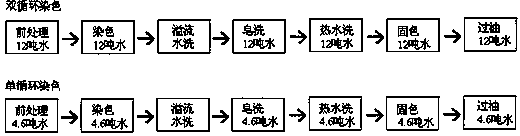

Unidirectional circulation dyeing process for cheese

A unidirectional circulation, cheese yarn technology, applied in liquid/gas/vapor yarn/filament processing, textile material processing equipment configuration, etc., can solve problems such as high electricity consumption, high steam energy consumption, and inability to reduce liquor ratio , to avoid layer difference and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The invention relates to a unidirectional circulation dyeing process of cheese, in which the dye liquor is driven to circulate unidirectionally from the inside of the cheese to the outside through the change of the rotational speed of the main pump in the dyeing vat.

Embodiment 2

[0025] The invention relates to a unidirectional circulation dyeing process of cheese, in which the dye liquor is driven to circulate unidirectionally from the inside of the cheese to the outside through the change of the rotational speed of the main pump in the dyeing vat.

[0026] After the main pump runs at 70% full speed for 20 seconds, the rotating speed drops by 20%, and then returns to 70% full speed alternately after 20 seconds.

Embodiment 3

[0028] The invention relates to a unidirectional circulation dyeing process of cheese, in which the dye liquor is driven to circulate unidirectionally from the inside of the cheese to the outside through the change of the rotational speed of the main pump in the dyeing vat.

[0029] After the main pump runs at 95% full speed for 20 seconds, the rotating speed drops by 20%, and returns to 95% full speed alternately after 20 seconds.

[0030] The bath ratio of the dyeing is 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com