Brand new PBT fabric processing process

A processing technology and fabric technology, applied in the direction of fabric surface trimming, heating/cooling fabric, processing textile material untwisting device, etc., can solve the problems of low production efficiency, long processing process, large energy consumption, etc., to improve production efficiency, The effect of reducing the processing steps and reducing the amount of sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

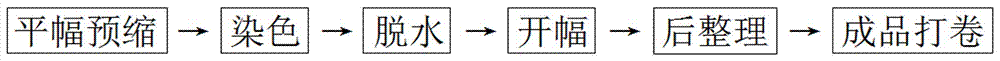

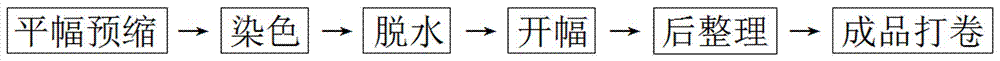

[0020] Embodiment 1: as attached figure 1 As shown, a new PBT fabric processing technology, the process is open-width pre-shrinking → dyeing → dehydration → opening → finishing → finished product rolling, the specific steps are as follows:

[0021] (1) Open-width pre-shrinking process: use an open-width washing machine, which is divided into seven washing boxes, and the temperature of each washing box is set at 40°C → 50°C → 60°C → 90°C → 90°C ℃→70℃→40℃, add 2.0g / L degreaser to the washing box in the first two sections, adjust the pH value to about 5.5, the water temperature in the washing box in the third and fourth sections will gradually increase, and the fabric width will further return shrink, and wash off the oil stains on the cloth surface by means of hot water spray and overflow out of the third and fourth sections of the washing tank, and the temperature of the last three sections of the washing box gradually decreases;

[0022] (2) Dyeing process: after being pre-sh...

Embodiment 2

[0027] Embodiment 2: as attached figure 1 As shown, a new PBT fabric processing technology, the process is open-width pre-shrinking → dyeing → dehydration → opening → finishing → finished product rolling, the specific steps are as follows:

[0028] (1) Open-width pre-shrinking process: use an open-width washing machine, which is divided into seven washing boxes, and the temperature of each washing box is set at 40°C → 50°C → 60°C → 90°C → 90°C ℃→70℃→40℃, add 3.0g / L degreaser to the washing box in the first two sections, adjust the pH value to about 5.5, the water temperature in the washing box in the third and fourth sections will gradually increase, and the fabric width will further return shrink, and wash off the oil stains on the cloth surface by means of hot water spray and overflow out of the third and fourth sections of the washing tank, and the temperature of the last three sections of the washing box gradually decreases;

[0029] (2) Dyeing process: After being pre-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com