Valve opening degree detection device

A detection device, valve opening technology, applied in valve device, valve operation/release device, valve details, etc., can solve the problems of needing more space and troublesome adjustment operation, so as to improve work efficiency, save space, reduce The effect of the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

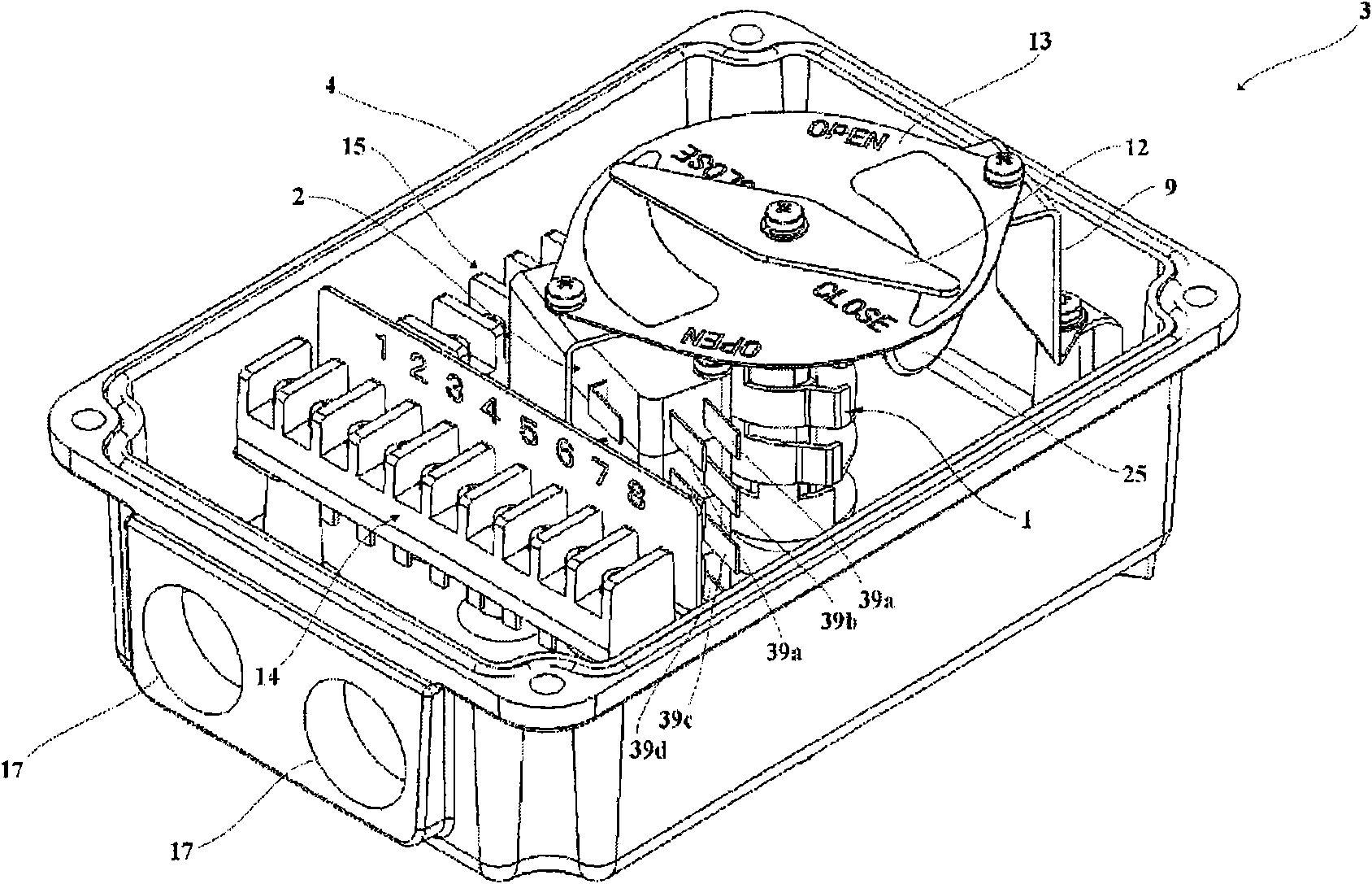

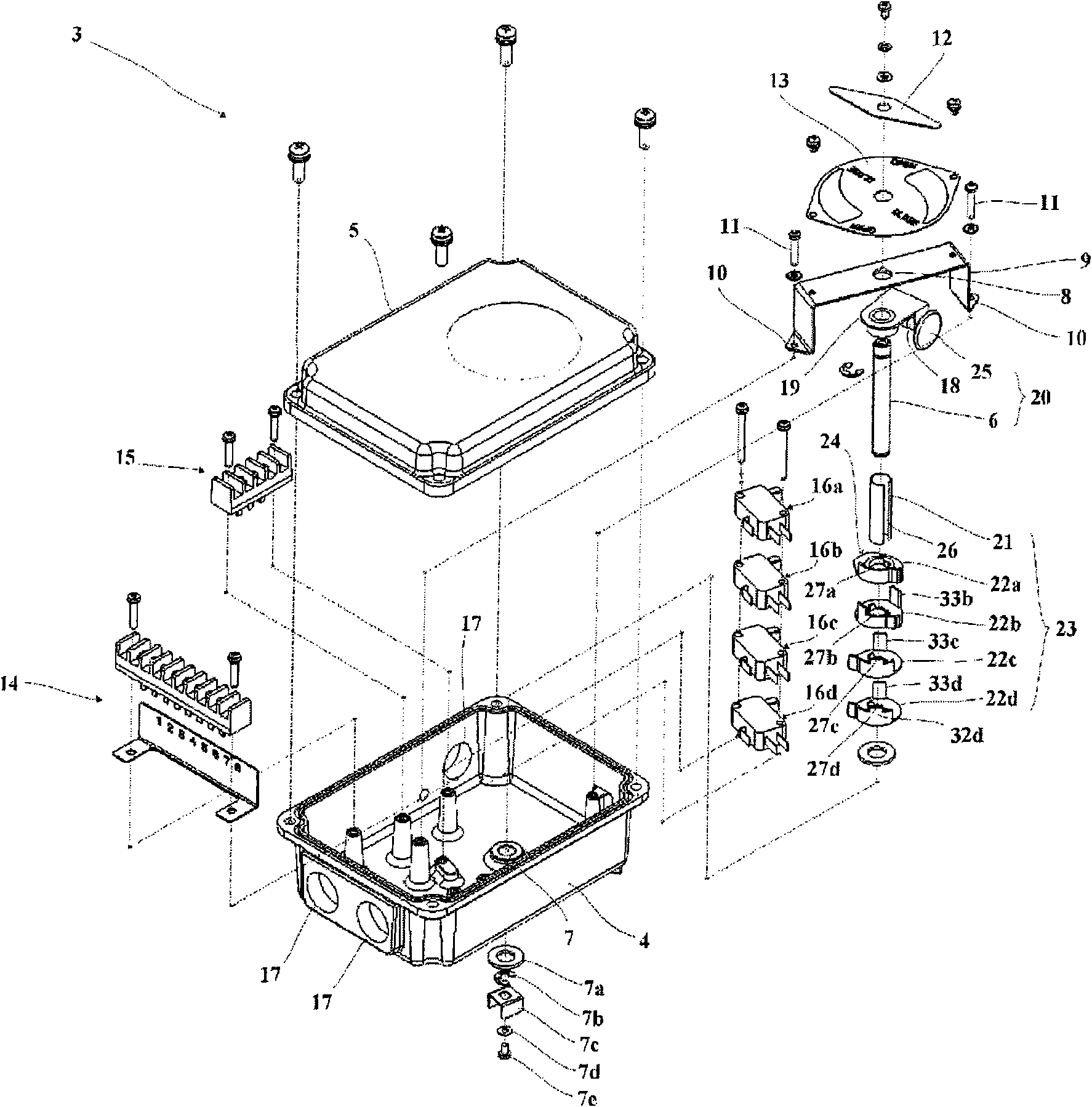

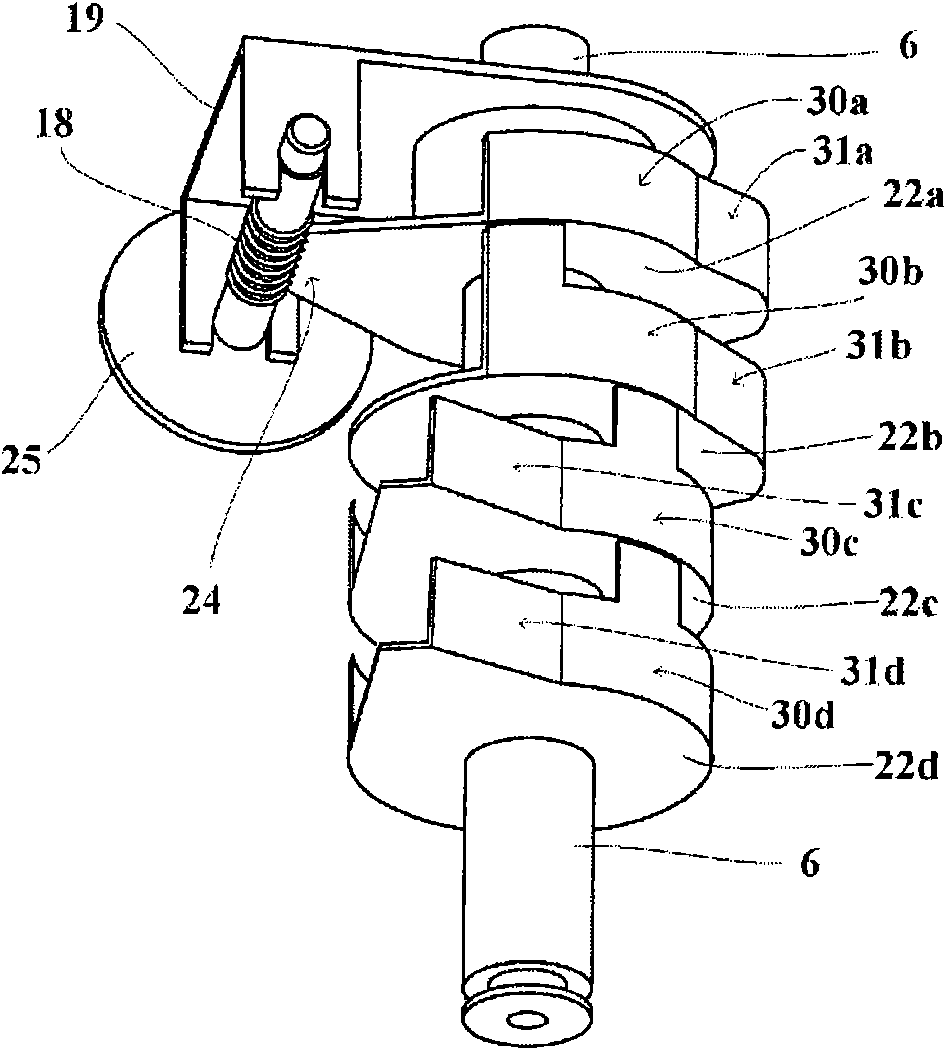

[0020] Embodiments of the present invention will be described in detail below with reference to the drawings. figure 1 Among them, (1) is the cam unit, and (2) is the limit switch unit. figure 1 It is a perspective view of the whole valve opening detection device (3) applied to the valve device (not shown) having the cam unit (1) and the limit switch unit (2) of the present invention. Such as figure 1 As shown, the valve opening detection device (3) in this embodiment has a box-shaped casing ( 4) and a roughly plate-shaped cover (5) that closes the upper opening. A cam unit (1) including a detection shaft (6) vertically erected from the bottom surface of the housing (4) is provided in a substantially central portion of the housing (4). Adjacent to the cam unit (1), a limit switch unit (2) is arranged close to the cam unit (1), and is linked with a certain action of the cam unit (1) to perform ON / OFF operation.

[0021] The detection shaft (6), which is the main component o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com