Load bearing pad for metallization sintering of high-voltage direct-current ceramic relay shell and sintering process

A high-voltage DC and relay technology, applied in circuits, electrical switches, electrical components, etc., can solve problems such as side wall sinking deformation, and achieve the effects of avoiding side wall sinking deformation, uniform atmosphere, and improving the quality of metallization and sintering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

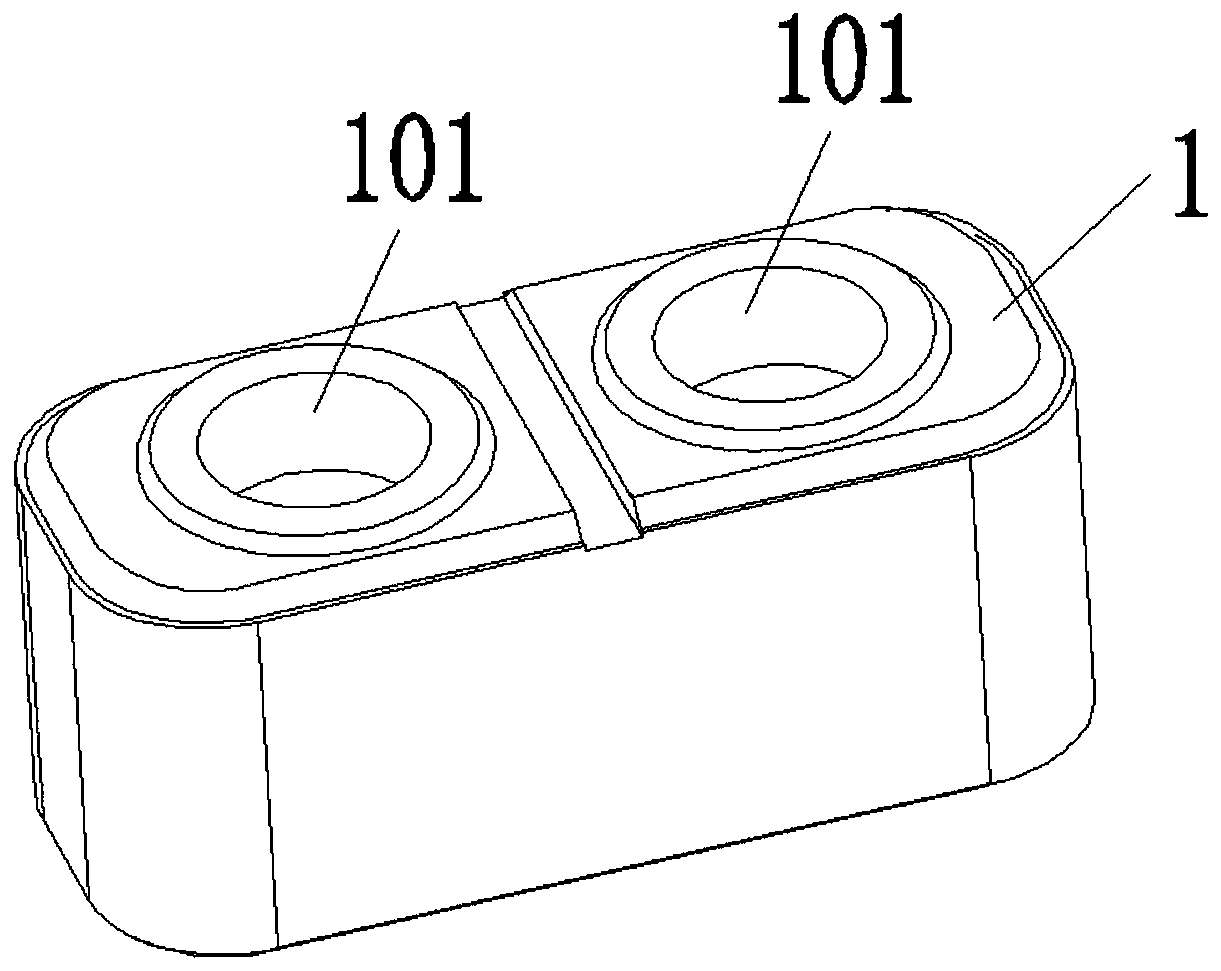

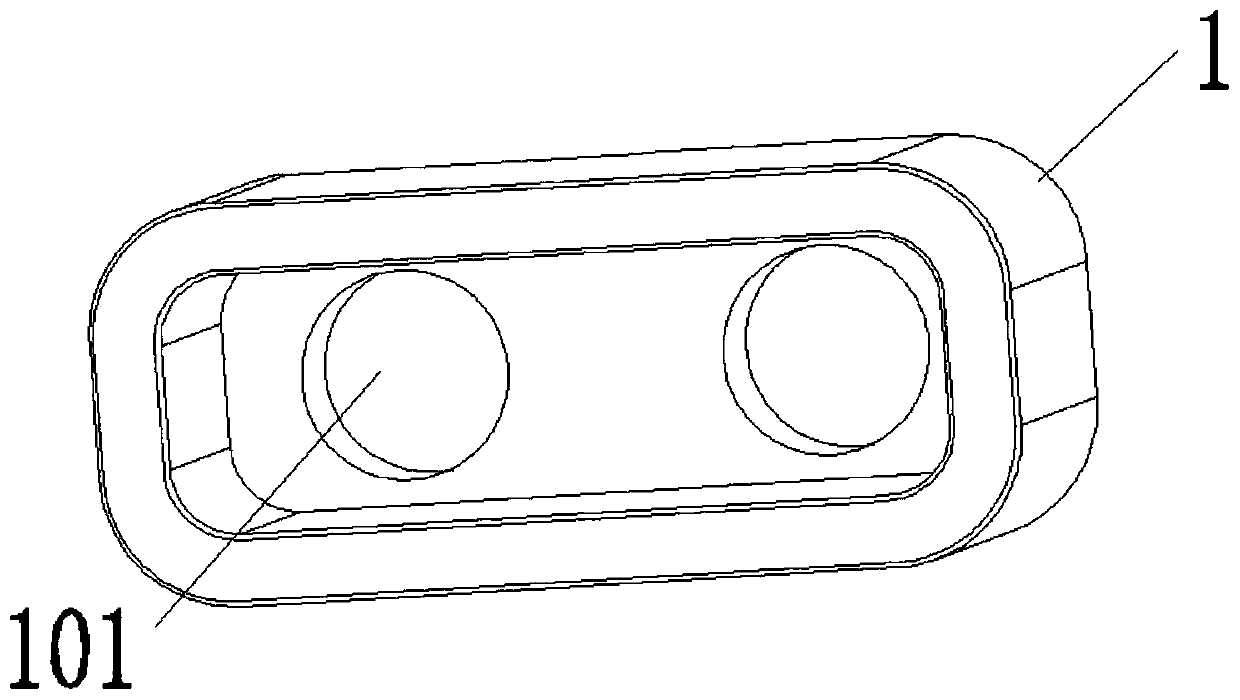

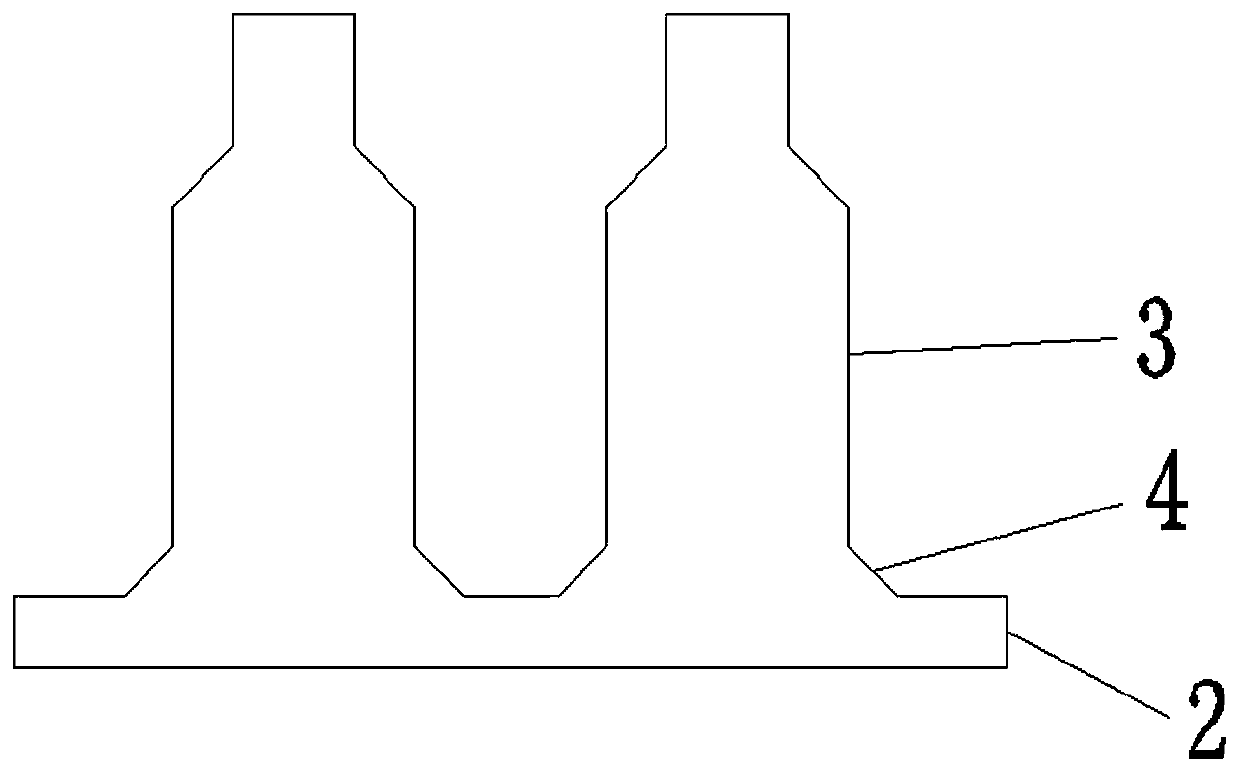

[0026] like Figure 1-6 As shown, the metallized sintering pad of the high-voltage DC ceramic relay housing of this embodiment is used. The relay housing 1 is a cuboid with a hollow inside and an open bottom surface. Two through holes 101 are provided on the top surface of the cuboid. It includes a bottom plate 2 and a pillar 3 fixed on the bottom plate 2 for matching with two through holes 101 and supporting the relay case 1 .

[0027] In this embodiment, the outer wall of the pillar 3 near the through hole 101 is in the shape of a truncated cone.

[0028] In this embodiment, the distance h1 between the contact between the pillar 3 and the relay case 1 and the top of the pillar 3 is greater than the thickness h2 of the top surface of the relay case 1, and the distance k1 between the contact between the pillar 3 and the relay case 1 and the top of the pillar 3 is greater than that of the relay The inner cavity height k2 of the housing 1 .

[0029] In this embodiment, the pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com