Automatic safety monitoring system of liquid composite wax and emulsifier feed and storage

A technology of safety monitoring system and liquid compound wax, which is applied in the direction of control/regulation system, non-electric variable control, electrical program control, etc., can solve the problems of industrial automation and low batching accuracy, achieve good heat preservation effect and save production cost , The effect of ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

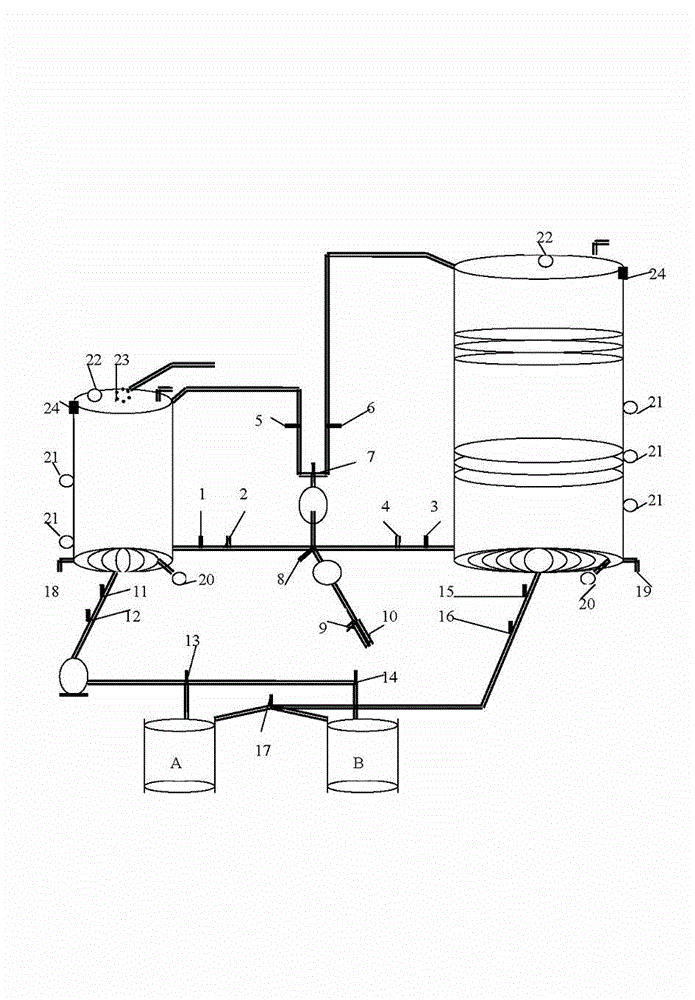

[0020] In order to facilitate the understanding of those skilled in the art, the structural principles of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0021] Such as figure 1 As shown, an automatic safety monitoring system for feeding and storing liquid composite wax and emulsifier, which includes a feed bellows sealing butt joint 10 connected to the discharge port of the tank car, a liquid composite wax storage tank and an emulsifier storage tank And its accessories such as pipes, valves, meters, insulation materials, etc., feeding or circulating public chemical pumps, the liquid composite wax storage tank and the emulsifier storage tank are respectively connected with the automatic safety monitoring device, and the automatic safety monitoring device includes Temperature sensor, solenoid valve set on the tank of liquid compound wax and temperature sensor, solenoid valve, pneumatic ball v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com