High-temperature thermostat for 3D printing production line

A constant temperature device, 3D printing technology, applied in the direction of additive processing, etc., can solve the problem of low strength of 3D printing wire, and achieve the effect of improving softness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

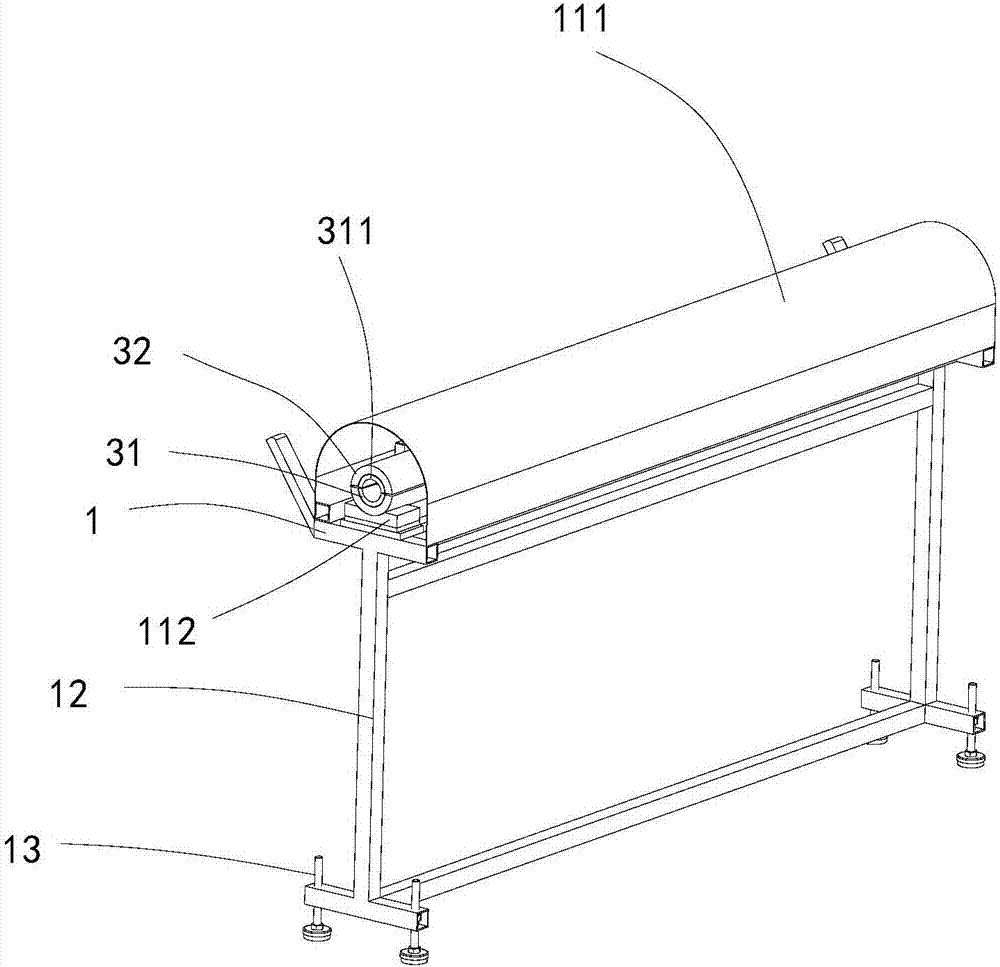

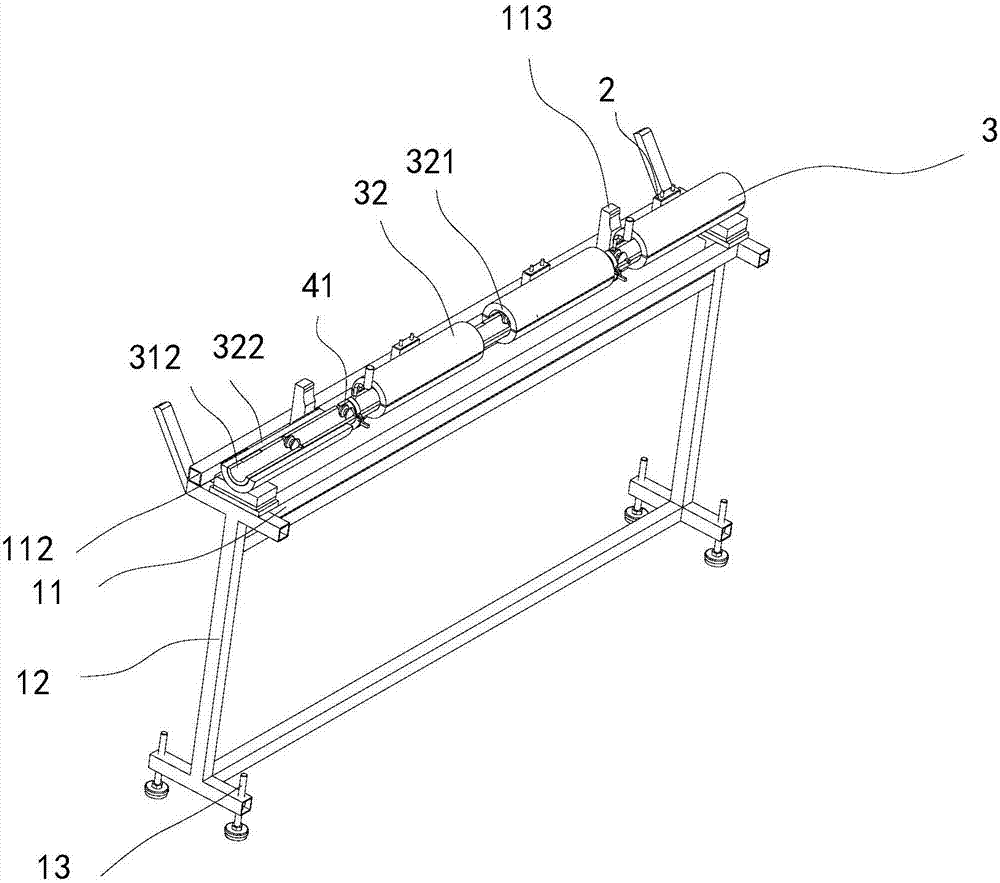

[0031] see figure 1 and figure 2 , figure 1 It is a schematic structural diagram of a high-temperature constant temperature device used in a 3D printing production line provided in this embodiment; figure 2 It is a schematic diagram of the local structure of the high temperature constant temperature device in this embodiment. The high temperature constant temperature device includes: a support 1, a heating component 2, a heat conduction component 3, a wire mechanism 4 and a control mechanism (not shown).

[0032] The support 1 includes a working platform 11 , a supporting rod 12 and a base 13 for supporting the working platform 11 , and the supporting rod 12 is located between the working platform 11 and the base 13 . In this embodiment, preferably, the number of bases 13 is four, and the four bases 13 are divided into two groups, and the two groups of bases 13 are arranged oppositely; The support rods 12 are arranged oppositely, and are located on two groups of bases 13...

Embodiment 2

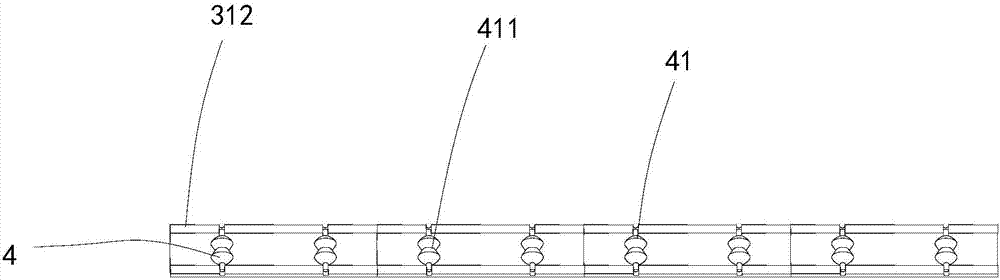

[0048] The difference between this embodiment and Embodiment 1 is that the heat-conducting inner tube 31 includes several sections, and a heat-insulating plate 314 is arranged between two adjacent sections of the heat-conducting inner tube, and a through-hole 315 for passing through a wire is provided on the heat-insulating plate 314 . The number of sections of the heat-conducting inner tube 31 is consistent with the number of the heat-conducting outer tube 32, and they are arranged correspondingly.

[0049] Such as Figure 4 As shown, in this embodiment, preferably, the heat-conducting inner tube 31 is divided into four sections, and each section of the heat-conducting inner tube 31 is provided with a heat insulating board 314 at the head end and the tail end; 314 corresponds to the head of the heat-conducting outer tube 32, and the heat-insulating plate 314 at the tail end of each heat-conducting inner tube 31 corresponds to the afterbody of the heat-conducting outer tube 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com