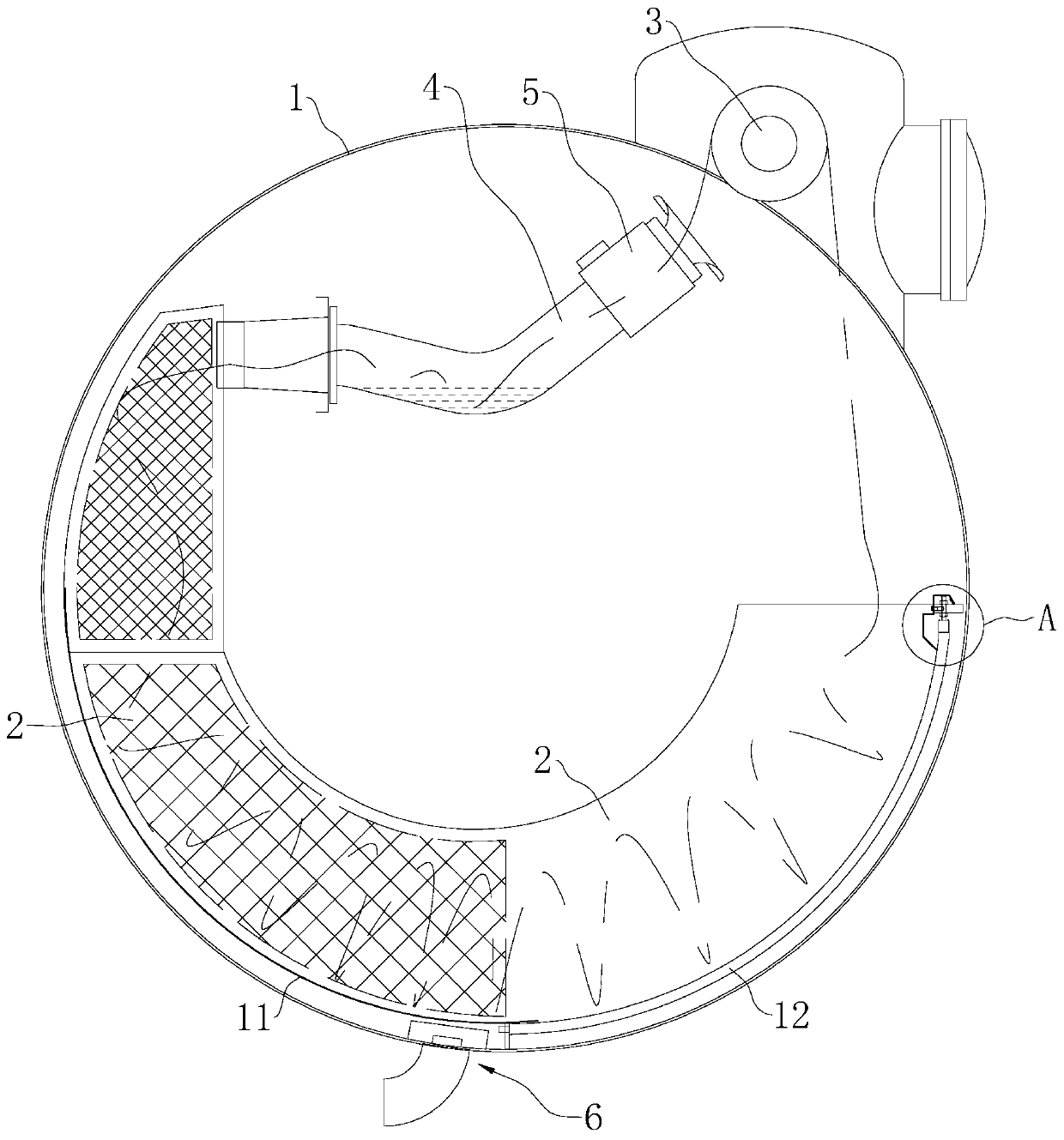

Cloth dyeing machine

A technology of dyeing machine and cloth storage tank, applied in the field of dyeing machine, can solve problems such as cloth damage, and achieve the effects of reducing damage, ensuring dyeing quality, and reducing self-rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

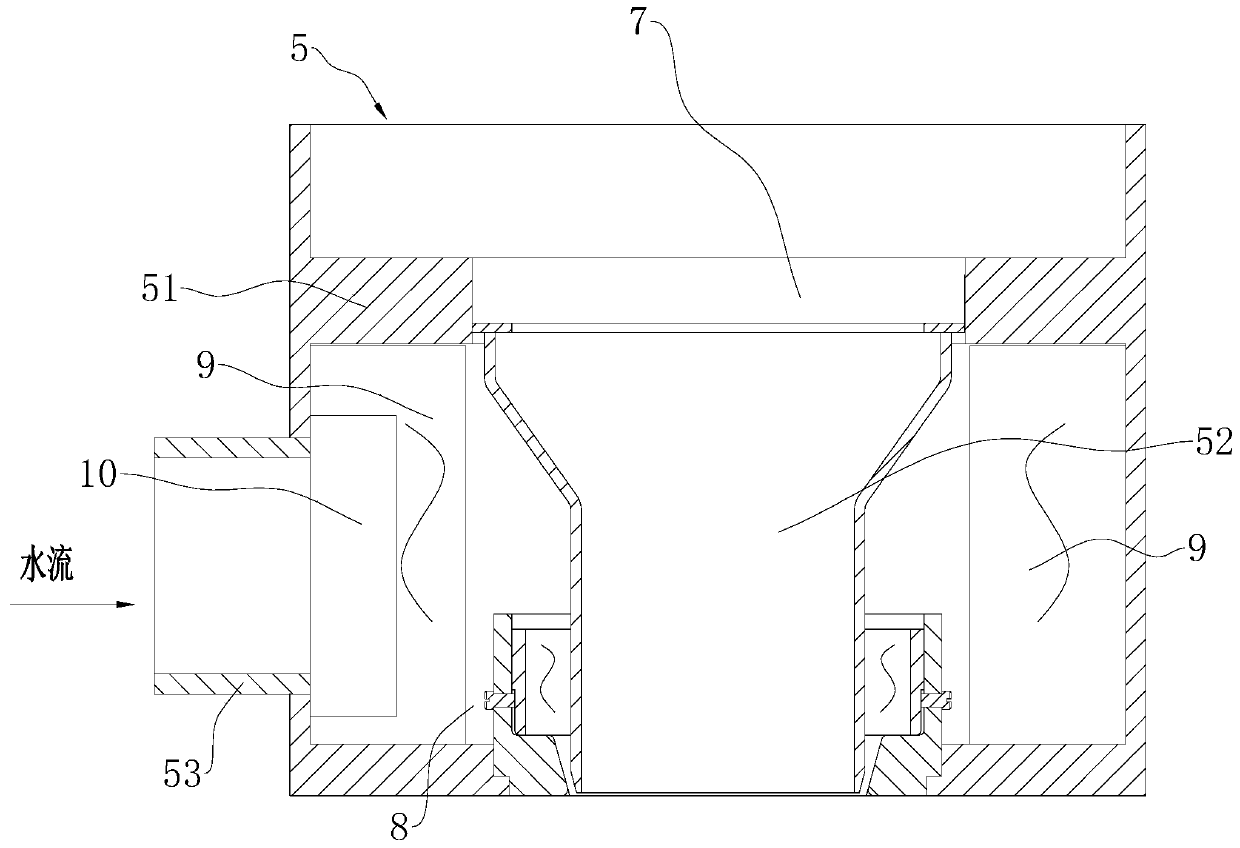

[0067] Embodiment 2: refer to Figure 11 The difference from Embodiment 1 is that the cylinder body 1 is externally connected with a heat exchanger 18, and the heat exchanger 18 communicates with the end of the liquid inlet pipe 53 opposite to the seat body 51, and the heat exchanger 18 is also connected with a liquid inlet pipe 23, The liquid inlet pipe 23 is connected with two water inlet pipes 22 and the drain pipe 61. The two water inlet pipes 22 and the drain pipe 61 are respectively provided with valves 21. The liquid inlet pipe is located at a section between the heat exchanger 18 and the water inlet pipe 22. A water pump 20 and a filter 19 are arranged on it; the valve 21 on the water inlet pipe 22 and the drain pipe 61 can be used to control the opening and closing of the corresponding pipe, thereby controlling the flow of water entering the heat exchanger 18, and at the same time, the cylinder 1 can be discharged After heat exchange, the water flow continues to pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com