Warp sheet sizing machine for proofing press

A kind of proofing machine and pulping machine technology, which is applied in the direction of processing textile material yarn guide device, textile and papermaking, liquid/gas/steam textile material processing, etc. It can solve the problem that the uniform sizing rate yarn strength effect is not obvious and affects the smooth production of small samples Problems that affect the smooth production of small sample weaving, etc., to achieve the effect of improving sizing effect, improving sizing efficiency, and good sizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

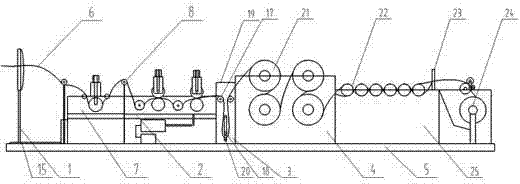

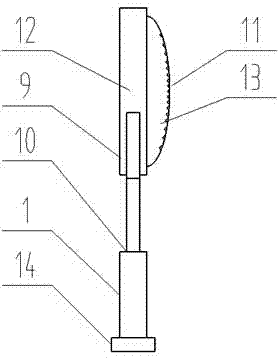

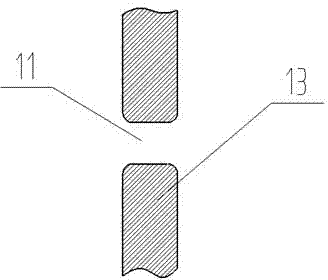

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0023] like figure 1 As shown, the sheet yarn sizing machine for the proofing machine is mainly a sheet yarn sizing machine, including a split reed 1, a size tank 2, a tension balance mechanism 3 and a subsequent processing mechanism 4 arranged in sequence from front to back on the same straight line. Twisted reed 1, pulp tank 2, tension balance mechanism 3 and subsequent processing mechanism 4 are fixedly arranged on the same base 5, among which sub-twisted reed 1, pulp tank 2, tension balance mechanism 3 and subsequent processing mechanism 4 are between the devices Keep a gap of 10-800mm. Through the cooperative work of the reed 1, the sizing tank 2, the tension balance mechanism 3 and the subsequent processing mechanism 4, the yarn 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com