Winding yarn taking device of yarn winding machine

A technology of reclaiming device and yarn twisting machine, which is applied in thin material handling, conveyor objects, transportation and packaging, etc., can solve the problems that are not conducive to the steady and continuous process of yarn reel taking, and can promote automatic setting and reduce work intensity. , the effect of avoiding collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

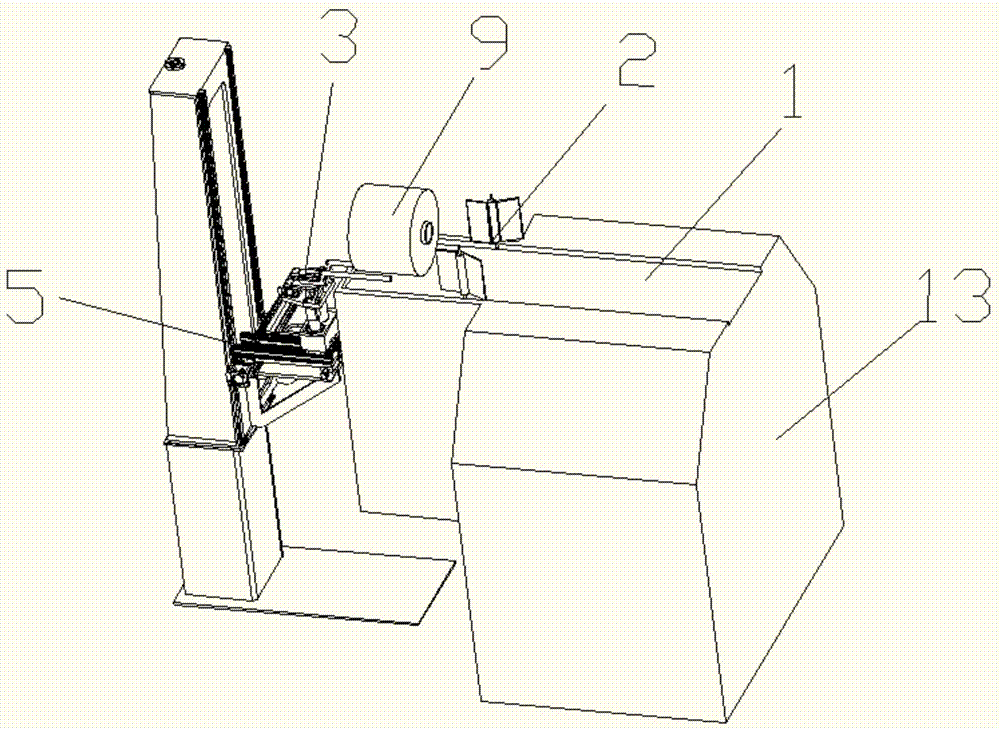

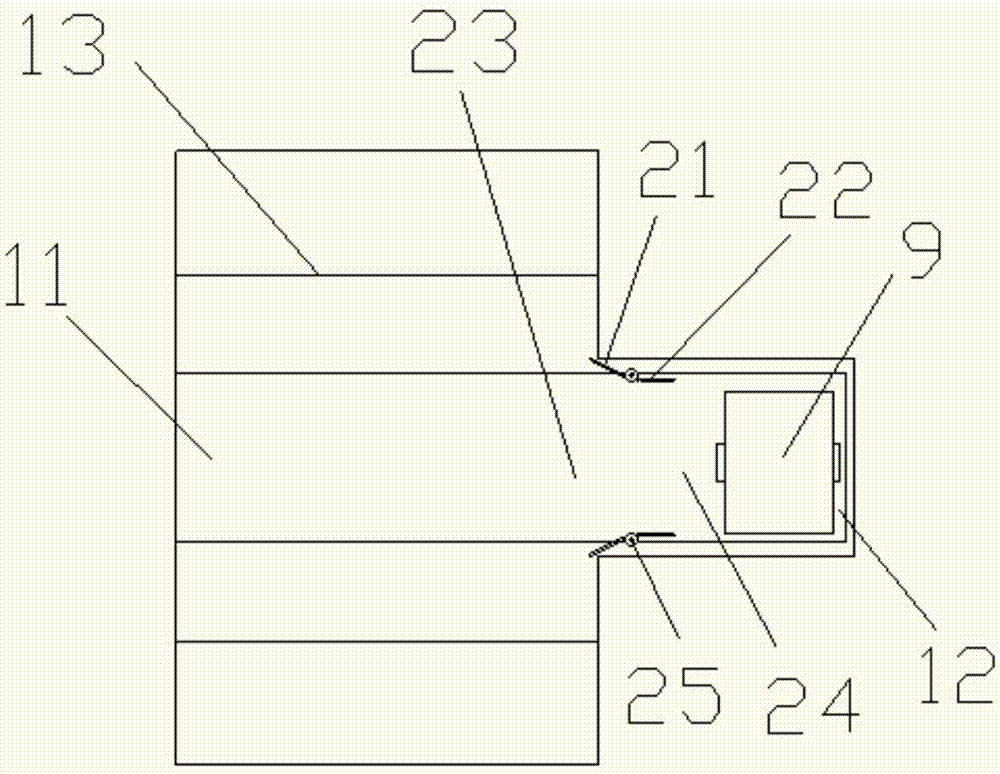

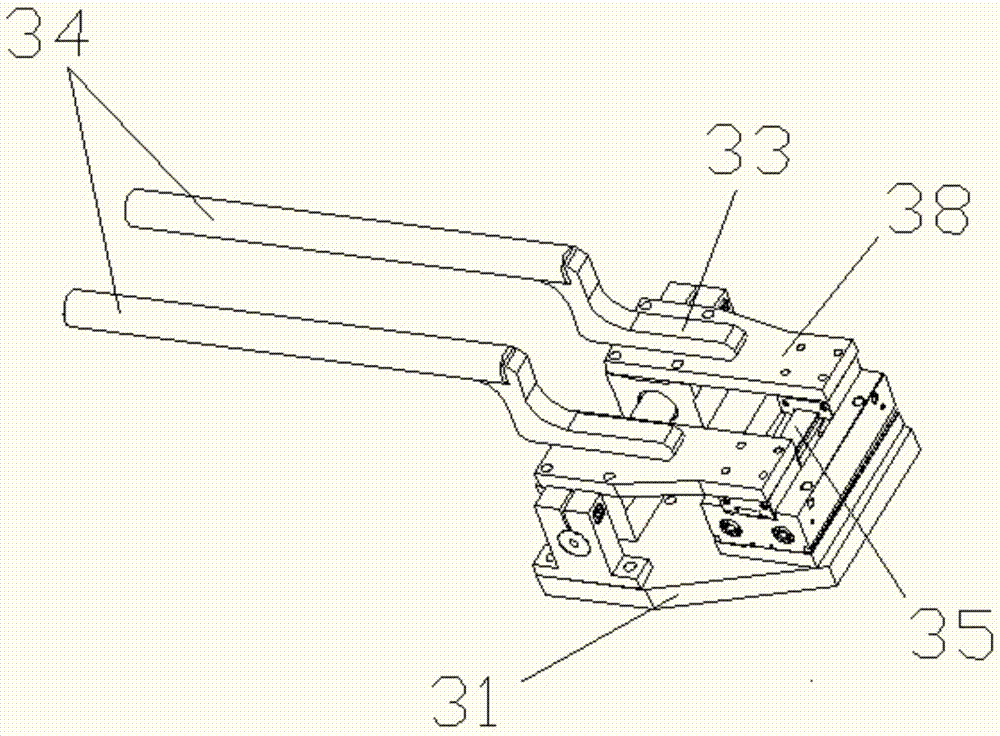

[0041] The machine platform 13 is formed by welding several metal plates, and two relatively parallel strip-shaped baffle plates are welded on the upward end surface of the machine platform 13 . A conveyor belt is arranged between the two baffles, and the moving direction of the conveyor belt is the same as the extending direction of the baffles. At this time, a yarn roll delivery channel 1 is formed between the two baffle plates, and the yarn roll inlet 11 of the yarn roll delivery channel 1 is connected with the finished product outlet of the twisting machine. At this time, the finished yarn roll moves from the exit to the yarn roll inlet 11 of the yarn roll transmission channel 1, and the yarn roll 9 remains relatively stable with the transmission device under the friction force of the contact surface with the transmission device, and then m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com