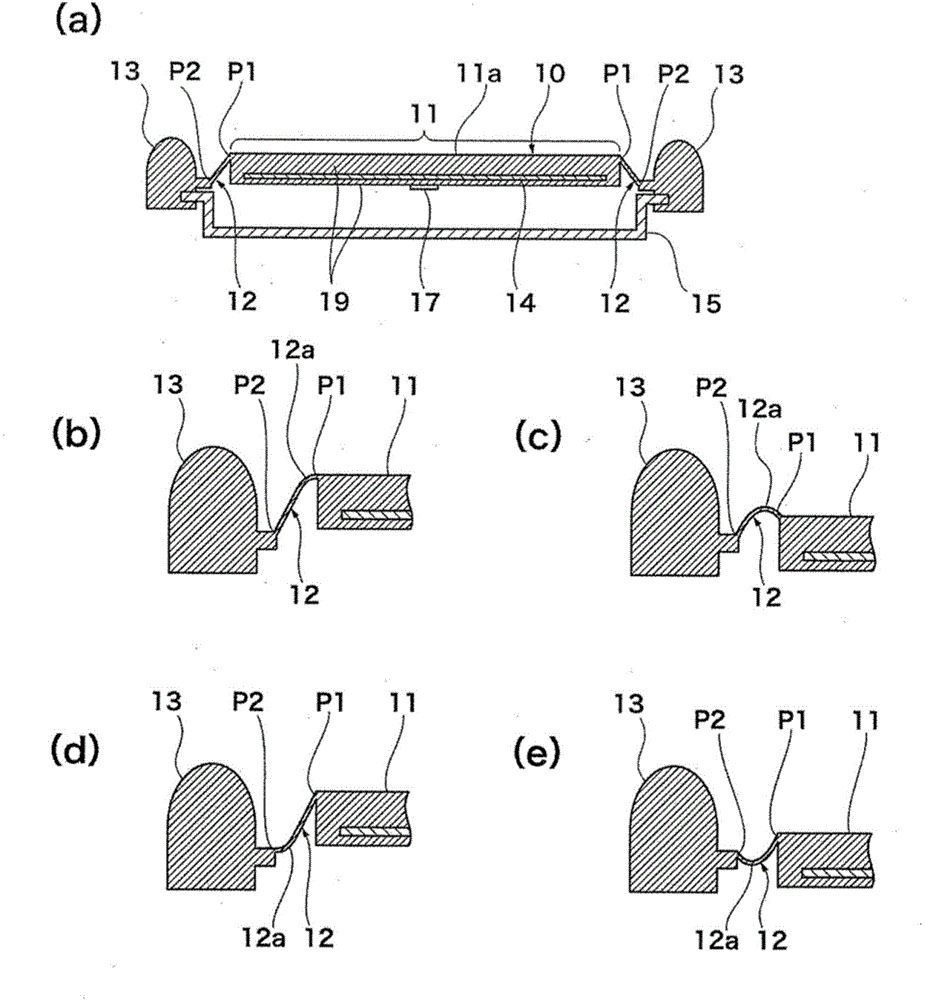

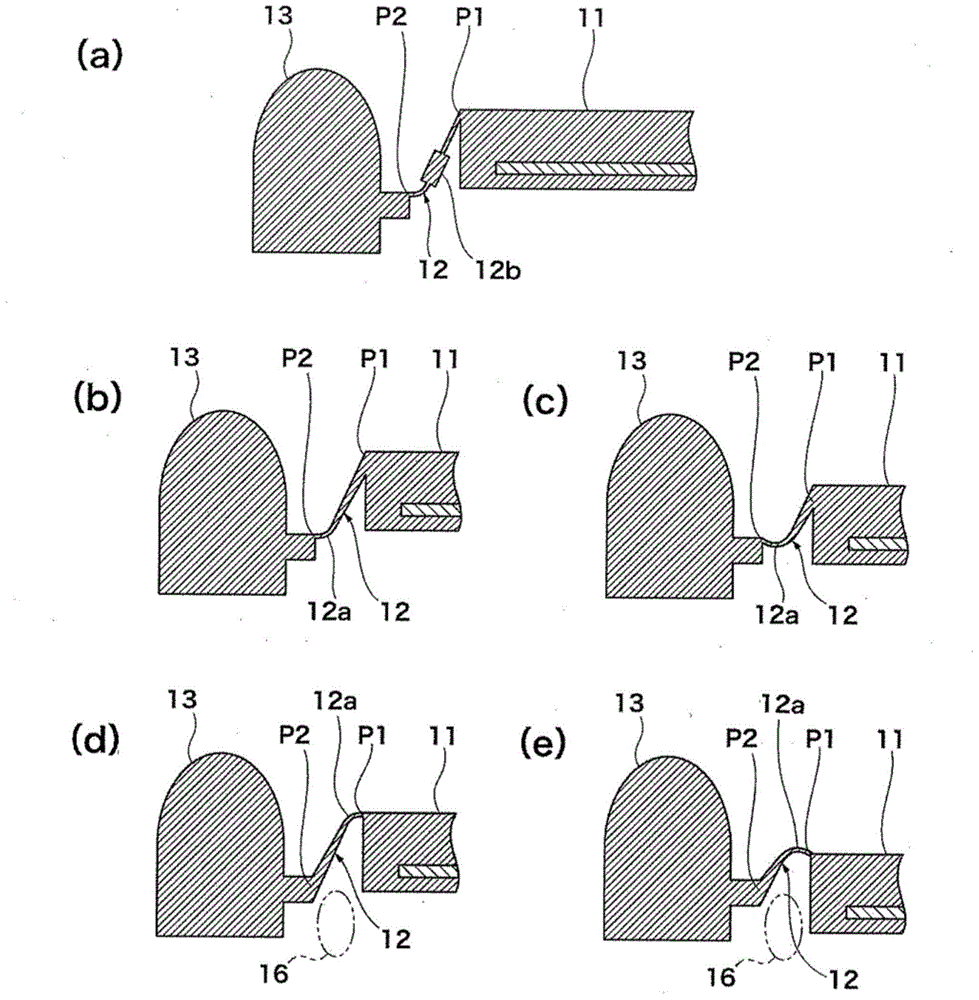

[0021] The pad 10 has a pad portion 11 , a connection portion 12 , a hoop portion 13 , and a case 15 . The casing 15 is placed on the ground or supported on the ground via a not-shown stand. The pad portion 11 has a soft portion 19 and a hard member 14 . A hard member 14 such as an iron plate is enclosed in the soft part 19 as a core material. The soft part 19 is softer than the hard member 14, and is formed integrally with the connection part 12 and the hoop part 13 usin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com