Loading and transporting integration type automatic material truck-loading device

An all-in-one, material technology, applied in conveyor control devices, loading/unloading, conveyor objects, etc., can solve problems such as affecting the production of enterprises, unavailability of enterprises, immature technology, etc., to improve production automation and reduce manpower cost, the effect of reducing heavy labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

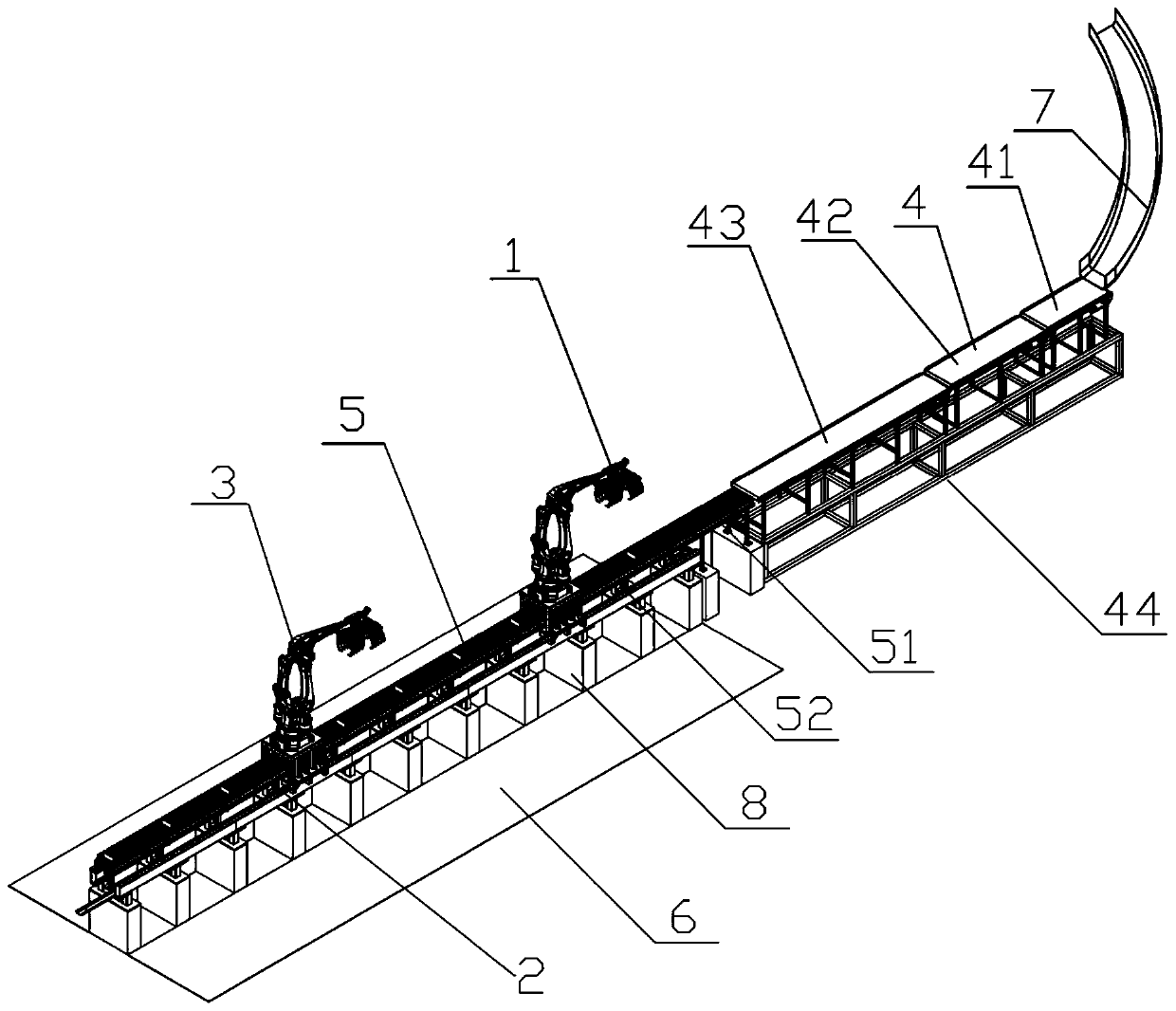

[0052] see Figure 1 to Figure 2 As shown, the integrated material automatic loading device for shipment in this embodiment includes:

[0053] Material conveying module for conveying materials;

[0054] The material grab module 1 is used to grab the material on the material delivery module to a designated location;

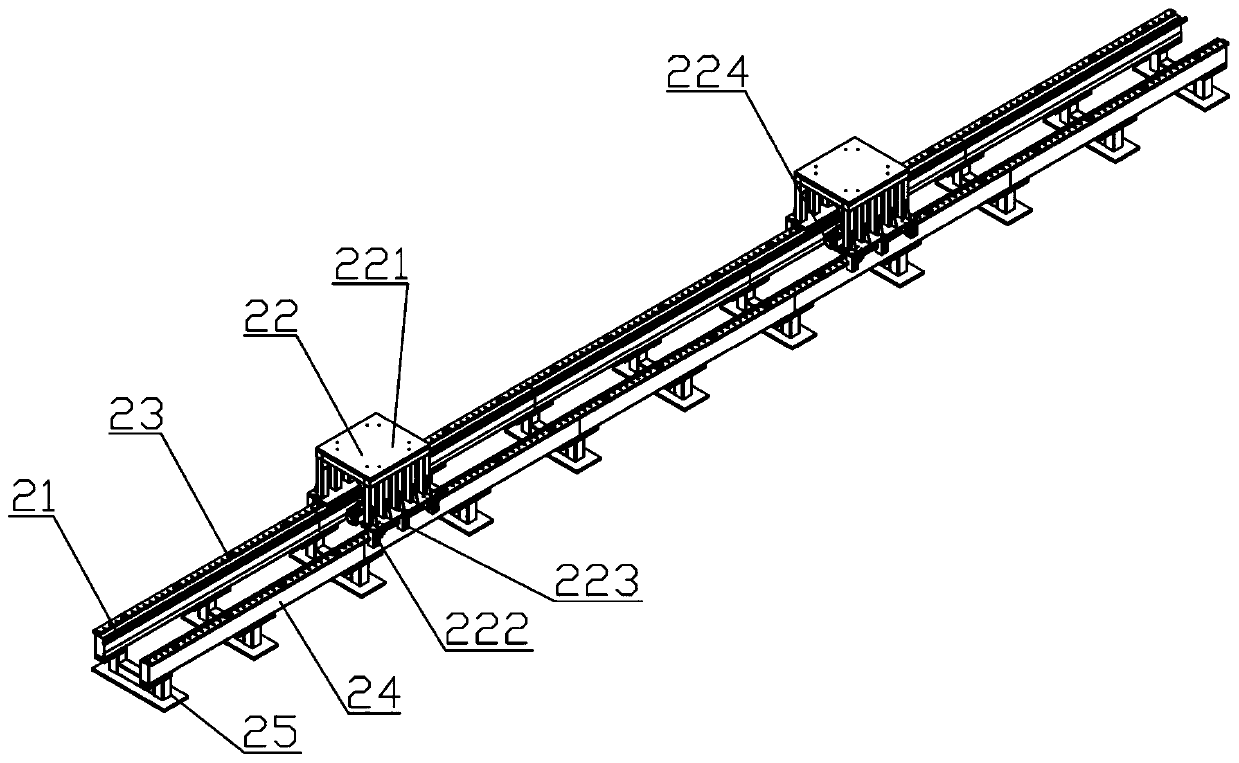

[0055] The moving track module 2 of the material grasping module, the material grasping module 1 can move on the moving track module 2 of the material grasping module;

[0056] The control module is connected with the material conveying module and the material grasping module 1 respectively;

[0057] The material conveying module can drive the material to move under the material handling module 1 . The material grabbing module 1 and the material conveying module maintain a relatively moving positional relationship.

[0058] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com