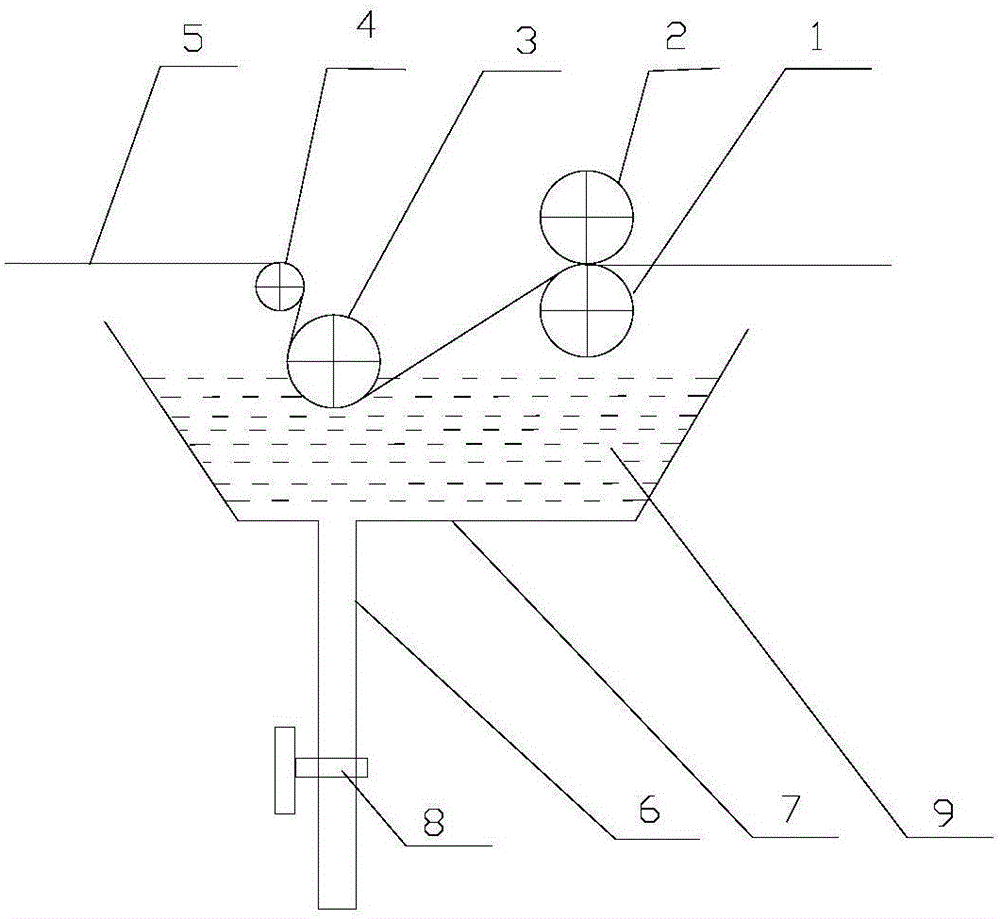

Method for preparing nanofiber aggregate and pretreatment device

A pretreatment device and nanofiber technology, which is applied in fiber treatment, textile material yarn guide device, liquid/gas/steam fiber/sliver/roving treatment, etc. It can solve the problem of loose combination of drawn filaments and nanofibers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The above-mentioned drawing filament pretreatment device is used to pretreat the drawing filament, the pretreatment liquid used is water, and the pretreatment time of the drawing filament in water is 10 seconds.

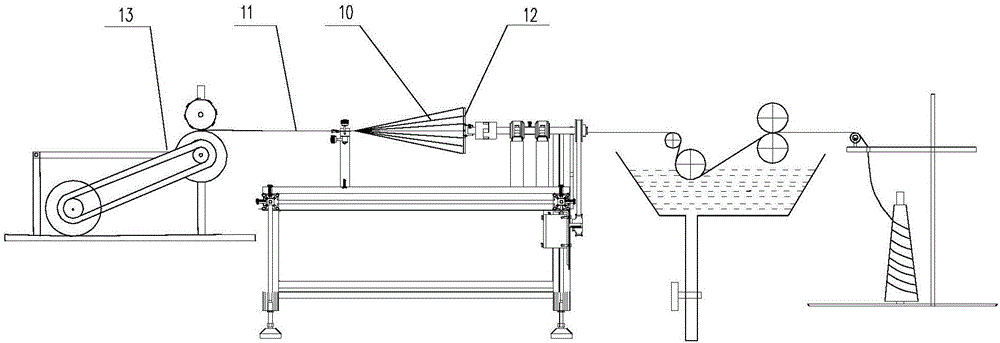

[0032] Then the pretreated drawn filaments are introduced into the electrospinner, the high-voltage electrostatic generator is turned on, and the polyurethane solution is used as the electrospinning solution for electrospinning to form polyurethane nanofibers. The nanofiber made of polyurethane is connected to the receiver and the drawing filament, the receiver is kept rotating at a certain speed, the nanofiber made of polyurethane is wound on the drawing filament, and the nanofiber assembly is obtained after further twisting by the roller.

[0033] Due to the moisture attached to the drawing filaments due to the pretreatment, the combination of drawing filaments and nanofibers in the nanofiber assembly prepared by subsequent twisting is more firm, and the stre...

Embodiment 2

[0035] The above-mentioned drawing filament pretreatment device is used to pretreat the drawing filament, the pretreatment liquid used is 20wt% carbon nanotube dispersion liquid, and the pretreatment time is 20s. The pretreated drawing filaments are drawing filaments with a layer of carbon nanotubes attached to the surface. The drawn filaments are introduced into the electrospinner, and then the electrostatic high voltage generator is turned on, and the electrospinning is performed using the polyurethane solution as the electrospinning solution to form polyurethane nanofibers. Polyurethane nanofibers are formed and attached between the draw filaments and receivers. Keeping the receiver rotating at a certain speed, the polyurethane nanofibers are wound onto the drawing filaments, and the nanofiber aggregates are obtained after further twisting treatment by rollers.

[0036] The nanofiber assembly prepared after the above-mentioned drawing filament pretreatment has a carbon nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com