High pressure water noise-reduction spinning nozzle

A technology of rotating nozzles and high-pressure water, applied in the direction of spraying devices, spraying devices with movable outlets, etc., can solve the problems of large-scale application of unfavorable products, health hazards of operators, and difficult processing, so as to facilitate wide-scale application and cleaning Good effect, easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

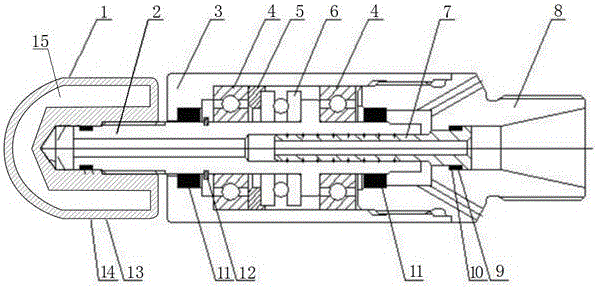

[0011] like figure 1 A high-pressure water noise-reducing rotary nozzle shown includes a rotary head 1 drilled with an eccentric hole, a rotary shaft assembly 2, a casing 3, and a water inlet joint 8. The rotary head is connected to the front end of the rotary shaft assembly through threads, and the rotary head It is a hollow structure, the outer layer is titanium alloy material, and the middle layer is rubber sound-absorbing material 15; the inner side of the outer casing 3 is provided with annular stepped steps, and the rotating shaft assembly is installed in the outer casing 3, and the rotating shaft assembly consists of a hollow rotating Shaft and hollow gap sealing rod 7, the gap sealing rod is installed in the hollow rotating shaft, the rotating shaft is fixed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com