Multifunctional warp yarn tension equalizer

A tension equalizer, multi-functional technology, applied in the direction of processing textile material yarn guide devices, other manufacturing equipment/tools, textiles and papermaking, etc. problem, to achieve the effect of smooth contact surface, easy to use, and reduce the chance of broken ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

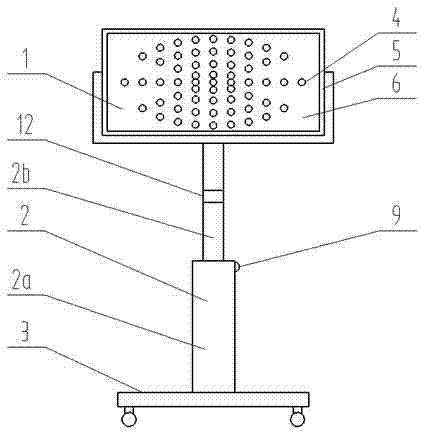

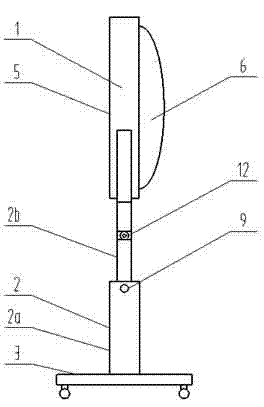

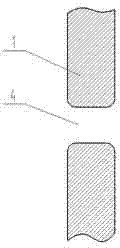

[0023] Such as figure 1 with figure 2 As shown, the multifunctional warp tension equalizer has a main body of a yarn guide plate 1, including a bracket 2, the bracket 2 is fixedly arranged on the base 3, and the top of the bracket 2 is fixedly provided with a rectangular yarn guide plate 1 perpendicular to the horizontal plane, and the yarn guide plate 1 The yarn guide magnetic eye 4 is arranged on the upper surface, the yarn guide plate 1 is an arc-shaped plate, the frame 5 around the yarn guide plate 1 is rectangular, and the interior is a spherical surface 6 sunken to any side. In this embodiment, the arc of the spherical surface 6 is 60° , a number of yarn guide magnetic eyes 4 are uniformly arranged on the spherical surface 6 . B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com