Sapphire printed circuit board LED lamp and manufacture method thereof

A technology for printed circuit boards and LED lamps, which is applied to circuits, electric light sources, and electrical components. It can solve problems such as the lack of ideal heat dissipation effect of metal plates, poor heat dissipation performance of conductive metal plates, and complex structure of lamps. It achieves simple structure and low cost. Low, light keeps bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

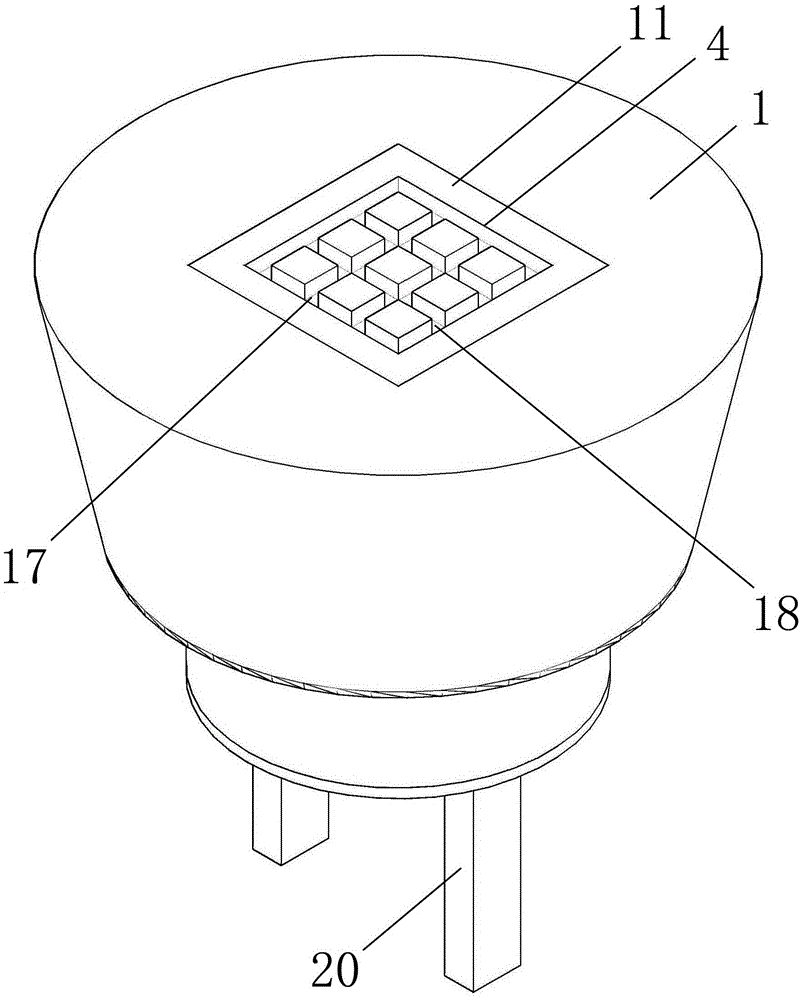

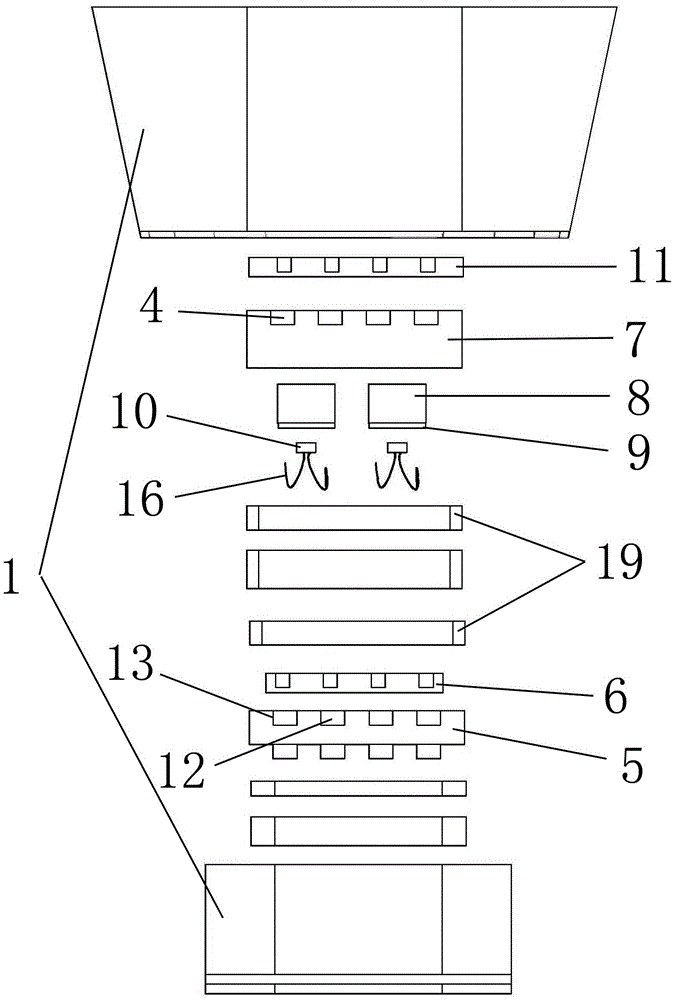

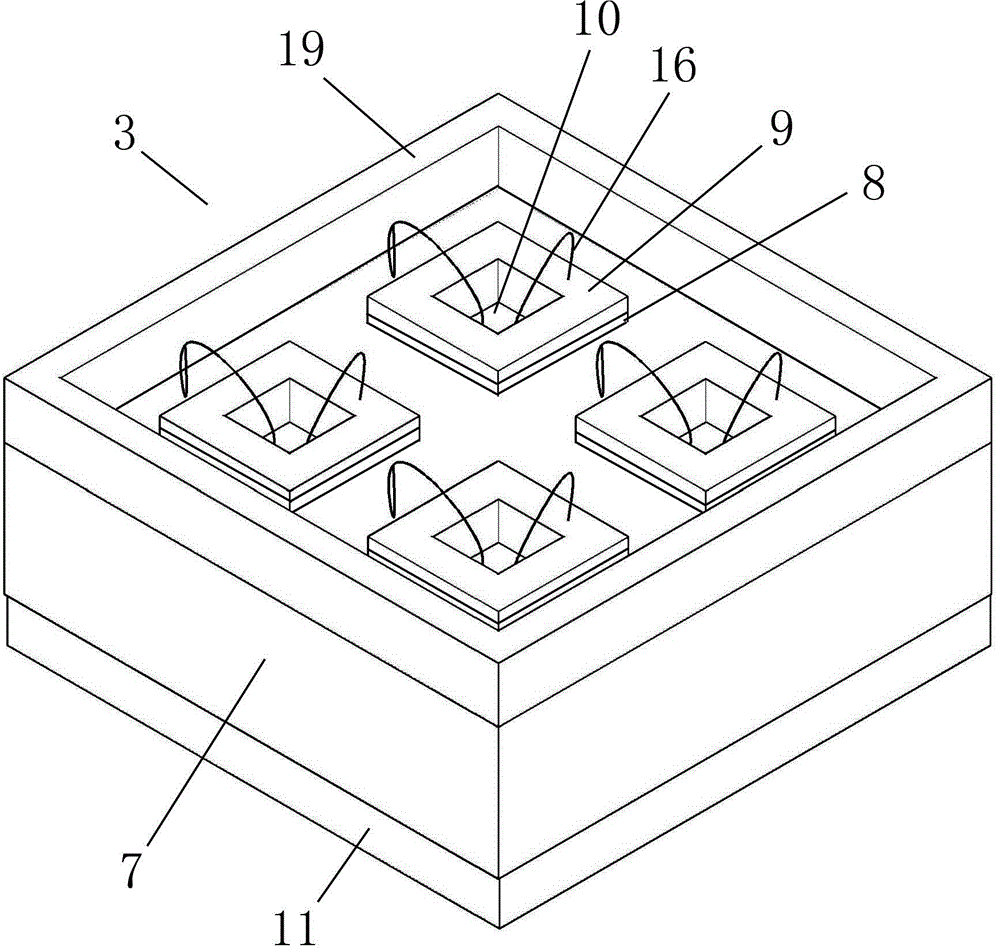

[0033] Such as Figure 1-7 As shown, a sapphire printed circuit board LED lamp includes a housing 1, a light guide module 2 and a light emitting module 3, the light guide module 2 and the light emitting module 3 are fixedly arranged in the housing 1, and the light guide module 2 and the light-emitting module 3 have a heat dissipation structure 4. The light-guiding module 2 further includes a first sapphire substrate 5 and a reflective layer 6. The reflective layer 6 is covered and fixed on the first sapphire substrate 5. The light-emitting module 3 It further includes a second sapphire substrate 7, a light-shielding layer 8, a metal conductive layer 9, a light-emitting module 10, and an anti-reflection layer 11. One side of the second sapphire substrate 7 is covered with an anti-reflection layer 11, and the other side is covered with an anti-reflection layer 11. The light-shielding layer 8 , the metal conductive layer 9 is covered and fixed on the light-shielding layer 8 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com