Three-layer type plastic master batch processing system

A processing system, plastic masterbatch technology, applied in ventilation systems, weighing equipment for materials with special properties/forms, heating methods, etc., which can solve the problems of small workshop area and large workshop area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

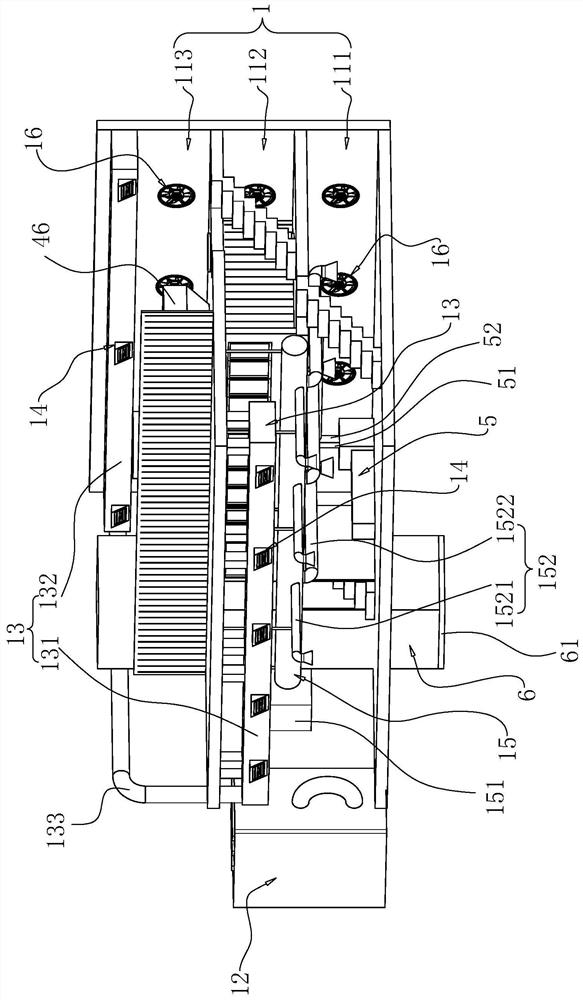

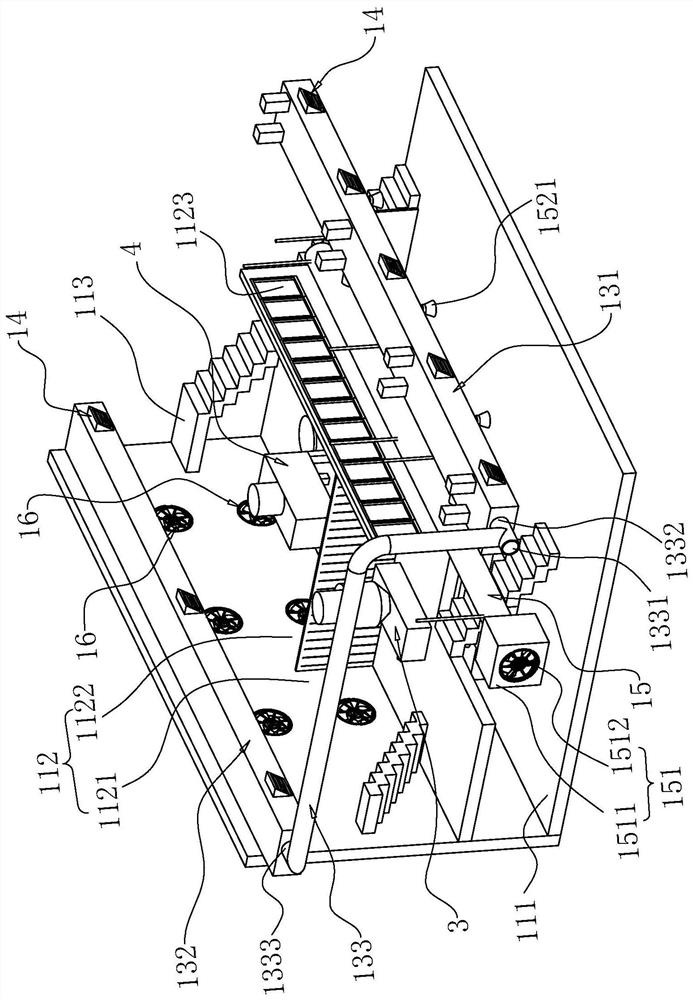

[0118] Contraction below Figure 1-21 Further detailed description of the present application.

[0119] Example 1 of the present application discloses a three-layer plastic masterbatch processing system, with reference to Figure 1 to 4 , Including a plant, dosing means for temporarily storing the raw material 2, for weighing said starting material feed means 3, a pre-stirred for secondary material stirring device 4 and the plastic extruder 5, comprising a workshop floor 111, 112 and 113 on the second floor, third floor, the first floor of the forming zone 111, 112 for the stirring zone floor, third floor region 113 of the ingredients;

[0120] 2 dosing device 113 is provided on the third floor of the dosing means 2 provided in the ingredients zone, said feeding device 3 and a stirring means 4 is provided on the second floor 112, said feeding device 3 and a stirring device 4 disposed stirring zone, plastic extruder 5 111 disposed on the first floor, plastic extruder 5 disposed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com