Marine high-pressure spraying nozzle

A high-pressure nozzle and marine technology, applied in ship propulsion, ship parts, ship construction, etc., can solve problems such as low injection efficiency, insufficient injection power, large nozzle, etc., to improve injection effect, improve stability, and increase injection power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

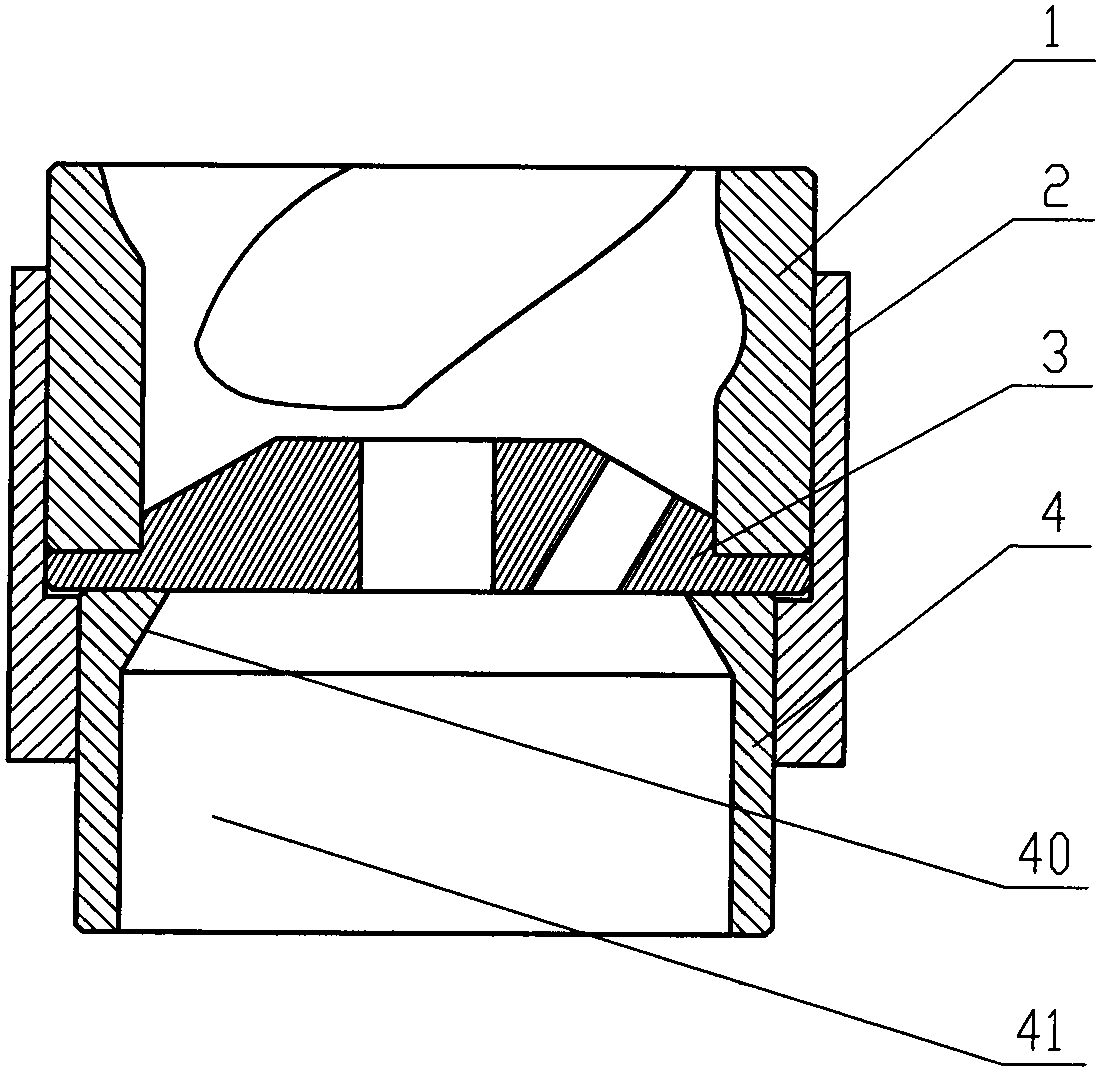

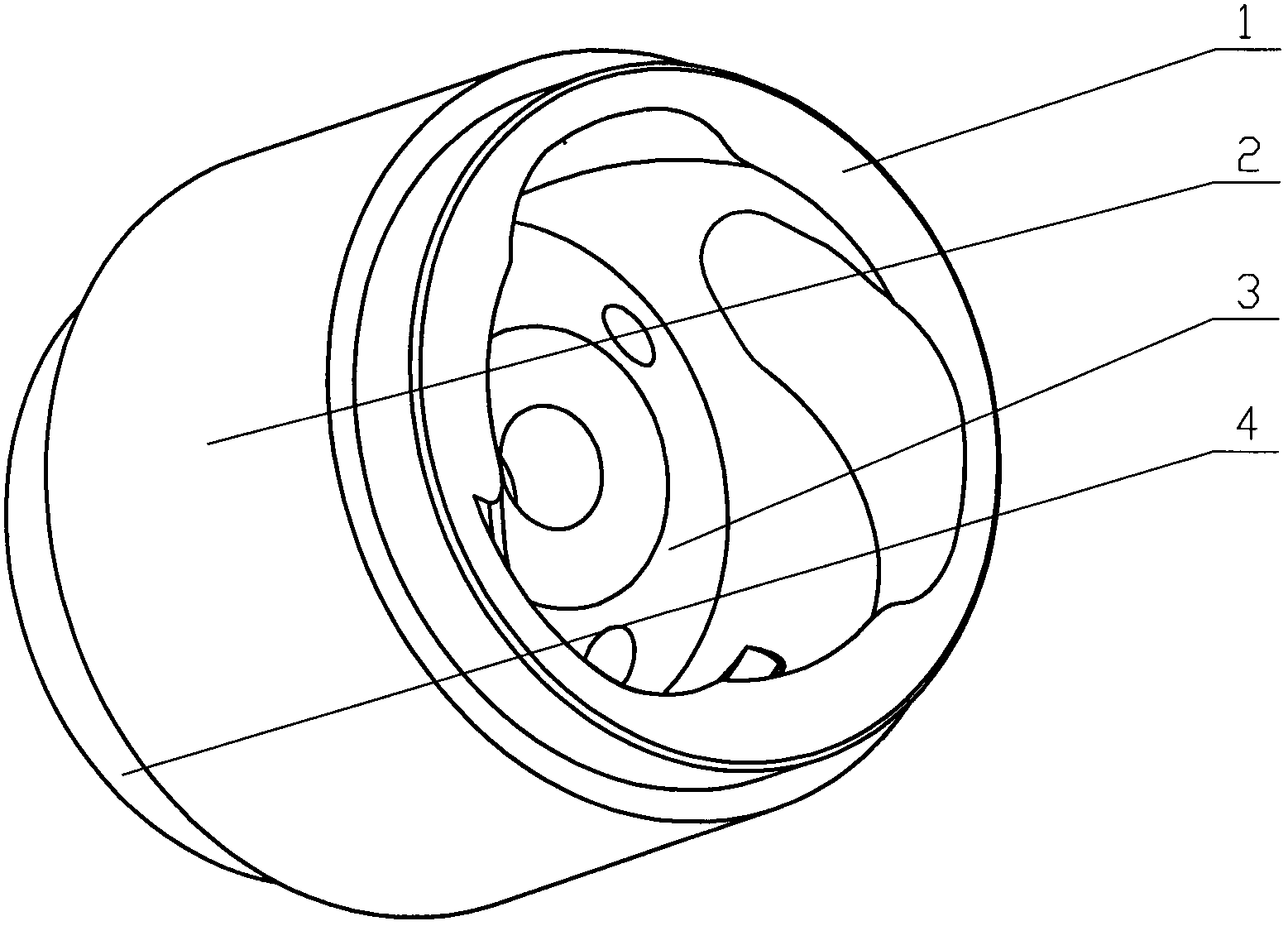

[0015] See figure 1 , figure 2 , the present invention includes a casing 2, a cavity 1, a cone 3 and a joint 4. The cone 3 is fixed between the cavity 1 and the joint 4 by means of the casing 2 . The joint 4 has a through hole 41, and the end surface has a conical surface 40, and the conical surface 40 can reduce the water outlet hole to increase the spray pressure.

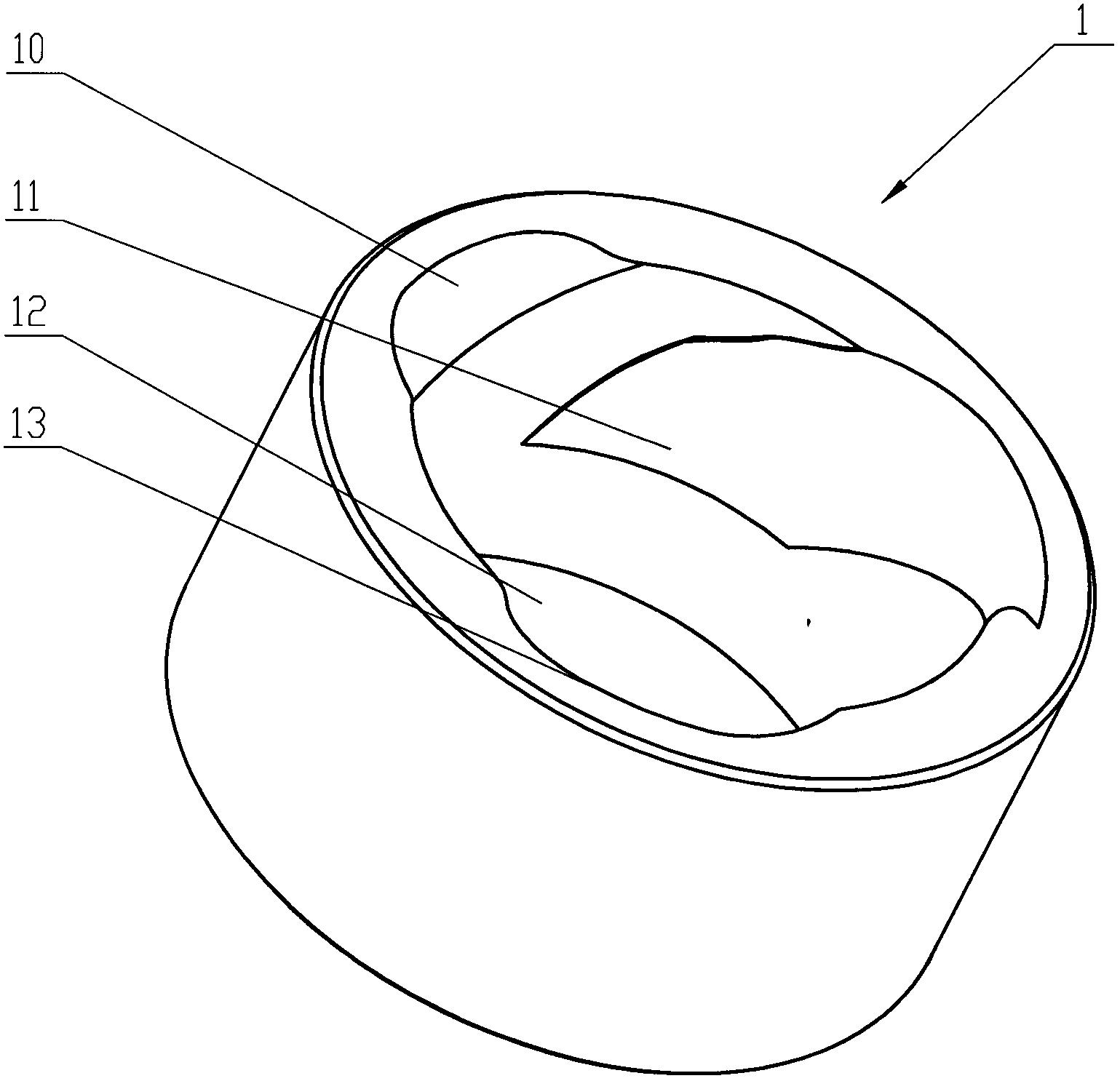

[0016] See Fig. 3, Figure 4 The conical body 3 has a conical surface 30 and spray holes, the spray holes include a central spray hole 31 and circumferential spray holes 32 , 33 and 34 perpendicular to the conical surface 30 . The cavity 1 has a central hole 12 and reflective surfaces 10, 11 and 13 corresponding to the circumferential injection holes of the cone body 3, and each reflective surface is an arc surface.

[0017] Working process of the present invention is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com