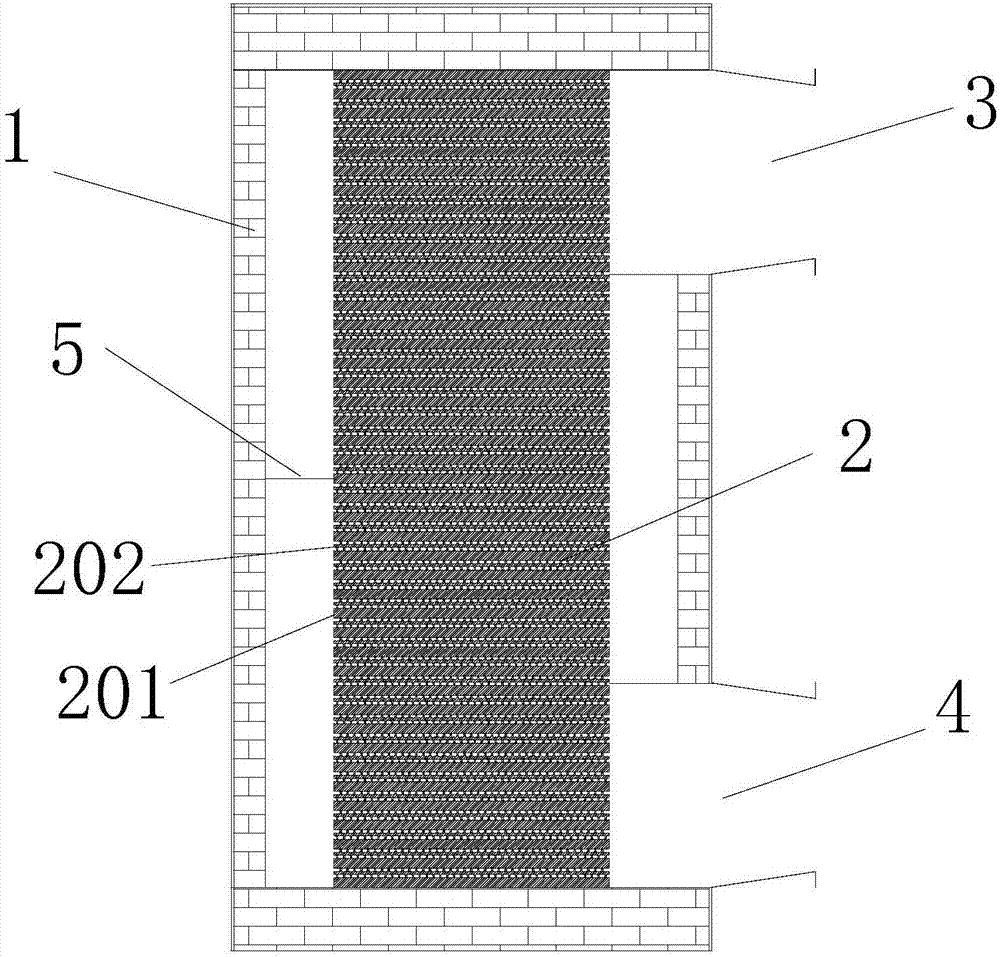

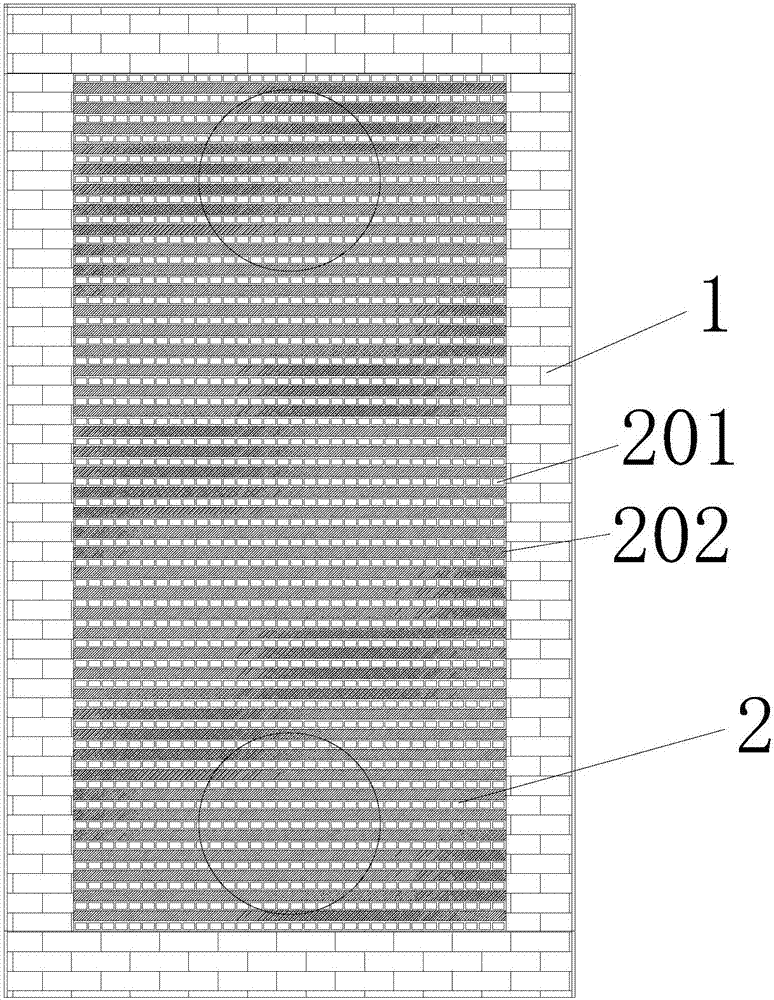

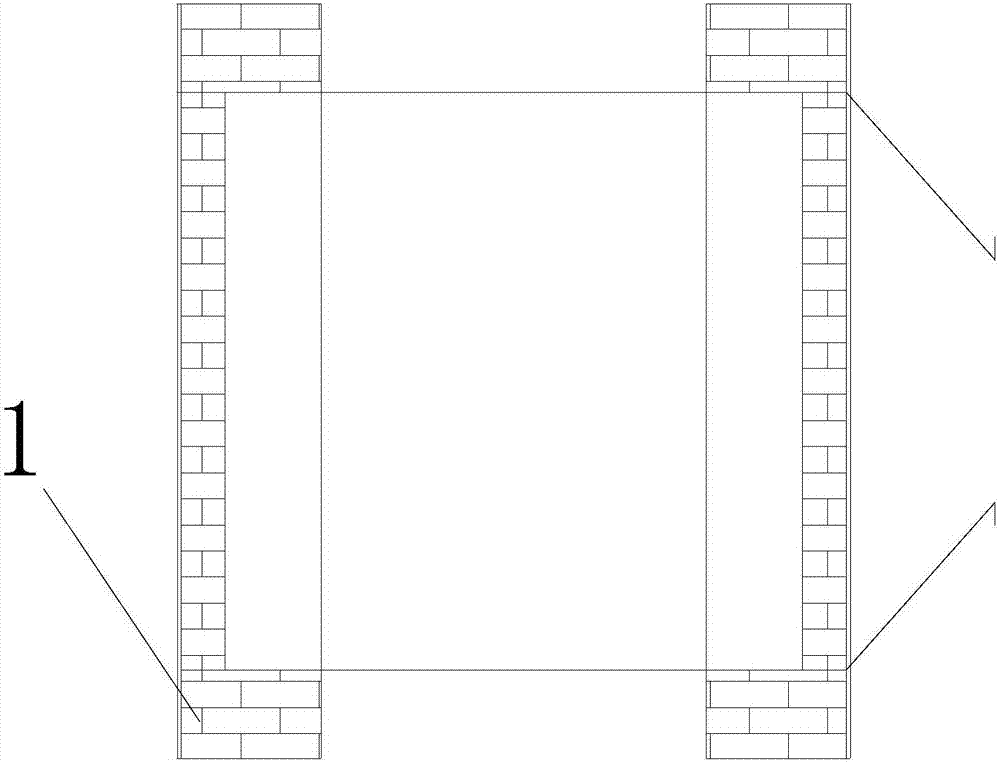

High-temperature constant-temperature blast furnace hot blast stove and preparing method thereof

A technology of hot blast stove and constant temperature, which is applied in the direction of brick blast furnace, etc., which can solve the problems of slow exchange air velocity, bulky equipment, and large accumulation density of heat storage balls, so as to improve heat exchange efficiency, reduce energy consumption, and large heat exchange area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The high temperature and constant temperature blast furnace hot blast stove of this embodiment is made of the following raw materials in parts by weight: 45 parts of black silicon carbide, 28 parts of green silicon carbide, 8 parts of mullite, 10 parts of Panlong Zimujie clay, Suzhou white clay 9 parts, 18 parts of water; Among them, the particle size of black silicon carbide is 0-1mm, the particle size of green silicon carbide is 800 mesh, the particle size of mullite is 800 mesh, and the particle size of Panlong Zimujie clay is The particle size of Suzhou white mud is 200 mesh.

[0035] The preparation method of the high temperature and constant temperature blast furnace hot blast stove of the present embodiment comprises the following steps:

[0036] 1) Mix green silicon carbide, mullite, Panlong Zimujie clay, and Suzhou white mud with water in the prescribed amount, and grind for 15 hours to obtain mud as a base material, and filter the mud to obtain 14% water conte...

Embodiment 2

[0042] The high temperature and constant temperature blast furnace hot blast stove of this embodiment is made of the following raw materials in parts by weight: 60 parts of black silicon carbide, 20 parts of green silicon carbide, 5 parts of mullite, 8 parts of Panlong Zimujie clay, Suzhou white clay 8 parts, 16 parts of water; Among them, the particle size of black silicon carbide is 0-1mm, the particle size of green silicon carbide is 1000 mesh, the particle size of mullite is 1000 mesh, and the particle size of Panlong Zimujie clay is The particle size of Suzhou white clay is 300 mesh.

[0043] The preparation method of the high temperature and constant temperature blast furnace hot blast stove of the present embodiment comprises the following steps:

[0044]1) Mix green silicon carbide, mullite, Panlong Zimujie clay, Suzhou white mud with water and grind for 10 hours to obtain mud as a base material, and filter the mud to obtain 15% water content mud cake;

[0045] 2) St...

Embodiment 3

[0049] The high temperature and constant temperature blast furnace hot blast stove of this embodiment is made of the following raw materials in parts by weight: 50 parts of black silicon carbide, 25 parts of green silicon carbide, 15 parts of mullite, 12 parts of Panlong Zimujie clay, Suzhou white clay 12 parts, 16 parts of water; Among them, the particle size of black silicon carbide is 0-1mm, the particle size of green silicon carbide is 900 mesh, the particle size of mullite is 900 mesh, and the particle size of Panlong Zimujie clay is The particle size of Suzhou white clay is 250 mesh.

[0050] The preparation method of the high temperature and constant temperature blast furnace hot blast stove of the present embodiment comprises the following steps:

[0051] 1) Mix green silicon carbide, mullite, Panlong Zimujie clay, and Suzhou white mud with water and grind for 12 hours to obtain mud as a base material, and filter the mud to obtain 16% water content mud cake;

[0052]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com