Substrate surface treating apparatus

A substrate surface and processing device technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve problems such as difficult to obtain thin films, achieve roughly uniform temperature, stable high-temperature heating effect, and highly homogeneous surface treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

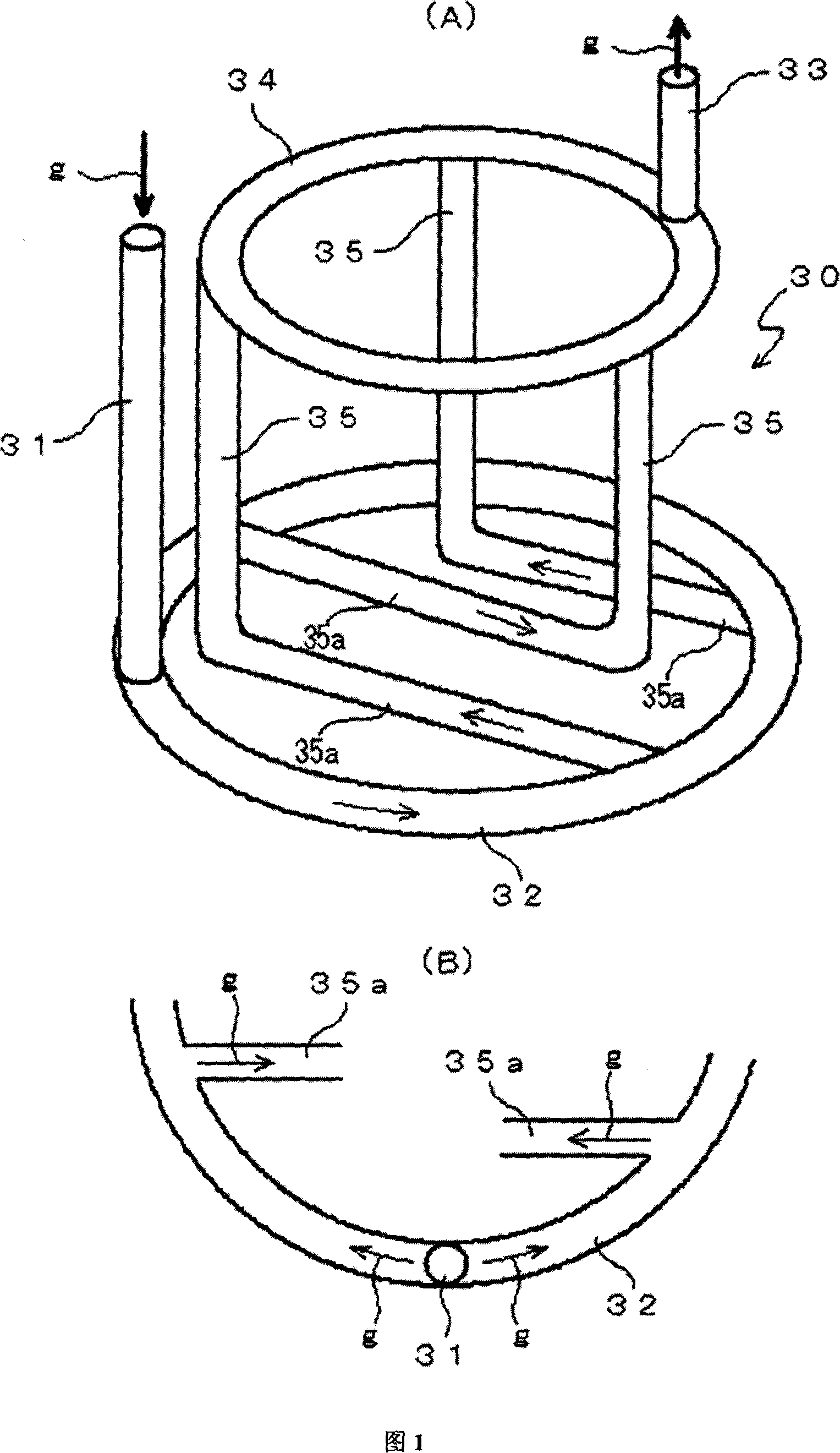

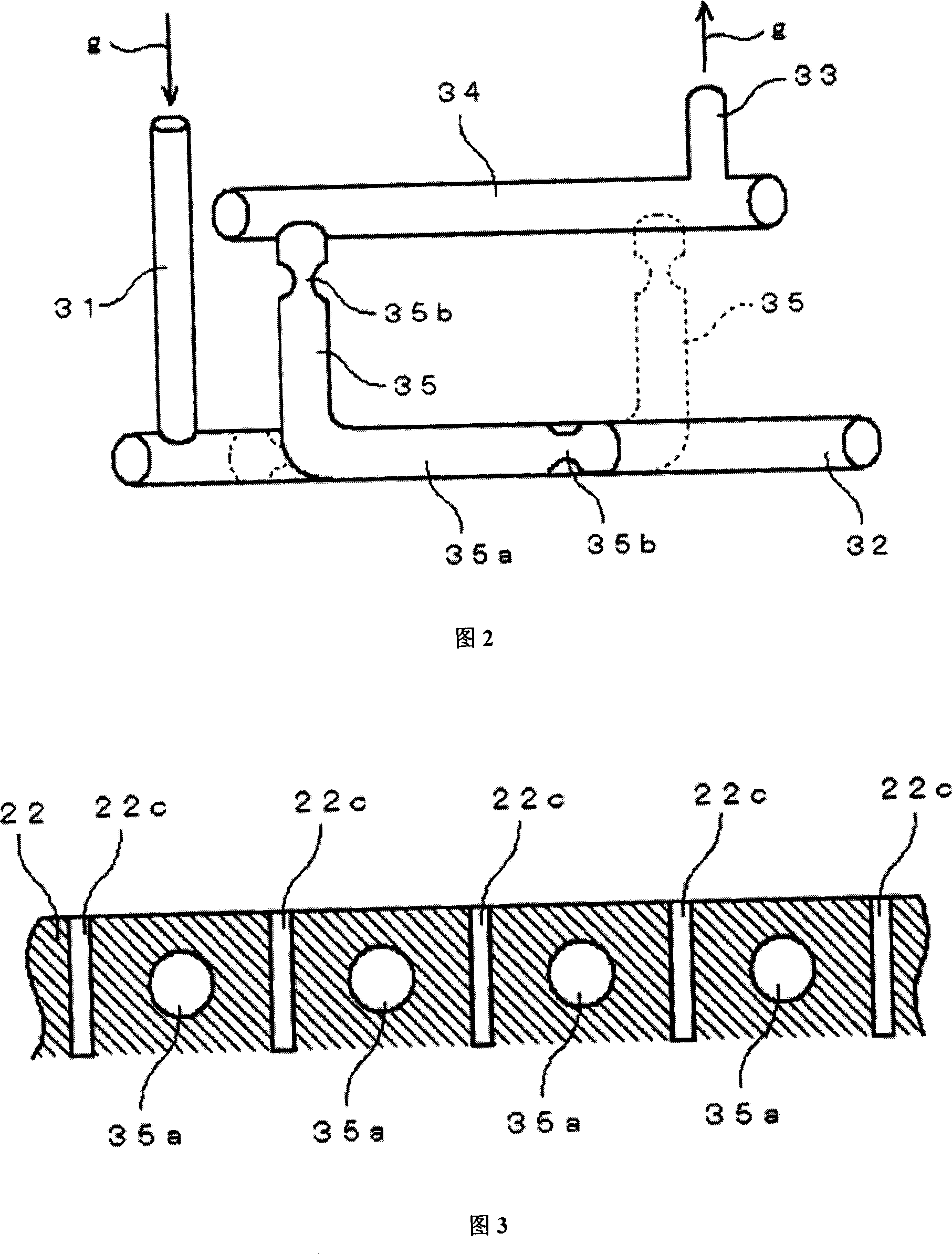

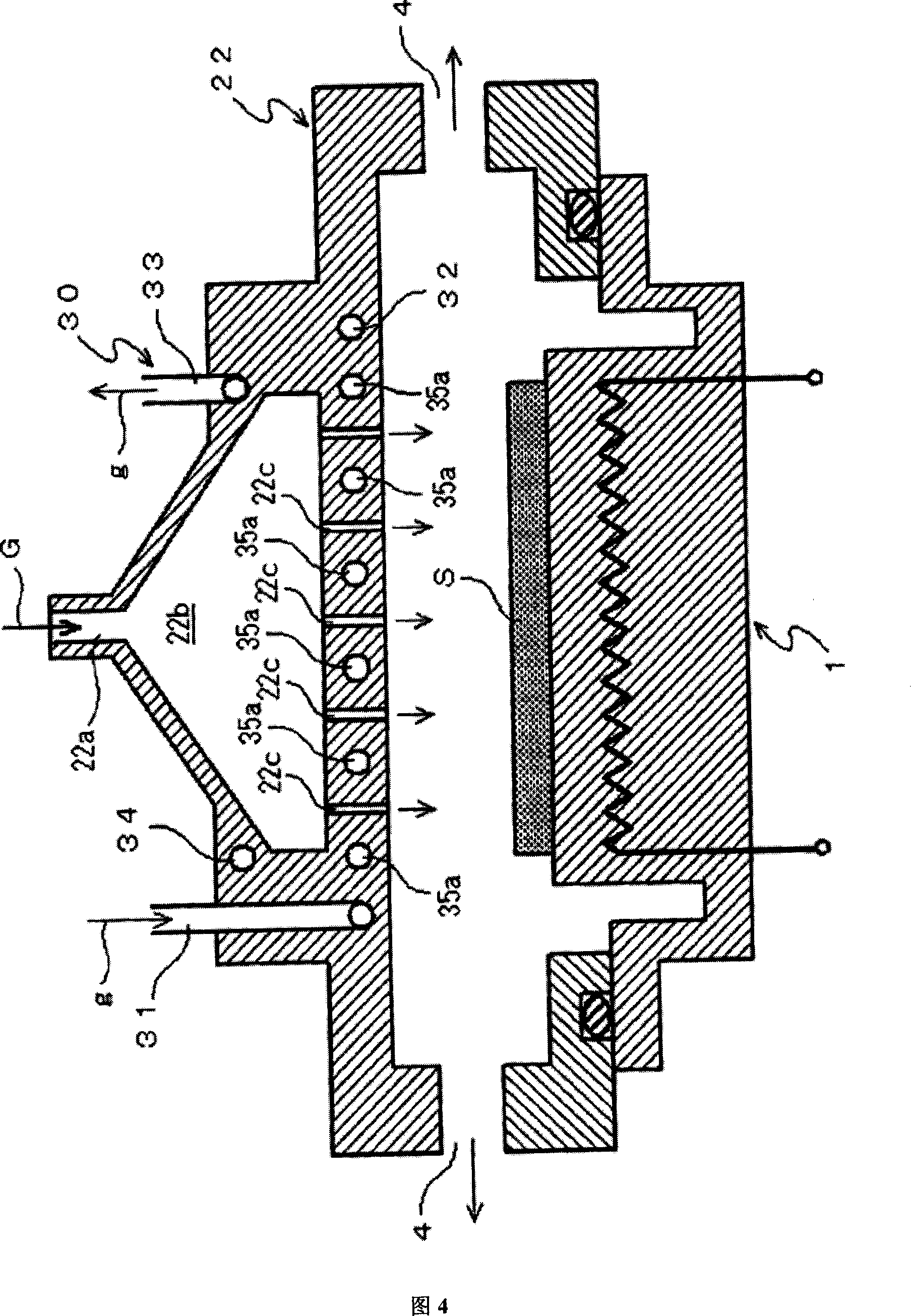

[0045] Embodiments of the substrate surface treatment apparatus according to the present invention will be described in detail with reference to the following drawings. Embodiments of the silicon substrate surface treatment apparatus of the present invention are shown respectively with reference to FIGS. 1 to 4 .

[0046] Discussion of problem points

[0047] If the object is in the shape of a disc, the greater the distance between the heat conduction path passing through the central axis and from the center to the periphery, generally, the less heat energy received from the heat source. Therefore, for this embodiment adopting several heat conduction paths, it is necessary to adjust the heat medium flow rate of each heat conduction path one by one. Moreover, the flow rate can be adjusted appropriately according to the experiment.

[0048]In addition, in FIG. 6 of Case 2 of the old model, a plurality of heat conduction paths 12b for heat medium are ensured in the gas nozzle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com