Turntable type frozen section staining device

A technology of frozen section and staining instrument, applied in the field of staining instrument, can solve the problems of quality stability, cost saving, increase of labor cost and time, damage to health, etc., to achieve high work efficiency, compact product structure, and ensure safety The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

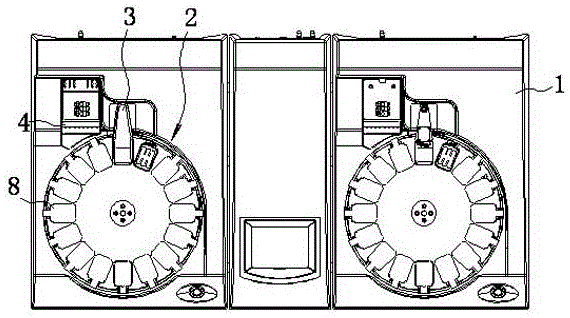

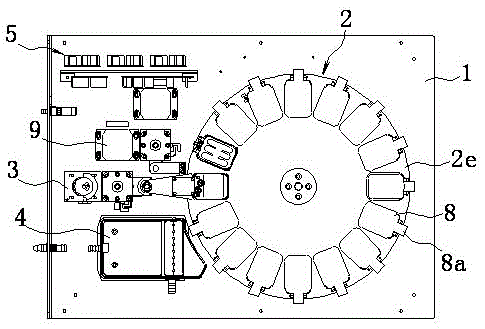

[0023] refer to Figure 1 to Figure 3 As shown, a turntable type frozen section staining instrument of the present invention includes a body 1, at least one set of dyeing units is arranged on the upper end of the body 1, and two groups of dyeing units are provided in this embodiment. Of course, according to the actual situation, also More sets of staining units can be set.

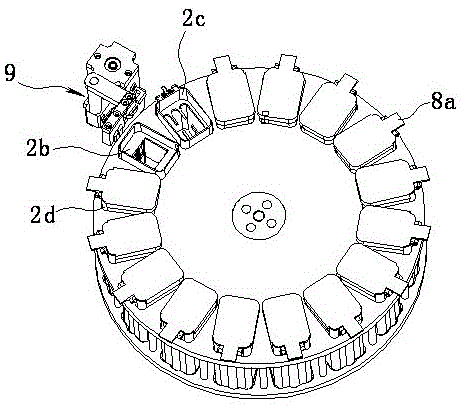

[0024] The dyeing unit is mainly composed of a turntable module 2, a lifting and clamping mechanism 3 arranged on the side of the turntable module 2, and a flushing tank 4 arranged on the side of the lifting and clamping mechanism 3; the turntable module 2 and the lifting and clamping mechanism 3 are respectively connected with the main control unit 5.

[0025] refer to Figure 5 and Figure 6 As shown, the lifting and clamping mechanism 3 is mainly composed of a lifting support 3a arranged on the body 1, a first lifting slider 3b arranged on the lifting bearing 3a, a lifting drive mechanism 6 connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com