Grab Overhead Crane Warehouse

A technology of bridge cranes and grabs, which is applied in the direction of walking bridge cranes, cranes, load suspension components, etc., and can solve the problem of long empty travel of grab bridge crane trolley transfer, increased floor space and civil construction investment and impact Crane operation status and other issues, to avoid the effect of dust affecting the working environment and causing secondary pollution, reducing equipment investment costs, and reducing civil engineering investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

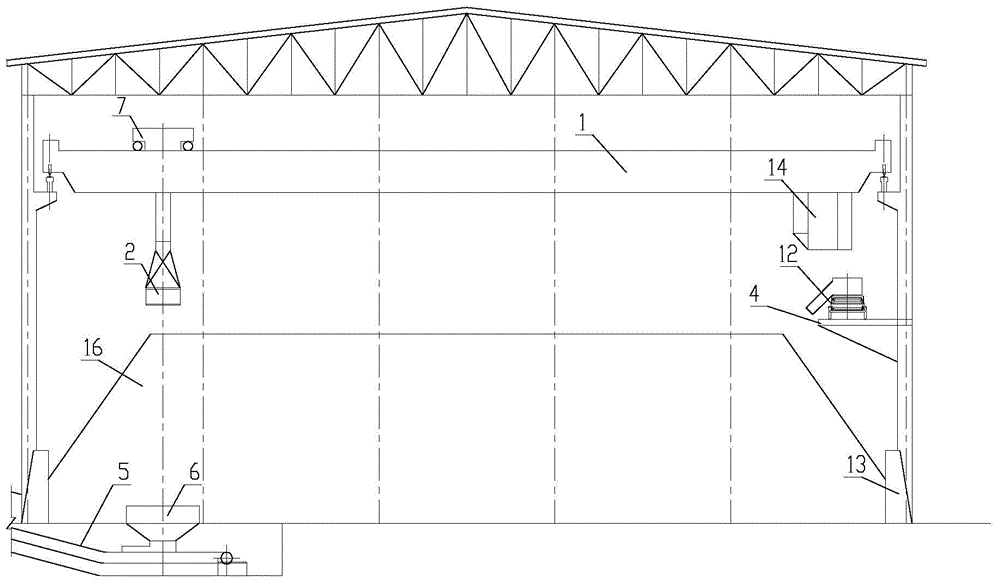

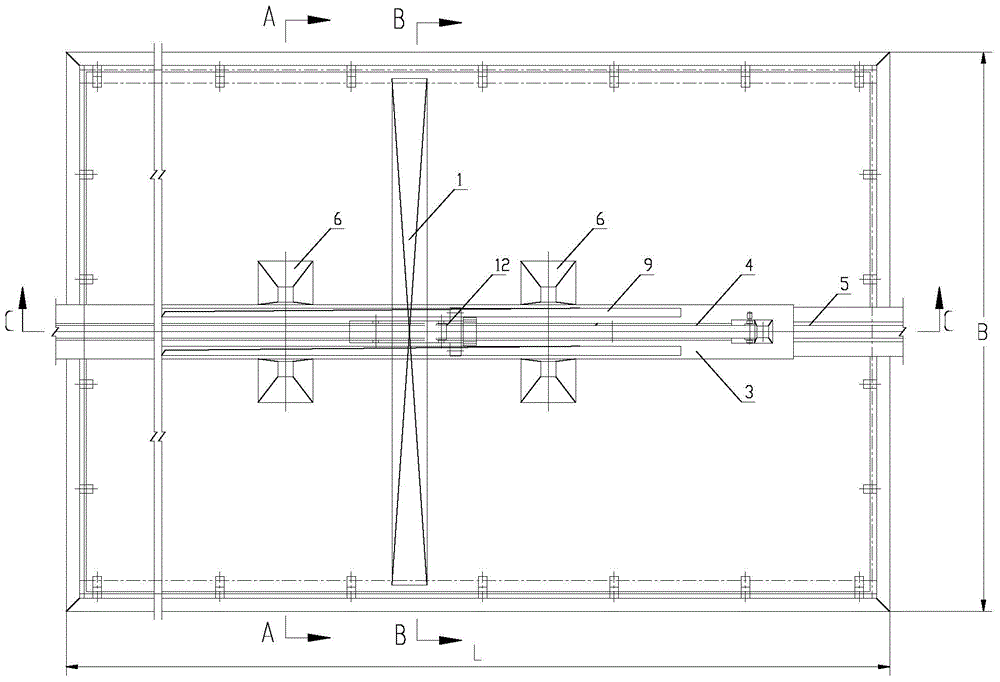

[0040] Embodiment 1 The implementation scheme of the warehouse of the grab bridge crane with the discharge conveyor arranged on the ground

[0041] The height of the warehouse of the grab bridge crane of the present invention is 14.50m, and the elevated trestle and the feed conveyor arranged longitudinally at the central EL7.00m of the warehouse, and the cart rails of the grab bridge crane are arranged horizontally at the warehouse top EL12.00m, Arrange the discharge conveyor and corridor on the plane of EL±0.00m. The discharge hopper is connected with the discharge conveyor through the chute, and is equipped with a high-level receiving hopper. The top elevation of the high-level receiving hopper is EL6.00m. The retaining wall is arranged on the long side; among them, EL is the abbreviation of the English word elevation, which means elevation (relative elevation).

Embodiment 2

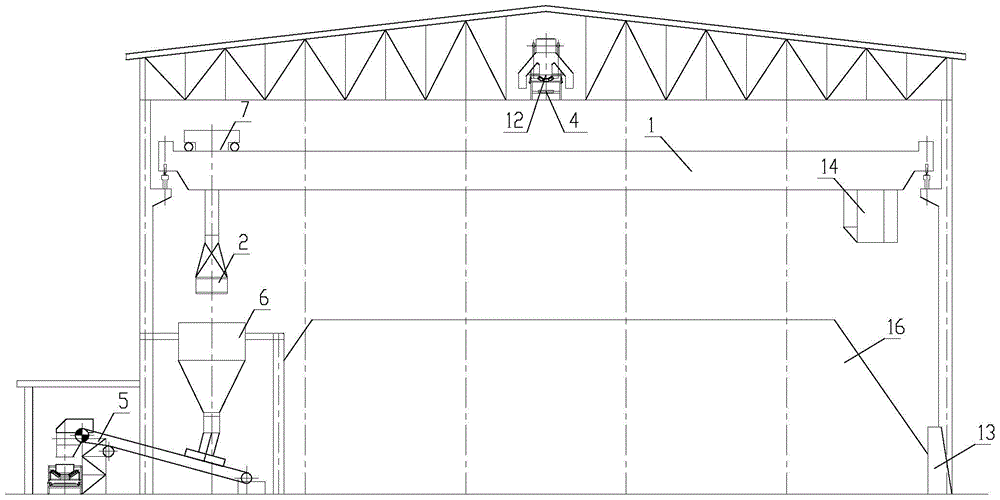

[0042] Example 2 The implementation scheme of the warehouse of the grab bridge crane with the discharge conveyor arranged under the ground

[0043] The height of the warehouse of the grab bridge crane of the present invention is 14.50m, and the elevated trestle and the feed conveyor arranged longitudinally at the central EL7.00m of the warehouse, and the cart rails of the grab bridge crane are arranged horizontally at the warehouse top EL12.00m, Arrange the discharge conveyor and corridor on the EL-2.40m plane. The discharge hopper is connected with the discharge conveyor through the chute, and is equipped with a high-level receiving hopper. The top elevation of the high-level receiving hopper is EL6.00m. Both sides of the warehouse are longitudinally Arrange the retaining wall on the long side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com