Method and device for preparing ultrathin carbon fiber bundle

A carbon fiber bundle, ultra-thin technology, applied in the field of preparation of ultra-thin carbon fiber bundles, can solve the problems of easy evaporation and shrinkage, hindering the development of carbon fiber products, etc., and achieve the effect of simple use, stable product quality, and online continuous and rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

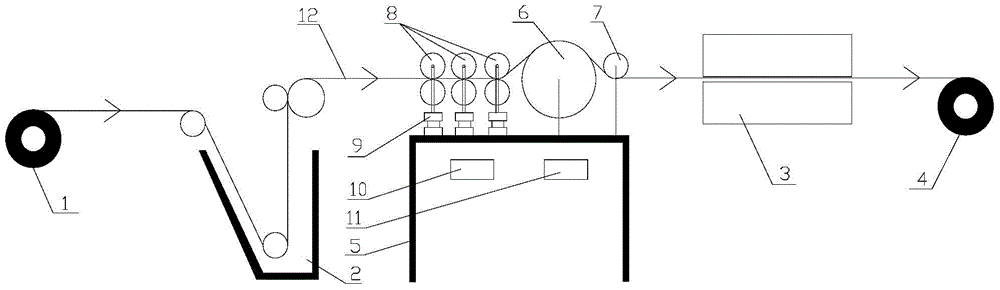

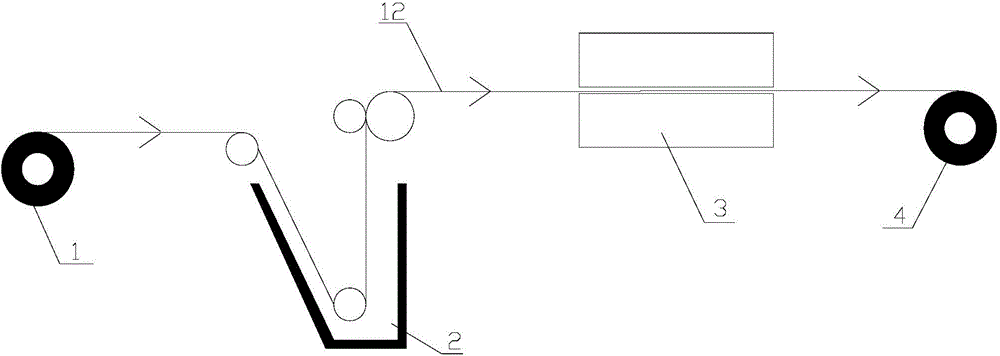

[0051] A kind of preparation method of ultra-thin carbon fiber bundle of present embodiment, such as figure 1 Indicated by the arrows, including the following steps:

[0052] (1) After the carbon fiber bundle is unrolled, it is first sent into the sizing tank, and the carbon fiber bundle is subjected to sizing treatment through the pre-prepared fiber treatment agent;

[0053] (2) Send the carbon fiber bundle with slurry on the surface into the fiber opening and setting device, through the extrusion of the spreading roller in the fiber opening and setting device and the lubrication of the slurry, the carbon fiber bundle is evenly widened, and the unevenness in the carbon fiber bundle The fibers are also flattened; then the carbon fiber bundles are shaped by the hot rollers in the fiber opening and shaping device, so that the carbon fiber bundles maintain the widened filament width, and the moisture content of the carbon fiber bundles is less than 1%; the hot rollers shape the c...

Embodiment 2

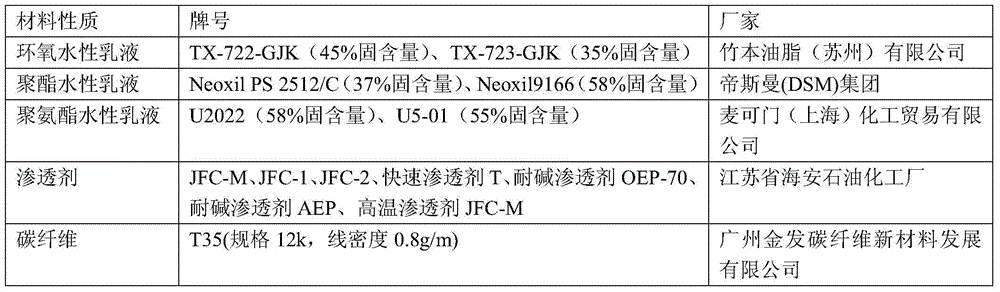

[0076] Compared with Example 1, the carbon fiber bundle preparation method and equipment of this embodiment differ in that:

[0077] The formula used is Ct-1, that is, the water-based emulsion is TX-722-GJK, the ion-exchanged water is deionized water with a conductivity less than 1us / cm, and no penetrant is used.

[0078] The carbon fiber bundle obtained in this embodiment has an initial filament width of 4.5 mm, a winding filament width of 5.3 mm, and a filament bundle surface density of 150 g / m 2 , the moisture content of carbon fiber bundles is 0.83%, see Table 3 for details.

Embodiment 3

[0080] Compared with Example 1, the carbon fiber bundle preparation method and equipment of this embodiment differ in that:

[0081] In each spreading roller, the gap between the upper roller and the lower roller is 0.1mm;

[0082] The temperature of the heat roll was 175°C.

[0083] The carbon fiber bundle obtained in this embodiment has an initial filament width of 5.5 mm, a winding filament width of 8 mm, and a filament bundle surface density of 100 g / m 2 , the moisture content of carbon fiber bundles is 0.75%, see Table 3 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com