Main cylinder dyeing liquor evenly-distributing device of high-temperature and high-pressure cone dyeing machine

A package dyeing machine, high temperature and high pressure technology, which is applied in the processing of textile material equipment configuration, liquid/gas/vapor yarn/filament processing, textile material carrier processing, etc. Large and other problems to achieve the effect of ensuring uniformity and dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

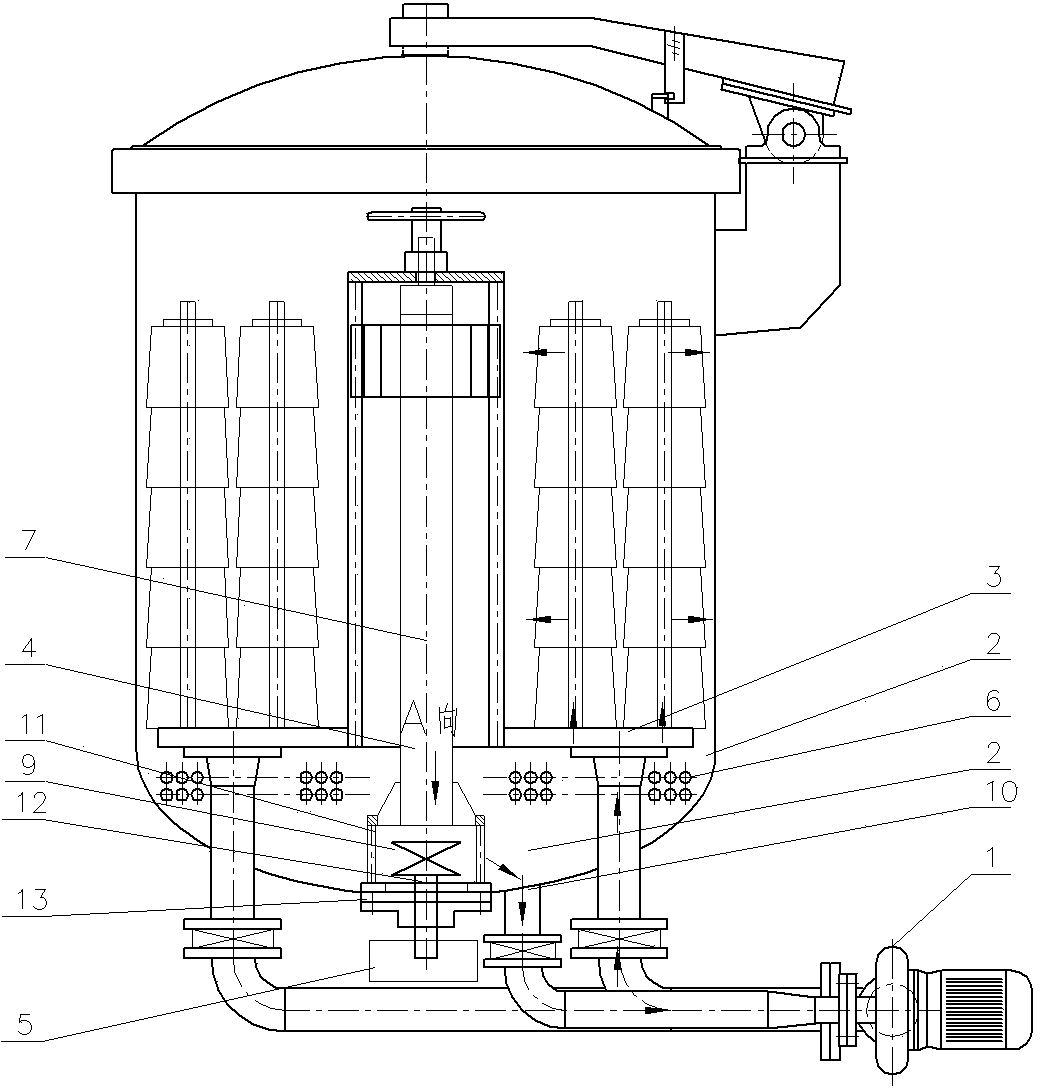

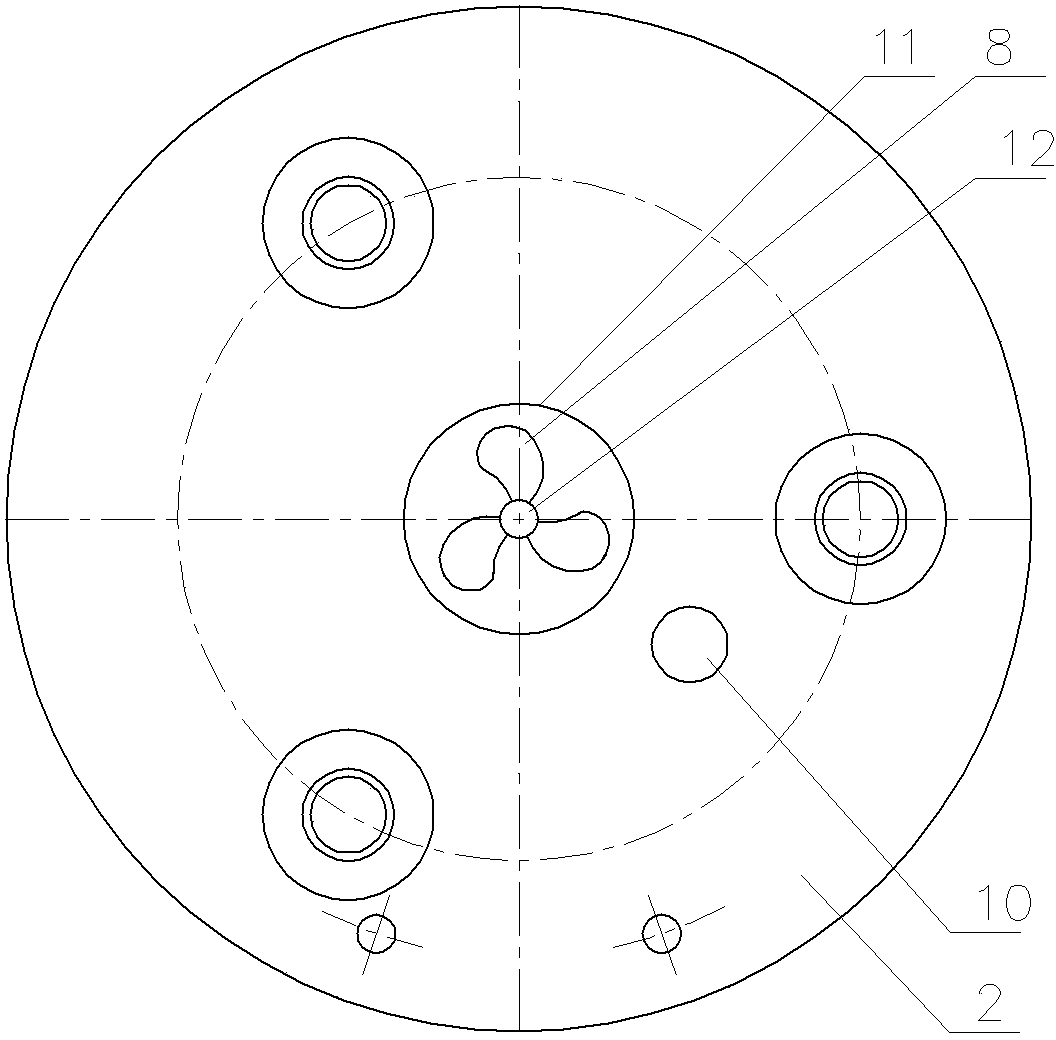

[0011] A device for evenly distributing the dye solution in the main cylinder of a high-temperature and high-pressure package dyeing machine, see figure 1 , figure 2 : It comprises sarong bottom main cylinder 2, sarong 3, sarong central tube 4, and sarong 3 is positioned at the top of sarong bottom main cylinder 2, and the bottom center position of sarong bottom main cylinder 2 is equipped with stirring device, and the central axis of stirring device is parallel to the sarong center The central line 7 of the tube 4 and the blades of the stirring device perform circular rotation along the central axis. The central axis of the stirring device is externally connected with a motor 5 , and a heater 6 is arranged inside the main cylinder 2 at the bottom of the sarong.

[0012] The stirring device is specifically an impeller structure 9 with at least three blades 8, the impeller structure 9 is located on the side of the main pump water inlet 10, the sarong central tube 4 is supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com