Coating machine oven

A technology for coating machines and ovens, which is applied to printing machines, general parts of printing machinery, printing, etc., and can solve problems such as needle belt malfunction, needle belt and needle belt sprocket not meshing well, printing cracks, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A kind of coating machine oven of the present invention is further described below in conjunction with accompanying drawing and specific embodiment:

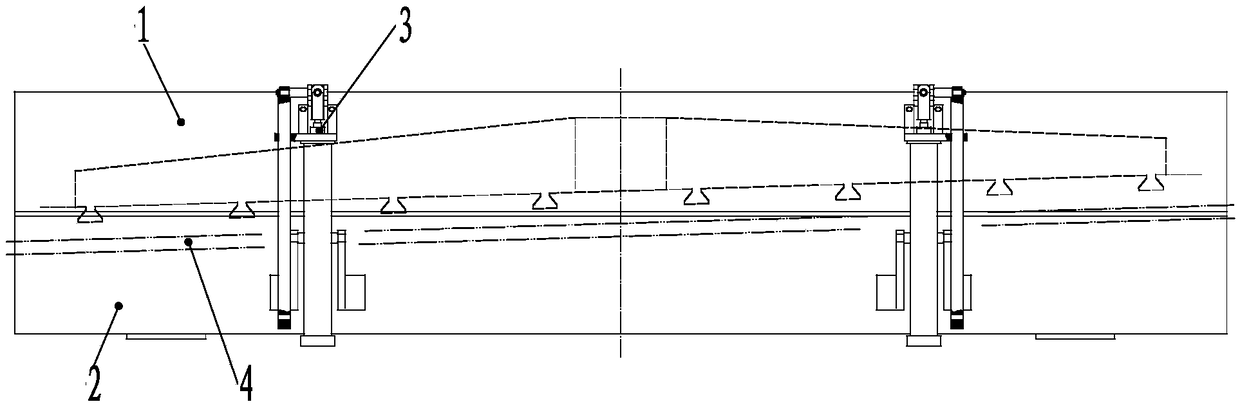

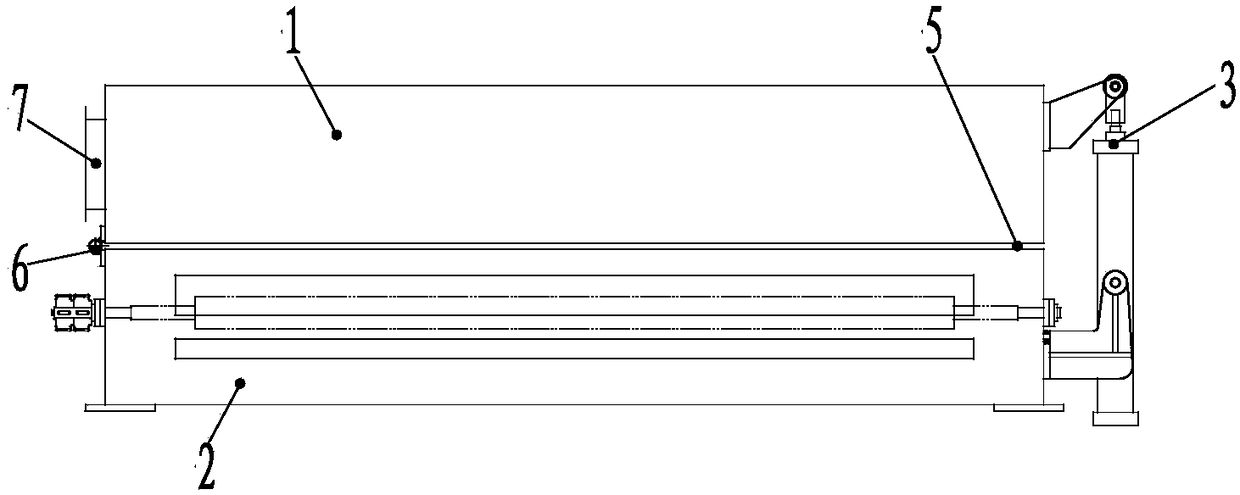

[0024] figure 1 It is a front view of a coater oven of the present invention, figure 2 yes figure 1 left view of

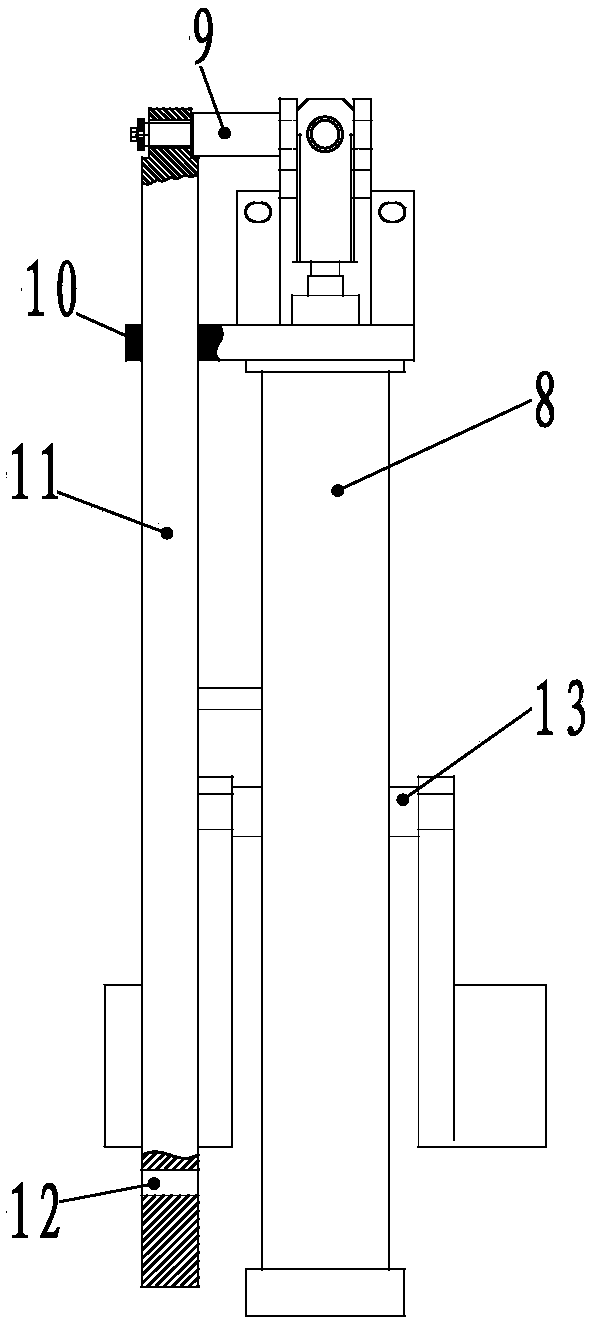

[0025] image 3 yes figure 1 Zoomed-in view of middleware 3, Figure 4 yes figure 1 Bottom view of middle piece 1, Figure 5 yes Figure 4 D-D section view in, Figure 6 yes Figure 5 The magnified view at A in the middle, Figure 7 yes Figure 5 The magnified view at B in the center, Figure 8 yes Figure 5 Enlarged image at C. In the figure, this coating machine oven is composed of upper and lower boxes 1 and 2, double sealing tapes 5 are arranged around the joint surfaces of the upper and lower boxes, hinges 6 are arranged at the back of the upper and lower boxes, and openings are arranged at the front of the upper and lower boxes. Close the cylinder 3, the cylinder body 8 of the open and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com