Titanium micro-pore aerator disc

A microporous aeration and chassis technology, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve problems such as corrosion, uneconomical, easy aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The titanium microporous aeration disc of the present invention will be further described below through specific implementation methods.

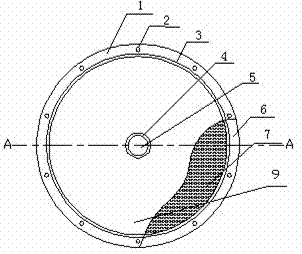

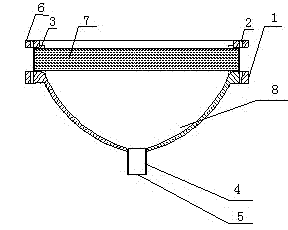

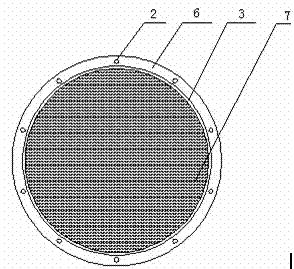

[0014] The chassis (9) of the titanium microporous aeration pan is circular, and is divided into an upper pan cover (6) and a lower pan cover (1). There are fixing holes (2) around the chassis (9), and through the fixing holes (2) Fixed with titanium perforated panel (7). The sealing strip (3) on the titanium metal porous panel (7) cooperates with the chassis (9) upper plate cover (6) and lower plate cover (1) to seal. A hemispherical cavity (8) is formed between the titanium metal porous panel (7) and the lower plate cover (1). There are many tiny pores on the titanium metal porous panel (7), and the equivalent diameter of the pores is 15-25 μm. 2 There are 5000-8000 micropores on the area. In order to connect the trachea, there is a ventilation hole (5) in the center of the lower plate cover (1). The chassis (9) and the air duc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com