High-temperature high-pressure dyejigger

A high-temperature, high-pressure, jigger technology, which is applied to textile processing machine accessories, textiles and papermaking, and textile material processing, can solve problems such as time-consuming and labor-intensive, uneven pressure and heat, and horizontal sliding of fabrics to ensure dyeing quality. , easy to operate and use, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

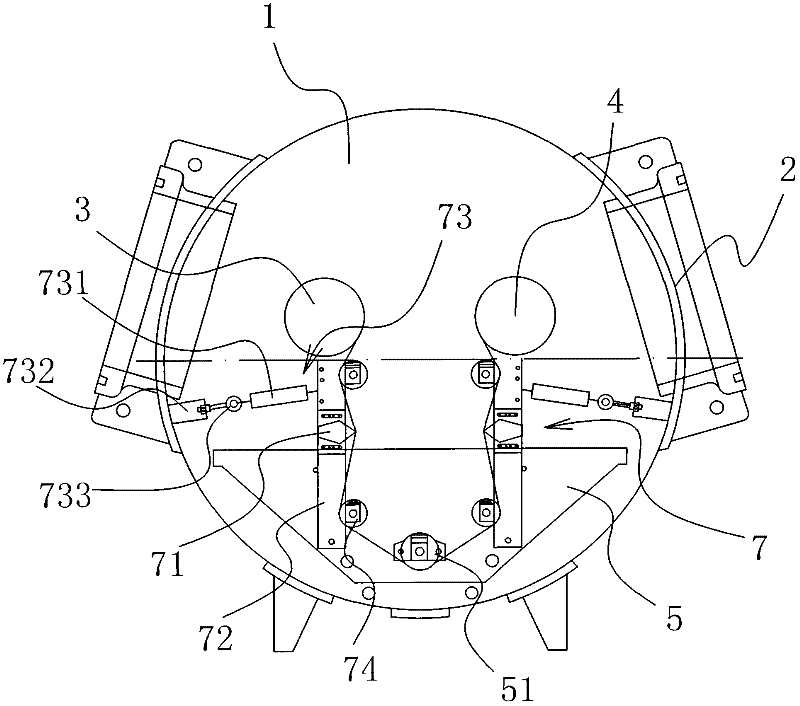

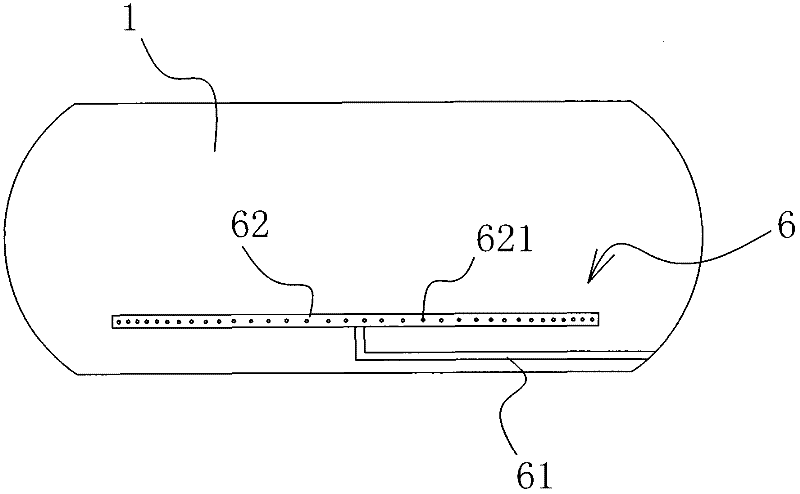

[0025] Such as figure 1 As shown, the high temperature and high pressure dyeing machine includes a pressure vessel 1, a window is opened on the side of the pressure vessel 1, a side cover 2 is arranged at the window, and an automatic sliding door mechanism is arranged between the pressure vessel 1 and the side cover 2. Such as Figure 4 and 5 As shown, the automatic sliding door mechanism includes a horizontally arranged walking beam 81 and a horizontally arranged suspension beam 82, the suspension beam 82 is provided with the side cover 2, and the suspension beam 82 and the walking beam 81 are provided with An electric driving structure 83 capable of driving the suspension beam 82 to move horizontally along the walking beam 81 .

[0026] The electric driving structure 83 includes a support frame 831 on which a traveling wheel 832 is arranged, and the traveling wheel 832 is connected to a driver 833 fixed on the support frame 831 . A transmission wheel 834 is provided betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com