Fuel-gas-powered nail gun allowing for convenient cleaning, exhaust and radiation

A technology for gas nail guns and exhaust caps, applied in nailing tools, manufacturing tools, etc., can solve problems such as poor heat dissipation, inconvenient disassembly and assembly, failure of one-way valves, etc., to achieve rapid heat dissipation, Easy to disassemble and clean, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

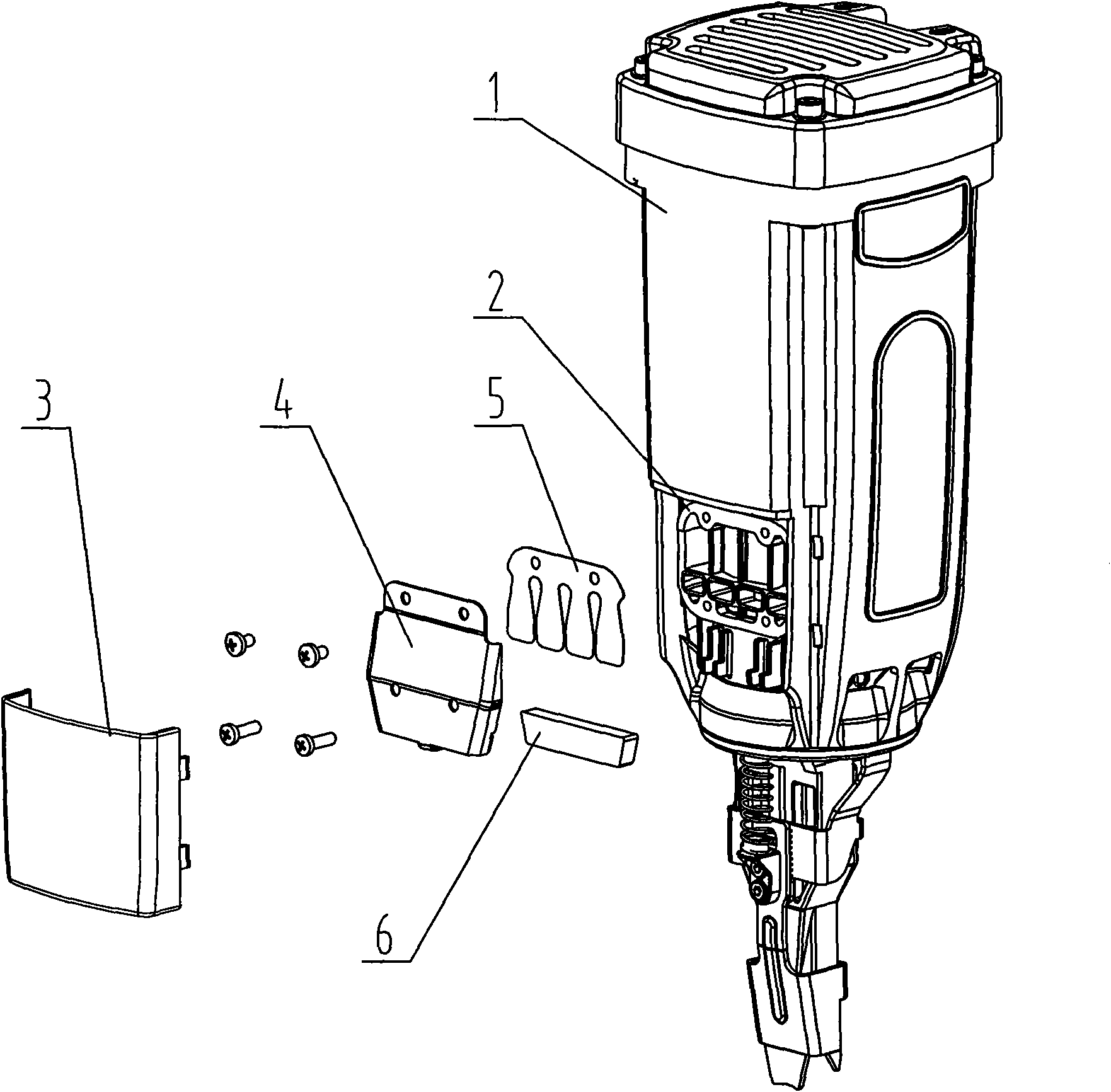

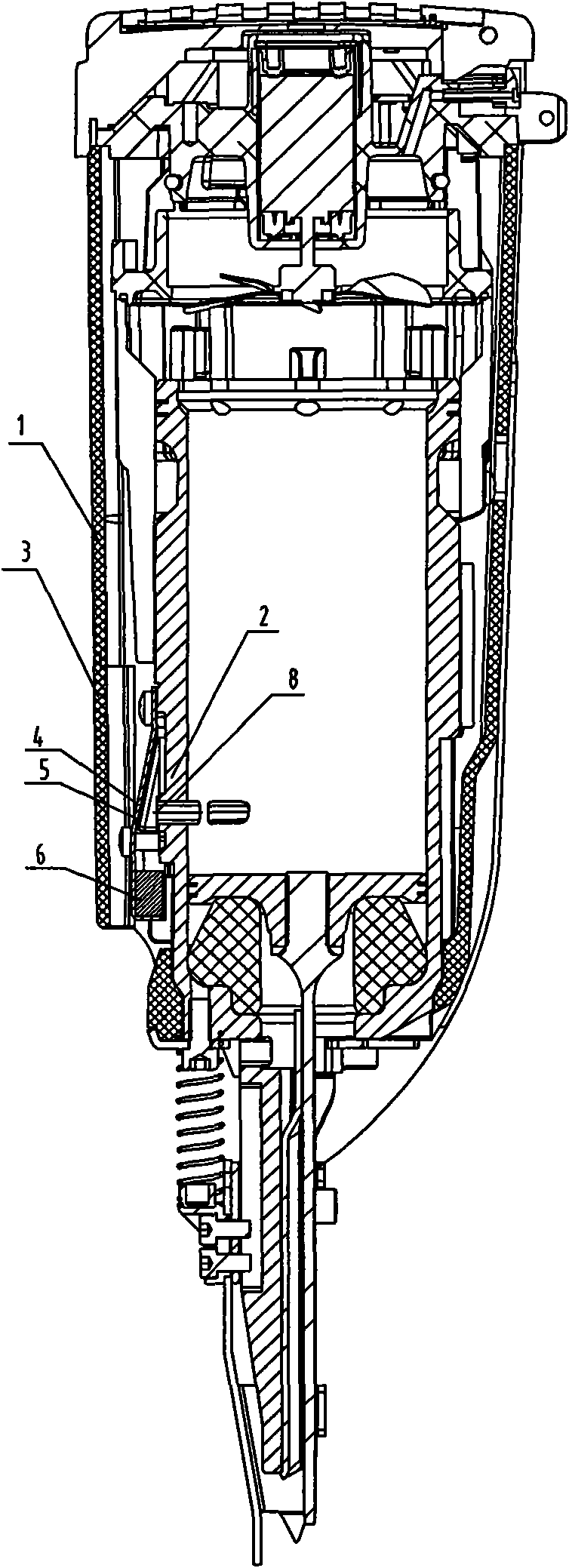

[0018] Embodiment 1: see specification attached Figure 1-3 As shown, a gas nail gun that is convenient for cleaning and exhaust heat dissipation includes a cylinder block 2 arranged in a housing 1, an exhaust port 8 arranged at the bottom of the cylinder block 2, a one-way valve plate 5, and an exhaust filter element 6 and the exhaust cover 4, characterized in that: the exhaust port 8 is in close contact with the one-way valve plate 5, the one-way valve plate 5 is connected with the exhaust cover 4, and the exhaust The upper part of the cover 4 is overlapped with the upper part of the one-way valve plate 5 and positioned and connected to the cylinder block 2, the exhaust filter element 6 is arranged at the lower part of the exhaust cover 4; the lower part of the housing 1 A window is provided, and the window is connected with the exhaust shield 3 of the peripheral device; the setting position of the window corresponds to the position of the exhaust cover 4 .

[0019] When in...

Embodiment 2

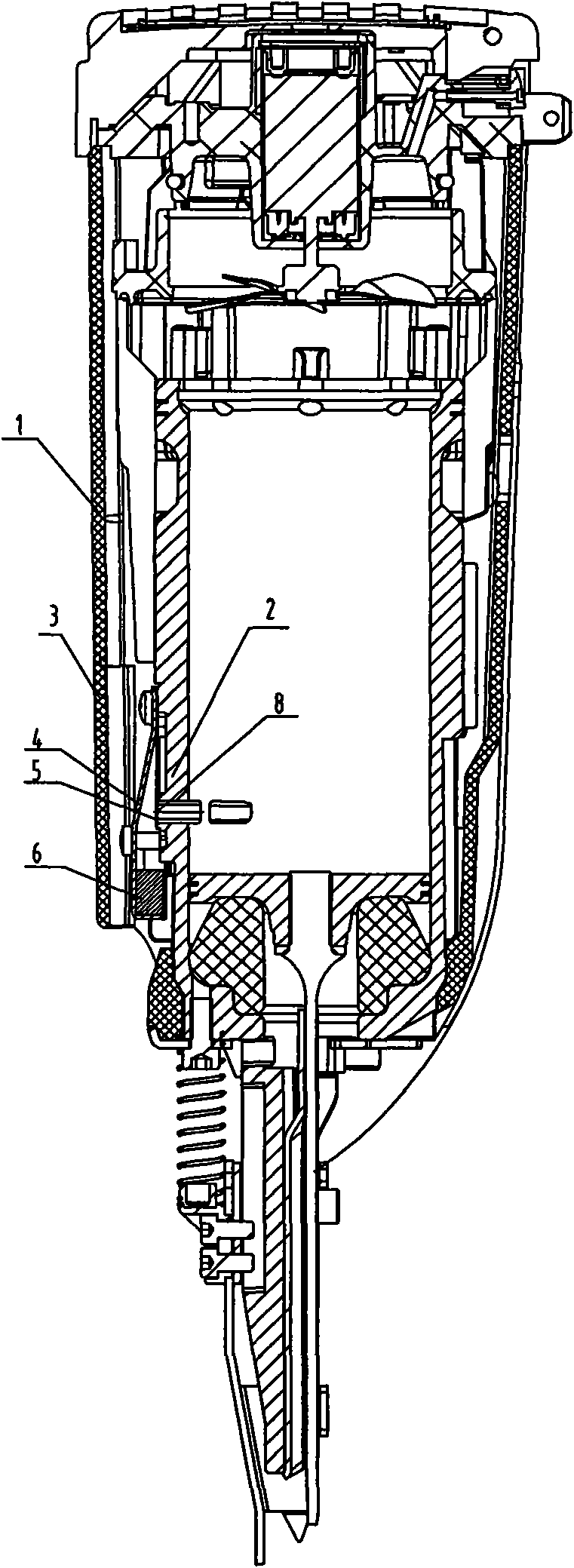

[0021] Embodiment 2: see specification attached Figure 4 As shown, the exhaust shield 3 is provided with an exhaust heat dissipation hole 7;

Embodiment 3

[0022] Embodiment 3: see specification attached Figure 5 As shown, the exhaust shield 3 is provided with a hole 9, and the exhaust cover 4 is provided with a hole 10, which are used to cooperate with the screw to fix the exhaust shield 3, and other structures are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com