Green petroleum coke mixing and homogenizing system device

A system equipment and petroleum coke technology, applied in the field of petroleum coke mixing and homogenization system equipment for raw materials in the carbon industry, can solve the problems of carbon product quality fluctuations, ash component changes, etc., to achieve uniform and stable quality, stable quality, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

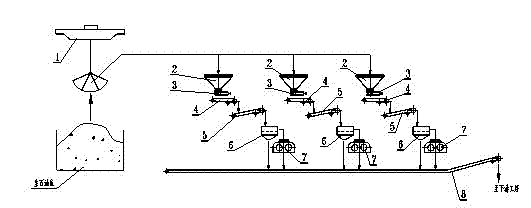

[0011] Embodiment of the present invention: including grab crane 1 and 3 sets of feeding, batching and screening, crushing, mixing and homogenizing systems, each system is provided with a grid sieve funnel 2, and a gate valve 3 is installed under the grid sieve funnel 2 , the belt quantitative feeder 4 is set under the gate valve 3, the belt conveyor 5 is set under the belt quantitative feeder 4, the vibrating screen 6 is set under the belt conveyor 5, and the total belt conveyor is set under the vibrating screen 6 8.

[0012] A crusher 7 is also arranged beside the vibrating screen 6 .

[0013] The gate valve 3 is a normally open manual gate valve.

[0014] When working, raw materials of 3 different origins and different batches stored in the raw petroleum coke warehouse are grabbed by the grab crane 1 into the corresponding grid sieve funnel 2, and a normally open manual slide valve is set under the grid sieve funnel 2 3. The raw petroleum coke enters into the belt quantit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com