High-strength Al-Si alloy welding wire and preparation method thereof

An alloy welding wire, al-si technology, used in welding equipment, metal processing equipment, welding media, etc., can solve the problems of low welding crack sensitivity, low thermal crack sensitivity, and inability to take both into account, and achieve mechanical and physical properties. The effect of improving and improving mechanical properties and high industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] A preparation method of high-strength Al-Si alloy welding wire, comprising the following steps:

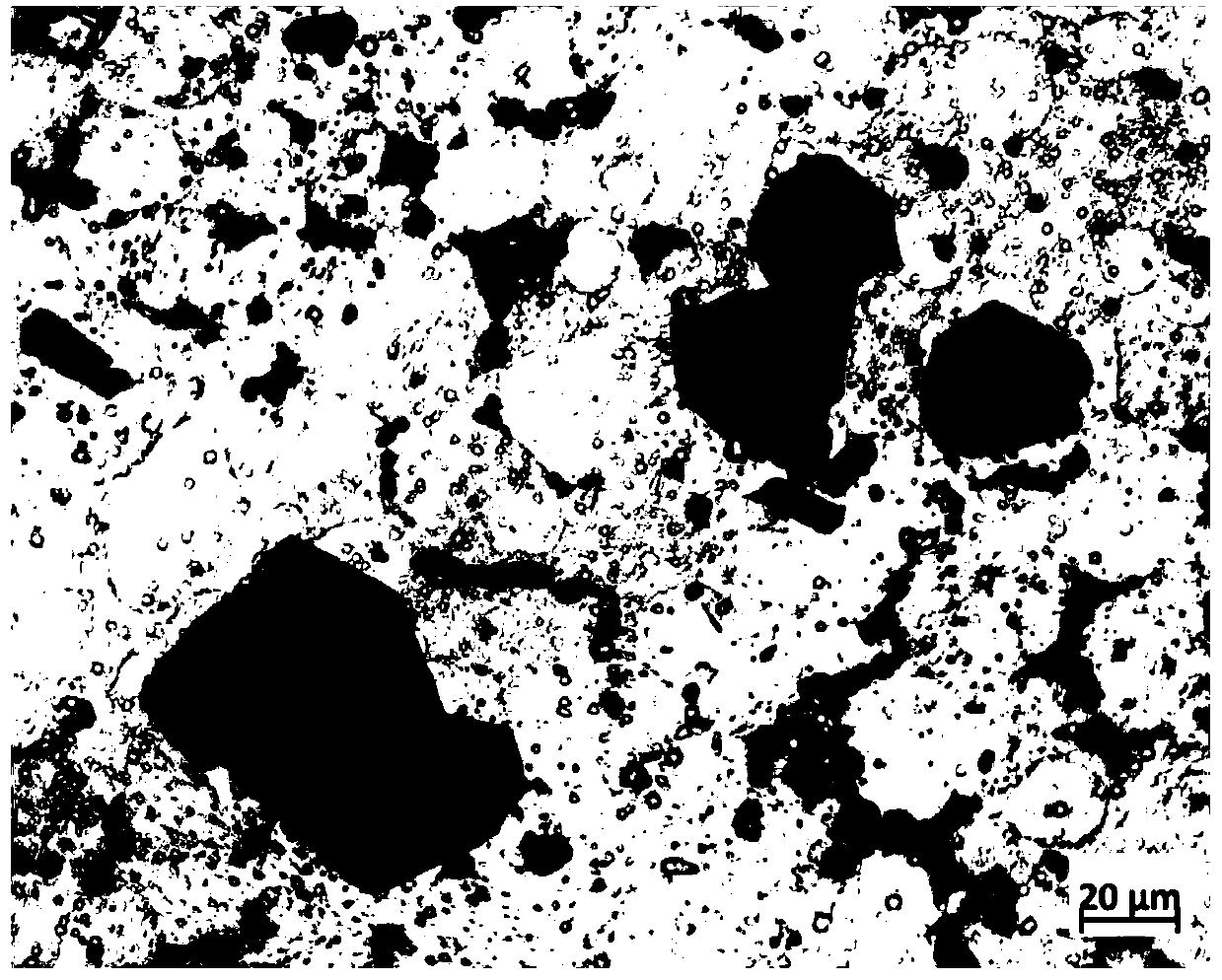

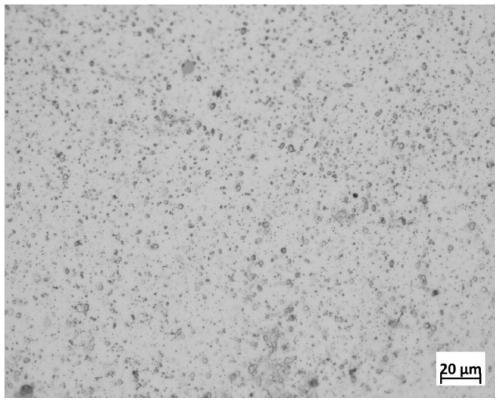

[0057] Step 1: Prepare 57.5Kg of TiB generated in situ 2 Granular Al-2.3Ti-B master alloy, in which TiB 2 The particle size is mostly 2-5μm, and after severe plastic deformation, it contains nano-TiB 2 Granular Al-2.3Ti-B master alloy, in which nano-TiB 2 The particle size is 50-1000nm.

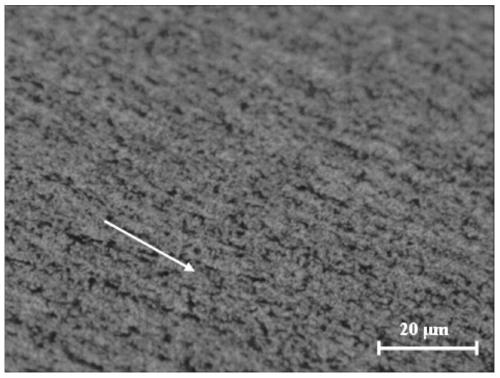

[0058] Among them, severe plastic deformation can adopt high-speed friction stirring process or equal channel angular extrusion process or high-pressure torsion process. process, the torsion range is 0.5 to 5 turns; the equal channel angular extrusion process, the channel angle is 90 to 120 degrees, and the number of cycles is 1 to 5 times; the high-speed friction stir process is used in this embodiment.

[0059] Step 2: the nano-TiB obtained in step 1 2 The granular Al-2.3Ti-B master alloy is used as the matrix raw material, 15kg of Al-2Sc master alloy is added, and 27.5kg of Al-20Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com