Rapid water sample heater

A heater and water sample technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as low heat and low heat exchange efficiency, and achieve low heat exchange efficiency, low heat, and great practicality. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

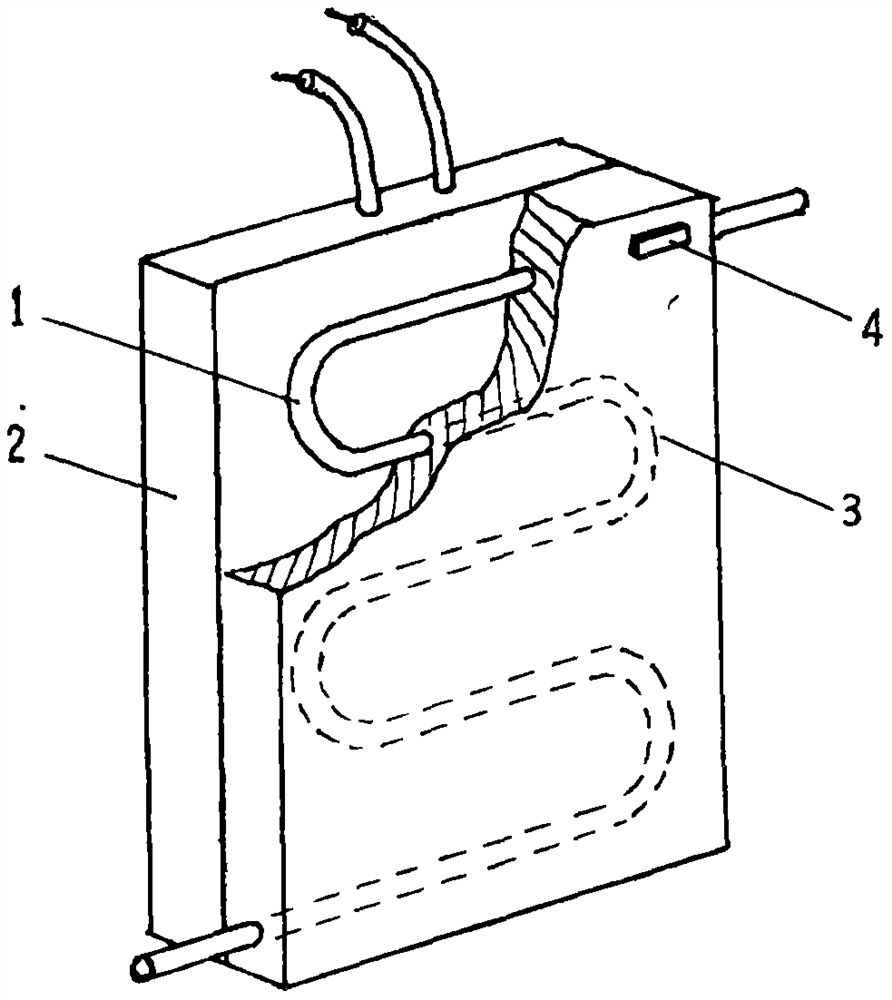

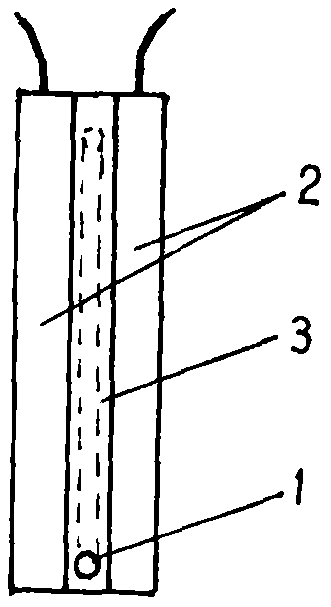

[0009] For example, the metal heat exchange tube 1 in the attached figure, after being bent and formed, the entire surface is hot-plated with tin, and the heat source 2 (here only takes the electric heating plate as an example) is also pre-hot-plated with tin on the side of the metal heat exchange tube to fix the heat exchange tube And assemble the mold, turn on the electricity to preheat the flat heat source, when its temperature is higher than the melting point of the tin-based alloy, pour in another melted tin-based alloy 3, for the non-metallic heat exchange tube, just change the material of the heat exchange tube , the overall structure and manufacturing process are exactly the same. The most important thing to pay attention to is the selection of tin-based alloys with low melting points, such as 63 tin with a melting point of only 183°C (63% tin content and 37% lead content). is very safe. In the same way, for metal heat exchange tubes, the alloy composition and its mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com