Processing equipment and method for continuous fiber tows

A technology of fiber tow and processing equipment, applied in the field of fiber tow, can solve the problems of reduced expansion effect, inability to obtain high-quality products, and incomplete presentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

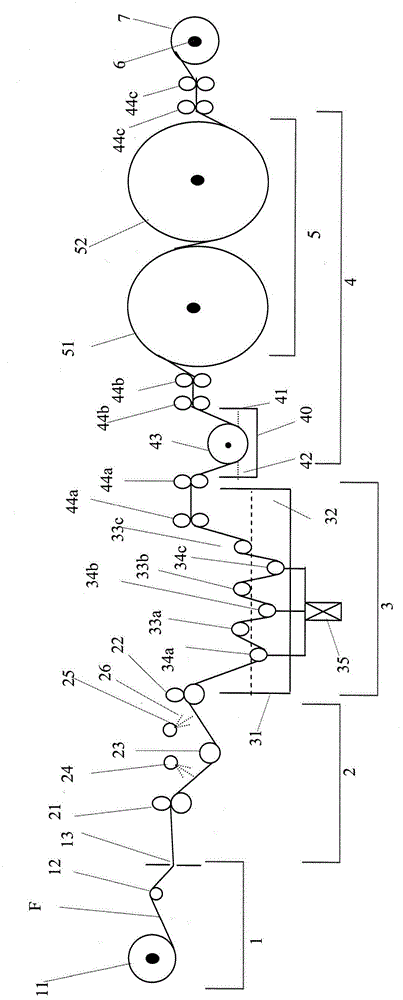

[0099] For the specific implementation of the processing equipment of the continuous fiber tow of the present invention, please refer to figure 1 As shown, the filament supply unit 1 fixes the fiber tow F to a fixing device 11, and the fixing device 11 has a fixed tension controller, which can keep the fiber tow F at a fixed and stable tension when it is pulled out. Then, when the fiber tow F is output from the yarn supply unit 1 through the guide roller 12 and the guide hole 13, the fiber tow F can be prevented from being pulled out unstable or the state of unstable tension can be avoided.

[0100] In order to ensure stable tension and fixed fiber tow F width when the fiber tow F enters or leaves the desizing unit 2, a pair of guide rollers are respectively arranged at the inlet and outlet of the desizing unit 2 21 / 22, the guide wire roller group 21 / 22 is respectively arranged at the feed inlet and the discharge outlet of the desizing unit 2, and the feed inlet is to accept t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com