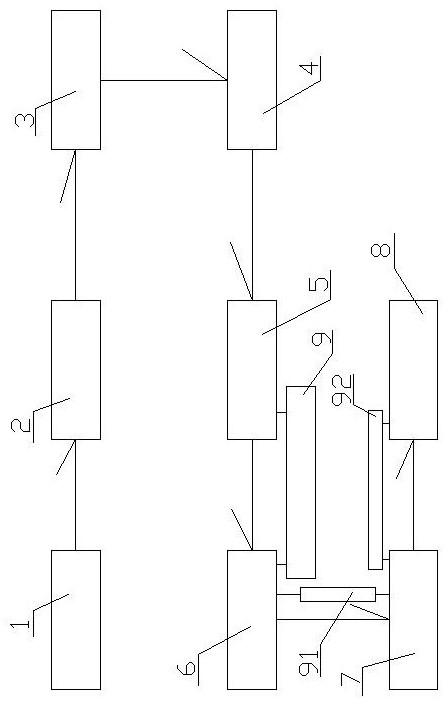

Raw material, preparation device and method for preparing foamed ceramic insulation board based on rolling method

A technology for foaming ceramics and preparation equipment, which is applied in the direction of ceramic products, ceramic material production, ceramic molding machines, etc., and can solve the problems of small deformation coefficient and affecting the production efficiency of foamed ceramic insulation boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] A raw material for preparing foamed ceramic insulation boards based on a calendering method, one of the first embodiments of the present invention, contains: 20-45% fly ash, 10-30% polishing slag, 10-25% % feldspar, 10-30% tailings slag, 0-4% purple wood knot, 1-7% bentonite and 0.1-0.3% foaming agent,

[0067] In this embodiment, the blowing agent is set to contain 55-68% SiO by weight 2 , 15-20% Al 2 o 3 , 1-4%CaO, 1-3%K 2 O, 1-3%Na 2 O, 0.1-5.0%Fe 2 o 3 , 1-4%MgO,

[0068] The blowing agent is set to be silicon carbide.

[0069] The second embodiment of the first embodiment of the present invention contains: 20% fly ash, 10% polishing slag, 10% feldspar, 10% tailings slag, 1% purple wood knot, 1% bentonite and 0.1 % blowing agent,

[0070] In this embodiment, the blowing agent is set to contain by weight: 55% SiO 2 , 15% Al 2 o 3 , 1%CaO, 1%K 2 O, 1%Na 2 O, 0.1%Fe 2 o 3 , 1%MgO.

[0071] The second embodiment of the first embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com