Cloth dyeing machine of cloth lifting wheel-free cloth conveying system

A conveying system and a cloth-lifting wheel technology, applied in the field of dyeing machines, can solve the problems of scratches on the cloth surface, uneven dyeing of the cloth, high energy consumption of the cloth-lifting wheel cloth conveying device, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

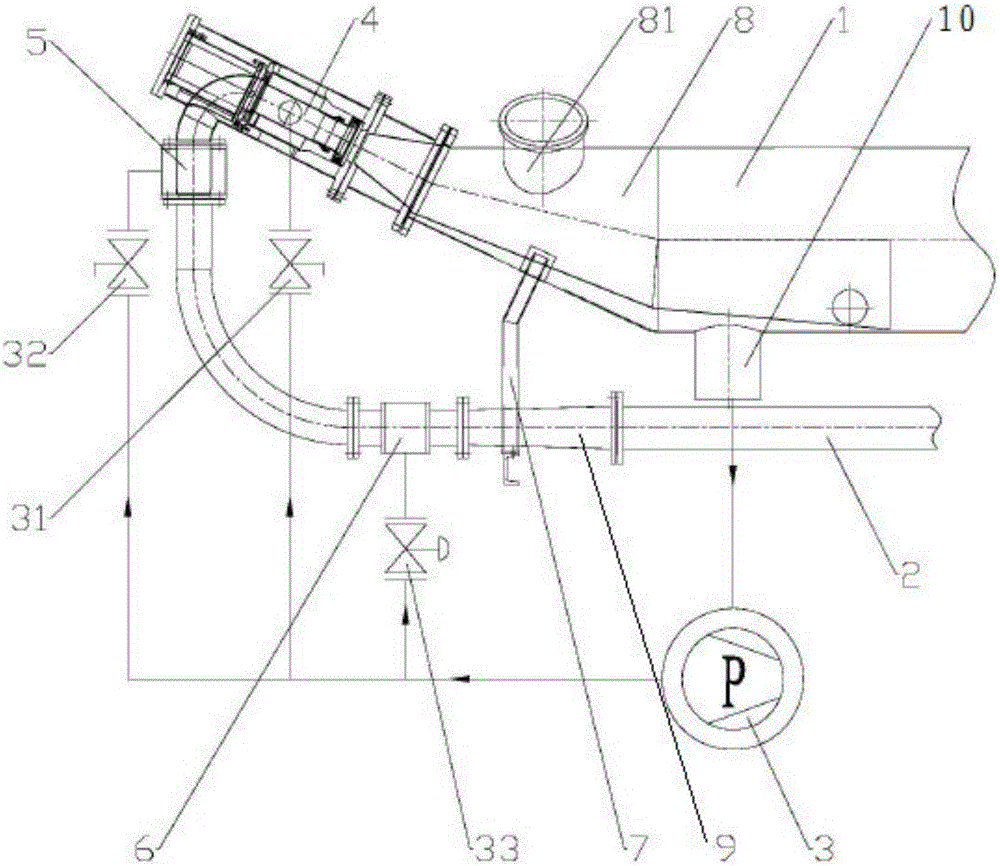

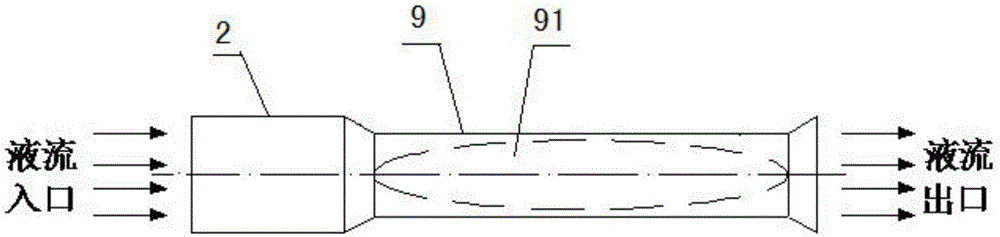

[0023] The cloth dyeing machine without the cloth conveying system, as shown in the figure, includes the main cylinder 1, the cloth guide pipe 2 and the pump 3, the main cylinder 1 is connected with the pump 3, and the main nozzle 4 is arranged on the cloth guide pipe 2 , cloth feeding nozzle 5 and reverse thrust nozzle 6, cloth guide pipe 2 is connected with main cylinder 1 through main nozzle 4, cloth guide pipe 2 is installed with cloth feeding nozzle 5 and reverse thrust nozzle 6 sequentially along the flow direction, main nozzle 4 and the pump 3 are provided with a first valve 31, a second valve 32 is provided between the cloth feeding nozzle 5 and the pump 3, a third valve 33 is provided between the reverse thrust nozzle 6 and the pump 3; There is a tapered barrel body 8, which reduces the height of the cloth to the main nozzle 4, thereby reducing the work to be done by the main nozzle 4 to lift the cloth. The tapered barrel body 8 is equipped with a support frame 7, The...

Embodiment 2

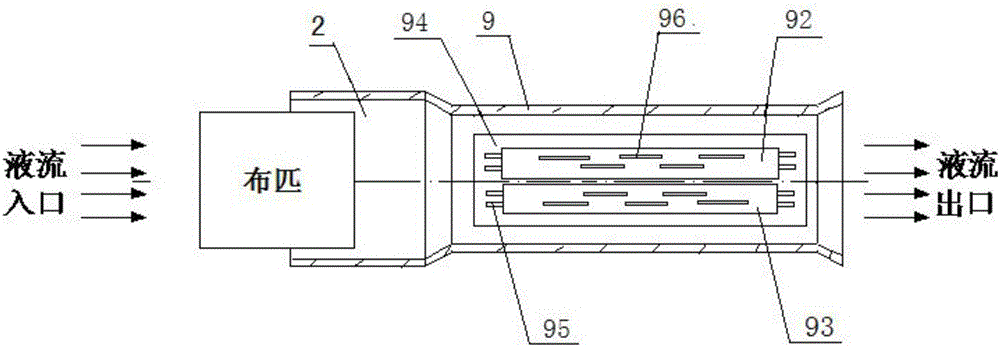

[0025] With embodiment 1, the difference is that the setting of the elliptical groove 91 in the anti-rotation pipe 9 is changed to the left belt 92 and the right belt 93 located on the bottom of the inner surface of the anti-rotation pipe 9, and the left belt 92 and the right belt 93 are all perpendicular to the The direction of cloth movement is turned outward. Both the outer surfaces of the left belt 92 and the right belt 93 are provided with convex strips 96 . The bottom of the anti-rotation pipe 9 inner surface is equipped with a positioning plate 94, four rolling shafts 95 are installed on the positioning plate 94, the left belt 92 is installed on the two rolling shafts 95, and the right belt 93 is installed on the other two rolling shafts 95 , the left belt 92 and the right belt 93 are all driven by the rolling shaft 95 to run. All have a rolling shaft 95 to be connected with motor in the rolling shaft 95 that is connected with left belt 92 and right belt 93. The left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com