Uniform-thickness high pressure spraying grouting method used for diaphragm wall construction

A technology of anti-seepage wall and equal thickness, which is applied in the direction of basic structure engineering and construction, and can solve the problems of only one side forming a wall, the wall forming range is small, and the forming wall is asymmetrical, so as to increase the spray force and penetration force, and improve the The anti-seepage ability of the wall and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

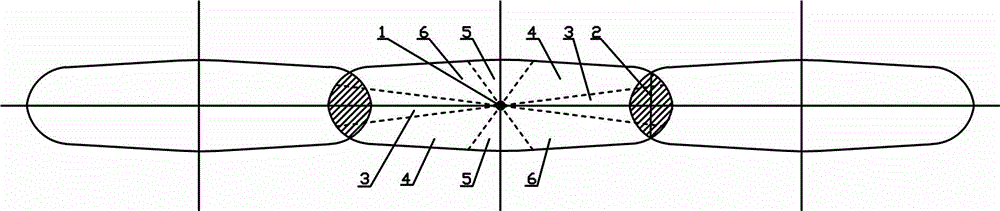

[0018] As shown in the figure, a method of constant-thickness high-spray grouting for the construction of cut-off walls is characterized in that it includes the following steps:

[0019] Construction preparation:

[0020] Temporary construction, grout mixing, high-jet drilling, grouting in place, etc.;

[0021] Use the grouting machine to carry out construction by means of variable speed rotary spraying and spray boom variable speed lifting, including the following steps:

[0022] 1. Spraying starts when the nozzle faces the wall-forming direction. When the spraying direction of the nozzle changes from facing the wall-forming direction to leaving the wall-forming direction, the rotation speed of the spray bar 1 is kept at the lowest speed, and the lifting speed of the spray bar is the lowest. The segment is low-speed segment 3;

[0023] 2. When the spraying direction of the nozzle is from away from the wall-forming direction to before the vertical wall-forming direction, adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com