Strand positioning guide having reversely oriented v-shaped slots for use in connection with strand coating applicators

A technology for positioning guides and positioning guide blocks, which is applied to the device for coating liquid on the surface, the yarn guide device for processing textile materials, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

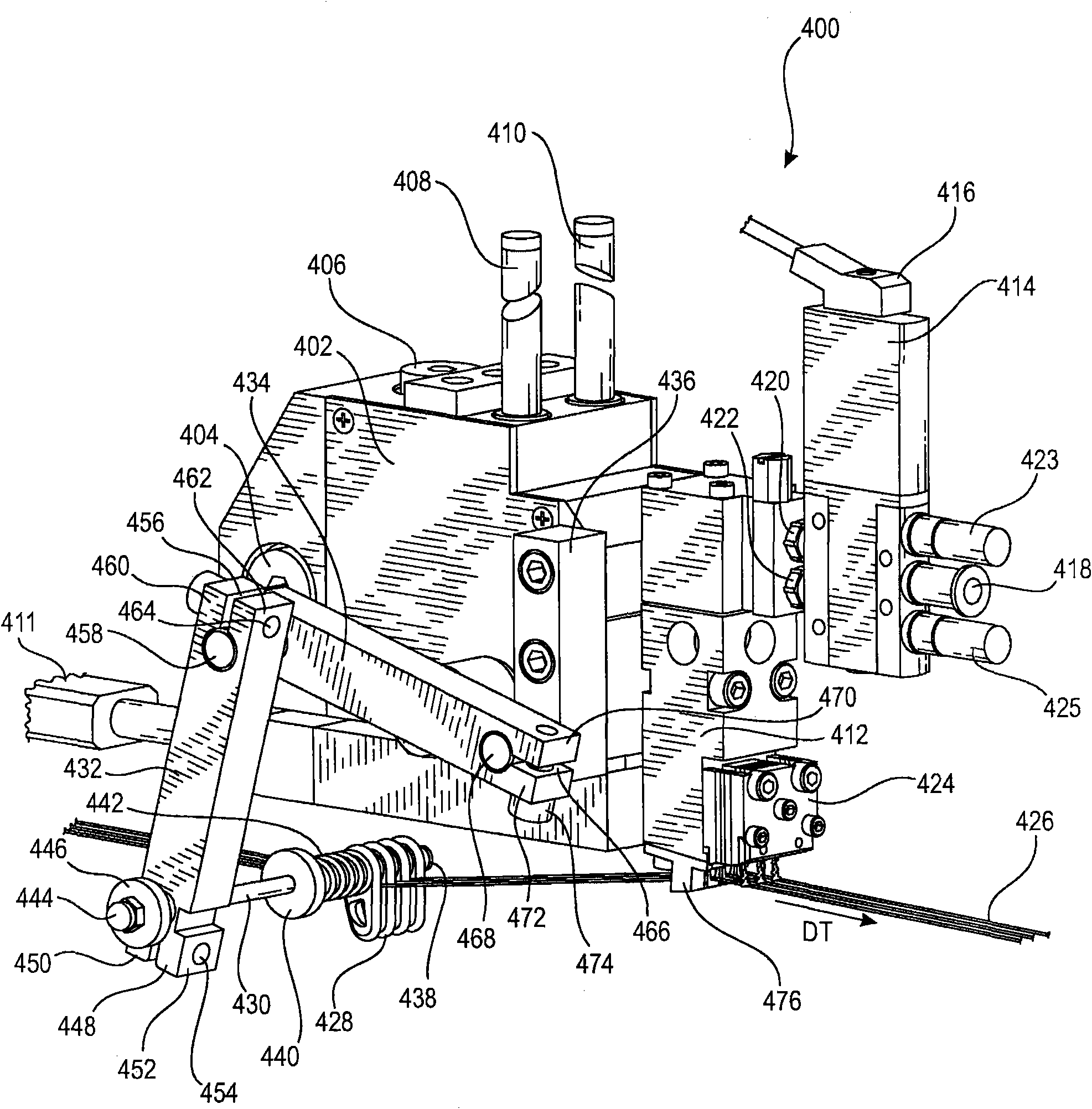

[0020] Referring now to the accompanying drawings, specifically image 3 , discloses a new and improved twisted wire applicator assembly constructed in accordance with the principles and teachings of the present invention and generally indicated by reference numeral 400 . More specifically, it can be seen that the new and improved twisted wire applicator assembly 400 includes an applicator head 402 to which, for example, a hot melt adhesive material is supplied through a suitable hose or conduit (not shown) The hose or conduit may be operatively connected to the applicator head 402 through, for example, either of the two hose inlets 404 or 406 formed in the left side and upper surface portions of the applicator head 402, respectively. The applicator head 402 also has a power control connector or assembly 410 and a hot melt adhesive material temperature sensor connector or assembly 408 for an applicator heater and ground operatively connected to the upper surface portion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com