A kind of diaphragm of zinc-silver secondary battery and its preparation method and zinc-silver secondary battery

A secondary battery, zinc-silver technology, applied to secondary batteries, battery components, circuits, etc., can solve the problems of zinc-silver secondary batteries such as short life, waste of resources, high cost, etc., to improve cycle stability, prolong Lifespan, growth-inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

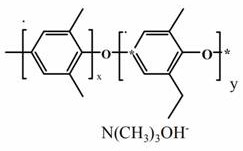

[0040] This embodiment proposes a zinc-silver secondary battery diaphragm, which is formed by embedding a quaternized polyphenylene ether membrane with porous silicon-aluminum oxide. The amount of porous silicon-aluminum oxide is 5% of the weight of the quaternary ammonium salt anion exchange membrane. And the pore size of the porous silicon aluminum oxide is less than 2nm.

[0041] In this example, the zinc-silver secondary battery diaphragm is used for assembling button-type zinc-silver batteries for performance testing, and the specific preparation process is as follows:

[0042] Add 200 nM of NH 4-X zeolite was calcined at 350°C for 2 h to obtain porous silica-alumina oxide; 1 g of quaternized polyphenylene ether was dissolved in 100 mL nitrogen-nitrogen dimethylformamide (DMF), and 0.05 g of porous silica-alumina oxide was added to The above mixed solution is stirred and ultrasonically treated to obtain a uniformly mixed film solution; the prepared film solution is poure...

Embodiment 2

[0044] This embodiment proposes a zinc-silver secondary battery diaphragm, which is formed by embedding a quaternized polyphenylene ether membrane with porous silicon-aluminum oxide. The amount of porous silicon-aluminum oxide is 0.5% of the weight of the quaternary ammonium salt anion exchange membrane. And the pore size of the porous silicon aluminum oxide is less than 2nm.

[0045] In this example, the zinc-silver secondary battery diaphragm is used for assembling button-type zinc-silver batteries for performance testing, and the specific preparation process is as follows:

[0046] Add 200 nM of NH 4 -X zeolite was calcined at 350°C for 2 h to obtain porous silica-alumina oxide; 1 g of quaternized polyphenylene ether was dissolved in 100 mL nitrogen-nitrogen dimethylformamide (DMF), and 0.005 g of porous silica-alumina oxide was added to The above mixed solution is stirred and ultrasonically treated to obtain a uniformly mixed film solution; the prepared film solution is p...

Embodiment 3

[0048] This embodiment proposes a zinc-silver secondary battery diaphragm, which is formed by embedding a quaternized polyphenylene ether membrane with porous silicon-aluminum oxide. The amount of porous silicon-aluminum oxide is 20% of the weight of the quaternary ammonium salt anion exchange membrane. And the pore size of the porous silicon aluminum oxide is less than 2nm.

[0049] In this example, the zinc-silver secondary battery diaphragm is used for assembling button-type zinc-silver batteries for performance testing, and the specific preparation process is as follows:

[0050] Add 200 nM of NH 4 -X zeolite was calcined at 350°C for 2 h to obtain porous silica-alumina oxide; 1 g of quaternized polyphenylene ether was dissolved in 100 mL of nitrogen-nitrogen dimethylformamide (DMF), and 0.2 g of porous silica-alumina oxide was added to To the above mixed solution, after stirring, ultrasonic treatment, etc., a uniformly mixed membrane solution was obtained; the prepared m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com