Automated textile equipment and control system

A technology for textile equipment and pulp storage, which is applied in the processing of textile material equipment configuration, textile and papermaking, and textile material processing, and can solve problems such as sticking, filament breakage, and uneven sizing on filament surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention are described below by specific specific embodiments. Those who are familiar with the technology can easily understand other advantages and effects of the present invention from the contents disclosed in this specification. Obviously, the described embodiments are part of the present invention. , not all examples. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

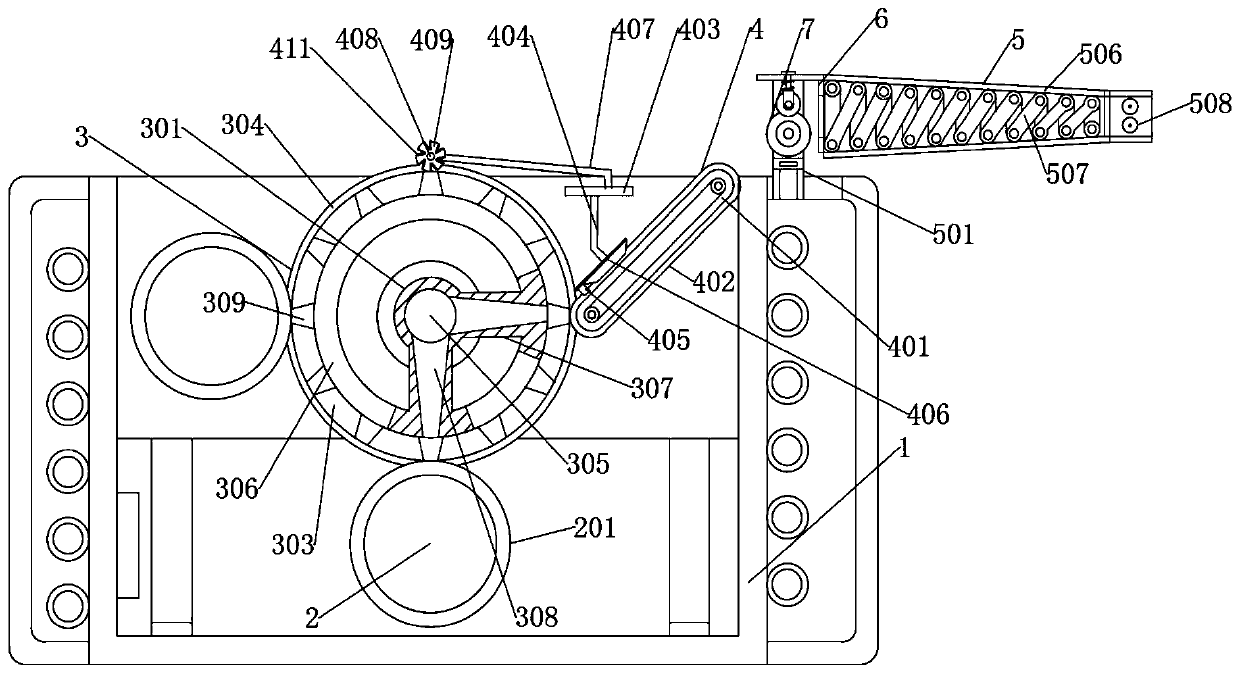

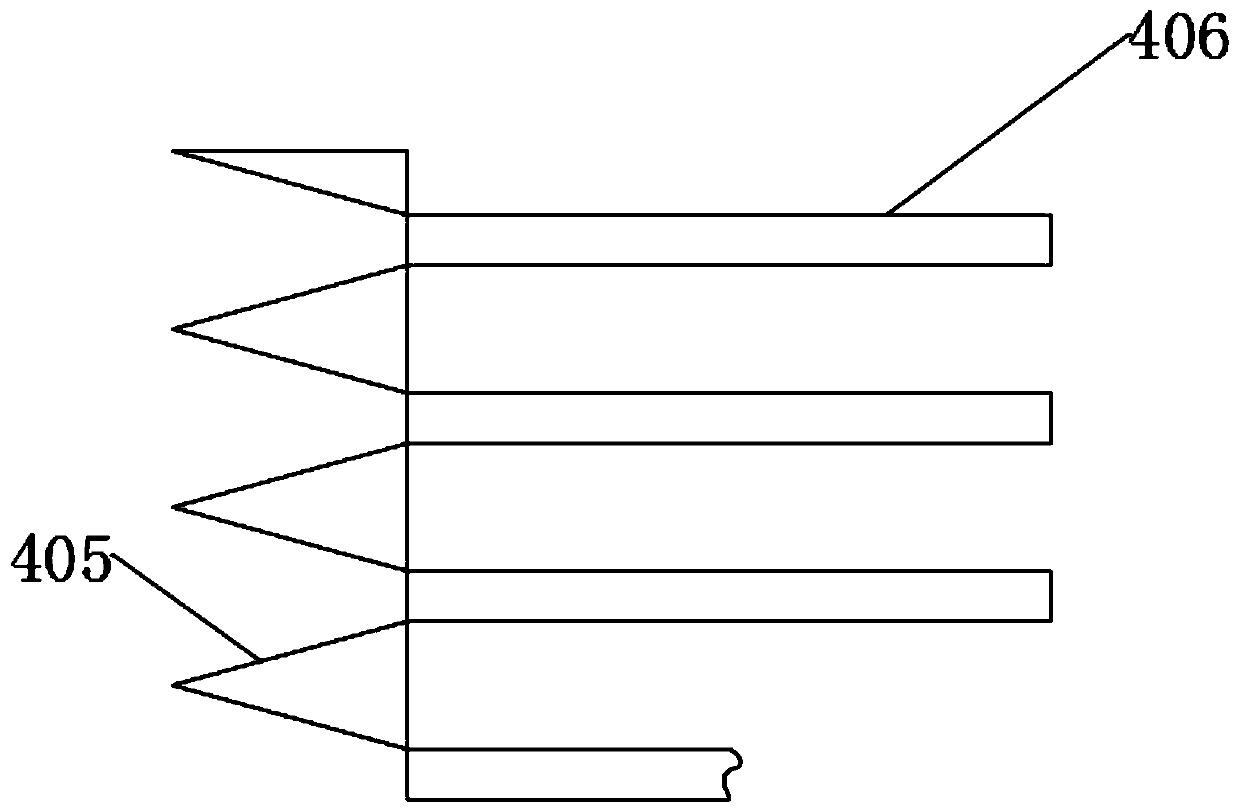

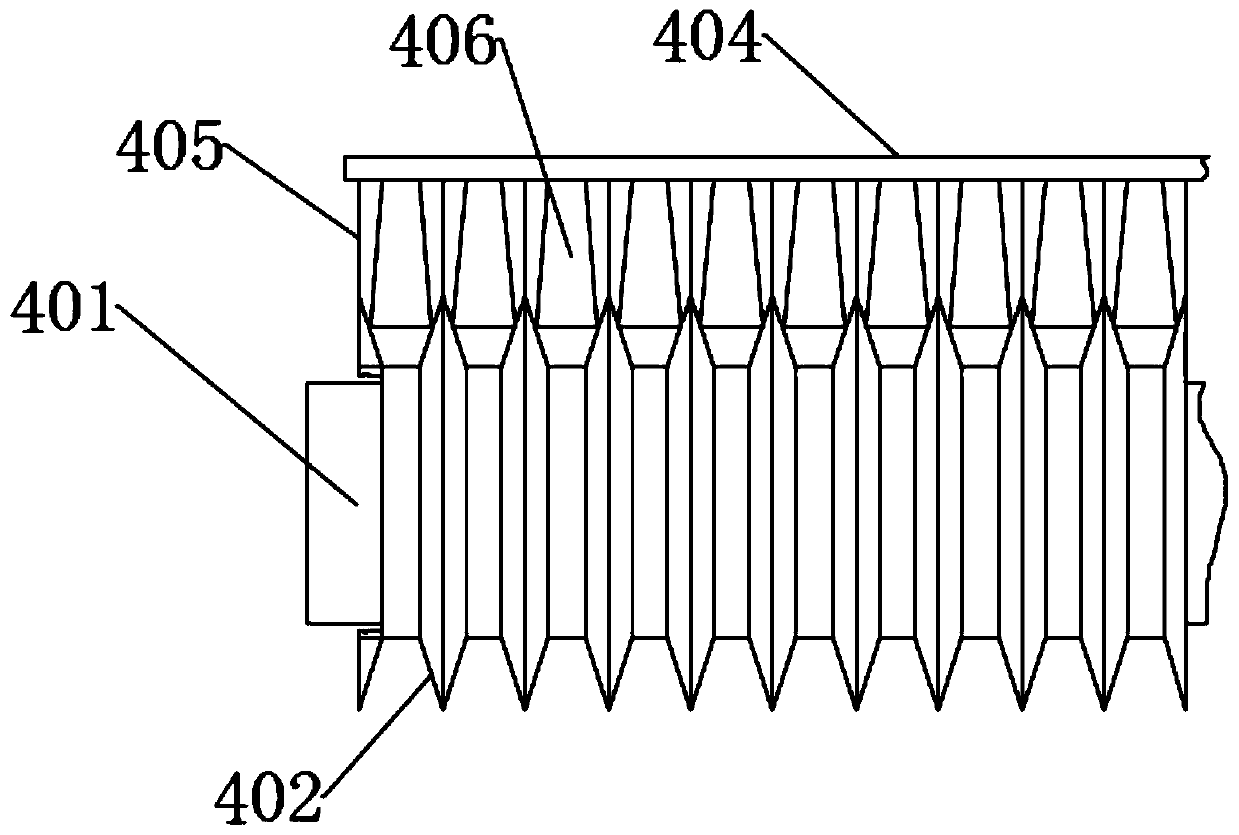

[0043] like figure 1 As shown, the present invention provides an automatic textile equipment, which can separate the yarns immersed in the size solution by the separator bar 402 and the spacer block 405, so that the adjacent yarns will not appear to stick together, and at the same time When the original yarn is immersed in the cylinder 3 and rolls, the scraping block 411 can roll along with it, and scrape off t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com