Patents

Literature

60results about How to "Improve production automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Detecting device and method

InactiveCN103257465AImprove accuracyWide spectral response rangeImage enhancementImage analysisImaging processingLiquid-crystal display

The invention relates to the technical field of detection, and discloses detecting device and method. The detecting device comprises an image acquiring module and an image processing module, wherein the image acquiring module acquires image information of a liquid crystal display panel to be detected, and the image processing module is in signal connection with the image acquiring module. The image processing module compares received image information with a defect database and judges defect level of the liquid crystal display panel to be detected. During use of the detecting device, the image acquiring module can acquire image information of any position of the liquid crystal display panel to be detected, the image processing module compares received the image information acquired by the image acquiring module with the defect database and judges the defect level of the liquid crystal display panel to be detected. Accordingly, by the detecting device, defect identification rate and detection efficiency of the liquid crystal display panel are improved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

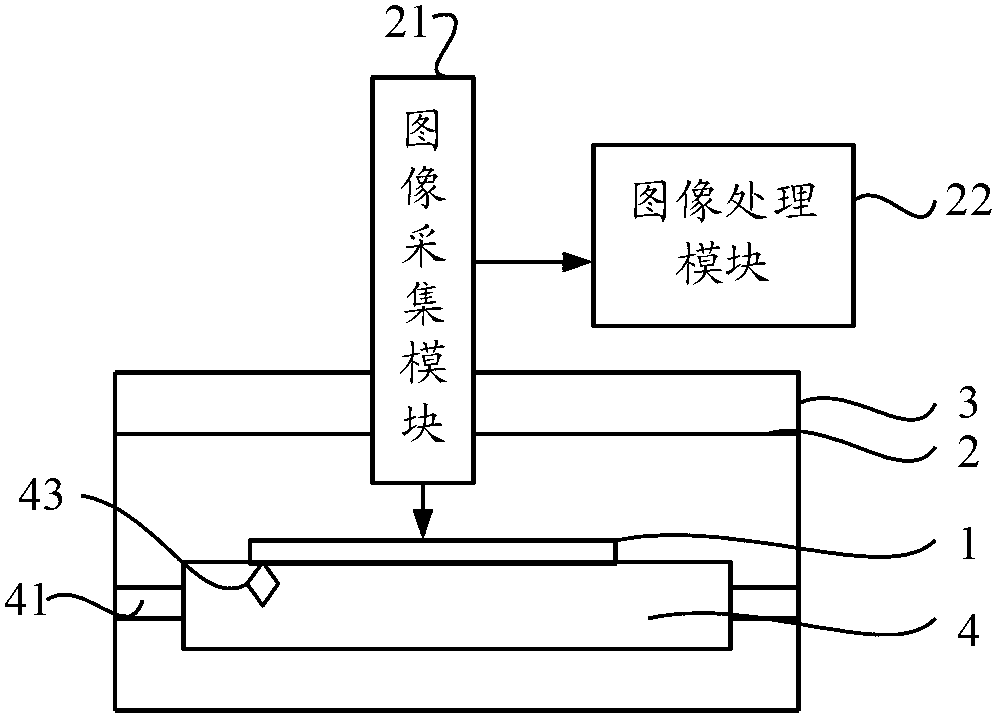

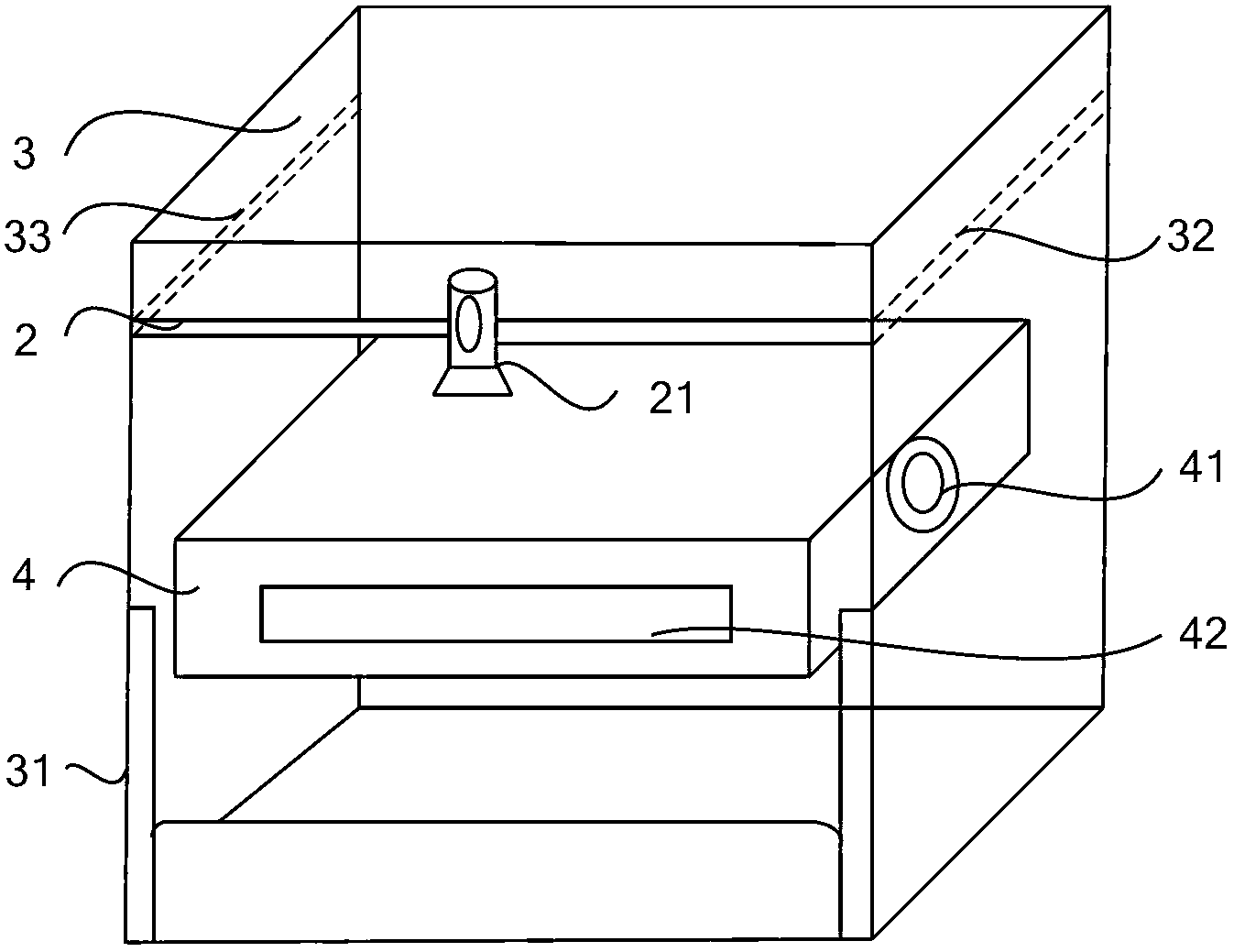

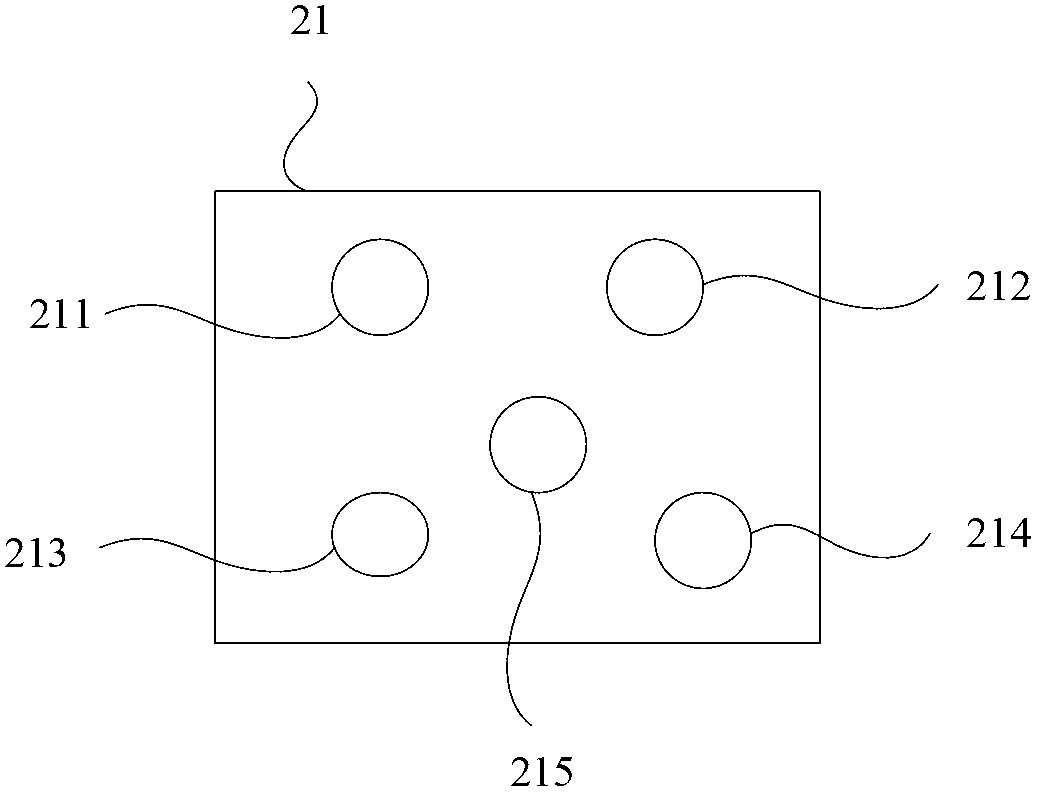

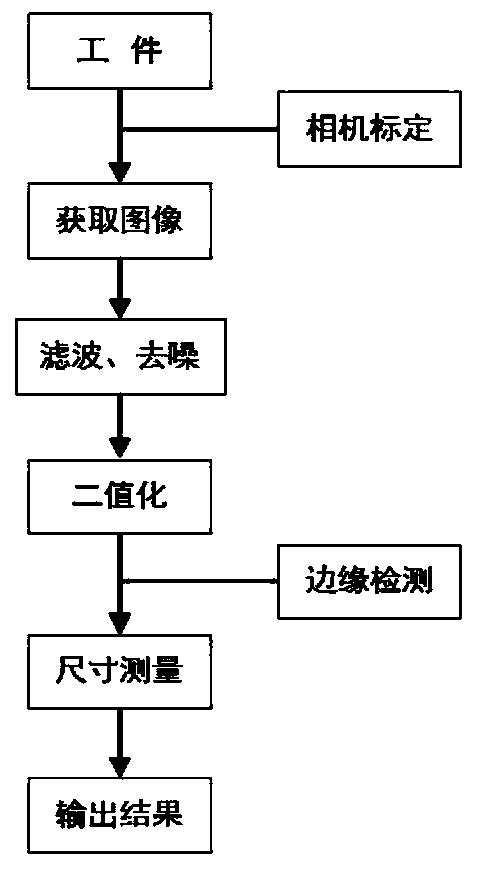

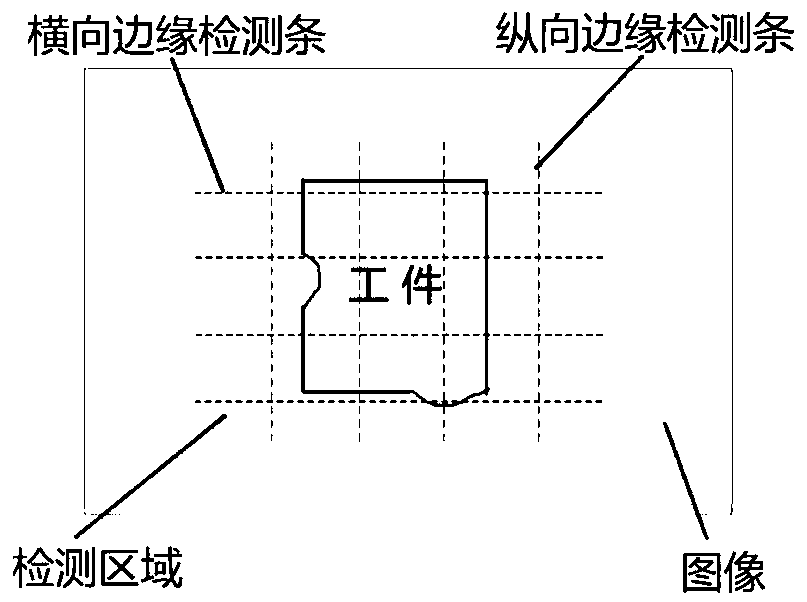

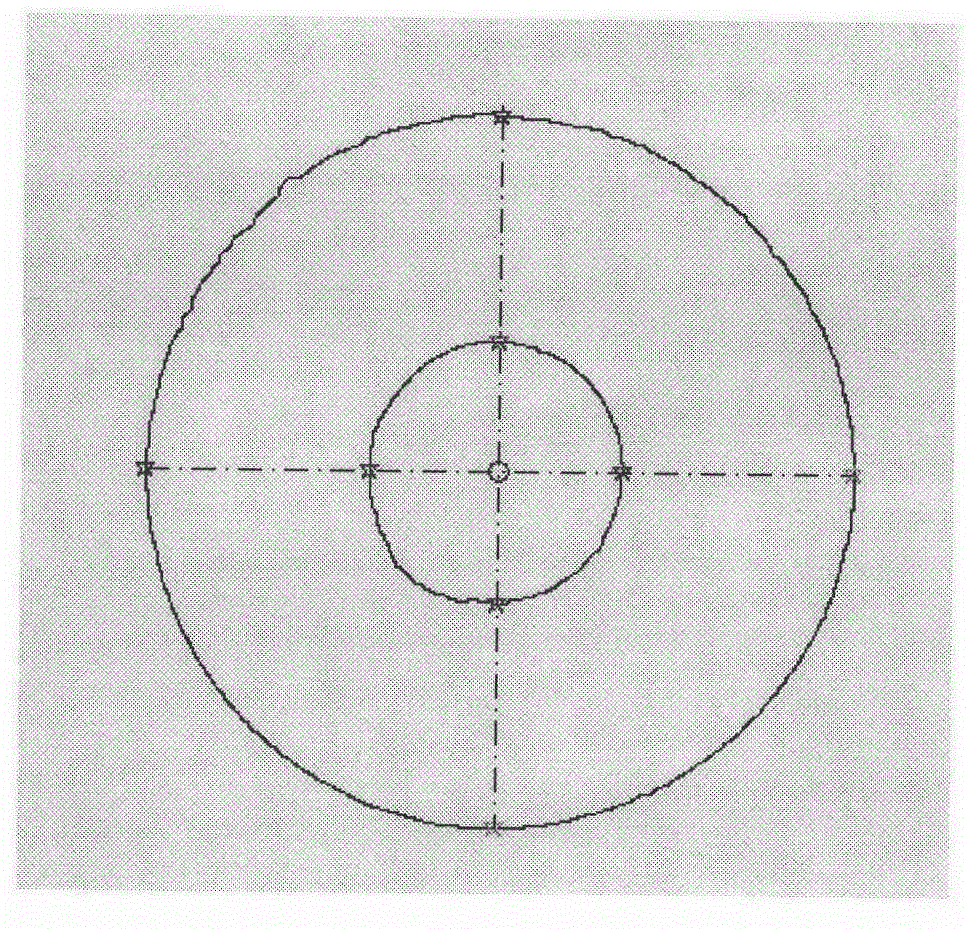

Workpiece detection method based on vision

InactiveCN109934839ARealize real-time online high-precision detectionReduce manufacturing costImage enhancementImage analysisVision basedIterative method

The invention discloses a workpiece detection method based on vision. The workpiece detection method is used for calibrating an industrial camera. The method comprises: placing a workpiece in the detection area, the camera is used for photographing the workpiece in the detection area, and an original image of the workpiece in the detection area is obtained; and filtering and denoising the original image; binarizing the image by using an iteration method; and acquiring a plurality of groups of transverse and longitudinal dimension data of the workpiece in a detection area in the image by utilizing an edge detection principle; edge detection can be accurate to unit pixels, so that the detection precision of the method is also a unit pixel point, and the precision is extremely high; if the two edges on the same detection strip exceed the standard size of the workpiece, the workpiece can be judged to be under-processed; on the contrary, if the distance between the two edges is smaller than the standard distance, it can be determined that the workpiece is a defective part; and if the distance between the two edges is equal to the standard distance or within an allowable error range, determining that the workpiece is qualified. The method can help enterprises to reduce the production cost and promote the improvement of the production automation rate.

Owner:BEIJING UNIV OF TECH

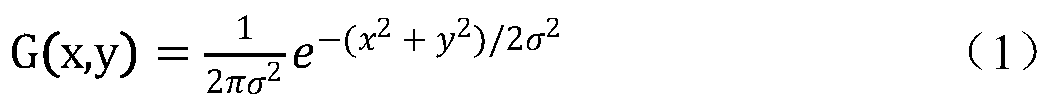

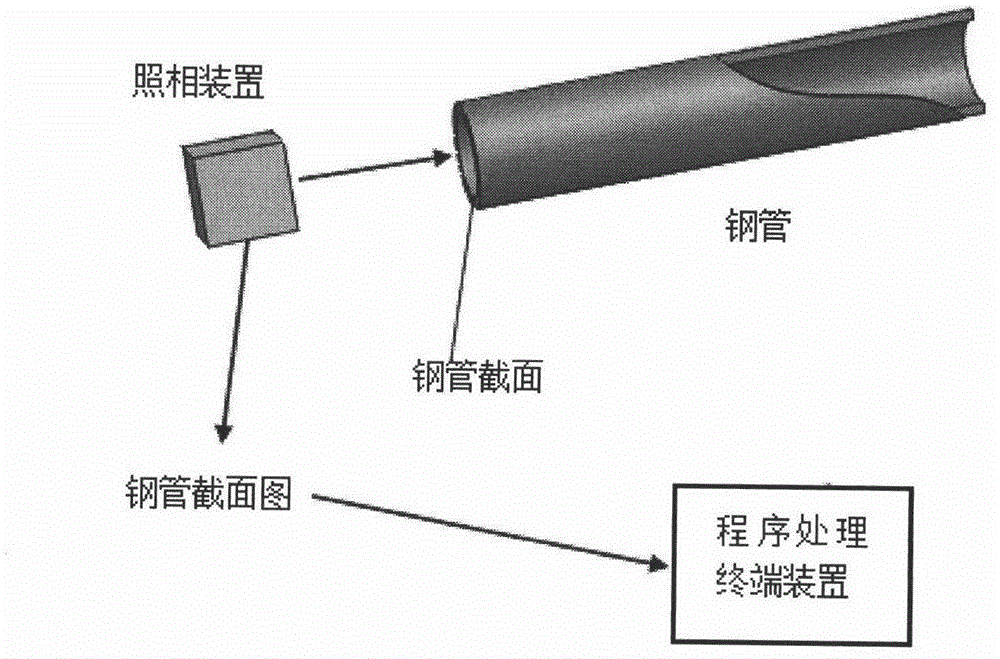

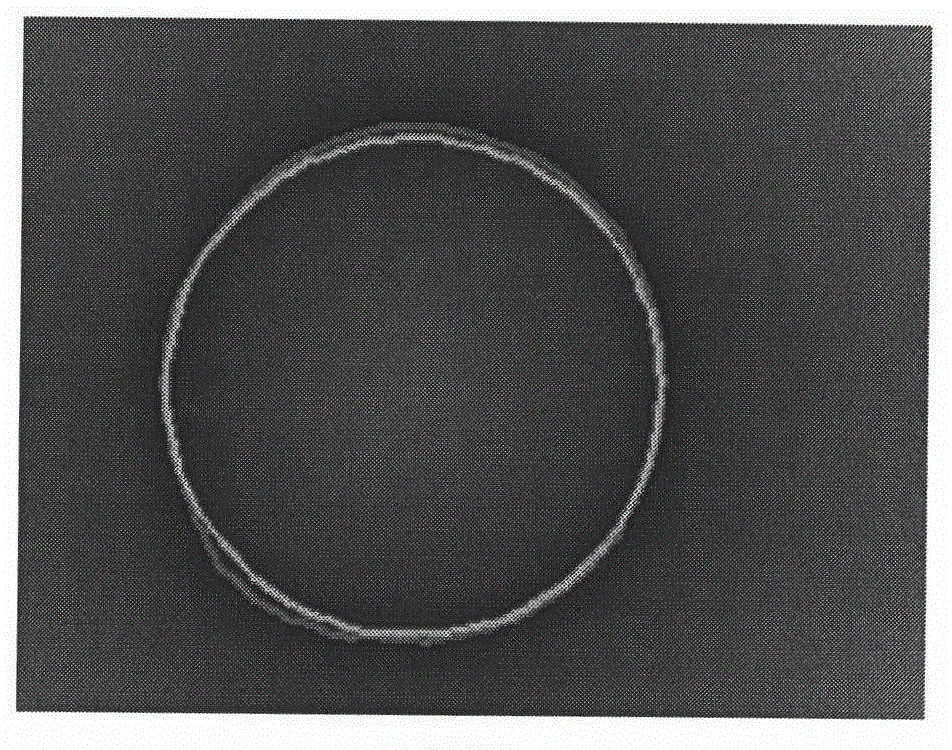

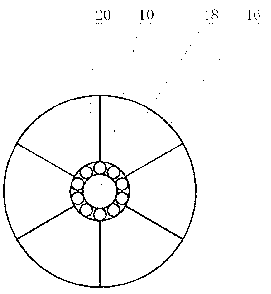

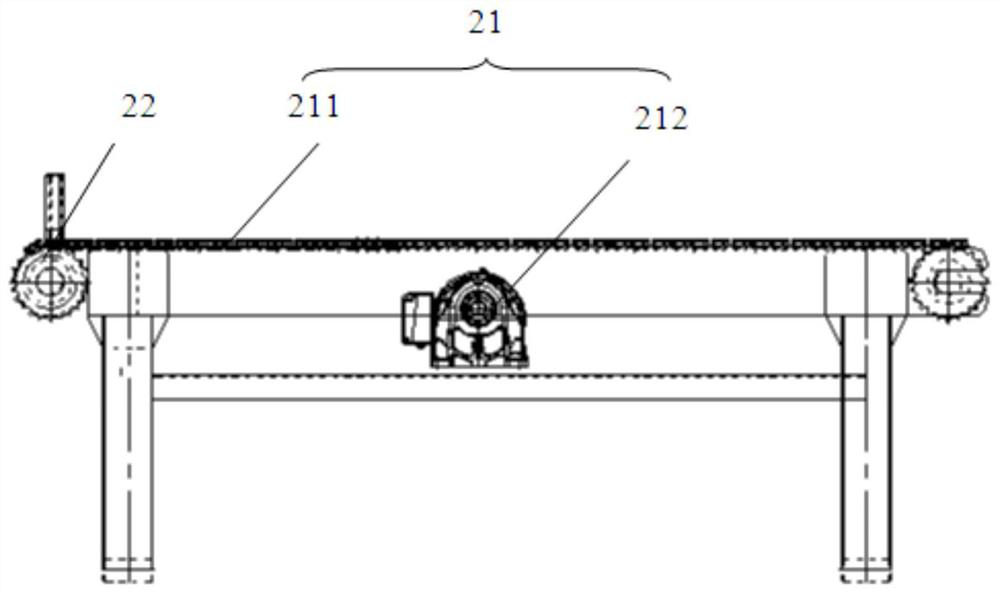

Automatic device capable of realizing wall thickness deviation measurement of steel tube

InactiveCN105890527AImprove production automationEasy to operateUsing optical meansSteel tubeSoftware

The invention relates to the field of wall thickness measurement for annular section materials such as steel tubes, particularly relates to an automatic device cable of realizing wall thickness deviation measurement of a steel tube, and solves a problem that wall thickness measurement at present is low in efficiency and complex in operation. According to steel tube cross section picture acquired before software processing, an effective graphic area of the picture is intercepted and guided into a designed automation program so as to realize acquisition of wall thickness deviation data of the steel tube, and a wall thickness deviation curve is fitted; and mathematical morphology related operations are carried out on image information, an inner ring contour of the steel tube is acquired, and inner ring roundness evaluation is carried out. The automatic device provided by the invention can fit the wall thickness deviation of the steel tube automatically and evaluate the unevenness degree of the steel tube wall thickness, the measurement efficiency is high, and the operation is simple.

Owner:CENT SOUTH UNIV

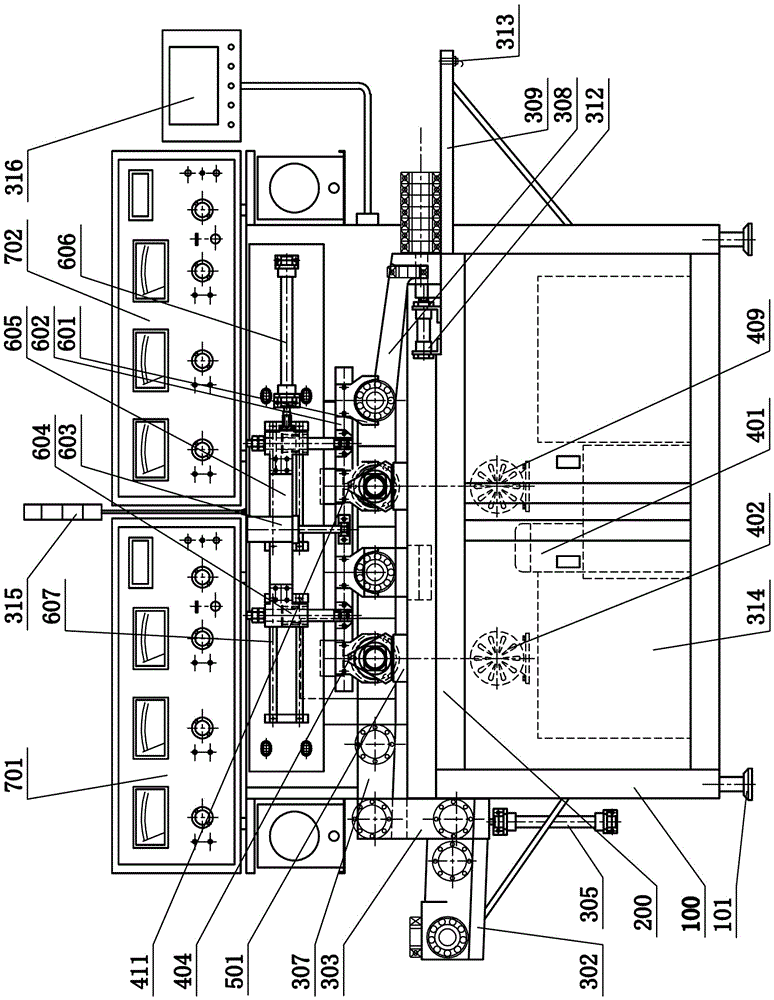

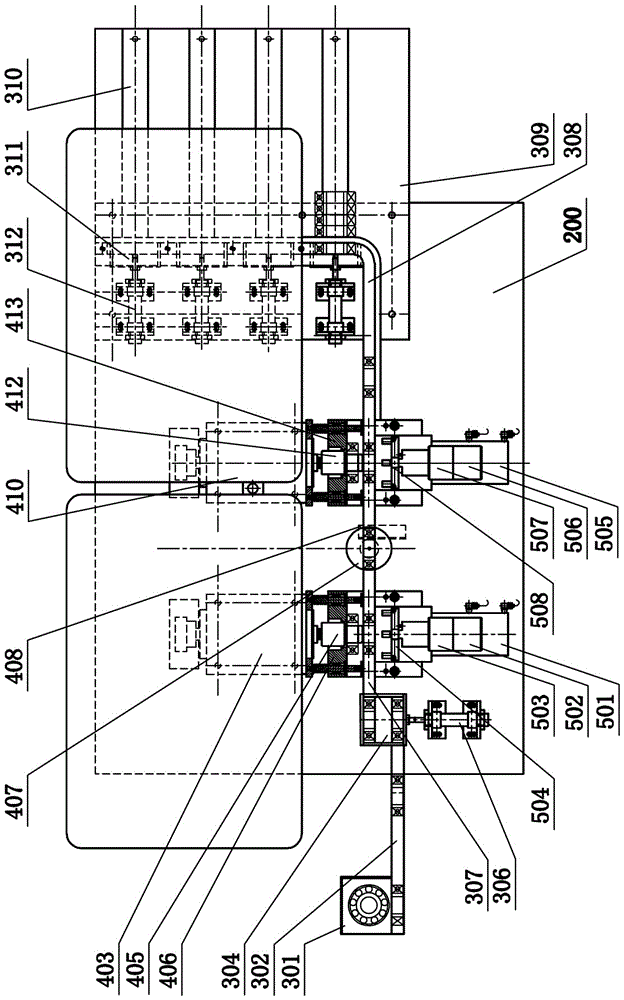

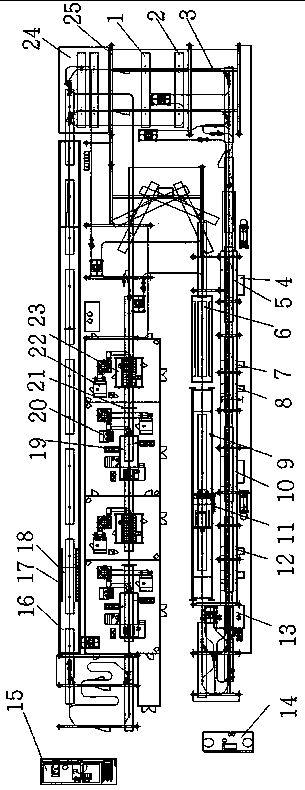

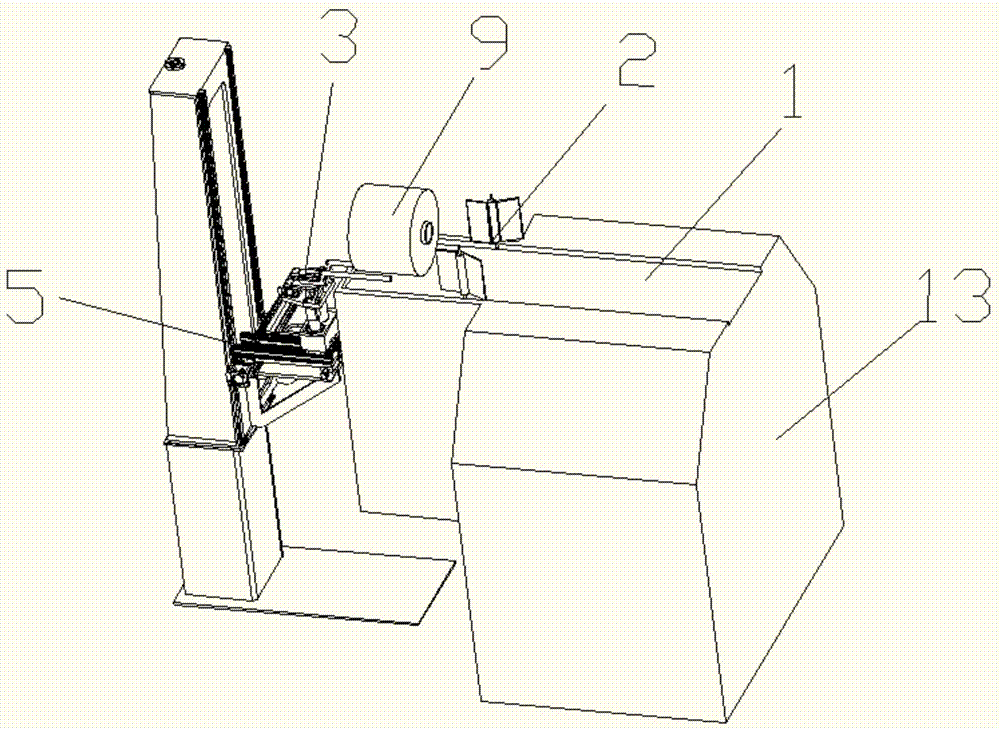

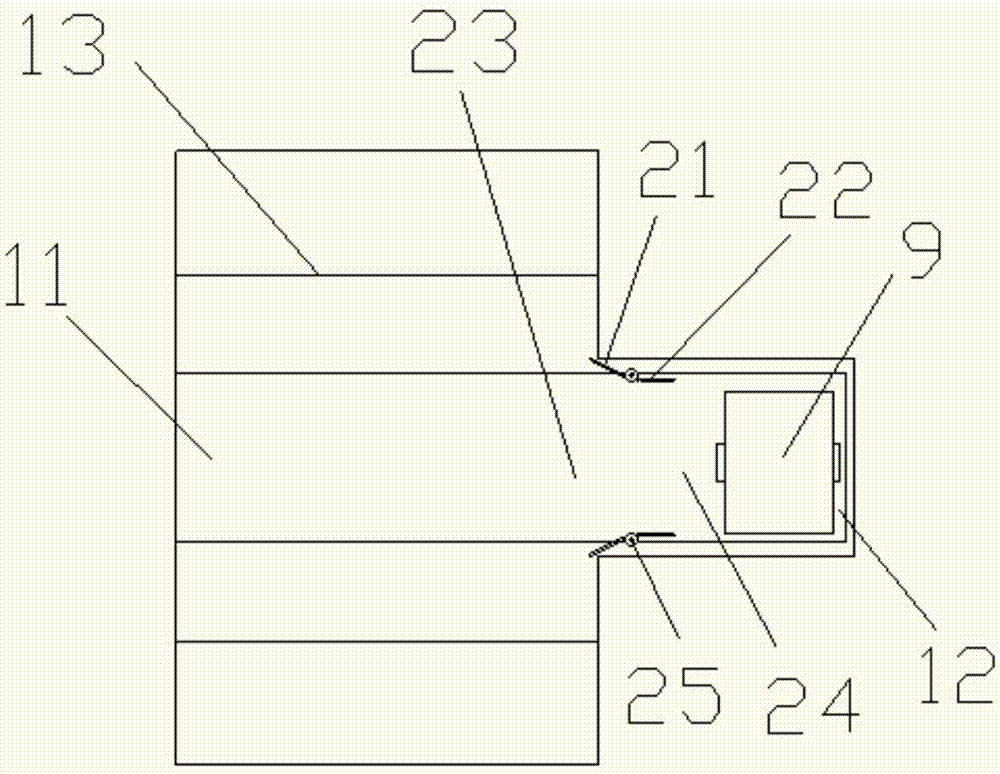

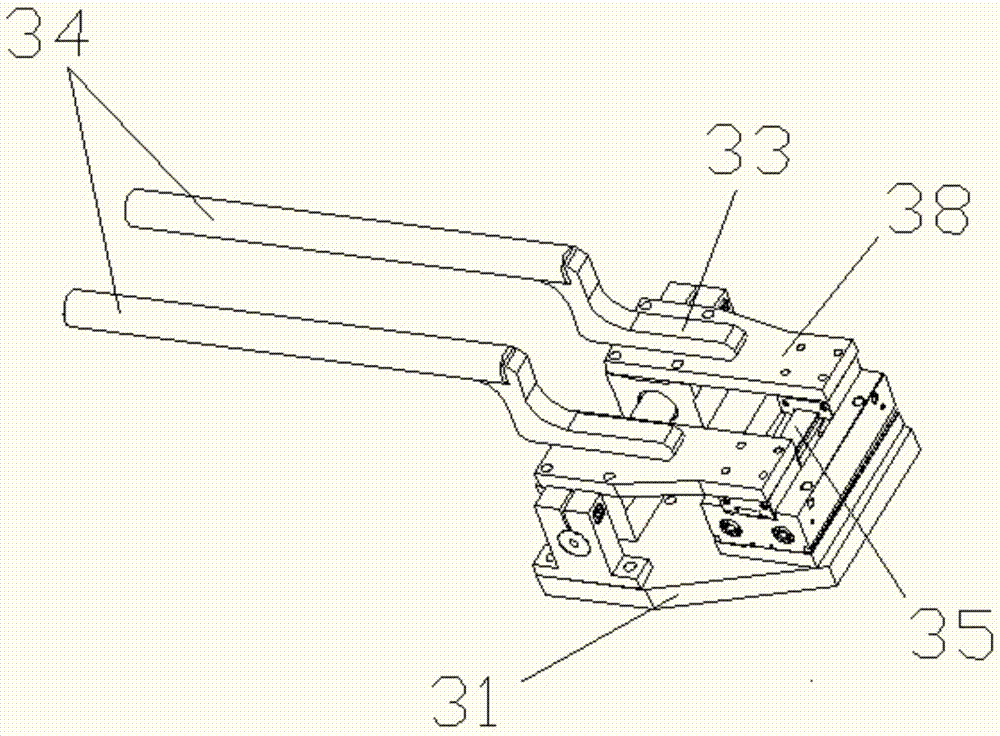

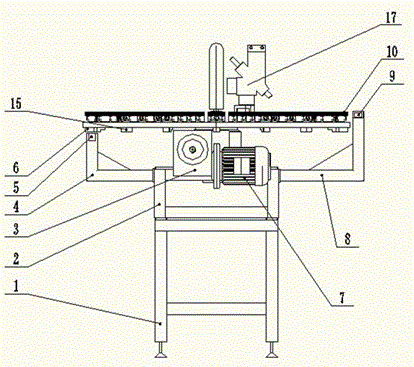

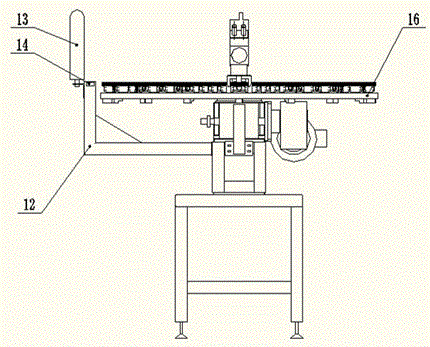

Automatic bearing sound inspection machine

InactiveCN105537147AEasy to operateLow technical requirementsSortingManufacturing cost reductionNoise detection

The invention discloses an automatic bearing sound inspection machine, and belongs to the technical field of rolling bearing vibration, noise detection and sorting technologies. The automatic bearing sound inspection machine comprises a feeding module, a rotating module, a loading module and a locating module. The feeding module comprises a working material channel. The rotating module comprises an A-axis motor, an A-axis spindle, a B-axis motor and a B-axis spindle, wherein the A-axis spindle and the B-axis spindle are installed behind the working material channel; the A-axis motor is connected with the A-axis spindle through a conveying belt; the B-axis motor is connected with the B-axis spindle through a conveying belt; a face turning device is arranged between the A-axis spindle and the B-axis spindle. The automatic bearing sound inspection machine has the advantages that operation is facilitated, the technical requirement for operators is not high, precision consistency of detected products is good, quality is stable, production efficiency and product quality can be remarkably improved, and manufacturing cost is reduced; besides, through the automatic line connection of bearing assembly, automatic detection of bearing vibration and noise detection is achieved.

Owner:HANGZHOU ANDELON EQUIP PROD

Electroplating post-treatment apparatus

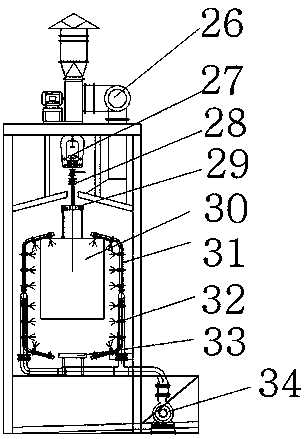

ActiveCN103276423AReduce risks to your healthImprove production automationElectroplatingWaste management

The invention discloses an electroplating post-treatment apparatus, which comprises a treatment tank connected with a lifting device, and a clamper body arranged above the treatment tank and connected with a rotation device capable of intermittently rotating, wherein the treatment tank has an annular shape and is divided into a plurality of treatment sub-tanks along a circumferential direction, and at least a clamper is eccentrically arranged below the clamper body. With the electroplating post-treatment apparatus, a workpiece requiring treatment is fixed on the clamper, the lifting device drives the whole treatment tank to elevate so as to immerse the workpiece in a treatment liquid accommodated in one of the treatment sub-tanks to carry out an electroplating post-treatment, the lifting device drives the treatment tank to descend after completing the treatment so as to separate the workpiece and the treatment liquid, at this time the rotation device drives the whole clamper body to rotate a certain angle, the treatment tank is lifted through the lifting device again, the operations are cycled, and the workpiece is immersed in different treatment liquids to treat according to requirements of the post-treatment step, such that manual operation of a product staff is not required, and production automation is accelerated so as to increase production efficiency and effectively reduce risk on production staff body health.

Owner:四会市东升电镀有限公司

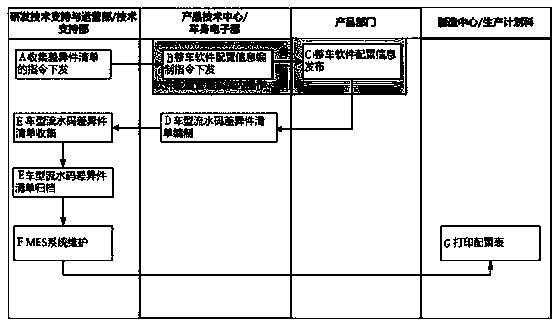

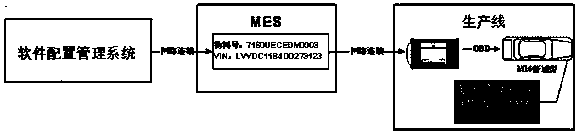

Software configuration method of vehicle control unit

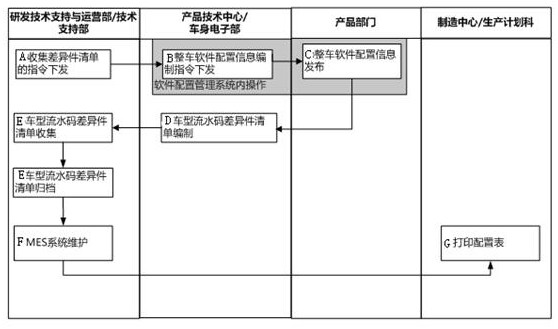

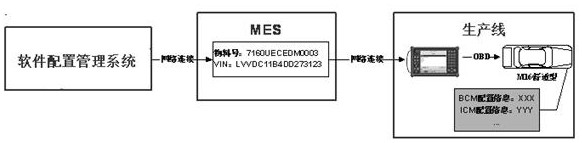

ActiveCN110851174AMeet development requirementsFast and smooth deliveryVersion controlSoftware engineeringSoftware configuration management

According to a software configuration method of a vehicle control unit, the software configuration technology of the vehicle control unit is optimized, and production automation can be improved. According to the software configuration method, by defining the transfer process of software configuration information from research and development to production and the work responsibility of related departments, the process is established to ensure rapid and smooth transfer of whole vehicle software configuration information, and the whole vehicle project development requirement is met; a software configuration technology of a controller is introduced into a software configuration management system, a replacing paper transfer era modeis avoided, professional uploading and recording of software configuration are realized, and the system automatically generates a code and automatically transmits the code to an MES system; off-line equipment automatically obtains configuration information, software configuration can be achieved by scanning VIN codes, and the production efficiency is improved in a whole-process automatic mode.

Owner:CHERY AUTOMOBILE CO LTD

Coating system for jib of section-steel-made crane

PendingCN110270462AIncrease temperatureSpeed up the flowPretreated surfacesCoatingsHeat flowCoating system

The invention provides a coating system for a jib of a section-steel-made crane. The coating system comprises a pretreatment unit, a powder spraying unit and a curing unit. The curing unit comprises a curing chamber for curing spraying and a second strong cooling chamber for cooling after curing. The curing chamber comprises a first chamber and a second chamber. The second chamber is arranged at the front end of the first chamber. A curing platform is arranged in the second chamber. A gas heating device is arranged in the curing platform. Electric heating devices connected in parallel are arranged on the two sides of the upper portion of the curing platform. The gas heating device and the electric heating devices are arranged to effectively complement each other, the gas heating device effectively increases the heat flow and compensates for the defects of poor heat flow and uneven heating of the electric heating devices, and the electric heating devices effectively compensate for the defects that the temperature rises slowly and the temperature is insufficient by the adoption of the gas heating device; and the heating efficiency and the heating uniformity of the jib are effectively improved, the solidification of the powder is facilitated, the generation of cracks is effectively reduced, and the production efficiency is improved.

Owner:湖南星沙机床设备有限公司

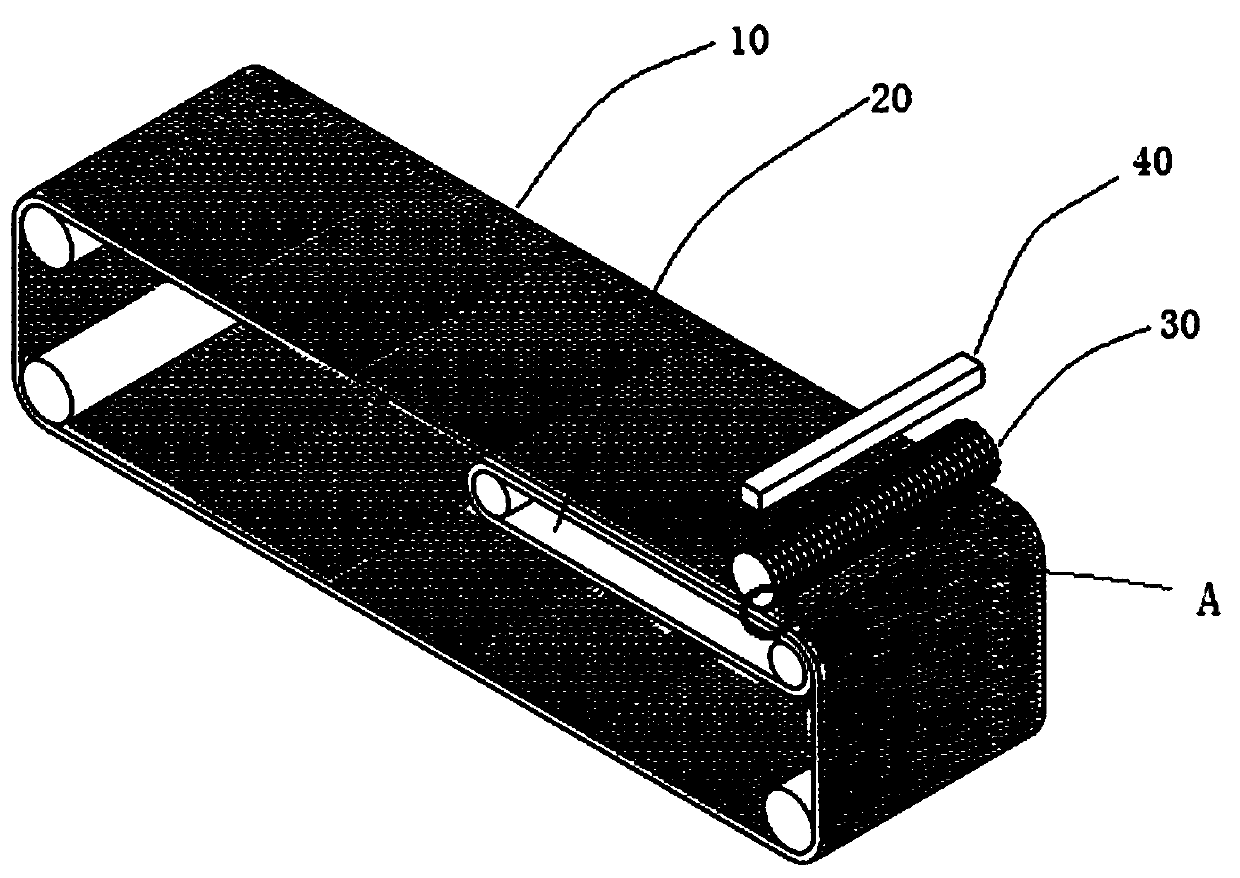

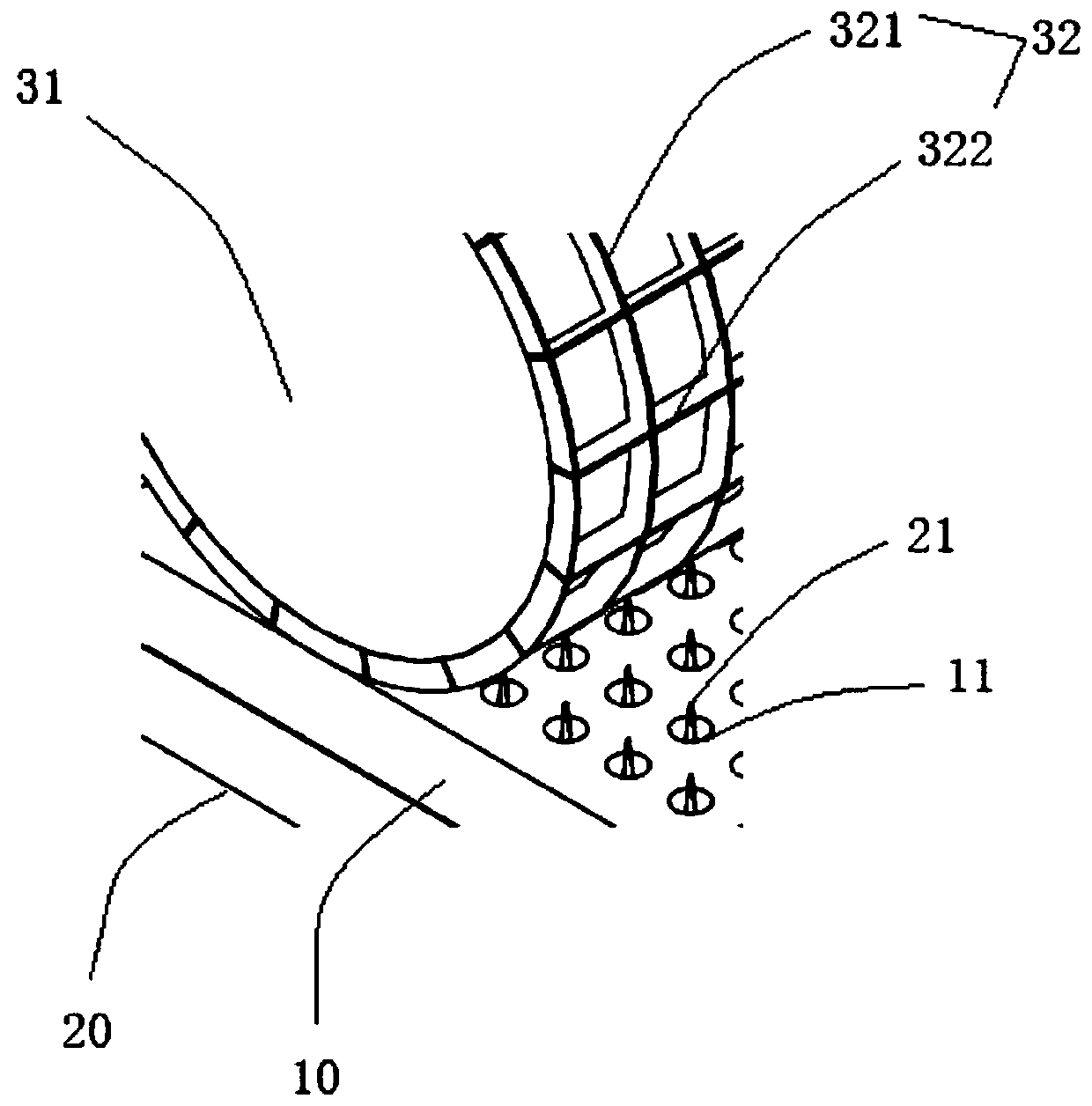

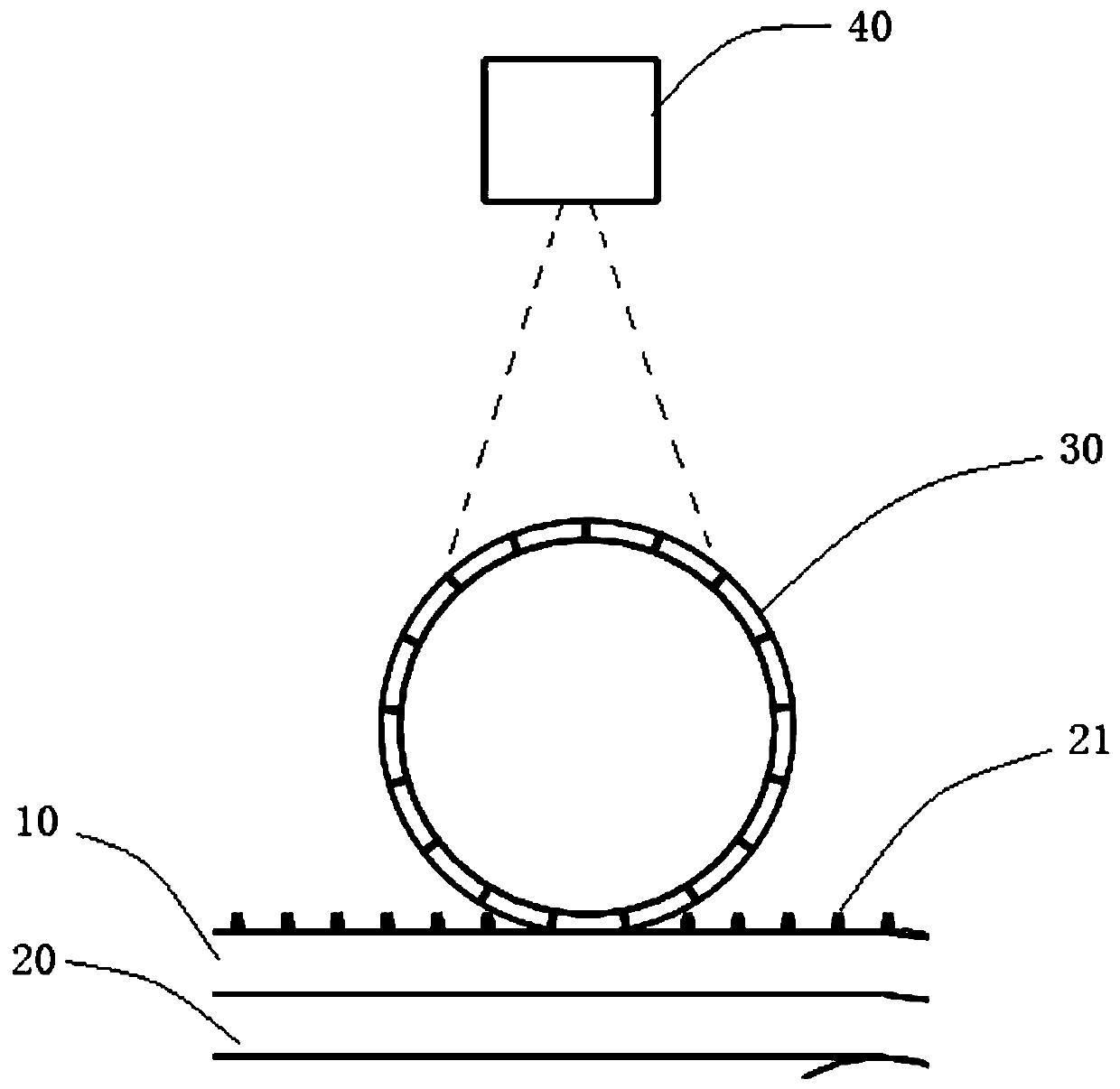

Drum-surface processing device

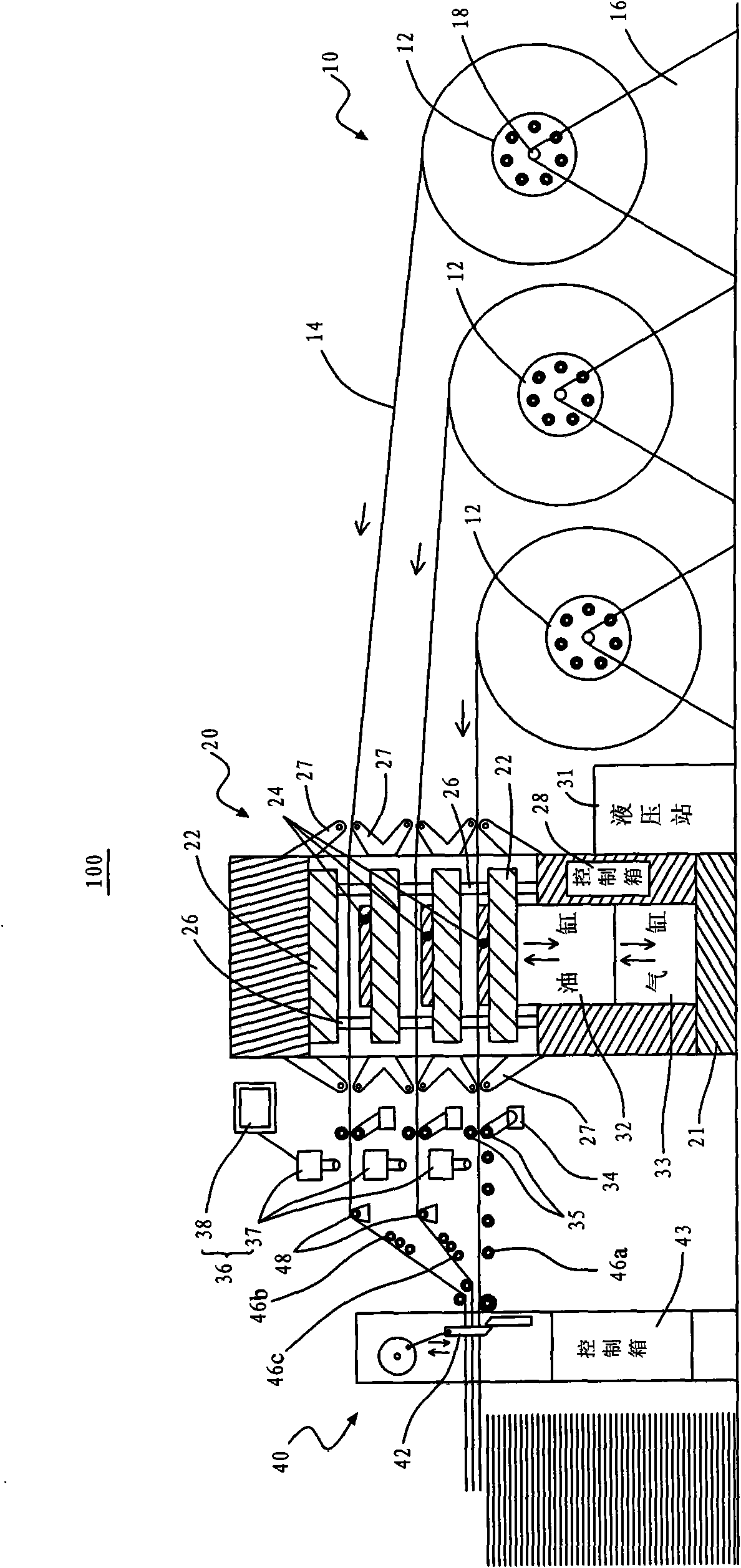

The invention relates to a drum-surface processing device which comprises a drum device for conveying materials to be processed, a hot press, a pressure output device and a dividing and cutting machine, wherein the hot press is used for pressing and modeling the materials conveyed by the drum device, the dividing and cutting machine is used for dividing and cutting the processed material, the hot press is connected in series and interlocked with the dividing and cutting machine and is internally connected in series with a plurality of heating plates and guide posts passing through the plurality of heating plates, and the spaces among the heating plates are divided into a plurality of heating spaces in which dies are arranged; the drum device comprises a plurality of drums corresponding to the heating spaces in amount and used for conveying materials to be processed to the corresponding heating spaces for heating and pressurizing; the pressure output device is located at the outer end of the first heating space that faces outside so as to push the heating plates to move upwards and downwards along the guide posts and combine together or separate from each other; and by pressure transfer, the heating plates are pressurized simultaneously. The device has the advantages of low energy consumption, high efficiency, low heat loss and wide application prospect.

Owner:JINCAI PRINTING & PACKAGING

Winding yarn taking device of yarn winding machine

ActiveCN107032188AAvoid taking one by oneReduce work intensityFilament handlingTextile disintegration and recoveryWinding machineYarn

The invention discloses a winding yarn taking device of a yarn winding machine applied to the technical field of textile equipment. The winding yarn taking device of the yarn winding machine structurally comprises a winding yarn conveying channel, clamping claws and a clamping claw conveying device, wherein the winding yarn conveying channel comprises a winding yarn inlet and a winding yarn outlet, a winding yarn position correcting device is arranged between the winding yarn inlet and the winding yarn outlet, and the winding yarn conveying channel is provided with a conveying device; the clamping claws are arranged at the winding yarn outlet; and the clamping claw conveying device comprises a plurality of conveying mechanisms and a movable piece connected with the clamping claws, the movable piece is provided with a swing device for changing the directions of the clamping claws, and the swing device comprises connecting ends for installing the clamping claws. According to the winding yarn taking device of the yarn winding machine, the process of manually taking out the winding yarns from the discharging port of the yarn winding machine one by one is avoided, the working intensity is reduced, the taking efficiency of the winding yarns is improved, the personal safety of workers is guaranteed, the automation of the production process is promoted, and the continuous proceeding of the processing process is ensured.

Owner:苏州和丰工业设备有限公司

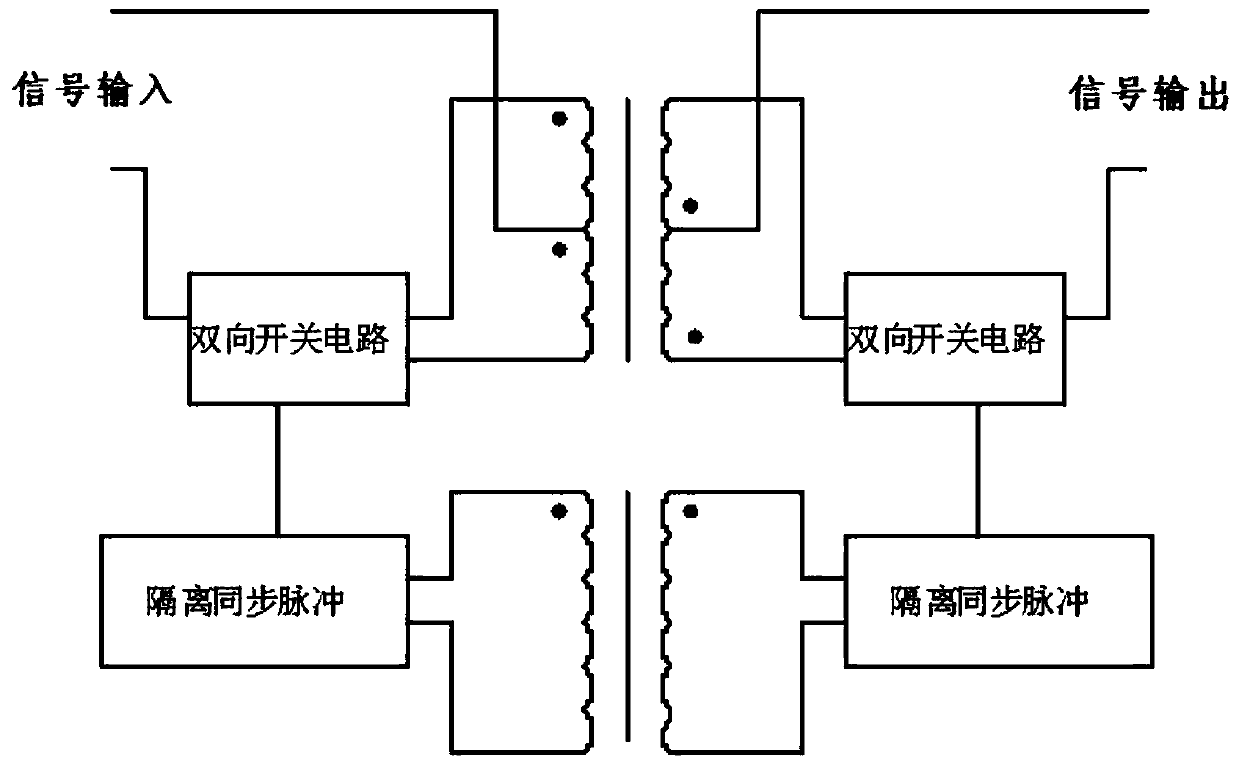

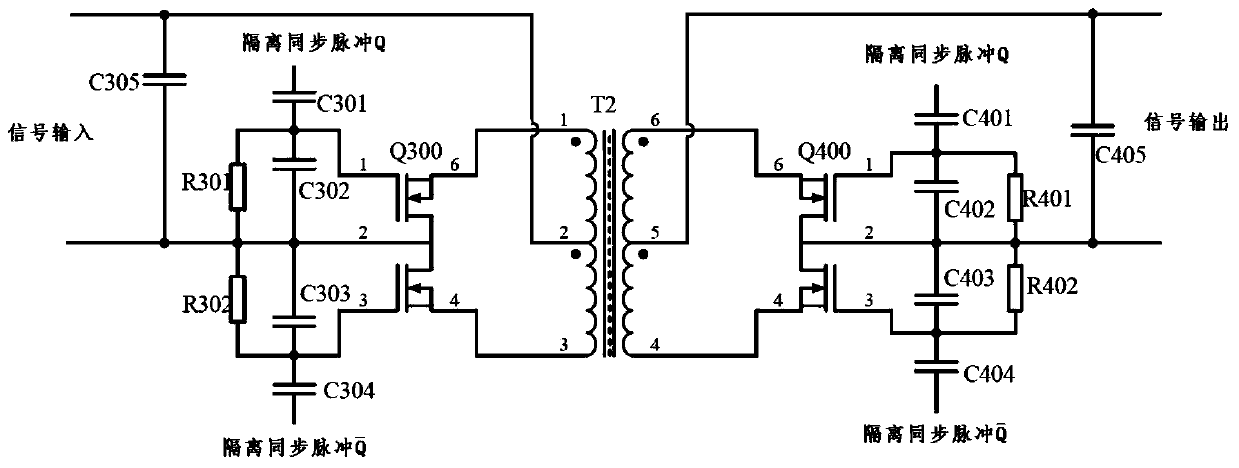

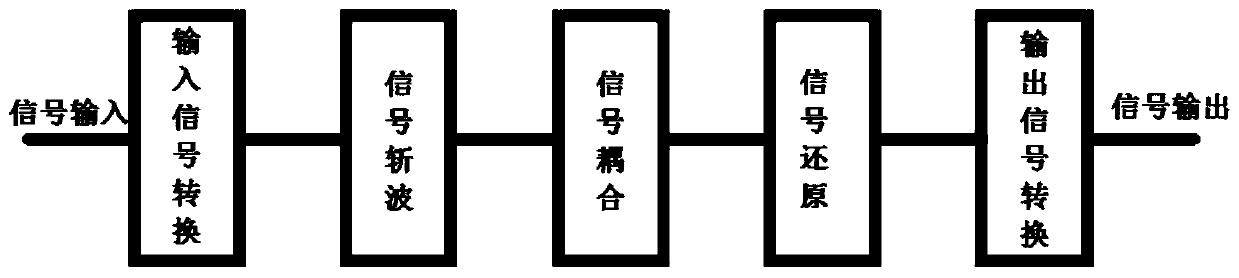

Signal isolation transmission circuit

ActiveCN111082799AReduce volumeRealize PCBizationLogic circuit coupling arrangementsLogic circuit interface arrangementsSquare waveformChopper

The invention provides a signal isolation transmission circuit, and the circuit comprises an input signal conversion circuit used for carrying out proportional operation on a direct current input voltage signal; a signal chopper circuit which is used for converting the direct current voltage signal into a positive and negative voltage square wave pulse signal; a signal coupling circuit which is used for isolating and coupling the positive and negative voltage square wave pulse signal; a signal restoring circuit which is used for restoring the positive and negative voltage square-wave pulse signals into direct-current voltage signals; and an output signal conversion circuit which is used for proportionally amplifying the voltage signal generated by the reduction circuit and outputting the amplified voltage signal. According to the invention, a direct-current input voltage signal in the circuit is converted into a positive and negative bipolar model after passing through the chopper circuit, single-winding signal isolation transmission of the signal isolation transformer in the signal coupling circuit can be realized, and the number of windings and the number of turns of the transformer can be greatly reduced, so the size of the transformer is reduced, the production process difficulty is reduced, and the production cost is greatly reduced.

Owner:MORNSUN GUANGZHOU SCI & TECH

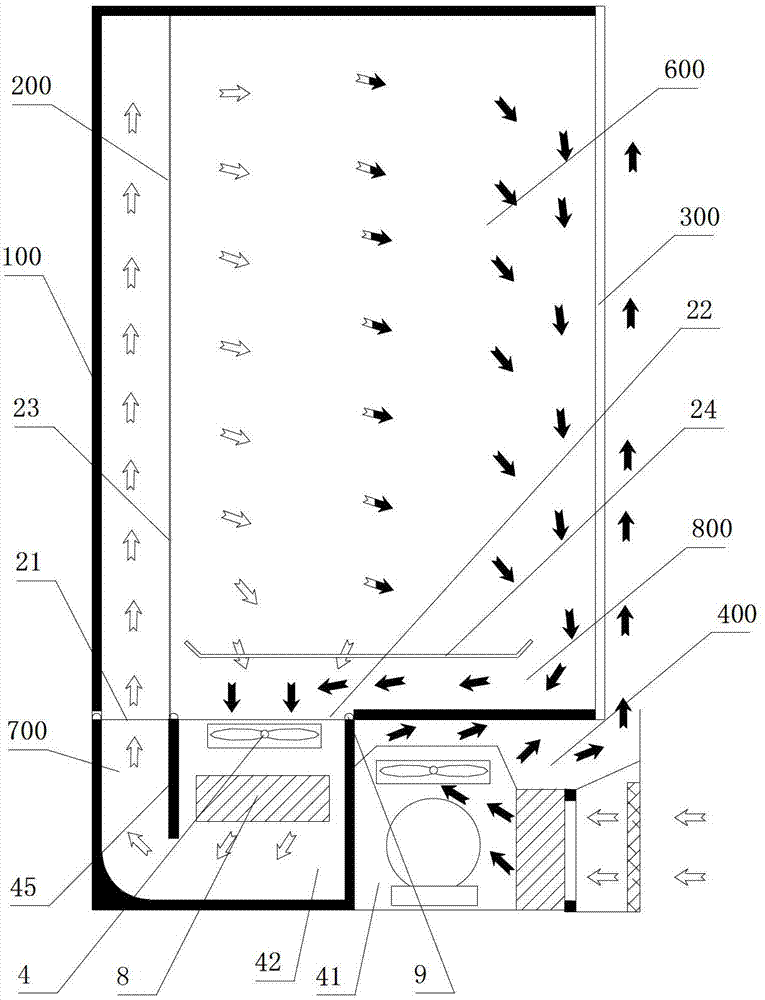

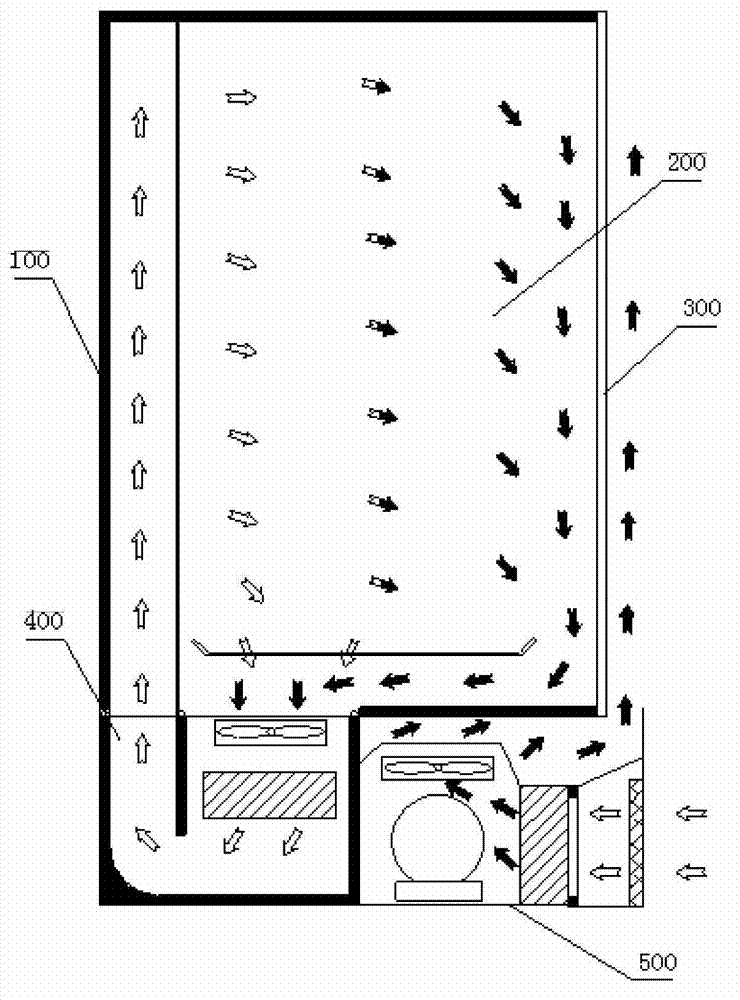

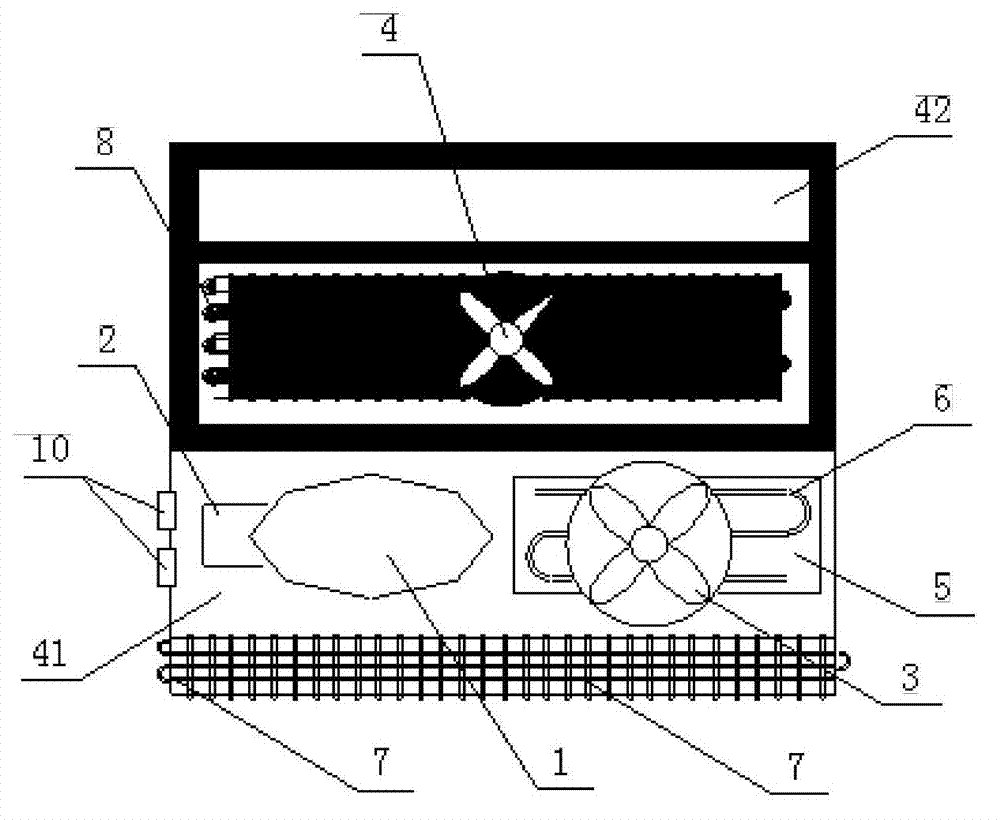

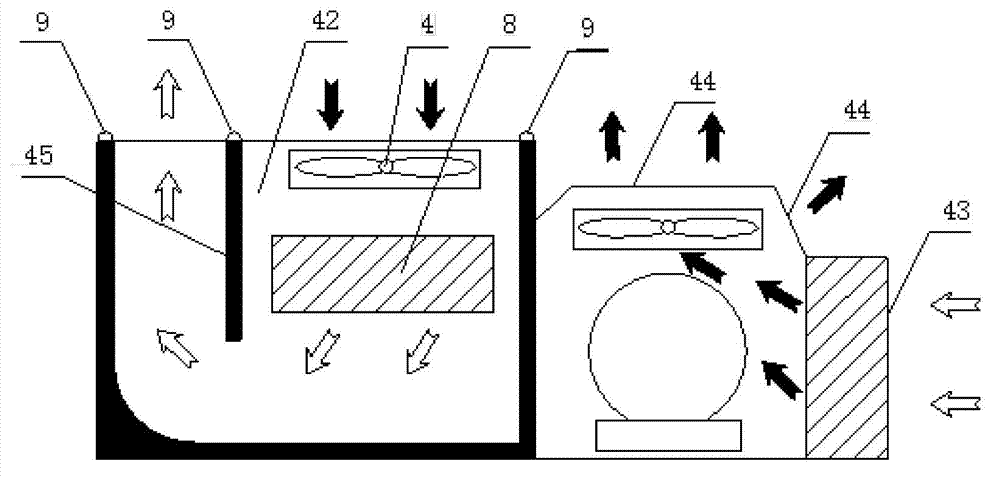

Refrigerator with independent refrigeration and usage method and manufacture method thereof

ActiveCN103082752ADoes not affect continuous useImprove freshnessShow cabinetsLighting and heating apparatusRefrigerator carContinuous use

The invention discloses a refrigerator with independent refrigeration and a usage method and a manufacture method of the refrigerator. An independent refrigerating unit is adopted. The refrigerating unit comprises major refrigerating parts like an evaporating set and a condensing set. When the refrigerator is under a using state, an evaporating room of the refrigerating unit and a circular air channel on the interior of a refrigerator body are in a butt joint, and the refrigerating unit and the refrigerator body are in electric signal connection of a power source and a control system. When the refrigerator is maintained, the refrigerating unit can be completely drawn out from the interior of the refrigerator body, continuous utilization of the refrigerator is not affected through direct replacement of a refrigerating unit with the same model, and the degree of food fresh keeping is improved. The refrigerating unit is provided with an independent integral structure and installed on the interior of the refrigerator body or completely drawn out from the interior of the refrigerator body. In a storage room, an air deflector with a plurality of air ports is arranged on one side of an air inlet along the air inletting direction. The air deflector extends from the top end of the storage room to the bottom end of the storage room along the vertical direction. A bottom tray is arranged along the vertical direction of an air outlet where air is led out and used for blocking airflow to be directly led out.

Owner:青岛海力商用电器有限公司

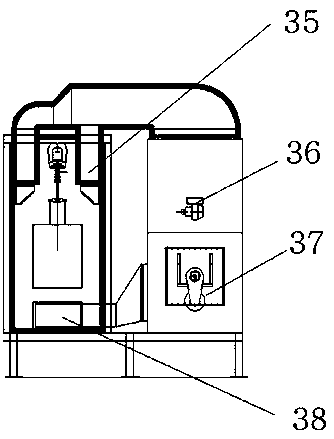

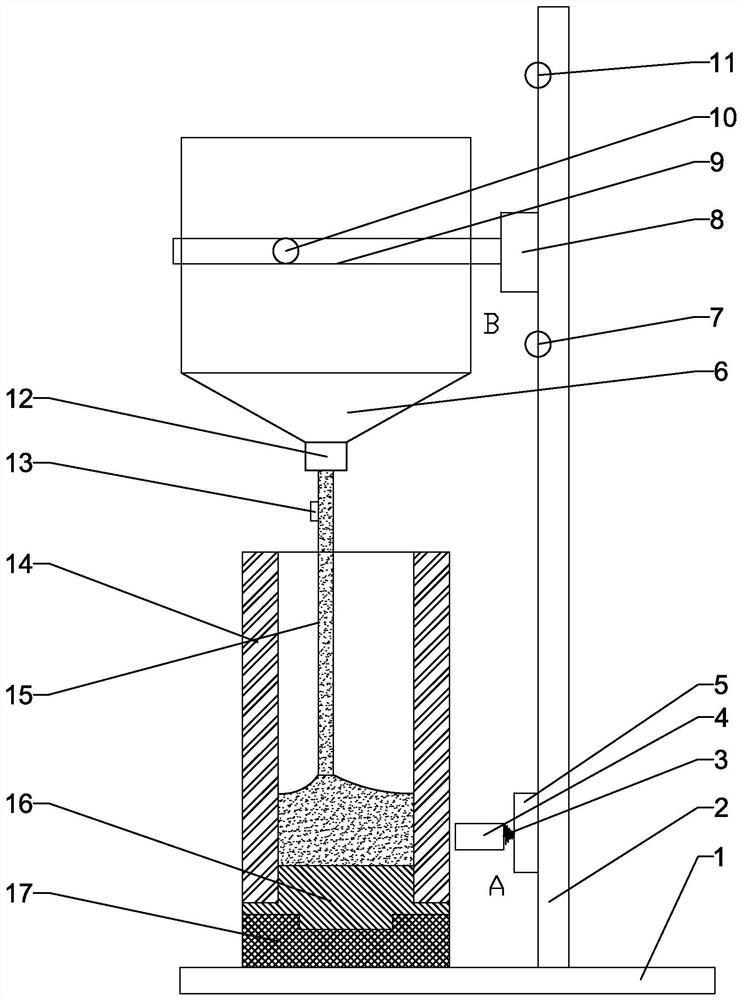

Isostatic pressing soft die sleeve weight-limiting isovolumetric powder filling process and device

The invention discloses an isostatic pressing soft die sleeve weight-limiting isovolumetric powder filling process and device. The process adopts the cooperation of spiral powder filling and synchronous rapping, adopts a multi-section feeding mode, and realizes the weight-limiting isovolumetric powder filling of hard alloy isostatic pressing powder through the real-time monitoring of the powder density and the variable-frequency ultrasonic compaction. According to the process, the powder density uniformity of all positions in a die sleeve in the powder loading process can be improved, the diameter difference of a final pressed blank at different positions is reduced, the roundness and cylindricity of the pressed blank are improved, and the casting yield and the size controllability of a rod blank are improved.

Owner:厦门金鹭硬质合金有限公司

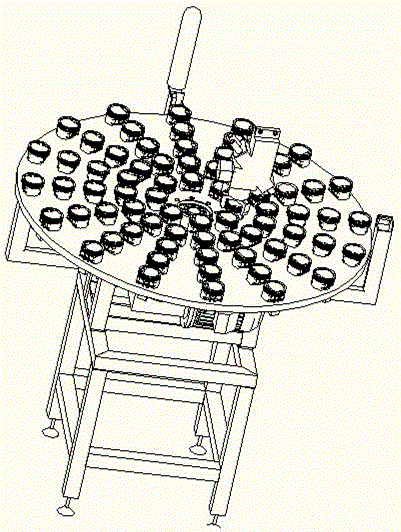

Automatic feeding equipment capable of storing aluminum pistons and production method of automatic feeding equipment

The invention provides automatic feeding equipment capable of storing aluminum pistons and a production method of the automatic feeding equipment, relates to the field of automatic feeding of aluminum pistons, and belongs to equipment capable of storing pistons well at a time and classifying and feeding the pistons step by step as well as a production method. The automatic feeding equipment comprises an equal divider (3) and a base (1), wherein the equal divider is mounted on the base; a material tray (16) is arranged above the equal divider, and equipped with a blank feature identification tooling; the blank feature identification tooling comprises a piston inner-cavity positioning block (11); a station distinction-detection tooling and a material existence detection tooling are arranged on two sides of the equal divider; and the station distinction-detection tooling comprises a station detection mounting arm (4), a station detection proximity switch (5) and a station detection block. The automatic feeding equipment provided by the invention has the positive effects that both material resources and the manpower are saved, the labor intensity is reduced, and the automated piston production is improved.

Owner:SHANDONG SHUANGGANG PISTON

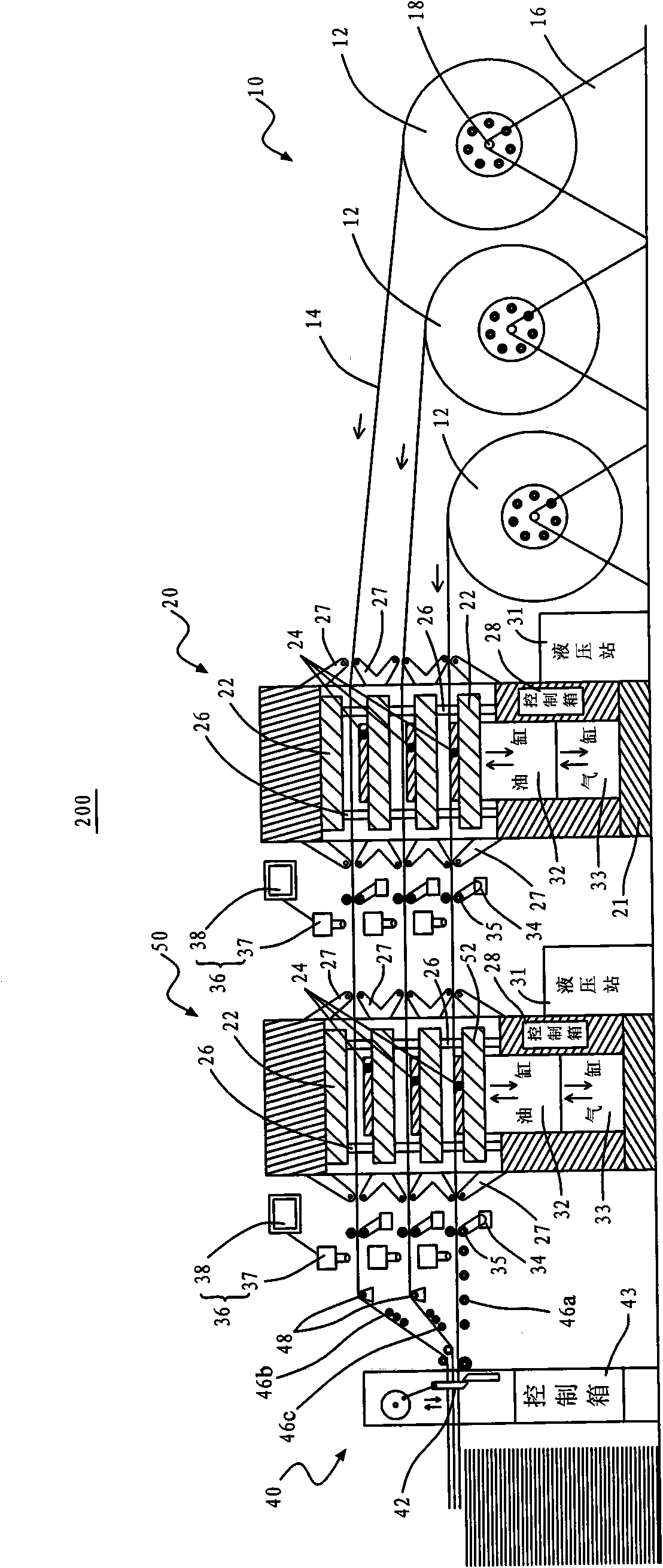

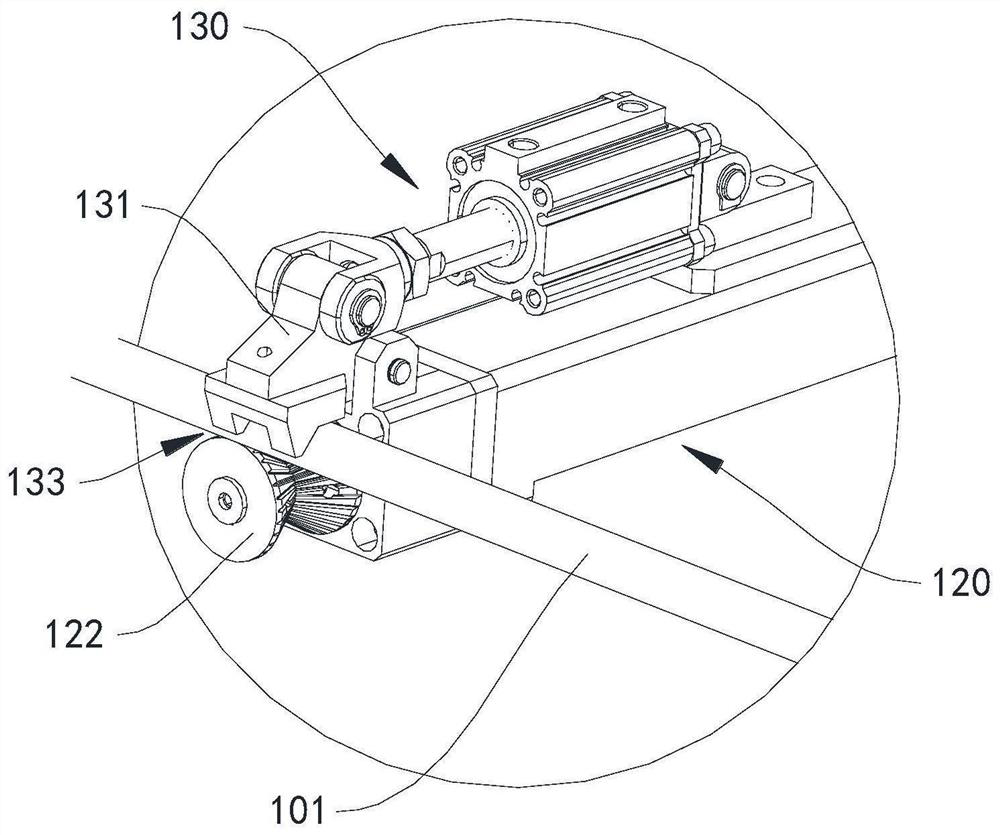

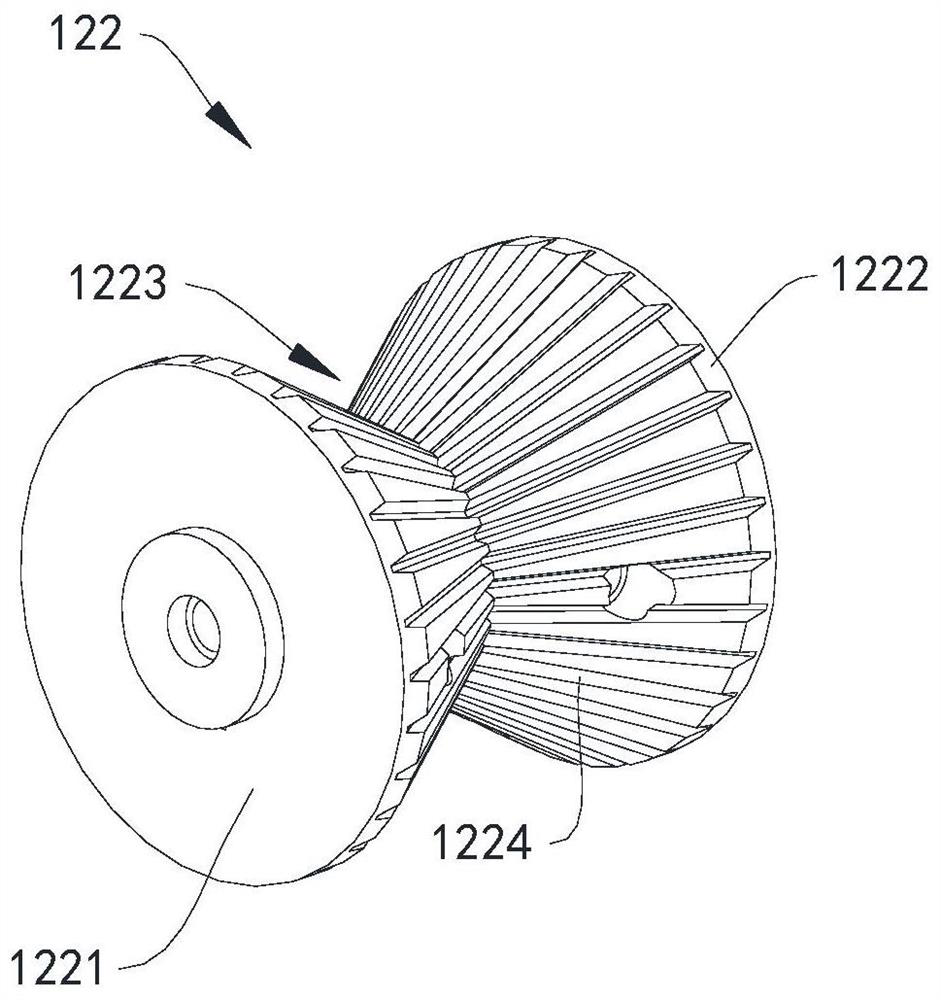

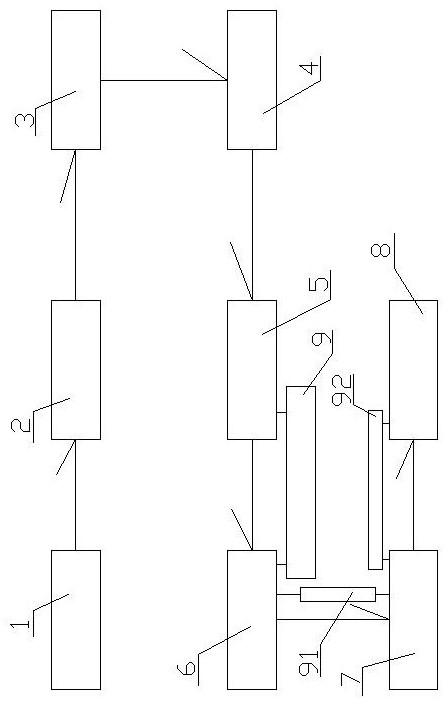

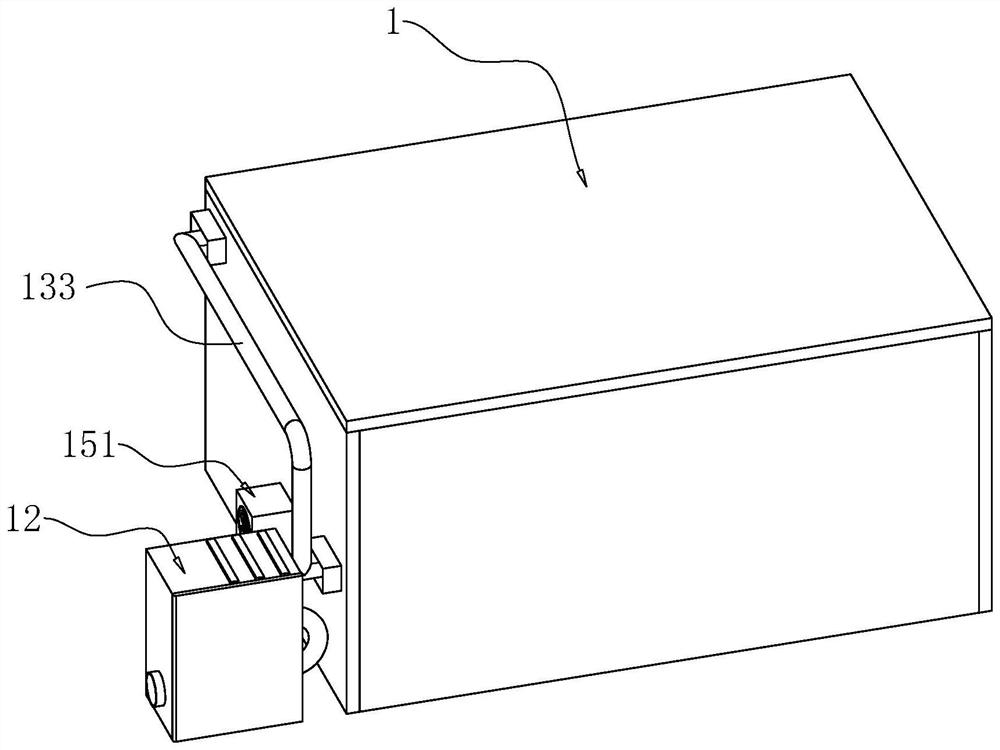

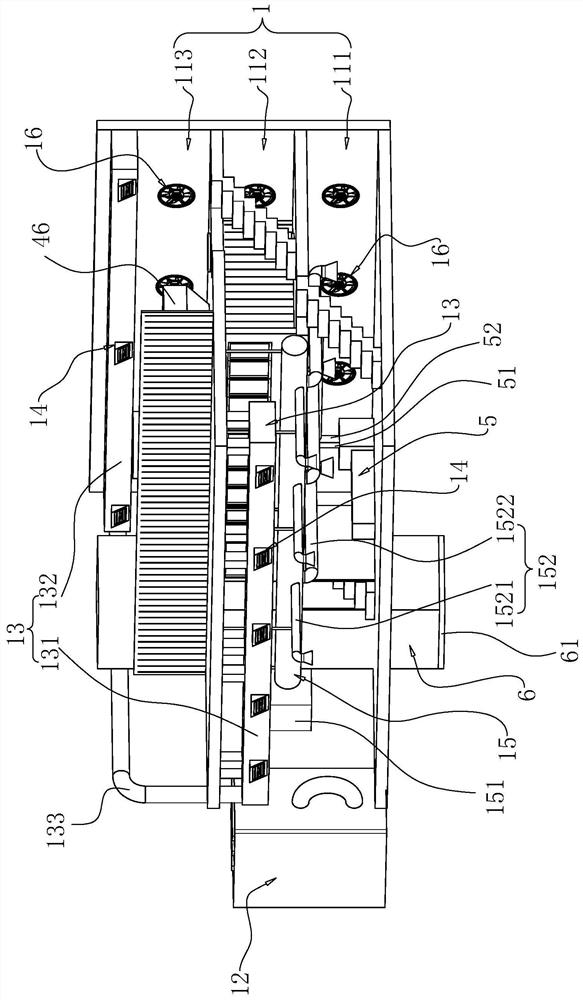

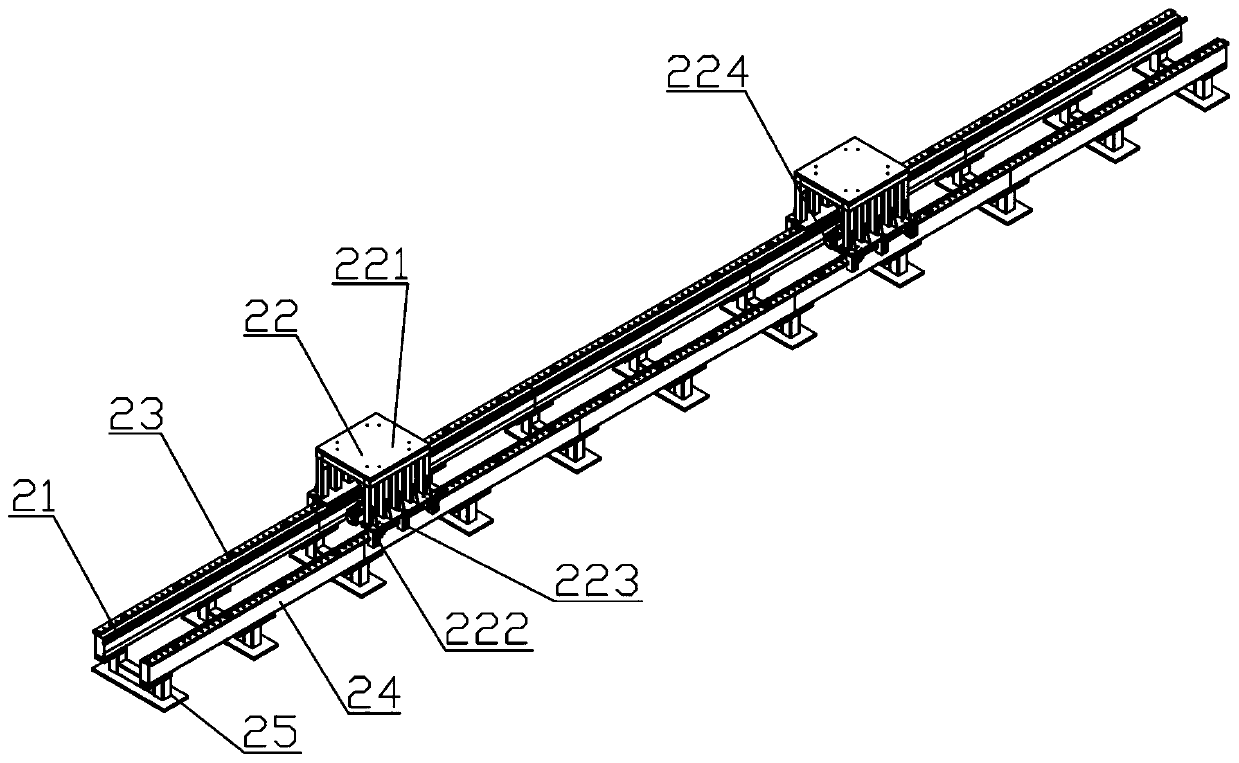

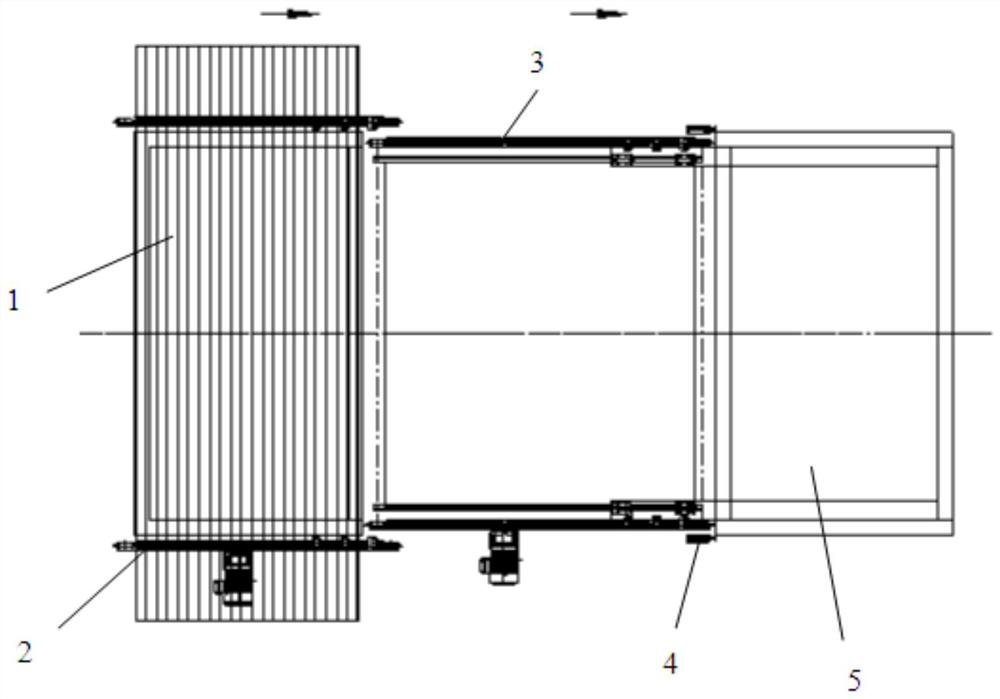

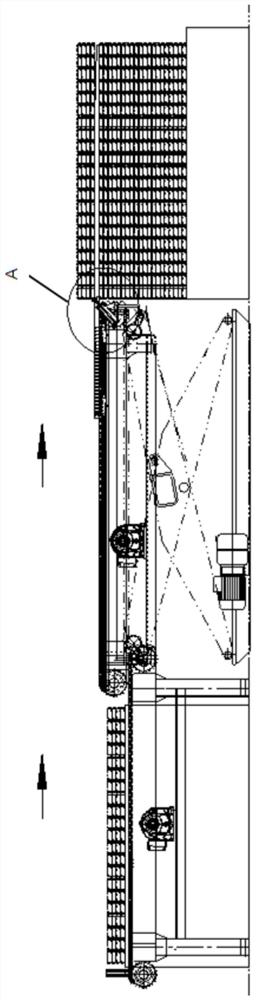

Longitudinal bar transporting positioning device and welding forming equipment

ActiveCN111842729AReduce demandRealize intelligenceWire networkControl engineeringStructural engineering

The embodiment of the invention provides a longitudinal bar transporting positioning device and welding forming equipment, and belongs to the technical field of architecture reinforcement cage machining. The longitudinal bar transporting positioning device includes a rack, a transporting mechanism, and a clamping mechanism, the transporting mechanism is arranged on the rack, the transporting mechanism includes a transporting wheel, and a first transmission assembly connected with the transporting wheel in a transmission mode, the first transmission assembly is used to drive the transporting wheel to rotate, and the clamping mechanism is connected with the transporting mechanism. The clamping mechanism includes a clamping part, and the clamping part can move relative to the transporting wheel, so that the clamping part is provided with a clamping state and an opening state. When the clamping part is in the clamping state, the clamping part is matched with the transporting wheel to forma clamping chamber for fixing longitudinal bars, and when the clamping part is in the opening state, the first transmission assembly drives the transporting wheel to rotate to transport the longitudinal bars. The longitudinal bar transporting positioning device achieves the purposes that the longitudinal bars can be transported automatically, and transported to an appropriate position to be clamped and positioned, the intelligence can be improved, the reliability is high, the labor strength of an operator is reduced, and the safety hazards can be lowered.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Raw material, preparation device and method for preparing foamed ceramic insulation board based on rolling method

PendingCN113185317AReduce usageReduced likelihood of hot crackingPress rollersCeramic materials productionKilnRaw material

The invention discloses a raw material, preparation device and method for preparing a foamed ceramic insulation board based on a rolling method. The preparation device comprises a rolling device (6) for carrying out rolling forming on the raw material of the foamed ceramic insulation board, an annealing kiln (7) which is connected with the rolling device (6) and is used for carrying out solidification treatment on the foamed ceramic insulation board; the roller plate forming of the raw material of the foamed ceramic insulation board is realized through the rolling device (6); and the cooling aggregation shaping is realized through the annealing kiln (7), and a mold is not needed for shaping any more, so that the production efficiency of preparing the foamed ceramic insulation board is improved.

Owner:内蒙古建亨能源科技有限公司

Three-layer type plastic master batch processing system

PendingCN111907028ASmall footprintAvoid flyingLighting and heating apparatusLarge containersProcess engineeringSmall footprint

The invention relates to the field of plastic processing equipment, and in particular relates to a three-layer type plastic master batch processing system which comprises a workshop, a batching deviceused for temporarily storing raw material, a weighing device used for weighing the raw material, a stirring device used for pre-stirring auxiliary material and a plastic extruder, wherein the workshop comprises a first floor, a second floor and a third floor; the batching device is arranged on the third floor, the weighing device and the stirring device are arranged on the second floor, the plastic extruder is arranged on the first floor, the plastic extruder comprises a main material filling hopper and an auxiliary material filling hopper, the lower portion of the batching device is connected with the upper portion of the weighing device, the lower portion of the weighing device is connected with the main material filling hopper, a feeding end of the stirring device is arranged on the third floor, and the lower portion of the stirring device is connected with the auxiliary material filling hopper. The three-layer type plastic master batch processing system is small in workshop floorarea, prevents dust pollution, is convenient for workers to operate and maintain, and does not need to work high above the ground; the materials are conveyed from the top down, and conveying efficiency is high.

Owner:东莞市鼎誉新材料有限公司

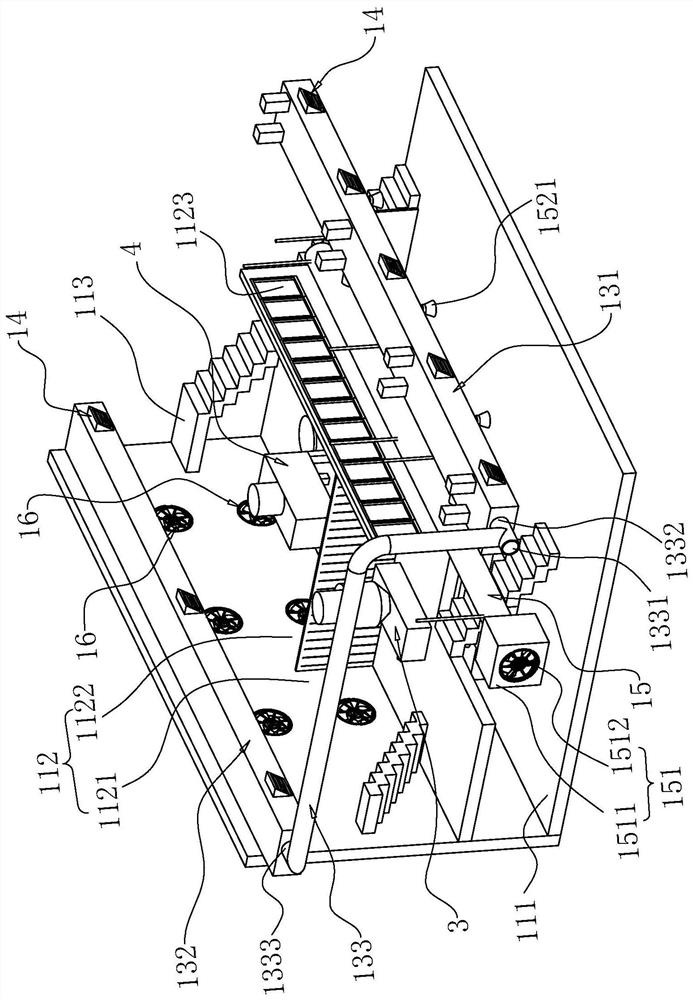

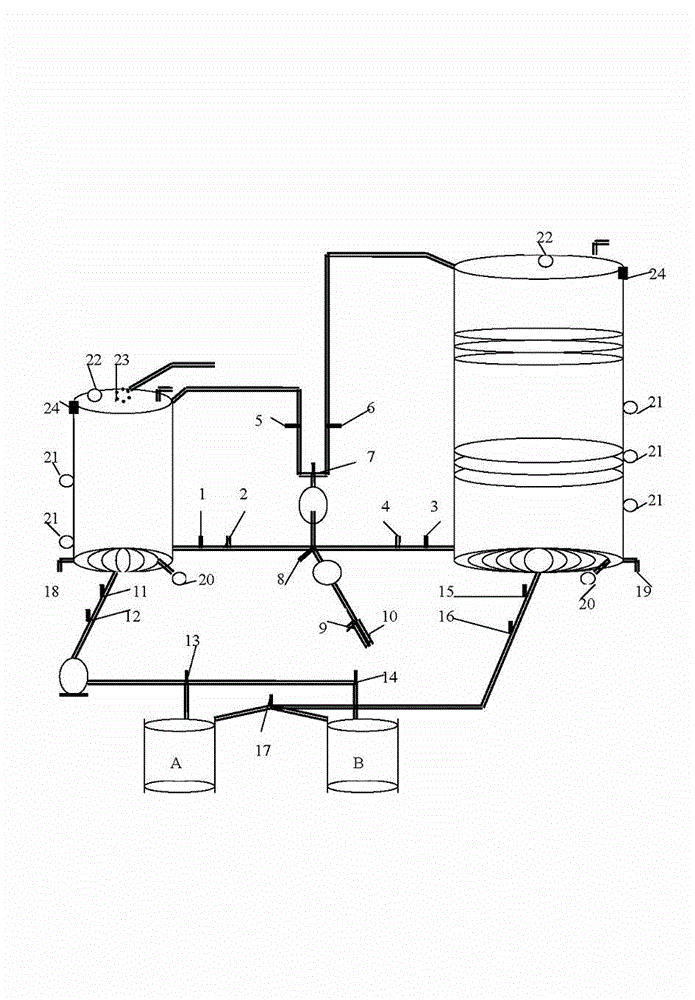

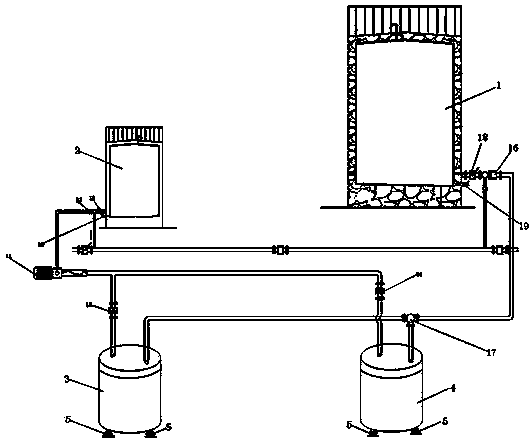

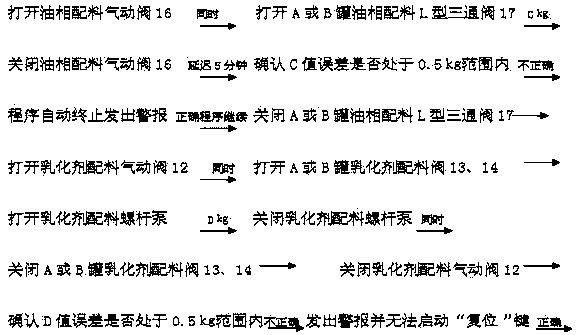

Automatic safety monitoring system of liquid composite wax and emulsifier feed and storage

InactiveCN102749879ASave human effortImprove production automationProgramme control in sequence/logic controllersSimultaneous control of multiple variablesWaxLiquid state

The invention discloses an automatic safety monitoring system of liquid composite wax and emulsifier feed and storage, and the system comprises a feed corrugated pipe sealing butt joint buckle in butt joint communication with the discharge opening of a tank car, a liquid composite wax storage tank, an emulsifier storage tank, a feeding or circulating shared chemical pump and an automatic safety monitoring device, wherein the feed corrugated pipe sealing butt joint buckle is connected with a feed high pressure scavenging manual valve, the feed high pressure scavenging manual valve is connected with a liquid composite wax and emulsifier feed and circulation four-way valve, and the two ends of the liquid composite wax and emulsifier feed and circulation four-way valve are respectively connected with the liquid composite wax storage tank and the emulsifier storage tank through a liquid composite wax and emulsifier circulation manual valve and a liquid composite wax and emulsifier circulation high pressure scavenging manual valve. The automatic safety monitoring system of liquid composite wax and emulsifier feed and storage disclosed by the invention has the advantages of high essence safety, simple production process, low production cost, high production efficiency and the capability of reducing the environmental pollution, etc.

Owner:GUANGDONG ZHENSHENG PACKAGING TECH

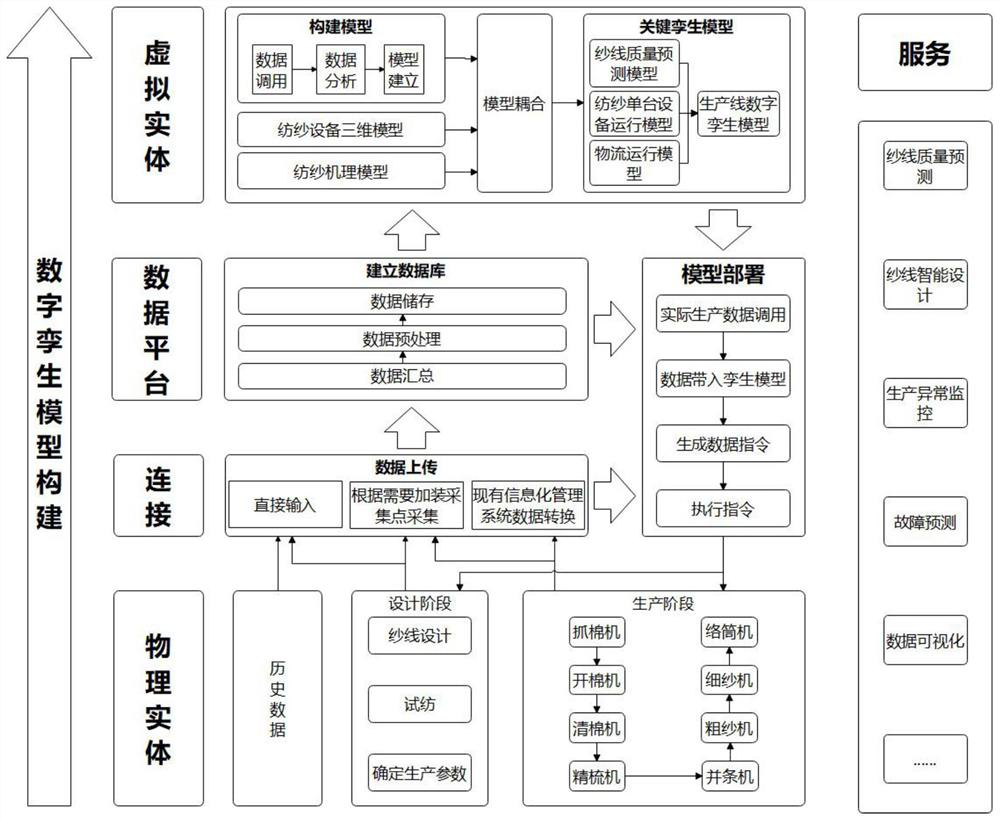

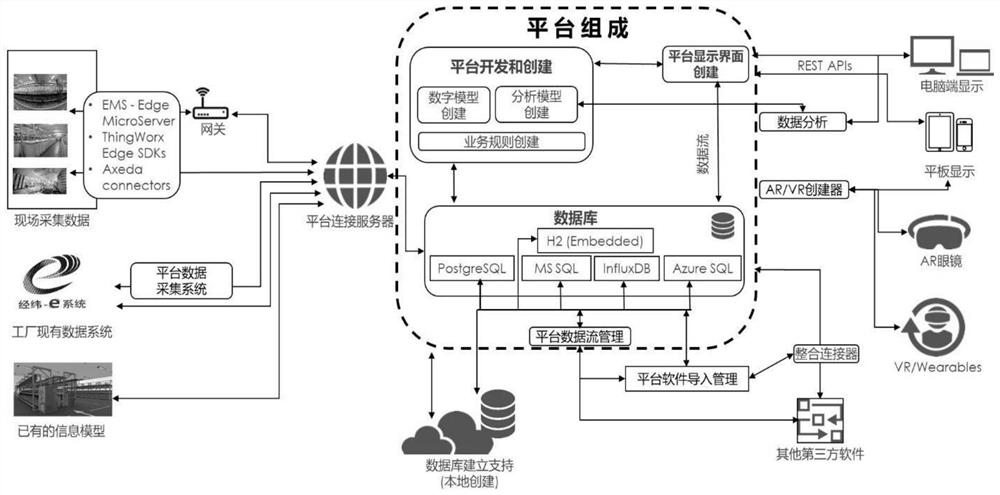

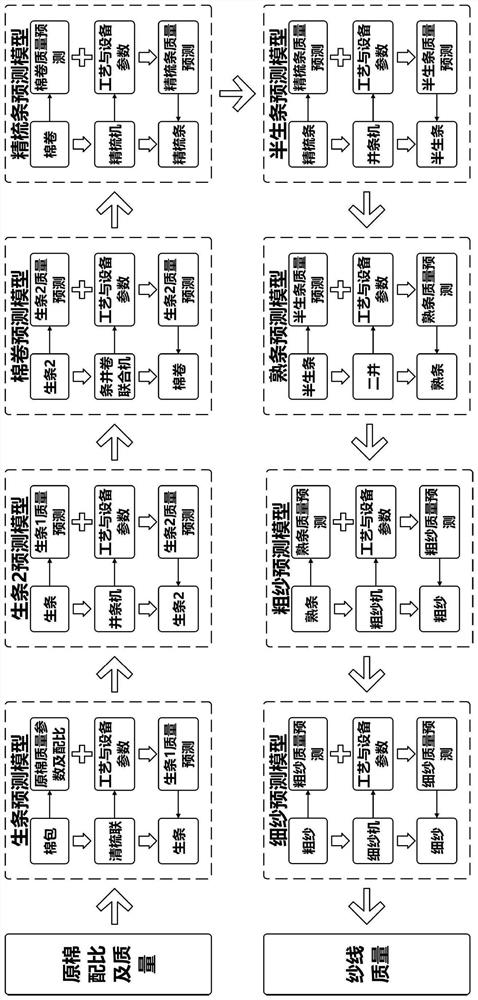

Spinning digital twin architecture system and implementation method thereof

PendingCN114547889AQuality improvementImprove design efficiencyDigital data information retrievalDesign optimisation/simulationYarnLogistics management

The invention discloses a spinning digital twinning architecture system and an implementation method thereof, and belongs to the field of spinning production, the spinning digital twinning architecture system comprises a physical entity, a connection part, a data platform, a virtual entity and a model deployment part which are matched with one another, and a twinning model in the virtual entity is constructed by calling data of the data platform. A twinning model and a spinning mechanism model are fused to construct a key digital twinning model, namely a yarn quality prediction model, a spinning single equipment operation model and a logistics operation model, and the three sub-models jointly form a production line digital twinning model. According to the method, the yarn design efficiency can be improved to a certain extent, the yarn production quality is improved, and the yarn quality production stability is improved. Meanwhile, the application of digital twinning in spinning production has important significance on transformation and upgrading of production in the spinning field, and a good demonstration and reference thought is provided for intelligent manufacturing in other fields of the textile industry.

Owner:TIANJIN POLYTECHNIC UNIV

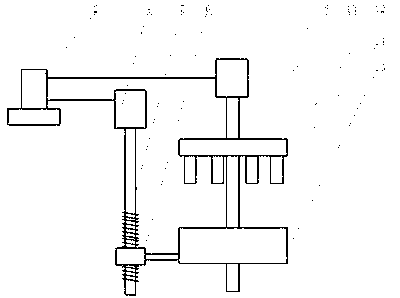

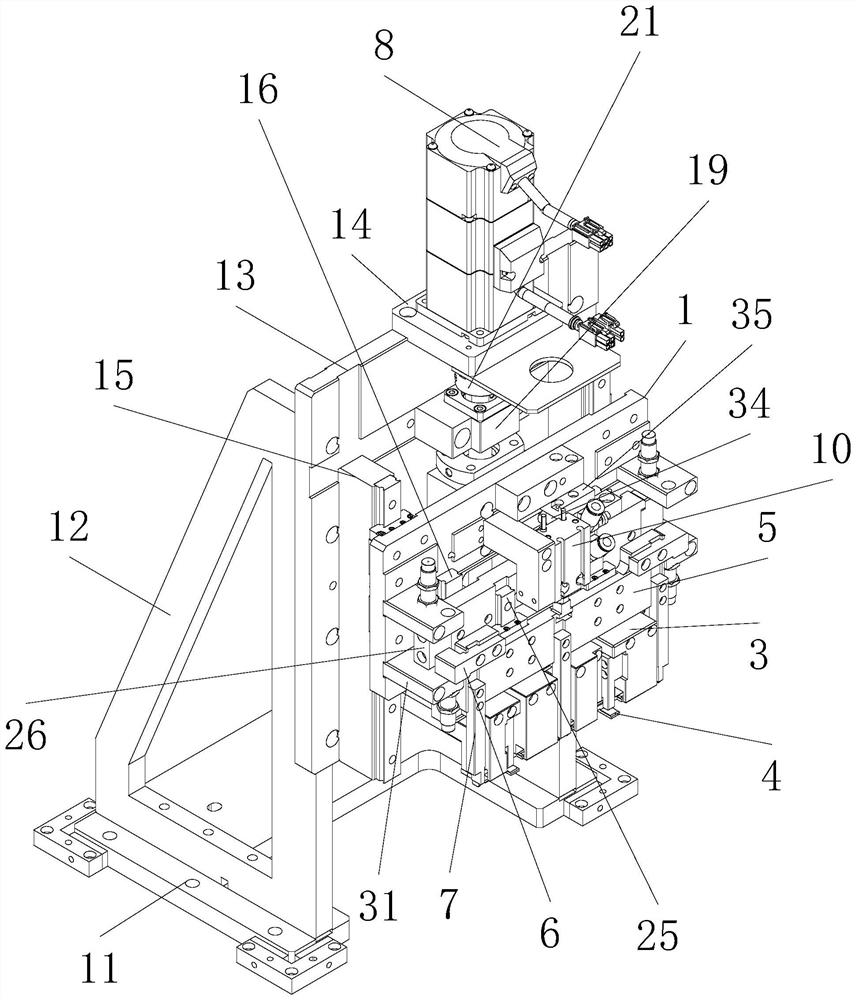

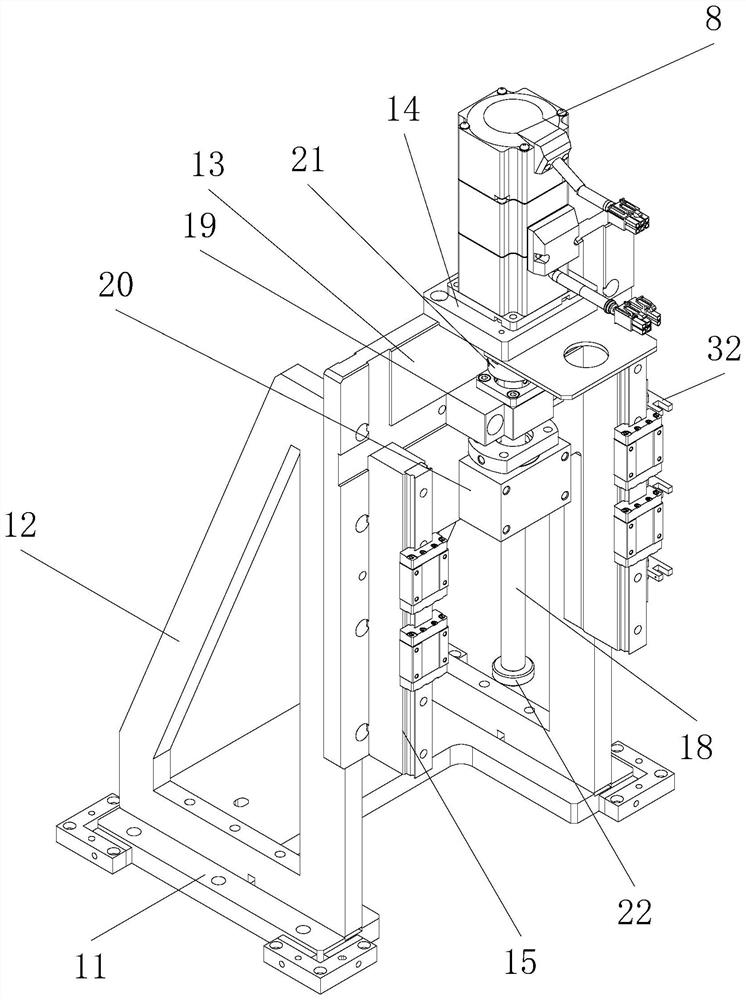

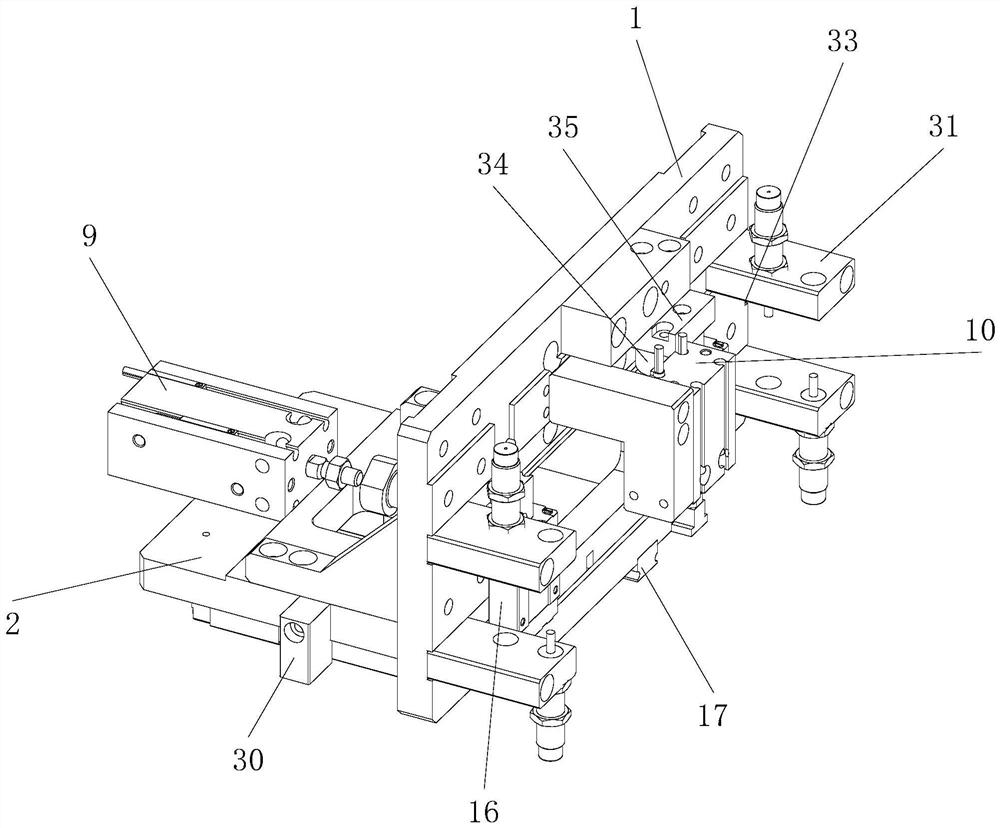

Up-down clamping mechanism

PendingCN114852669ACompact structureReduce in quantityFinal product manufactureConveyor partsEngineeringPower apparatus

The invention relates to an up-down clamping mechanism, and belongs to the technical field of mechanical automation. The clamping device comprises a support, a sliding device, an upper clamping jaw device, a lower clamping jaw device and a power device. The sliding device is slidably mounted on the bracket; the sliding device is provided with a transverse plate and a vertical plate; the upper clamping jaw device is provided with an upper clamping jaw and slidably installed on the vertical plate, and the lower clamping jaw device is provided with a lower clamping jaw and slidably installed on the transverse plate. The sliding device is driven by the power device to slide between the material taking station and the material placing station in a reciprocating mode in the radial direction. At the material taking station, the upper clamping jaw device is driven by the power device to slide on the vertical plate in the radial direction, and the upper clamping jaw is driven to slide towards the upper end of the product; the lower clamping jaw device is driven by the power device to slide on the transverse plate in the horizontal direction, drives the lower clamping jaw to slide towards the lower end of a product and is matched with the upper clamping jaw to clamp the product, then the lower clamping jaw device slides to a discharging station in the radial direction through the sliding device, the product is released through the upper clamping jaw and the lower clamping jaw, and clamping and transferring work of the product is completed.

Owner:成都铭毅智能科技有限公司

Refrigerator with draw-out type refrigerating unit and usage method and manufacture method thereof

ActiveCN103082751ADoes not affect continuous useImprove freshnessShow cabinetsLighting and heating apparatusElectricityRefrigerator car

The invention discloses a refrigerator with a draw-out type refrigerating unit and a usage method and a manufacture method of the refrigerator. The independent refrigerating unit is adopted. The refrigerating unit comprises major refrigerating parts like an evaporating set and a condensing set. When the refrigerator is under a using state, an evaporating room of the refrigerating unit and a circular air channel on the interior of a refrigerator body are in a butt joint, and the refrigerating unit and the refrigerator body are in electric signal connection of a power source and a control system. When the refrigerator is maintained, the refrigerating unit can be completely drawn out from the interior of the refrigerator body, an overhaul is carried out without limitation of a spatial condition, continuous utilization of the refrigerator is not affected through direct replacement of a refrigerating unit with the same model, and the degree of food fresh keeping is improved. The refrigerating unit is provided with a condensing room and the evaporating room which are separated from each other and communicated with a refrigerant circulating pipeline. The refrigerating unit is installed on the refrigerator body. A sealed butt joint structure is formed by the evaporating room and a storage room. The refrigerating unit is provided with an electric connector used for connection with the refrigerator power source and the control system. The electric connector is communicated with each refrigerating part.

Owner:青岛海力商用电器有限公司

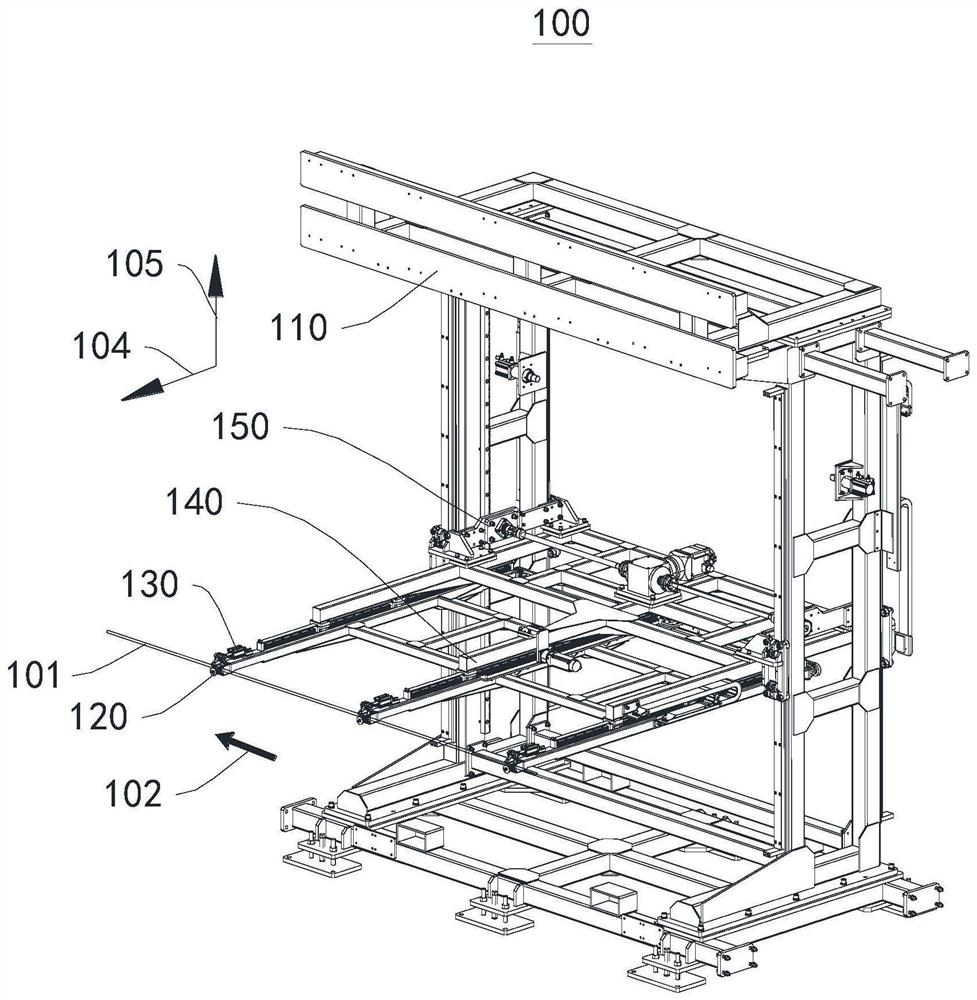

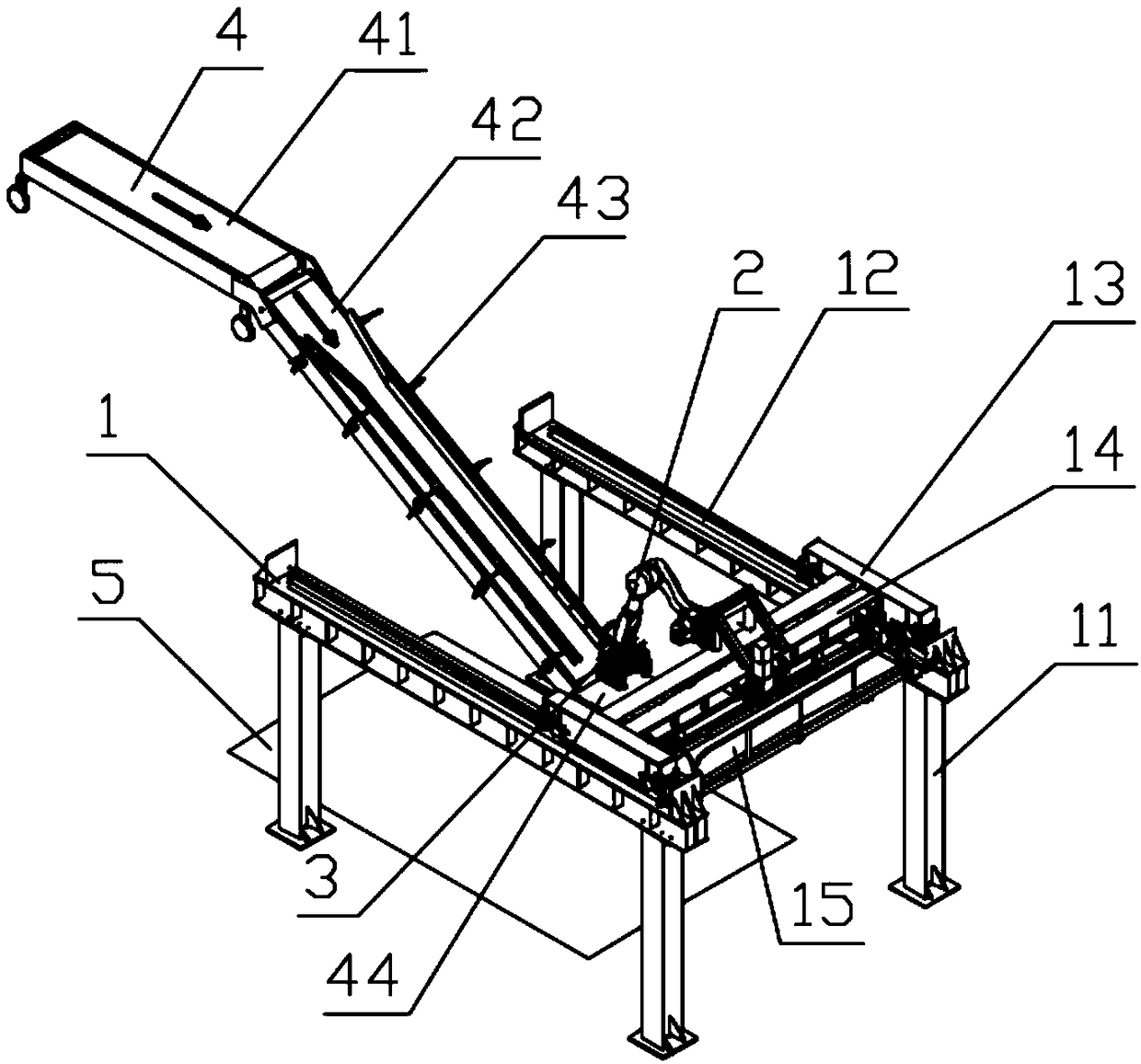

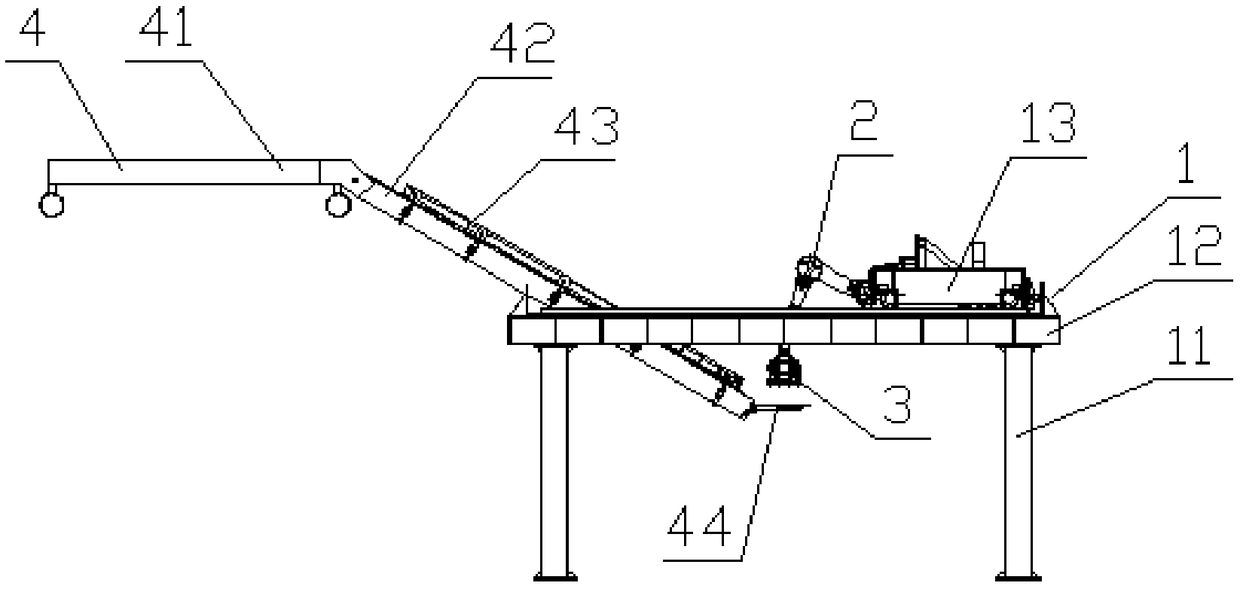

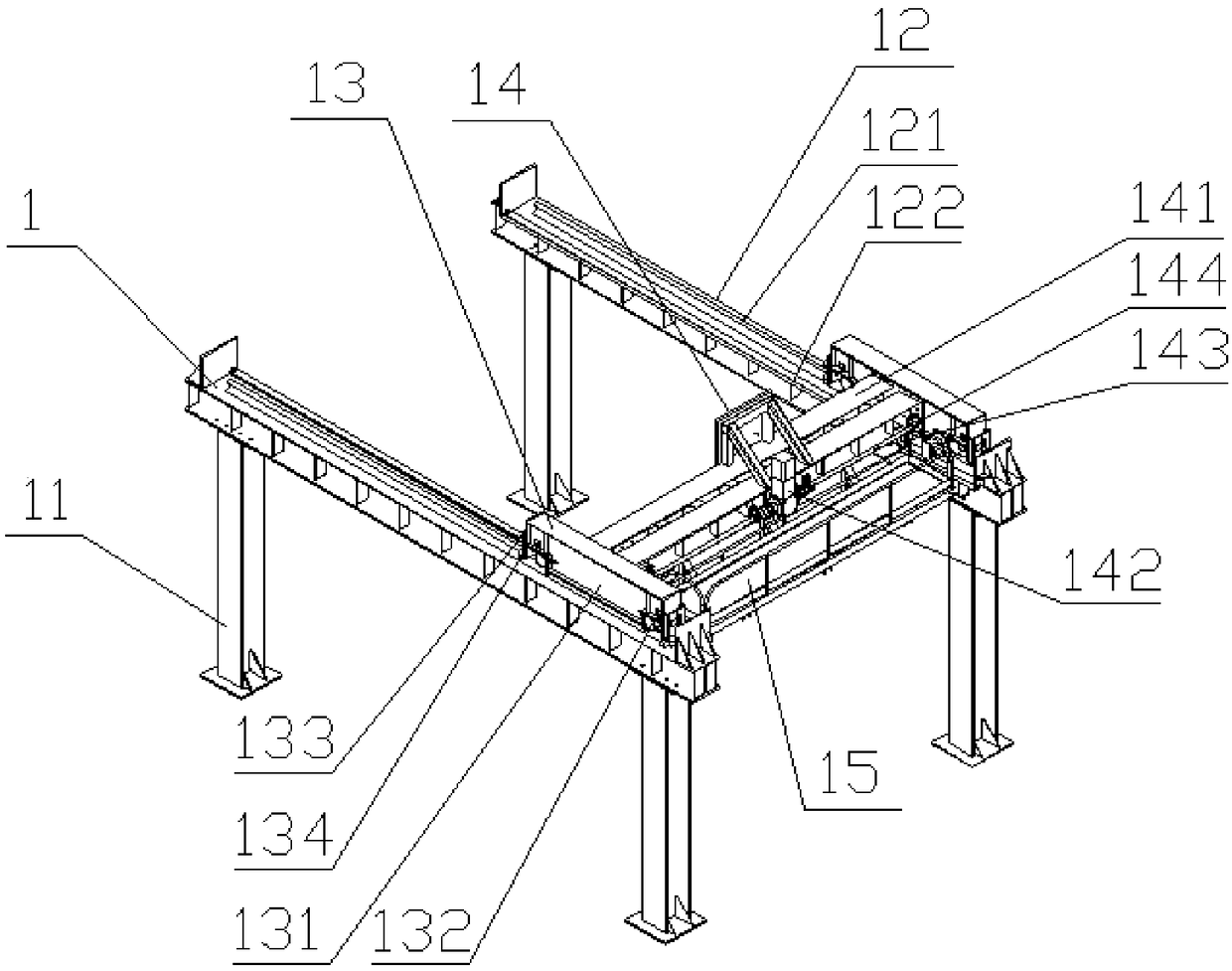

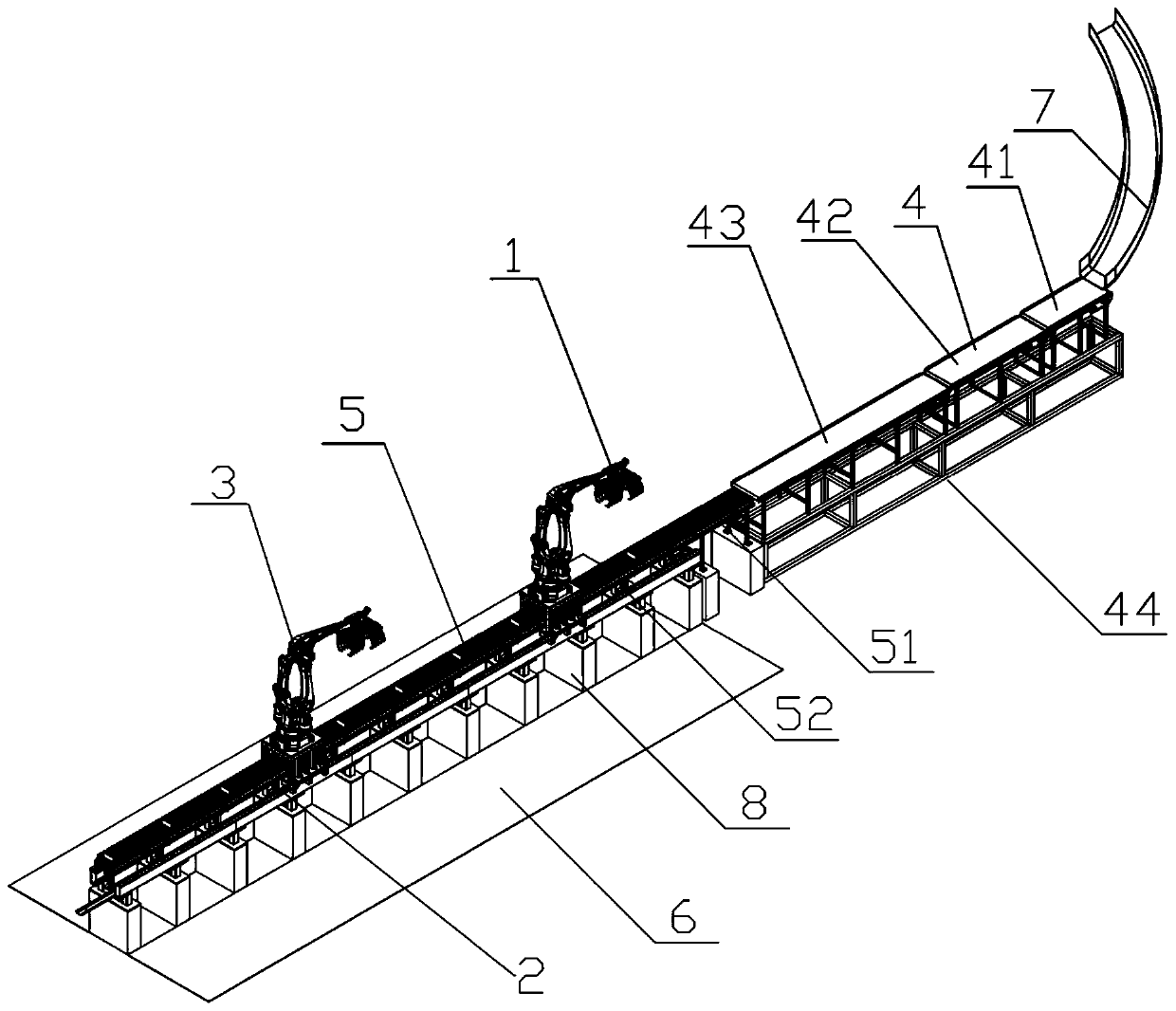

Automatic material loading device integrating loading and conveying and corresponding method

The invention relates to an automatic material loading device integrating loading and conveying and a corresponding method. The device comprises a material conveying module, a material gripping and transferring module, a gantry type robot truss module and a control module. Materials are transported through the material conveying module, the materials are loaded through the material gripping and transferring module which is mounted on the gantry type robot truss module, the gantry type robot truss module moves through a truss, and therefore, the materials are moved to different positions of different vehicles. By adopting the method matched with the device of the structure, production automation is greatly improved, the heavy work of labor is reduced, the manpower cost is lowered for enterprises, and materials doing harm to the health of people are prevented from doing harm to the health of the human bodies in a production environment.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

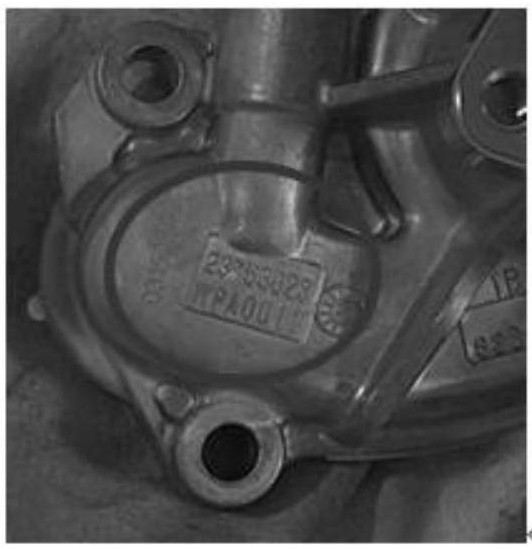

Engine label information visual detection system and method

PendingCN113567450AReduce operating tactImprove production automationCharacter and pattern recognitionOptically investigating flaws/contaminationPattern recognitionOriginal data

The invention provides an engine label information visual system and detection method . The system comprises a monitoring PLC signal module used for monitoring a trigger signal transmitted by a PLC; an image acquisition module which starts a camera program to acquire a current frame picture according to the trigger signal; an image processing identification module used for image preprocessing and identification to obtain a result; and a feedback module used for feeding back the result to the PLC. A visual identification model of the detection system adopts a deep learning framework, the model is obtained through collection of original data and software deep learning, key features of a label are remembered, the position of the label is automatically positioned, and part number information on the label is rapidly identified.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

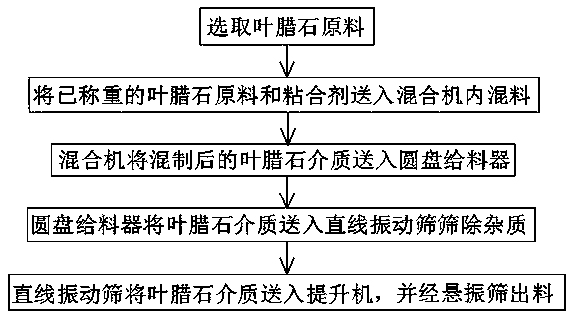

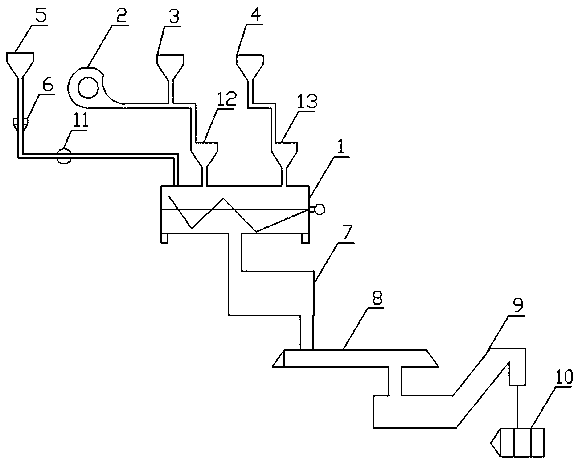

Raw material mixing method and system of superhard material industry

InactiveCN108854805ANo pollutionImprove the environmentTransportation and packagingMixersCircular discSuperhard material

The invention provides a raw material mixing method and system of a superhard material industry. The method comprises the following steps: step 1: selecting a pyrophyllite raw material; step 2: sending the weighed pyrophyllite raw material and a binding agent to a mixing machine for mixing; step 3: sending a mixed pyrophyllite medium to a disk feeder by the mixing machine; step 4: sending the pyrophyllite medium to a linear vibrating sieve for sieving impurities by the disk feeder; and step 5: sending the pyrophyllite medium to a lifting machine by the linear vibrating sieve, and discharging by a suspended vibrating sieve. A whole mixing process pipeline is sealed without overflowing dust, and a workshop environment is effectively improved. The ribbon-type mixing machine is capable of mutually diffusing materials in a process of mixing the pyrophyllite material, and performing convection and radial movement, and a mixing amount is 3 times greater than the mixing amount of a kneading machine, the mixed pyrophyllite medium is more uniform, and higher in quality. A whole mixing process is automatically controlled without a surplus working procedure, a worker does not need to operate manually, labor intensity of the worker is reduced, and the method is helpful to improve production automation of a workshop.

Owner:河南中南工业有限责任公司

Loading and transporting integration type automatic material truck-loading device

PendingCN111232639AReduce labor costsAvoid harmControl devices for conveyorsLoading/unloadingProcess engineeringHuman health

The invention relates to a loading and transporting integration type automatic material truck-loading device which comprises a material conveying module, a material grabbing and transporting module, amaterial grabbing and transporting module moving track module and a control module. The material grabbing and transporting module is used for grabbing materials on the material conveying module to designated spots, and can move on the material grabbing and transporting module moving track module; and the material conveying module can drive the materials to move under the material grabbing and transporting module. By adopting the device, the materials can be conveyed for a long distance, are conveyed to a plurality of different designated spots, and are grabbed and transported to a transport truck through the material grabbing and transporting module, so that the loading and transporting integration type operation is realized; and the production automation is greatly improved, the strenuous manual labor is reduced, the human cost of an enterprise is reduced, and the harm on the human health in a production environment caused by materials harmful to a human body is further avoided.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

Liquid composite wax and emulsifier automatic batching system and production process

ActiveCN102744003BSave human effortImprove production automationMixing methodsMixer accessoriesIntrinsic safetyWax

Owner:广东振声智能装备有限公司 +1

A kind of keel automatic handling equipment and its control method

Owner:BEIJING NEW BUILDING MATERIALS PLC

An integrated processing device for dehydrated vegetables and its manufacturing process

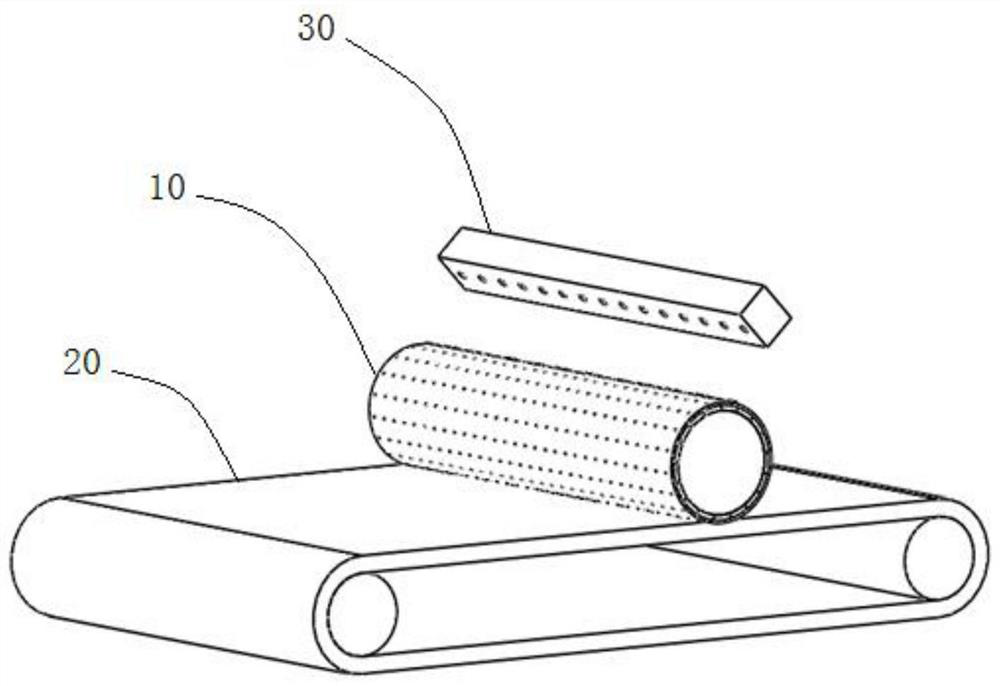

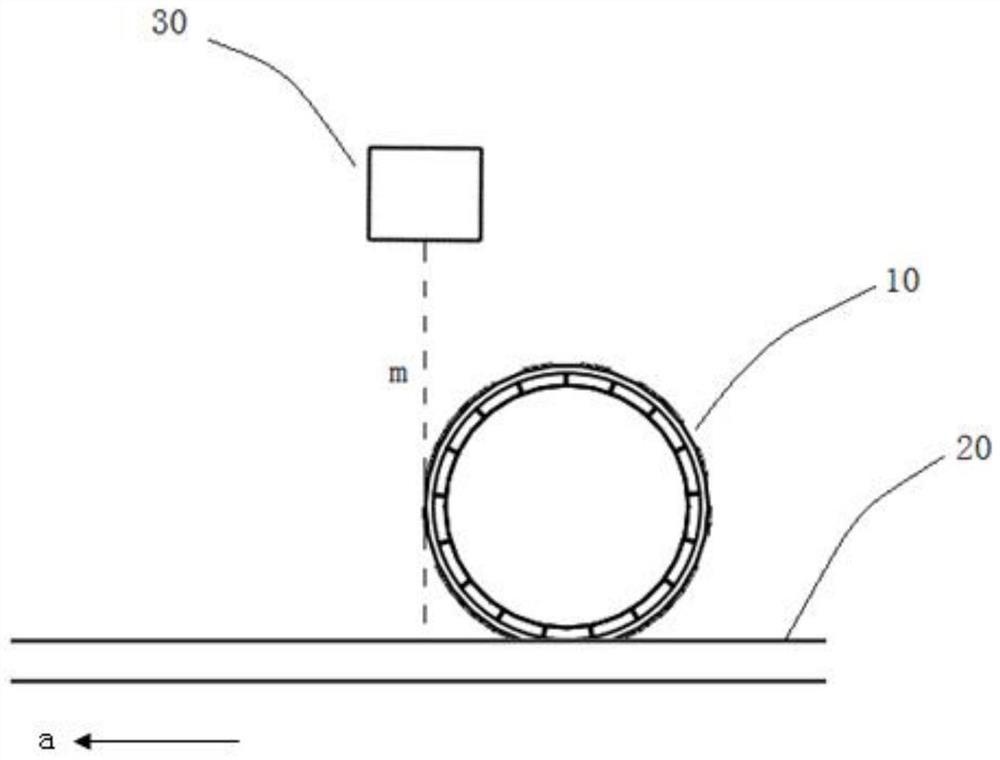

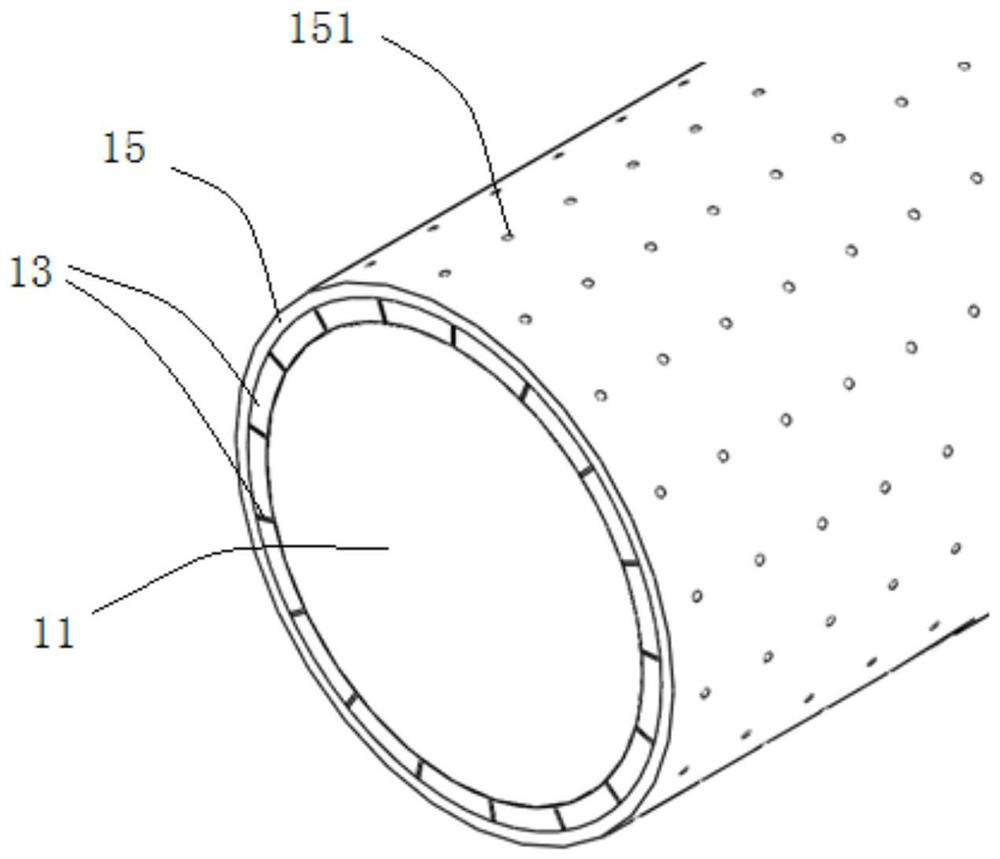

ActiveCN111213896BLarge specific surface areaDehydration fastFood dryingMetal working apparatusBiotechnologyNatural state

The invention discloses an integrated processing device for dehydrated vegetables, which includes a rolling roller and a vegetable conveyor belt, and the rolling roller and the vegetable conveyor belt can move relatively; the rolling roller includes a roller body, a sponge block wrapped outside the roller body, and a Some microneedles on the outer surface of the main body, the cutters and the auxiliary separation parts arranged on the outer surface of the rolling roller, when the sponge block is in a natural state, the tops of the several microneedles, the blades of the first part and the blades of the second part All are located in the sponge block. In the present invention, a number of microneedles touch the vegetables to form a number of needle gaps on the vegetables, so that the specific surface area of the vegetables is increased, and at the same time, a large number of needle gap wounds are added in addition to the cutting wounds of the vegetables, and the dehydration rate and water absorption rate of the vegetables are greatly improved. And it is possible to make vegetable blocks with larger area (volume), thereby increasing consumers' perception and improving the eating taste.

Owner:福建利众诚食品有限公司

Nailing control method and system based on visual positioning of seat cushion

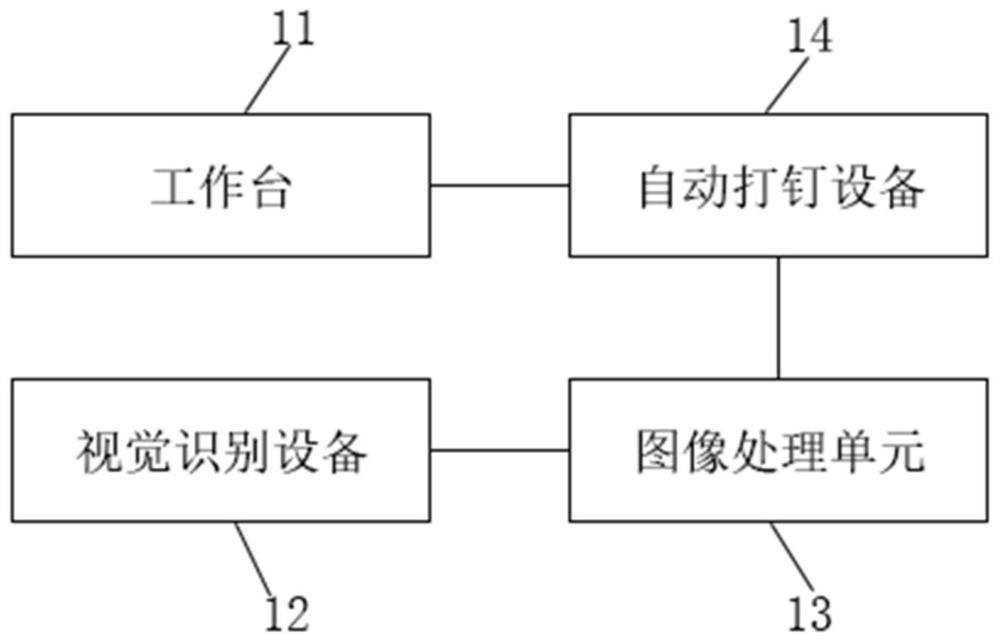

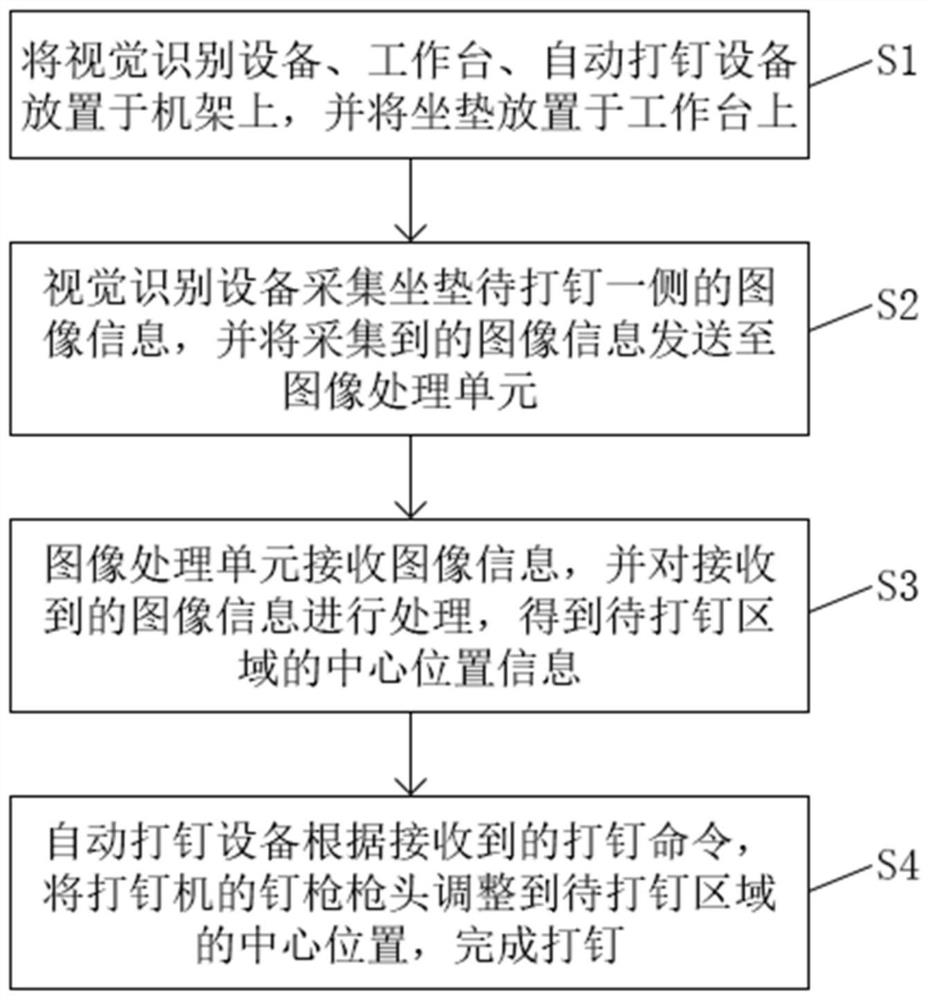

PendingCN114663400AImprove production automationImprove nailing efficiencyImage analysisCushionPhysical therapy

The invention discloses a nailing control method and system based on visual positioning of a seat cushion, and the nailing control system based on visual positioning of the seat cushion comprises a visual recognition device, an image processing unit, a workbench and an automatic nailing device. The workbench is used for placing and fixing the cushion; the visual identification equipment is used for collecting image information of the side, to be nailed, of the cushion and sending the collected image information to the image processing unit; the image processing unit is connected with the visual identification equipment and used for receiving the image information and processing the received image information to obtain center position information of the to-be-nailed area; and the automatic nailing equipment is respectively connected with the workbench and the image processing unit and is used for adjusting a nail gun head of a nailing machine to the central position of the to-be-nailed area according to the received nailing command so as to complete nailing.

Owner:HANGZHOU DIANZI UNIV

A software configuration method for a vehicle controller

ActiveCN110851174BOptimize software configuration technologyImprove production automationVersion controlSoftware configuration managementReliability engineering

The invention provides a software configuration method of the vehicle controller, which optimizes the software configuration technology of the vehicle controller and is beneficial to improve production automation. The software configuration method establishes a process to ensure the rapid and smooth transfer of vehicle software configuration information by clarifying the transfer process of software configuration information from research and development to production and the work responsibilities of relevant departments, and meets the requirements of vehicle project development; the software configuration technology of the controller Introduced into the software configuration management system, bid farewell to the era of paper delivery, realize the upload and entry of software configuration by specialty, the system automatically generates codes and automatically transmits the codes to the MES system; offline equipment automatically obtains configuration information, and software configuration can be realized by scanning the VIN code , The full automation mode improves production efficiency.

Owner:CHERY AUTOMOBILE CO LTD

Dehydrated vegetable cutting treatment equipment and dehydrated vegetable manufacturing process thereof

InactiveCN111165568ALarge specific surface areaDehydration fastFood dryingMetal working apparatusEngineeringConveyor belt

The invention discloses dehydrated vegetable cutting treatment equipment. The dehydrated vegetable cutting treatment equipment comprises a first conveyor belt used for conveying vegetables, a second conveyor belt and a grinding device, wherein the second conveyor belt and the grinding device are used for cutting the vegetables located above the first conveyor belt in a matched mode; the first conveyor belt is of a net structure and comprises a plurality of meshes; the first conveyor belt and the second conveyor belt are partially stacked; the first conveyor belt is located above the second conveyor belt; the tail end of the first conveyor belt does not completely coincide with the tail end of the second conveyor belt; a plurality of microneedles are evenly arranged on the surface of the second conveyor belt; and the microneedles located on the stacked part of the first conveyor belt and the second conveyor belt can penetrate through the meshes. According tot he invention, the pluralityof the microneedles abut against the vegetables to form a plurality of needle gaps in the vegetables, so the specific surface area of the vegetables is increased; meanwhile, a large number of needlegap wounds are added to the vegetables except cutting wounds; and the dehydration rate and the water absorption rate of the vegetables are greatly increased.

Owner:盐城摩因宝新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com