Automatic feeding equipment capable of storing aluminum pistons and production method of automatic feeding equipment

An automatic feeding and piston technology, applied in metal processing and other directions, can solve problems such as restricting the accuracy of pistons, scrapping pistons, and inconsistent piston characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

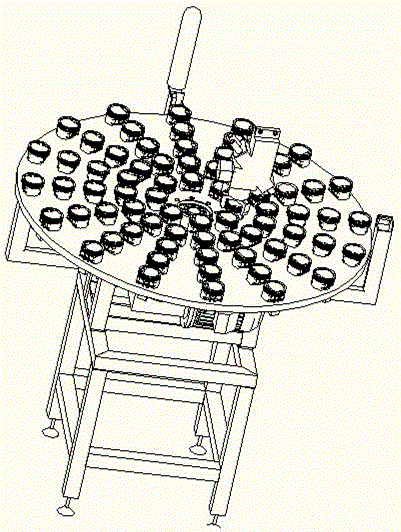

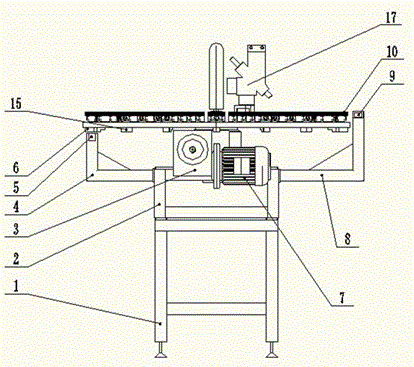

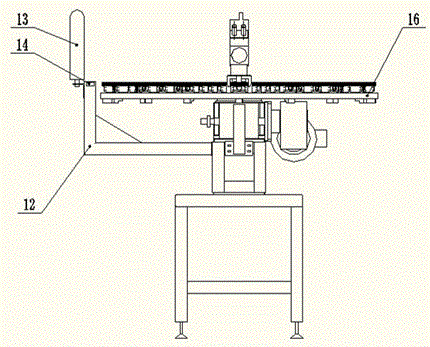

[0017] In the specific implementation process of the present invention, according to the needs, a multi-equal divider can be selected, and the present invention will be further described below by selecting a specific embodiment of a 16-equal divider.

[0018] The 16 equal divider is composed of 16 equal divider packer, reducer, three-phase brake motor, proximity switch, induction cam, induction bracket, etc. Its working principle is: when the three-phase brake motor gets the working signal, it starts to work , drives the reducer and drives the main shaft of the 16 equal divider to rotate through the worm gear and worm structure. Since the 16 equal divider rotates one station and the main shaft also rotates one position, it drives the induction cam to rotate one circle and return to the original position. At this time, it is close to The switch gets the signal, and feeds back to the three-phase brake motor, so that the three-phase brake motor is in a standby state.

[0019] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com