Bamboo charcoal fiber home textile fabric

A bamboo charcoal fiber and fabric technology, applied in the field of textile fabrics, can solve the problems of insufficient fabric strength, uneven yarn dyeing, insufficient drying, etc., and achieve the effects of increasing friction, improving drying efficiency, and improving drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of described bamboo charcoal fiber home textile fabric comprises the steps:

[0039] S1: blending white bamboo charcoal fiber, nylon fiber and metal wire to obtain yarn, and winding the yarn into a yarn roll;

[0040] S2: Dye and dry the yarn prepared in step S1 to obtain dyed yarn; install the yarn reel on the dyeing device, make the yarn on the yarn reel pass through the dyeing device, and dye the yarn in the dyeing device Finished dyeing;

[0041] S3: Making the dyed yarn obtained in step S2 into a fabric through textile equipment to obtain a finished product with bright colors;

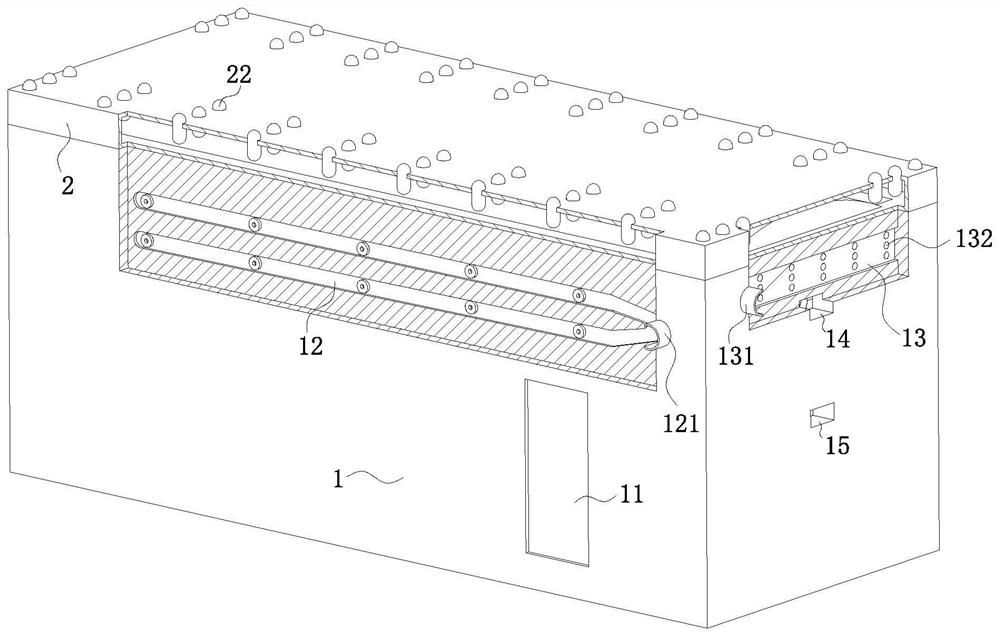

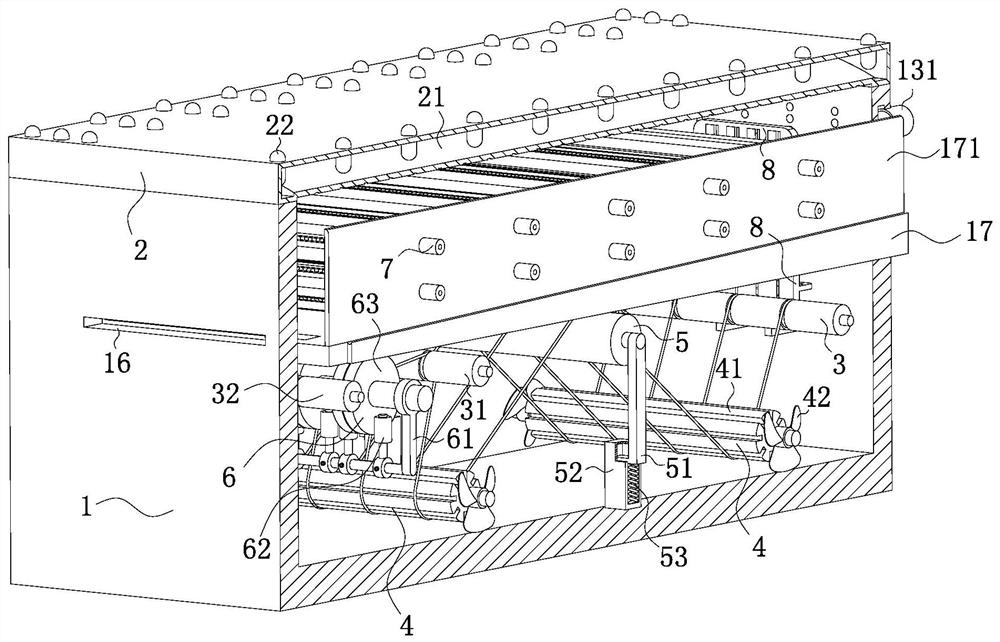

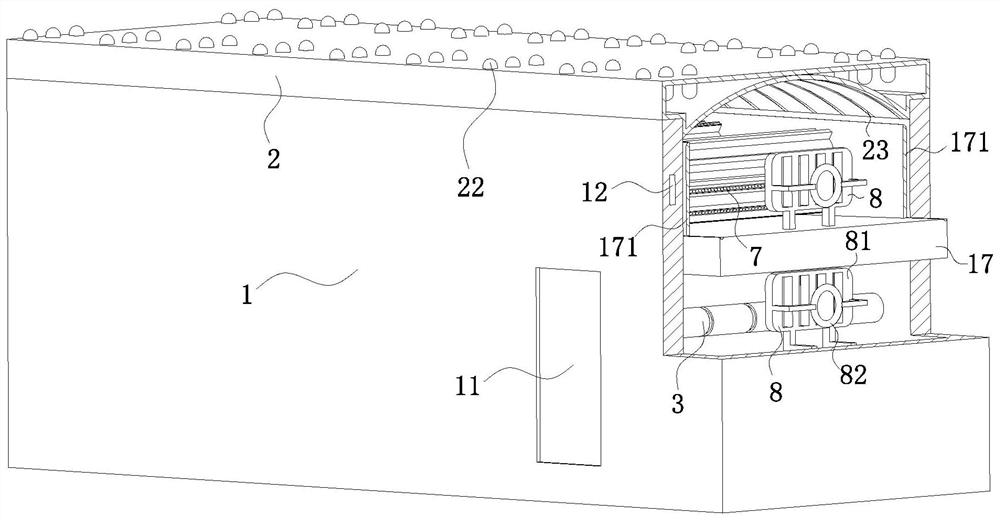

[0042] Wherein, the dyeing device in the S2 step includes a body 1 and a loam cake 2; the loam cake 2 is installed on the body 1; the side of the body 1 is provided with a discharge port 14; the side of the body 1 is provided with a feed inlet 15; the feed port 15 and the discharge port 14 are located on the same side, and the discharge port 14 is located above the ...

Embodiment approach

[0046] As an embodiment of the present invention, an extrusion mechanism 6 is installed in the body 1; the extrusion mechanism 6 is located between the guide roller two 31 and the guide roller three 32; the extrusion mechanism 6 and the guide roller three 32 are at the same height; the extruding mechanism 6 is located above the liquid level in the body 1; the extruding mechanism 6 includes a sponge disc 63, a mounting frame 61, and an extruding wheel 62; The rotating shaft is installed in the body 1; the sponge disc 63 can rotate freely; the mounting frame 61 is fixedly mounted on the rotating shaft; the mounting frame 61 is provided with a keyway; the extrusion wheel 62 is fixed on the mounting frame by screws 61; the squeeze wheel 62 has four groups, two in each group; each group of squeeze wheels 62 is located on both sides of the corresponding sponge disc 63, and squeezes the sponge disc 63; the squeeze wheel 62 is located on the sponge the bottom of the disc 63;

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com