Coating system for jib of section-steel-made crane

A crane and jib technology, which is applied in the field of coating systems for the crane jib made of section steel, can solve the problems affecting the processing quality of the workpiece, the products are prone to cracks, and the heating time is long, so as to facilitate production automation, facilitate production efficiency, and improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The jib 30 is made of section steel, the size of the section steel is 9627mm*1100mm*900mm (length, width and height when placed horizontally), and the weight is 508kg. It is used for the jib 30 on the crane. According to different types of cranes, the jib 30 The size and weight are different, but their shapes are basically the same. The above is just giving the size and weight information of one of them.

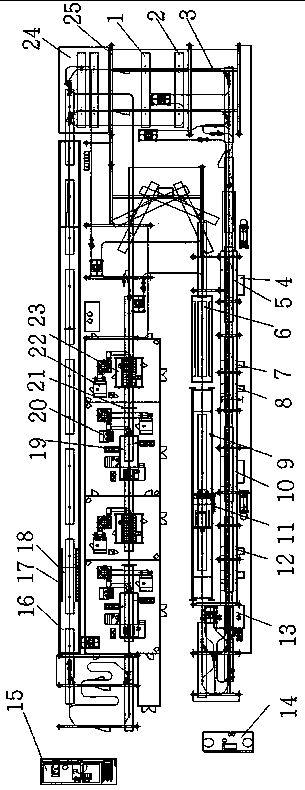

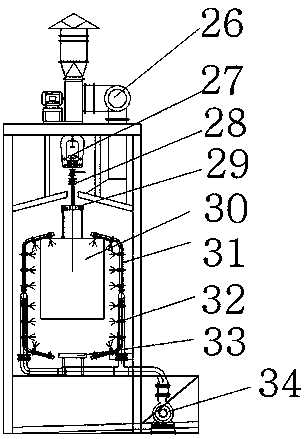

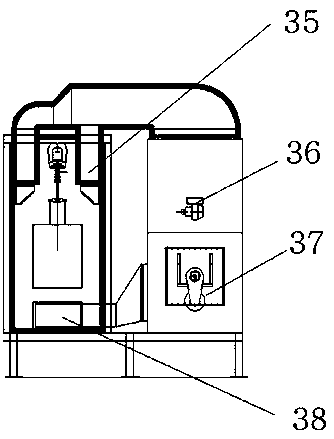

[0038] Such as Figure 1-12 Shown: a coating system for the crane jib 30 made of the above-mentioned section steel, including a pre-processing unit, a powder spraying unit and a curing unit, the pre-processing unit, the powder spraying unit and the curing unit are connected in series on the track 3, and the jib 30 passes through the track 3. Spraying is completed through the pre-processing unit, powder spraying unit and curing unit. The pre-processing unit is used for degreasing, dust removal and static electricity removal of the auxiliary arm 30; the powder spraying u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com