Cooling-water circulation system

A circulation system and cooling water technology, applied in the direction of water shower cooler, natural water treatment, water/sewage multi-stage treatment, etc., can solve the problems of decreased productivity, increased equipment cost, uneven product quality, etc., and achieve simple structure, The effect of water quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

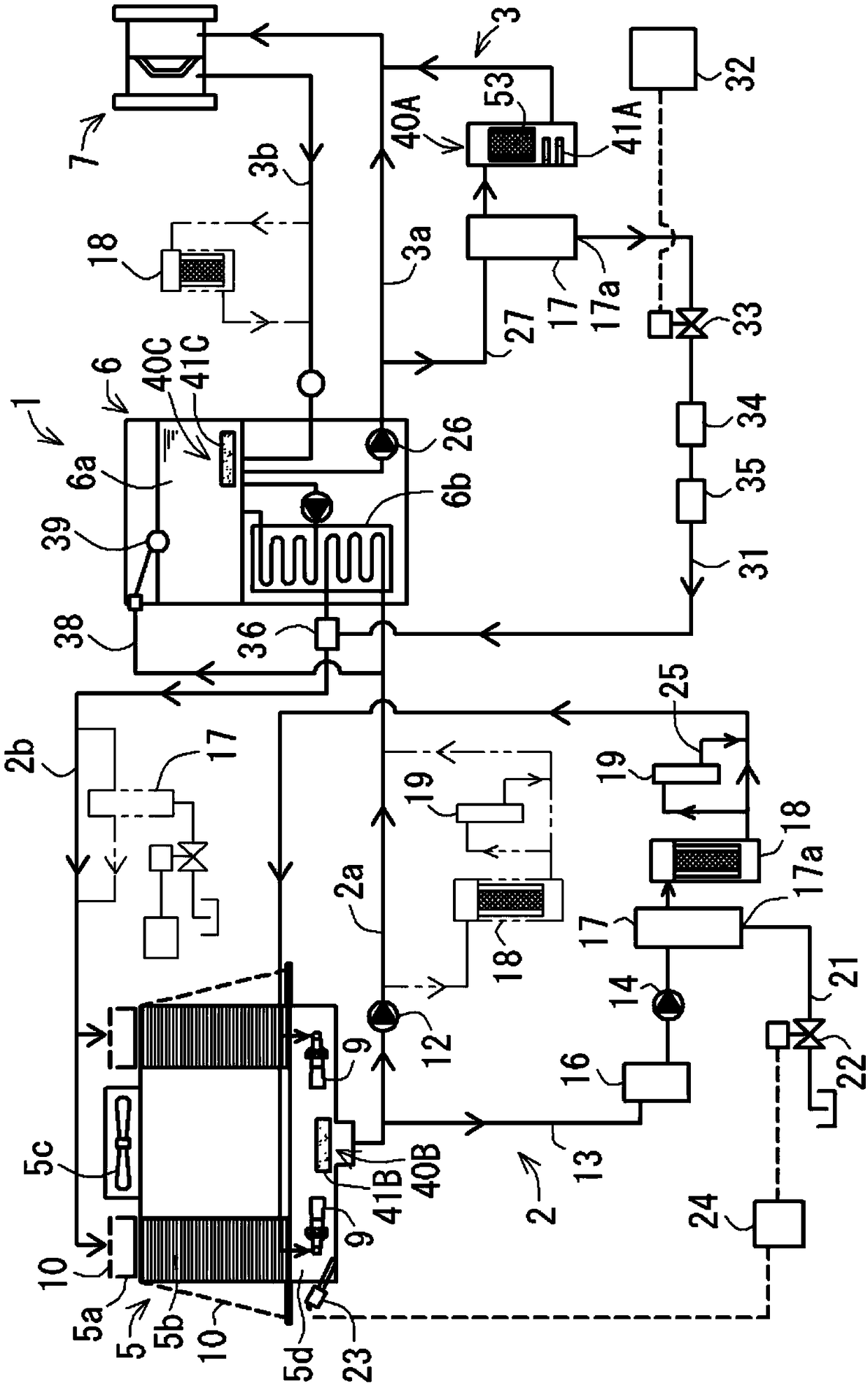

[0057] Hereinafter, the present invention will be specifically described using examples using the drawings.

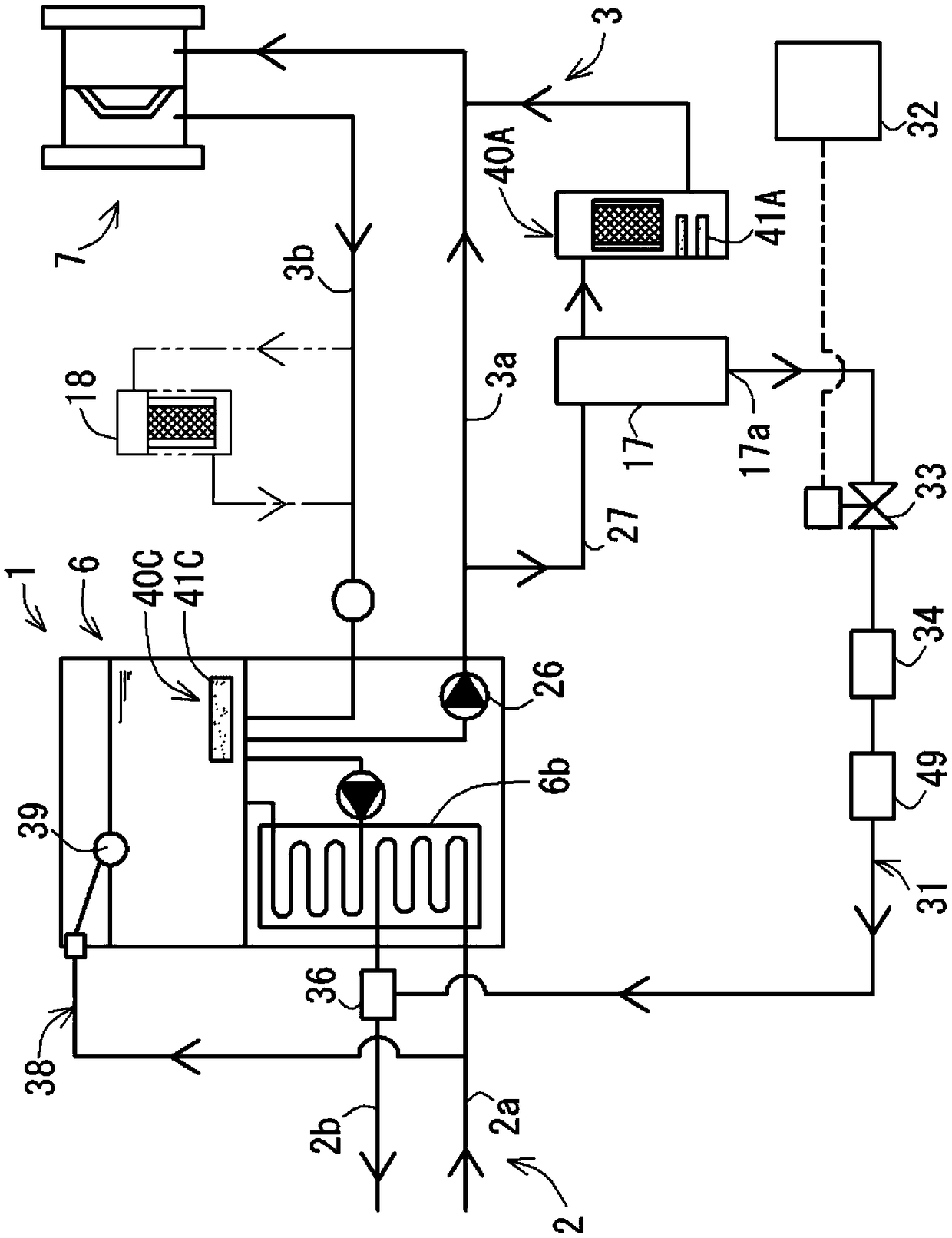

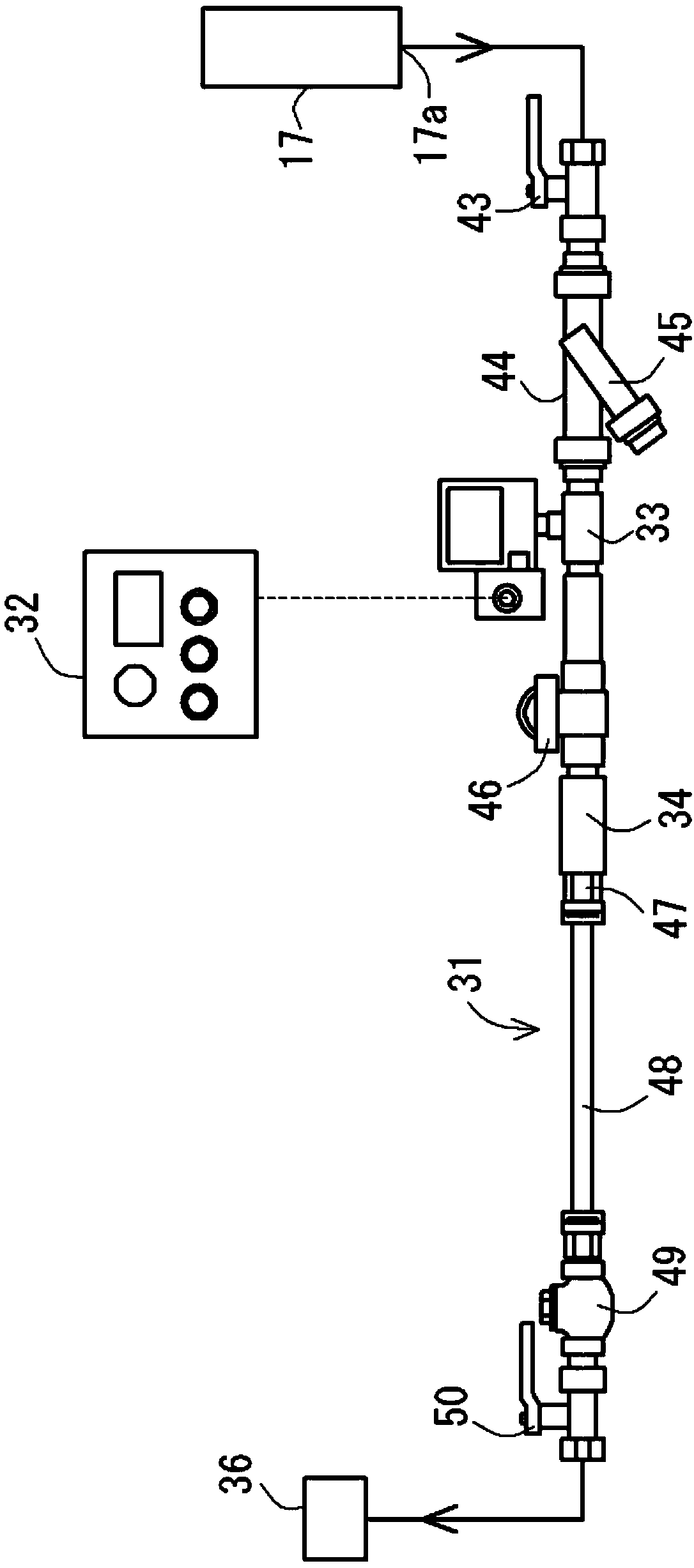

[0058] (1) The structure of the cooling water circulation system

[0059] Such as figure 1 As shown, the cooling water circulation system 1 of this embodiment includes a cooling tower side circulation path 2 (also called "primary circulation path") and a cooler side circulation path 3 (also called "secondary circulation path"). The cooling tower-side circulation path 2 circulates cooling water between the cooling tower 5 and the cooling machine 6 , and the cooling machine-side circulation path 3 circulates cooling water between the cooling machine 6 and the cooling target part 7 . In addition, examples of the cooling target portion 7 include injection molding devices, press processing devices, welding devices, heating devices, trimming devices, and the like.

[0060] The cooling tower 5 includes a water sprinkling tank 5a, a filling material 5b, a blower 5c, and a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com