Gas medium homogenizer for high power laser diode sintering

A laser diode and gas medium technology, applied in lasers, laser components, semiconductor lasers, etc., can solve the problems of high-power laser diode heat dissipation, power influence, oxide film is not easy to infiltrate chips, and high sintering void rate, so as to reduce sintering voids High efficiency, simple structure, uniform atmosphere effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

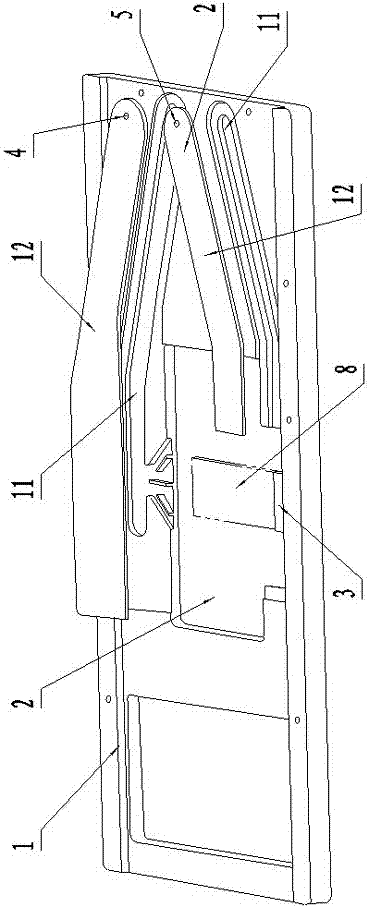

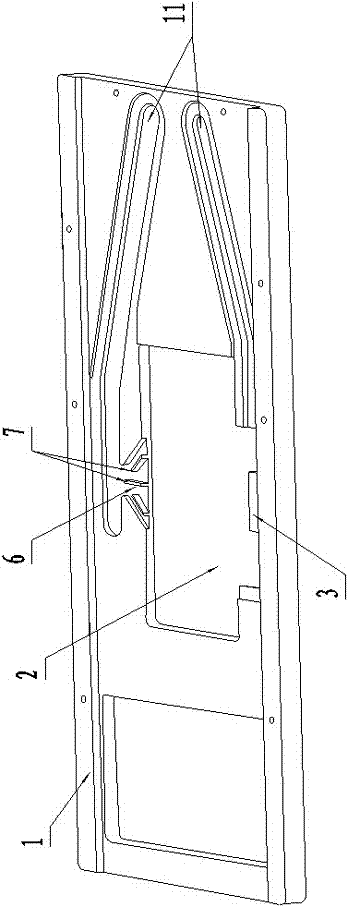

[0018] Such as figure 1 , 2 As shown, a gas medium homogenization device for high-power laser diode sintering includes a bracket 1 that can be installed on a sintering table. The middle part of the bracket 1 is a hollow area 2 where a high-power laser diode 8 can be placed. The hollow area 2. A connection plate 3 that can be connected to the heat sink of the sintering equipment is provided on one side of the support. The edge of the hollow area 2 can be sealed with the suction nozzle of the sintering equipment. The support 1 is provided with an air intake passage and an exhaust passage. One end of the air intake passage and the exhaust passage communicate with the air intake pipe and the air outlet pipe respectively, and the other end communicates with the hollow area 2 in the middle of the bracket 1 .

[0019] The air intake passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com