Oscillating laminar-flow grain dryer

A grain dryer, vibrating technology, used in dryers, drying, drying solid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

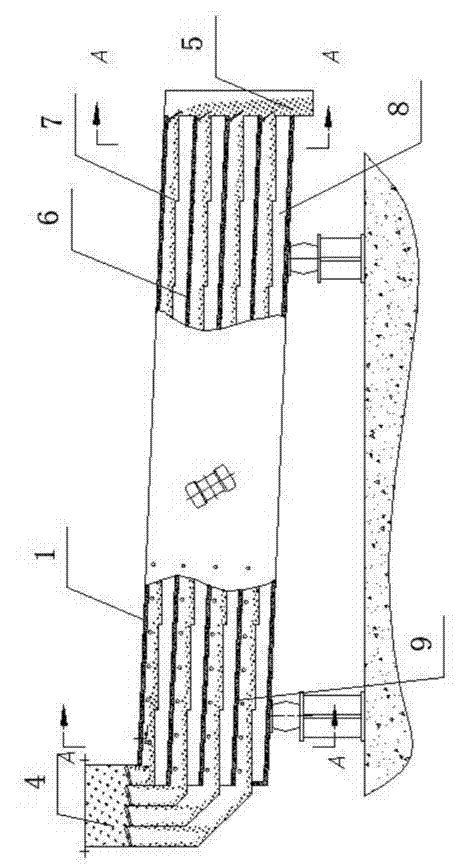

[0054] A vibrating laminar flow grain dryer, which consists of: a box body 1 with a shock absorption device, the box body 1 has a hot air inlet 2 and an air outlet 3, and the box has a heated The feeding port 4 and the discharging port 5 of the grain, the box body is equipped with a vibrating material bed 6, and the upper part of the vibrating material bed is the material chamber 7, and the heating chamber 8 is below. The opening is in communication with the material chamber, and the hot air inlet and outlet are in communication with the heating chamber.

[0055] After the heated grain enters the vibrating material bed 6 from the feed inlet 4, the vibrating material bed will convey the heated grain to the direction of the discharge port. During the conveying process, the heated grain will be heated and turned over by the vibrating material bed, so that the heated grain will be evenly combined with each other. The heating body is in contact with the vibrating material bed to eva...

Embodiment 2

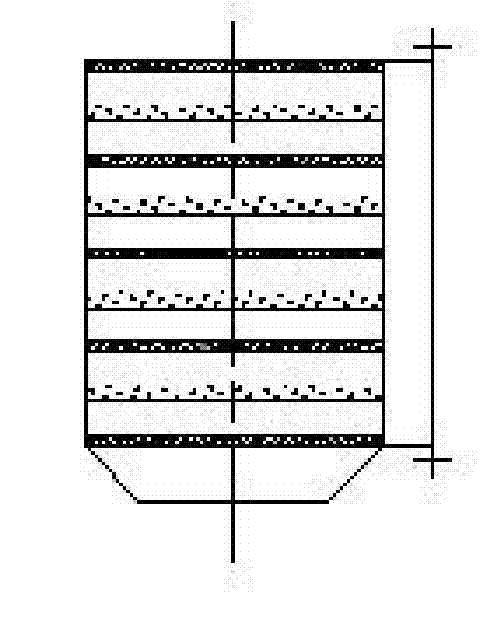

[0057] In the vibrating laminar flow grain dryer described in embodiment 1, the vibrating material bed has 1-15 layers, with 5-10 layers being more common, and a gas barrier 9 is installed between the vibrating material beds. , Divide the vibrating material bed into two unconnected spaces, the material chamber and the heating chamber. The heated and dried grain flows in the material chamber, and the heating gas flows in the heating chamber. The height of the material chamber and the heating chamber is generally about 10 cm. The height of 5 cm where the moisture is large is not less than 20 cm. In special cases, it is generally not more than 35 cm.

Embodiment 3

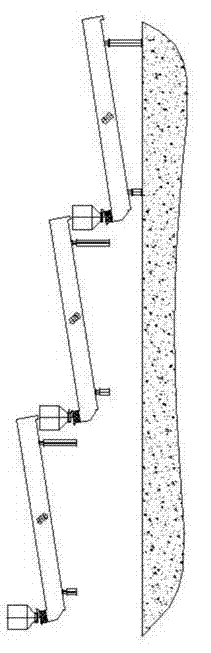

[0059] Embodiment 2 In the vibrating laminar flow grain dryer, the air baffle is equipped with a flow baffle 10, which is in contact with the vibrating material bed at the height of the baffle, and the gas path is regulated into a circuitous The curve makes the heating more balanced. The length of the flow baffle is not less than 60% of the width of the material bed where the baffle is located, and the flow baffle is provided with spoiler holes to avoid dead ends. The length of the vibrating material bed is more than 2 meters. The gas barrier has a far-infrared coating on the side facing the grain, and the far-infrared coating is located on the side of the discharge port.

[0060] The air barrier has a far-infrared coating on the side facing the grain, and when the temperature of the heating chamber 8 reaches the release temperature of the far-infrared material, the grain is heated by the far-infrared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com