Laser processing method and laser processing device

A laser processing method and laser processing technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of processing accuracy and productivity reduction, and achieve the effect of suppressing the reduction of processing accuracy and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

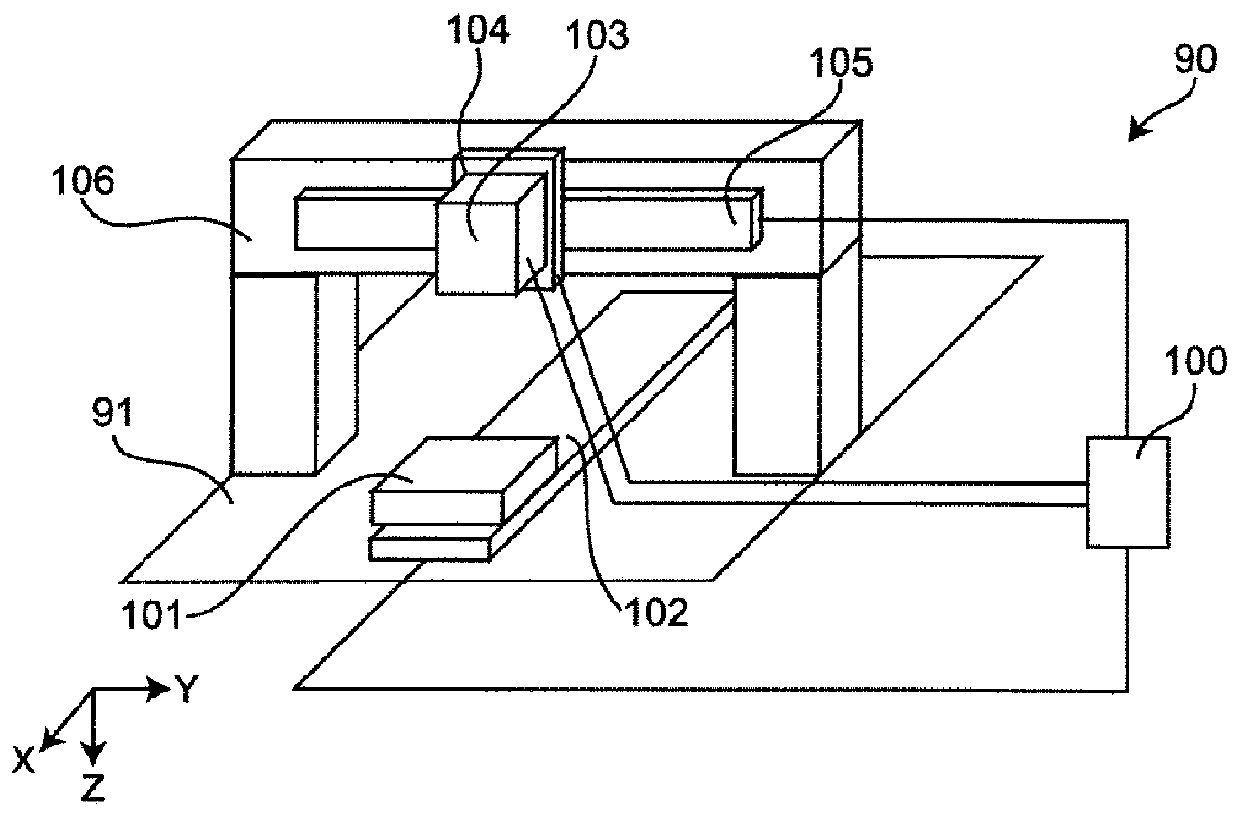

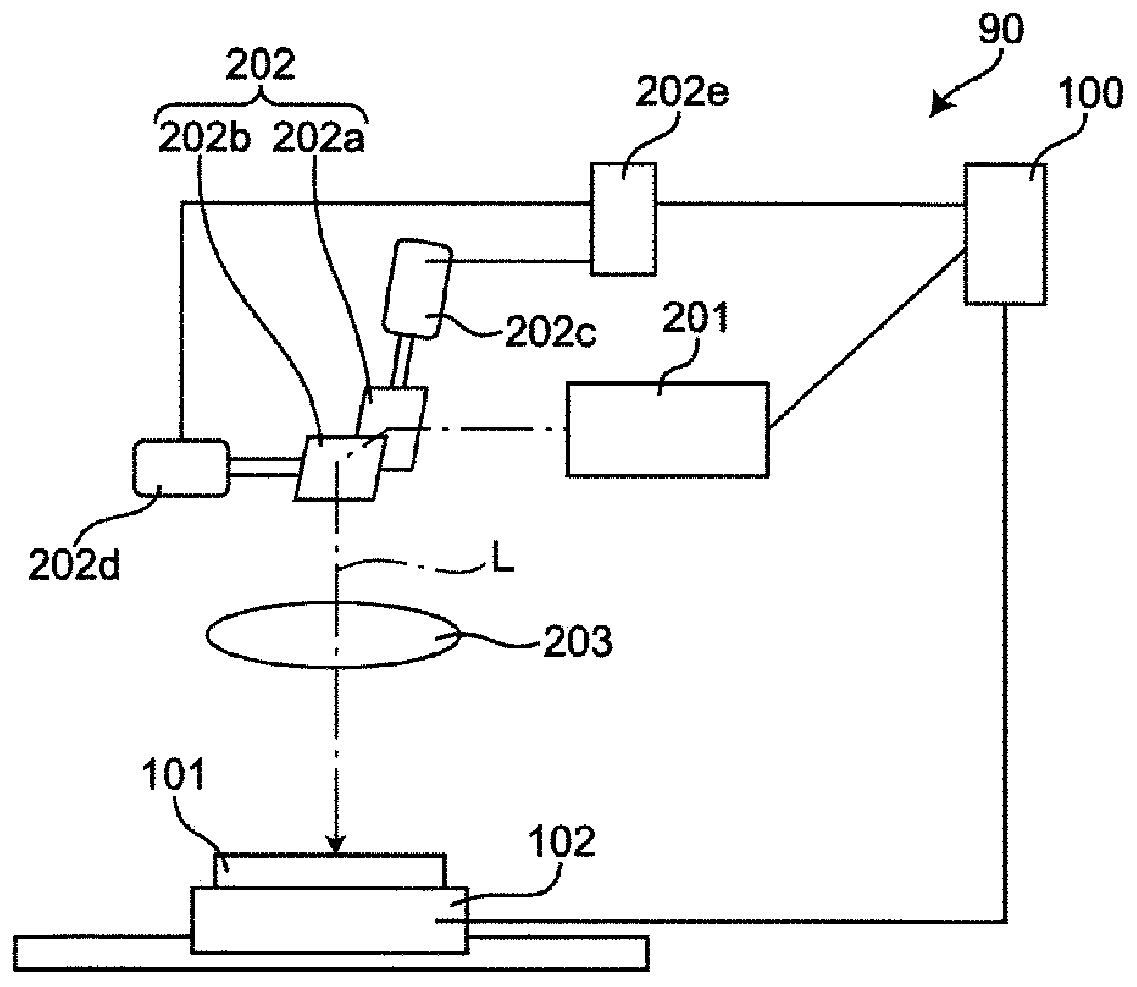

[0067] figure 1 It is a figure for the structure of the laser processing apparatus 90 which concerns on embodiment of this invention.

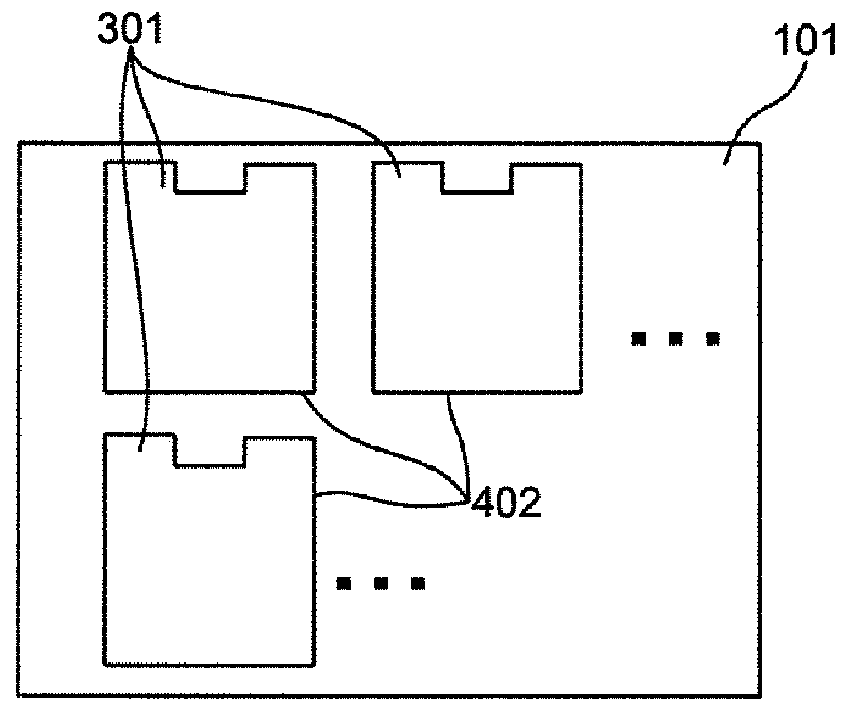

[0068] The laser processing method using the laser processing device 90 is to process the area (refer to Figure 4 The scanning trajectory 402 and the planned processing line 402a) of the scanning laser L are compared with the scanning area 401 of the scanning laser L (refer to Figure 4 ) A method of laser processing a large object 101 to be processed. Here, the scanning locus 402 is generated by scanning the laser light L, and the line on which the scanning locus 402 is generated is referred to as a line to be processed 402 a.

[0069] The laser processing device 90 includes at least: a driving table 102 for the object to be processed as an example of a first driving device, a laser emitting part, a galvano scanner (galvano scanner) 202, an fθ lens 203, and an example of a second driving device. The drive table and control unit 100 for sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com